Patents

Literature

39results about How to "Small thermal conductivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

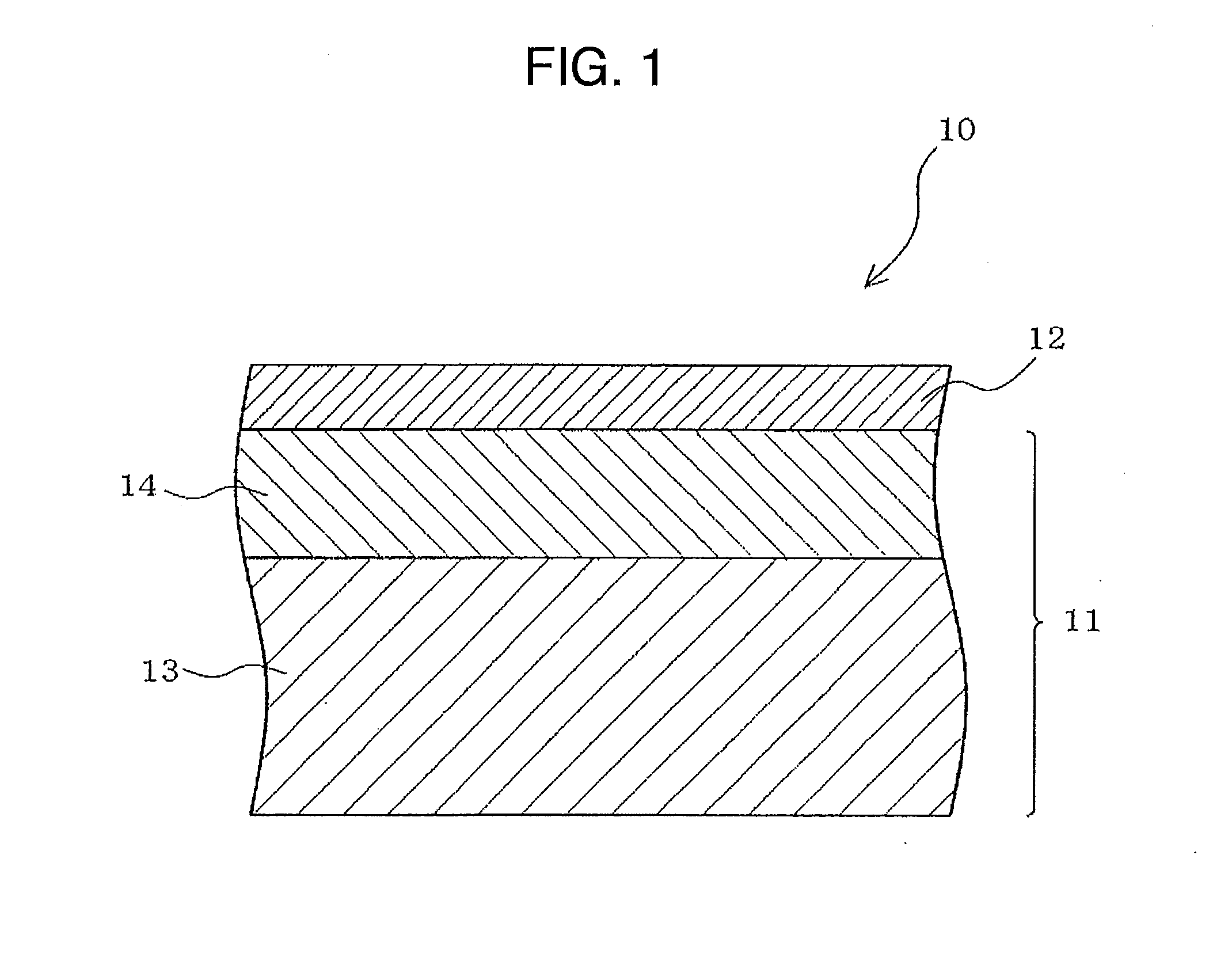

Thermoelectric conversion materials

InactiveUS20050268956A1Improve thermoelectric conversion efficiencyImprove batch productivityThermoelectric device with peltier/seeback effectThermoelectric device manufacture/treatmentProduction rateCore component

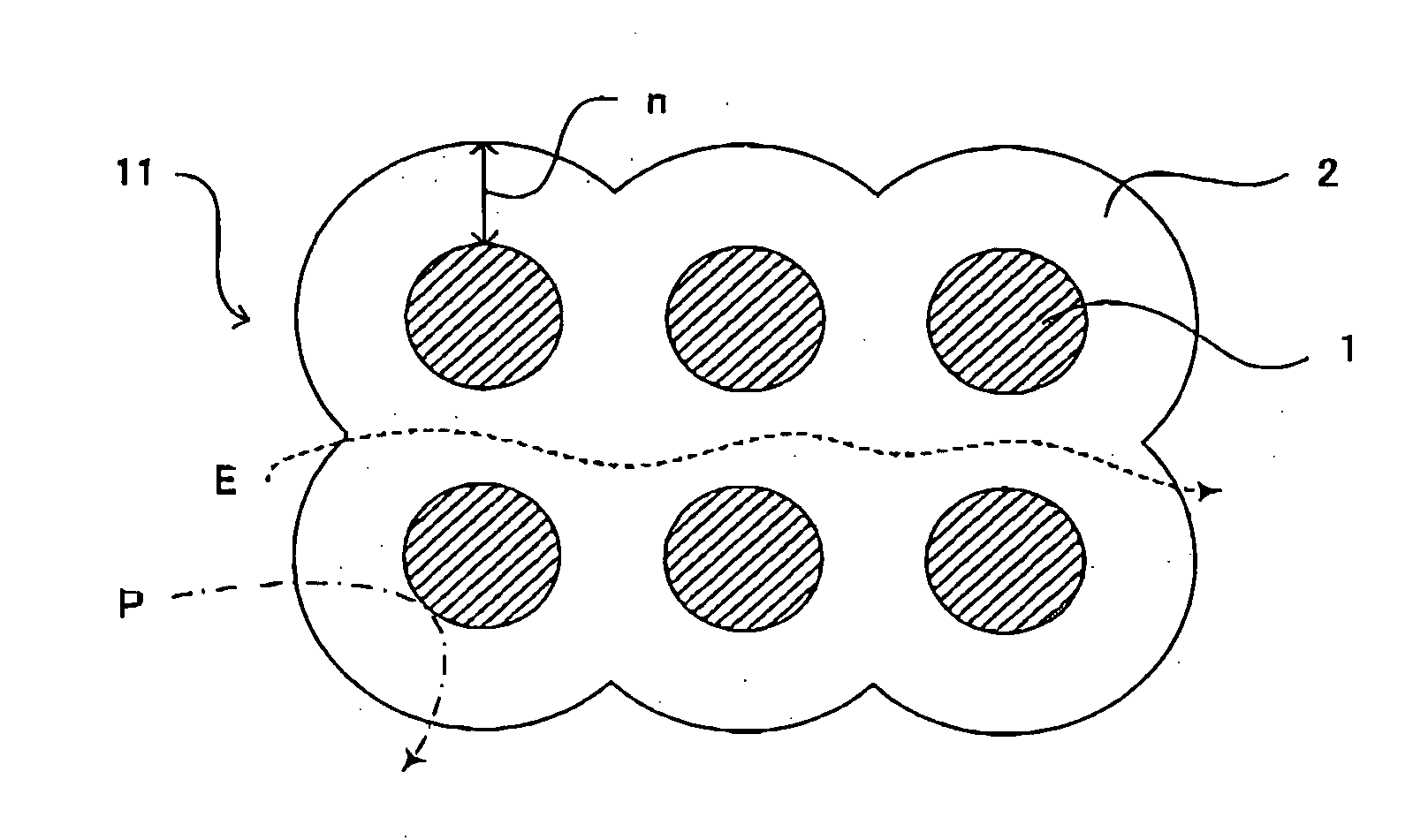

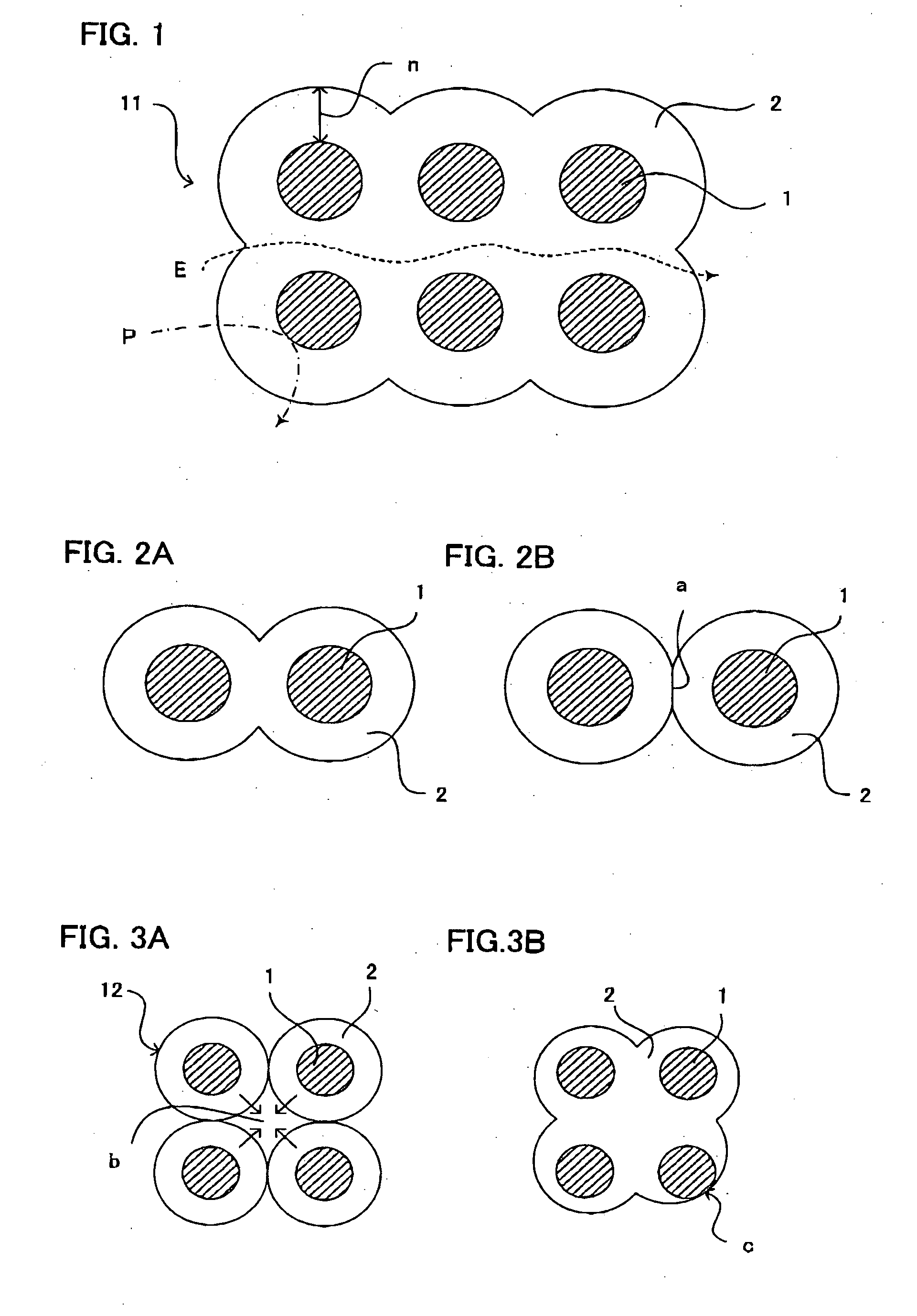

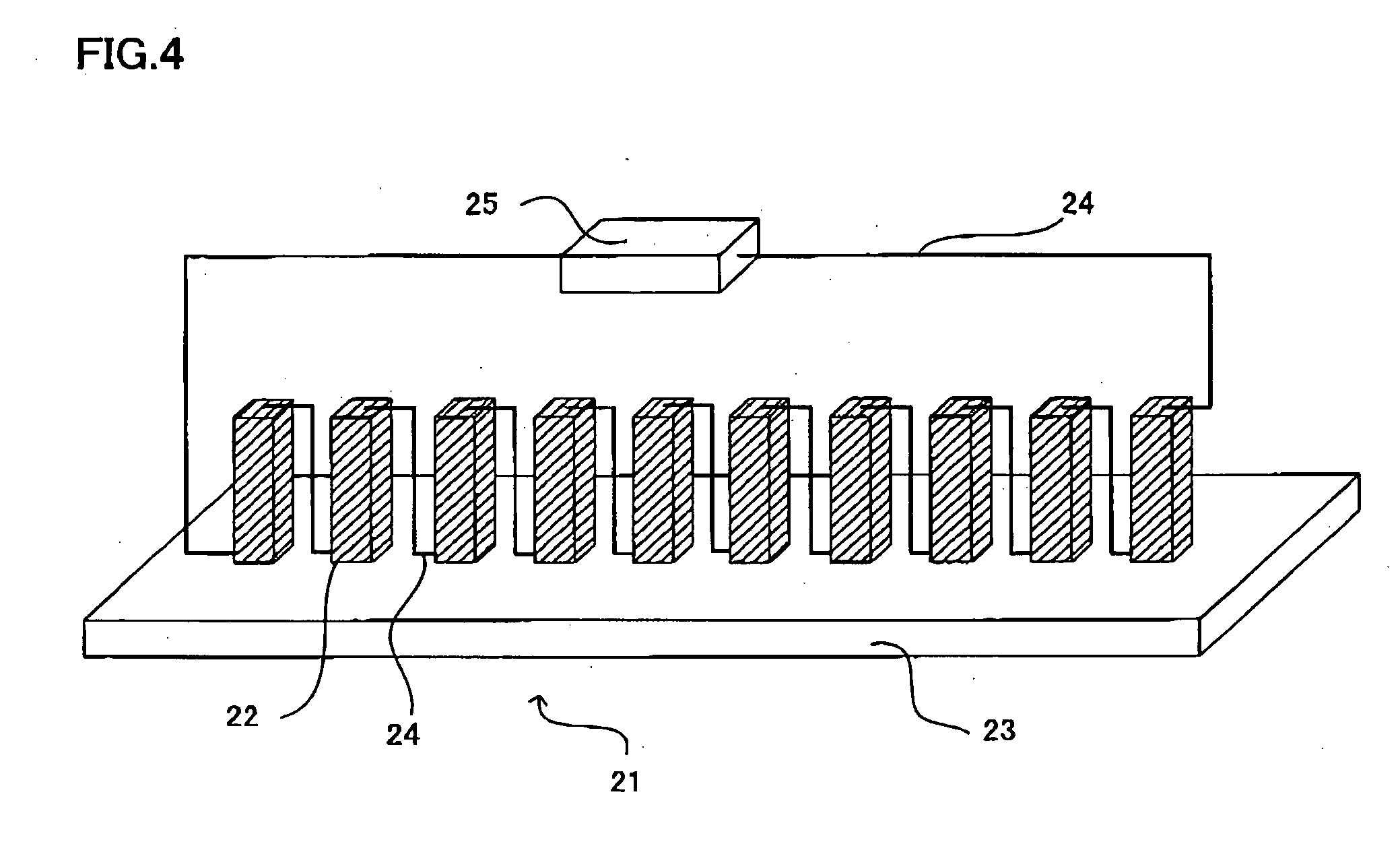

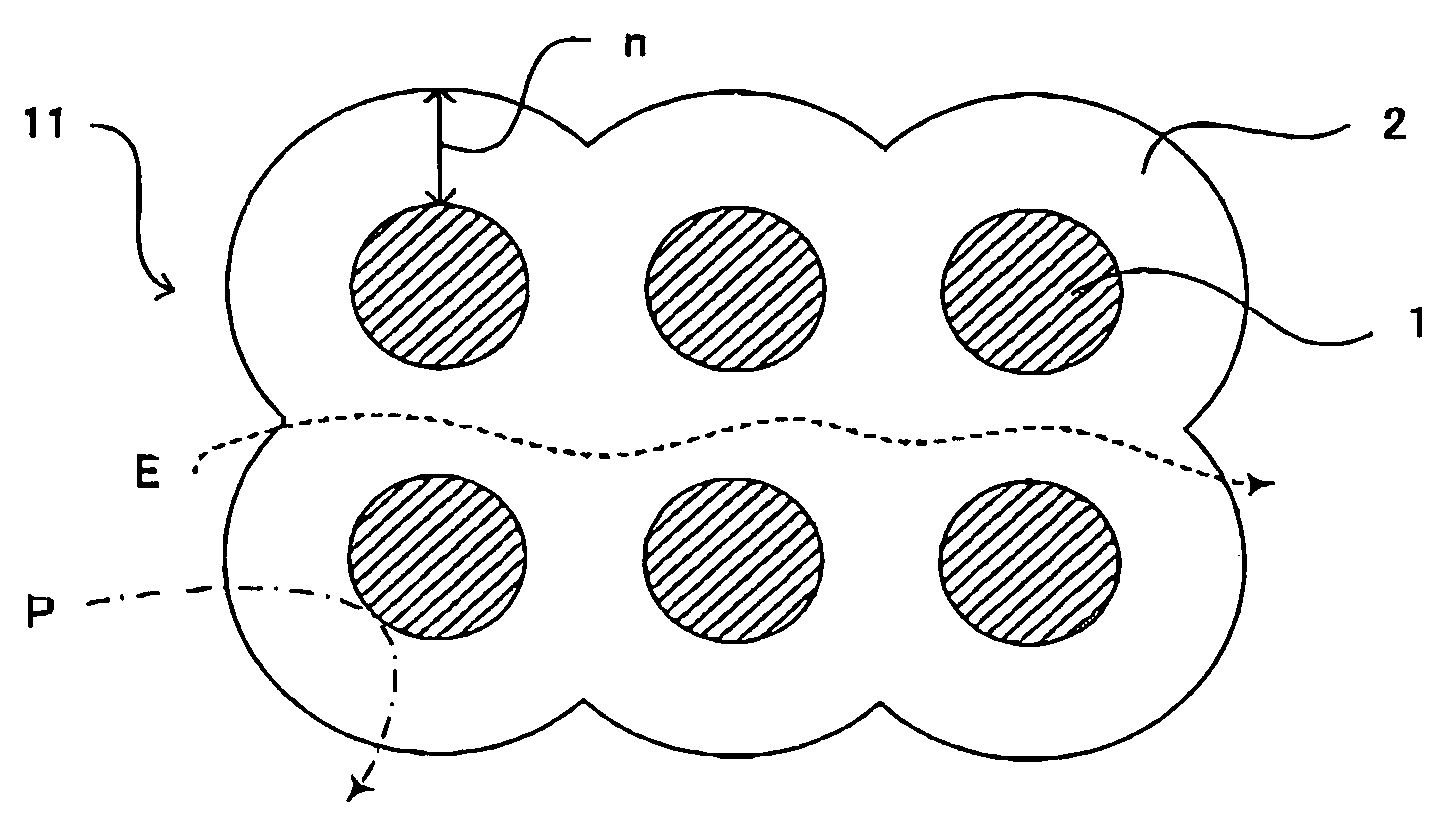

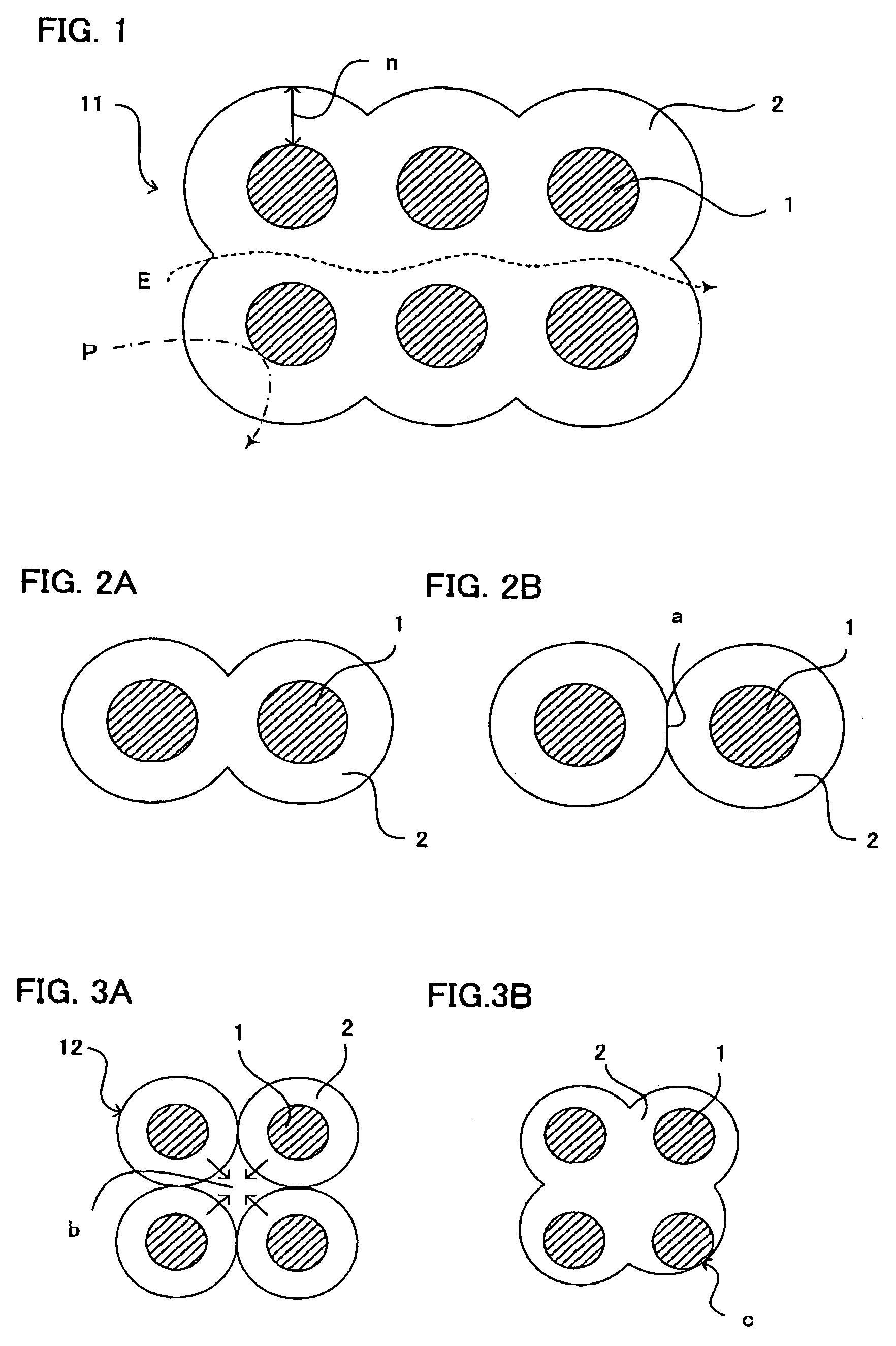

The main object of the present invention is to provide the thermoelectric conversion materials having a high thermoelectric conversion performance and the excellent mass productivity. The object of the present invention is achieved by providing the thermoelectric conversion materials comprising a core-shell structure having a plurality of core parts and shell parts for covering the above-mentioned core parts, wherein the plurality of the above-mentioned core parts are independent with each other and the above-mentioned shell parts are provided continuously.

Owner:DAI NIPPON PRINTING CO LTD

Thermoelectric conversion materials

InactiveUS7259320B2Improve thermoelectric conversion efficiencyImprove batch productivityThermoelectric device with peltier/seeback effectThermoelectric device manufacture/treatmentProduction rateThermoelectric conversion

Owner:DAI NIPPON PRINTING CO LTD

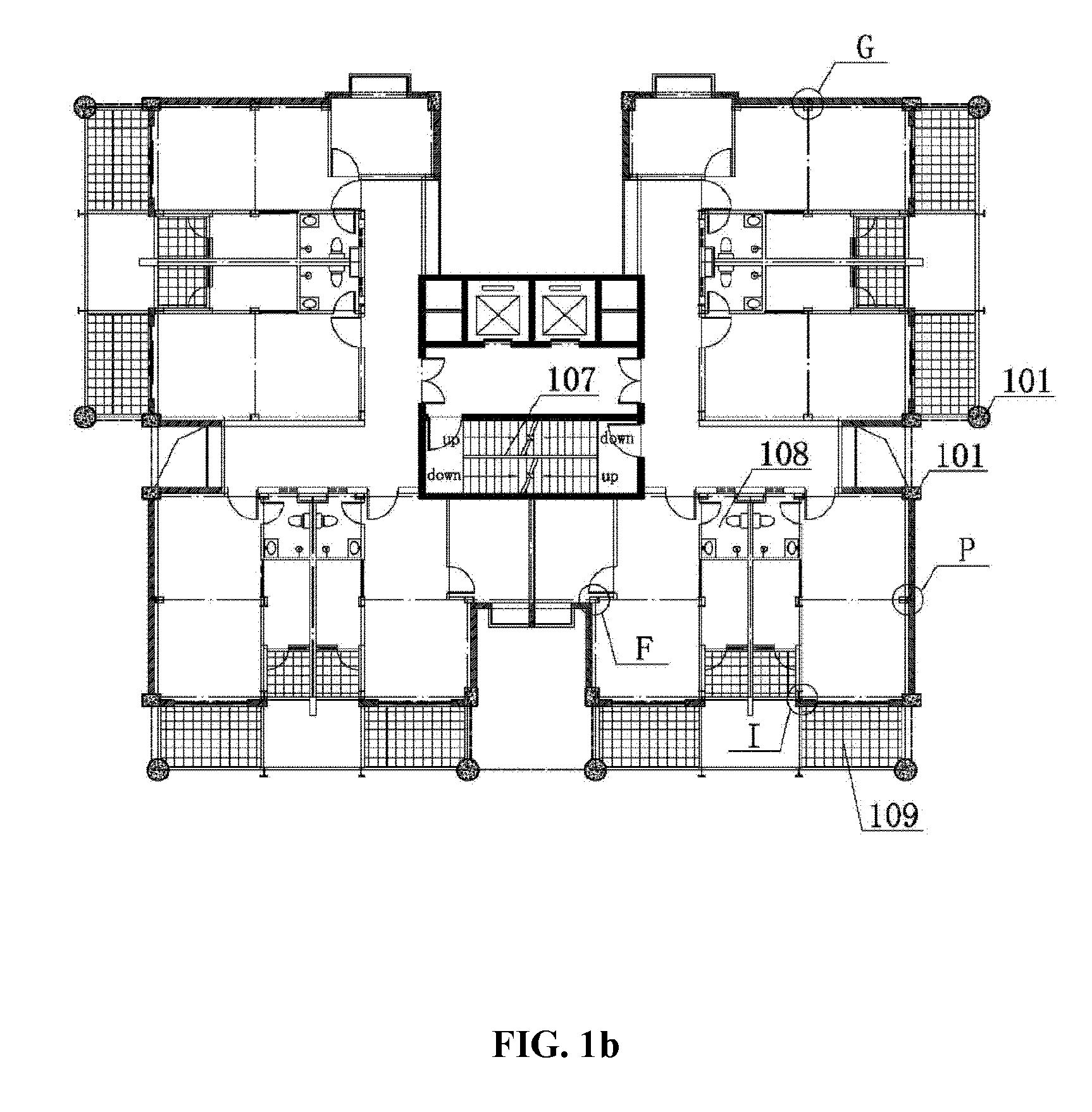

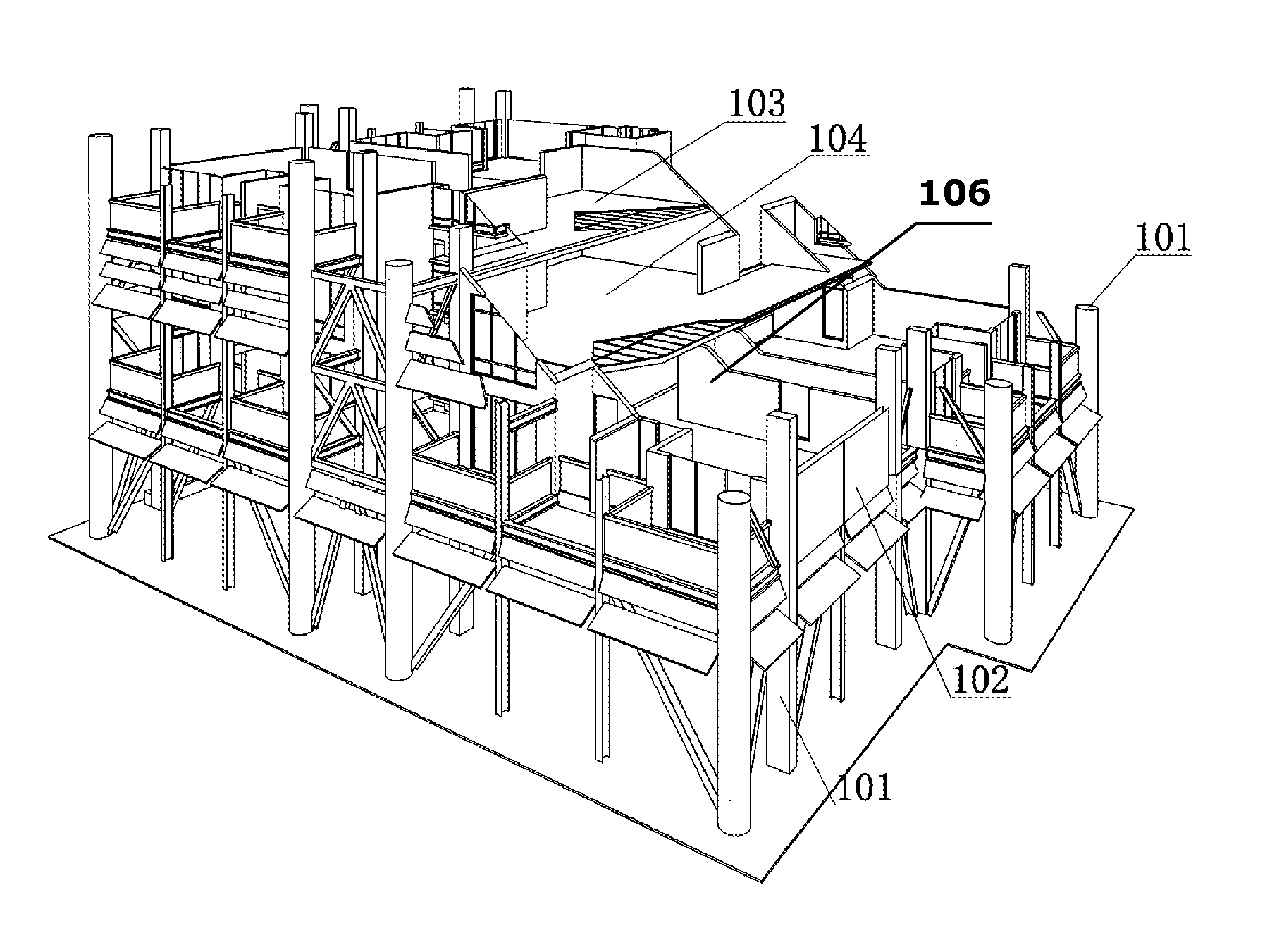

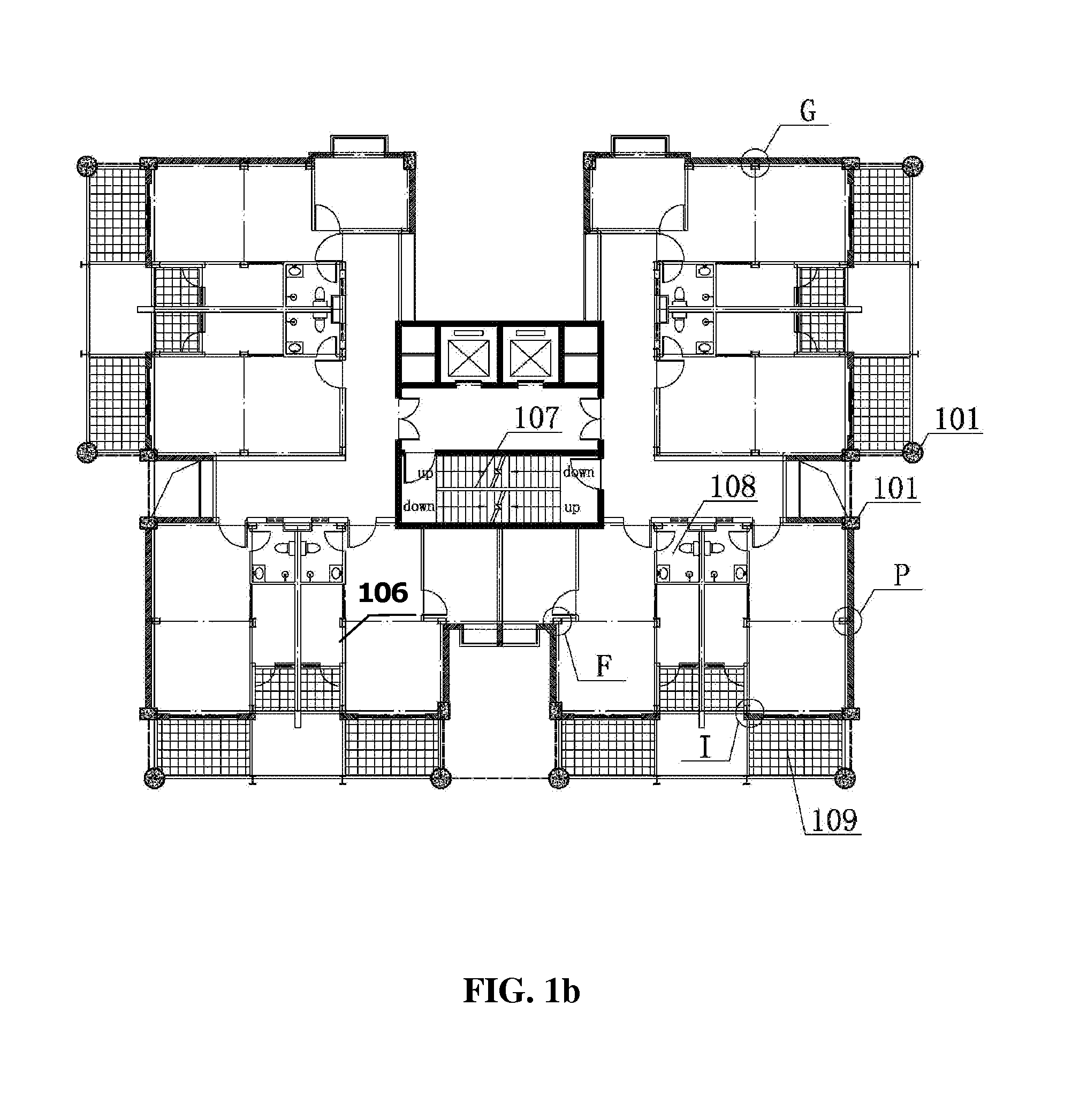

Energy Saving House

An energy-saving house, has a main frame, an enclosed wall, a floor cover plate, a top cover plate, a separation wall, a bathroom, and stairs. The enclosed wall is assembled from multiple integral composite prefabricated external wallboards and fixed on the main frame via an energy-dissipating connector. The bathroom and the stair are integrally prefabricated and directly installed. The energy-saving house features low power consumption, high construction efficiency, short construction time, low noise, low dust, light weight, good anti-seismic performance, and small thermal conductivity and is applicable to multi-floor houses and high rise buildings.

Owner:HUANG ZHENXI

Waterproof coating of carton

ActiveCN102704330AGood chemical stabilityImprove insulation performanceCoatingsPaper forming aids additionParaffin waxEmulsion

The invention relates to a waterproof coating, in particular to a waterproof coating of a carton, which comprises the following components in weight part: 30-120 parts of paraffin micro-emulsion, 50-90 parts of simethicone, and 4-8 parts of emulsifier. The waterproof coating is prepared according to a method as follows: (1) heating the paraffin micro-emulsion to 50-180 degree C; (2) adding simethicone and stirring for 0.5-3 hours; and (3) adding the emulsifier, stirring at a high speed for 10-40 minutes, and cooling to the room temperature. The waterproof coating of the carton, disclosed by the invention, has no pollution on the human body and the environment, can be combined with the base material firmly, and has excellent waterproof property.

Owner:ANHUI JINDUN PAINT

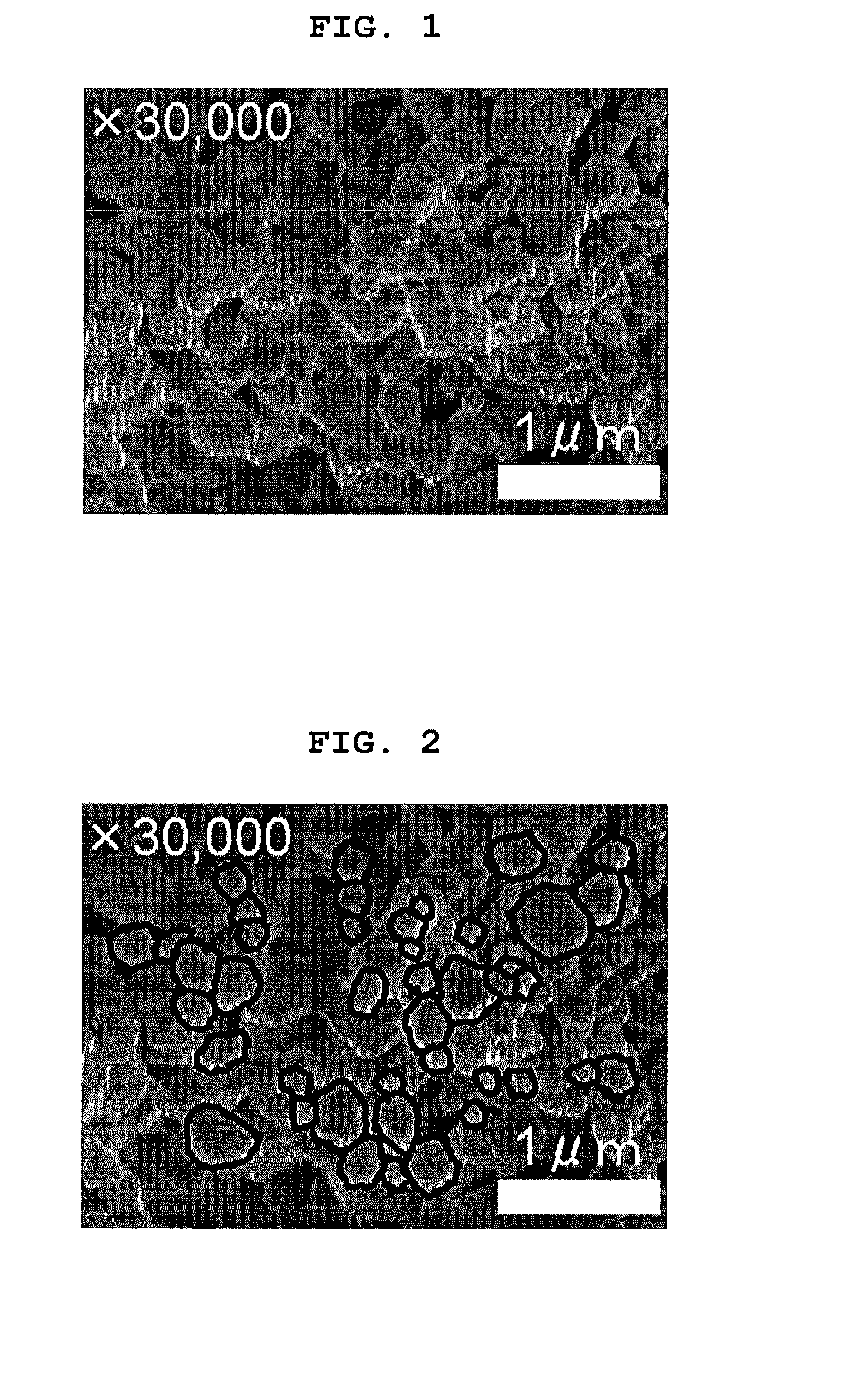

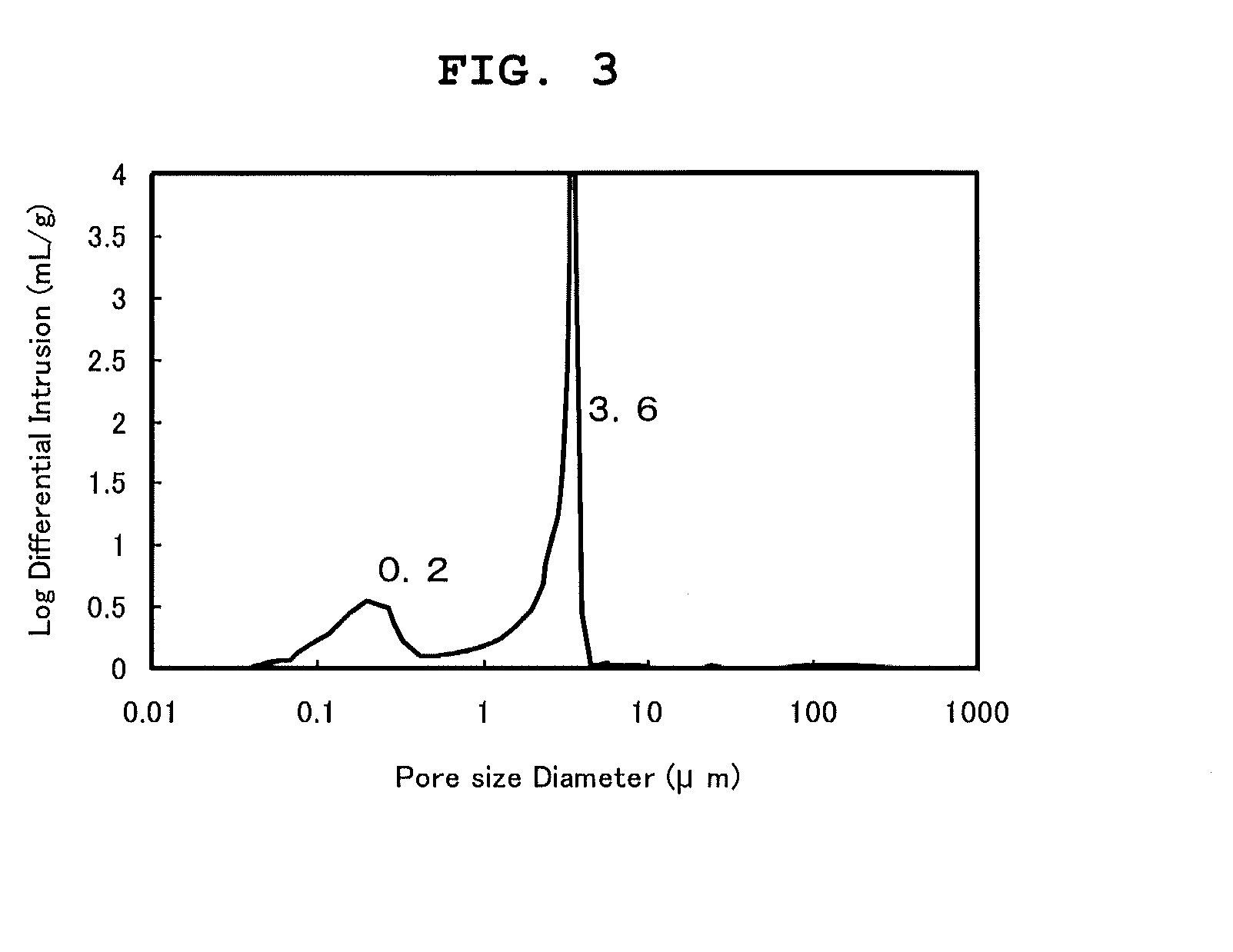

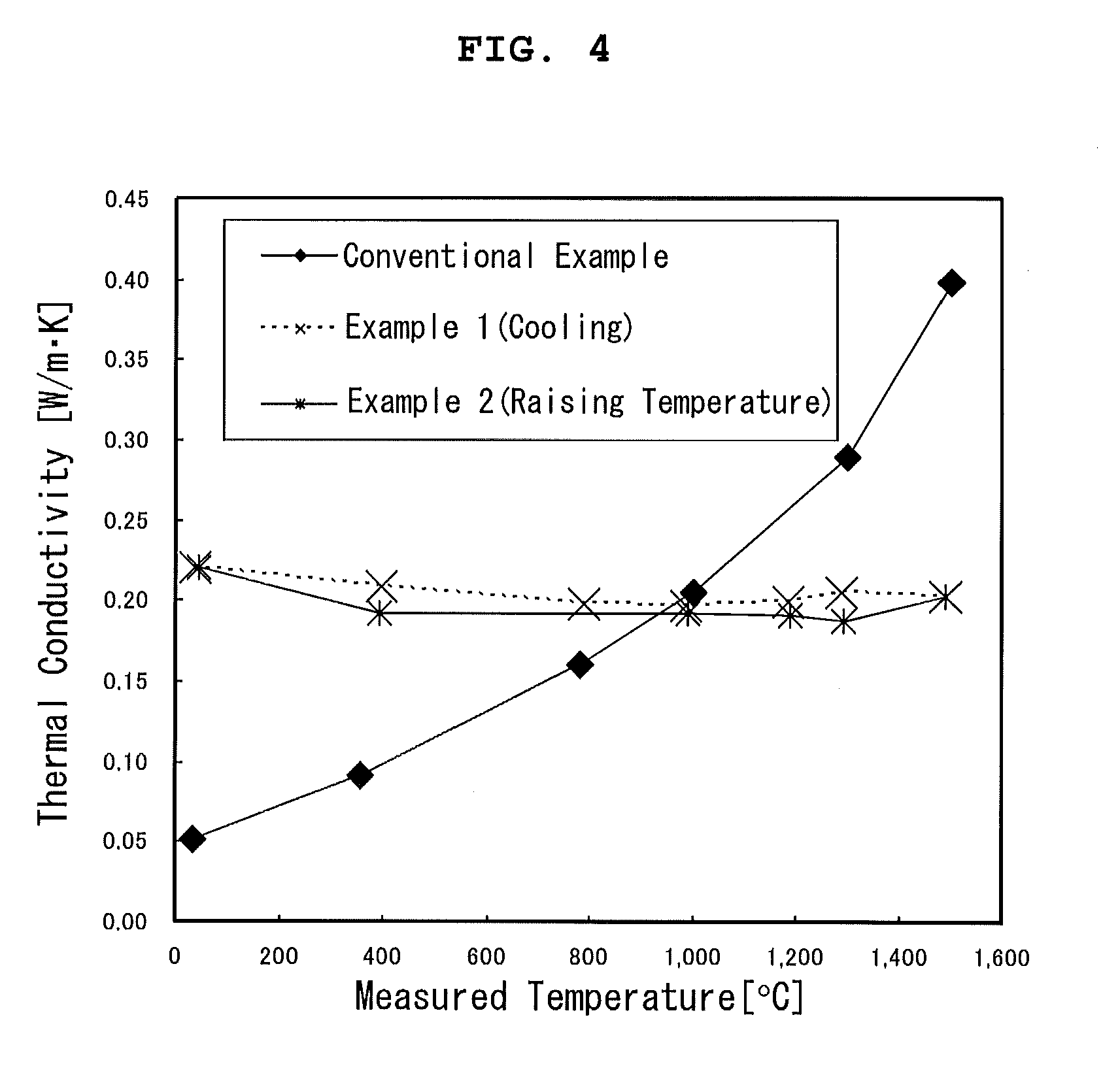

Heat-insulating material

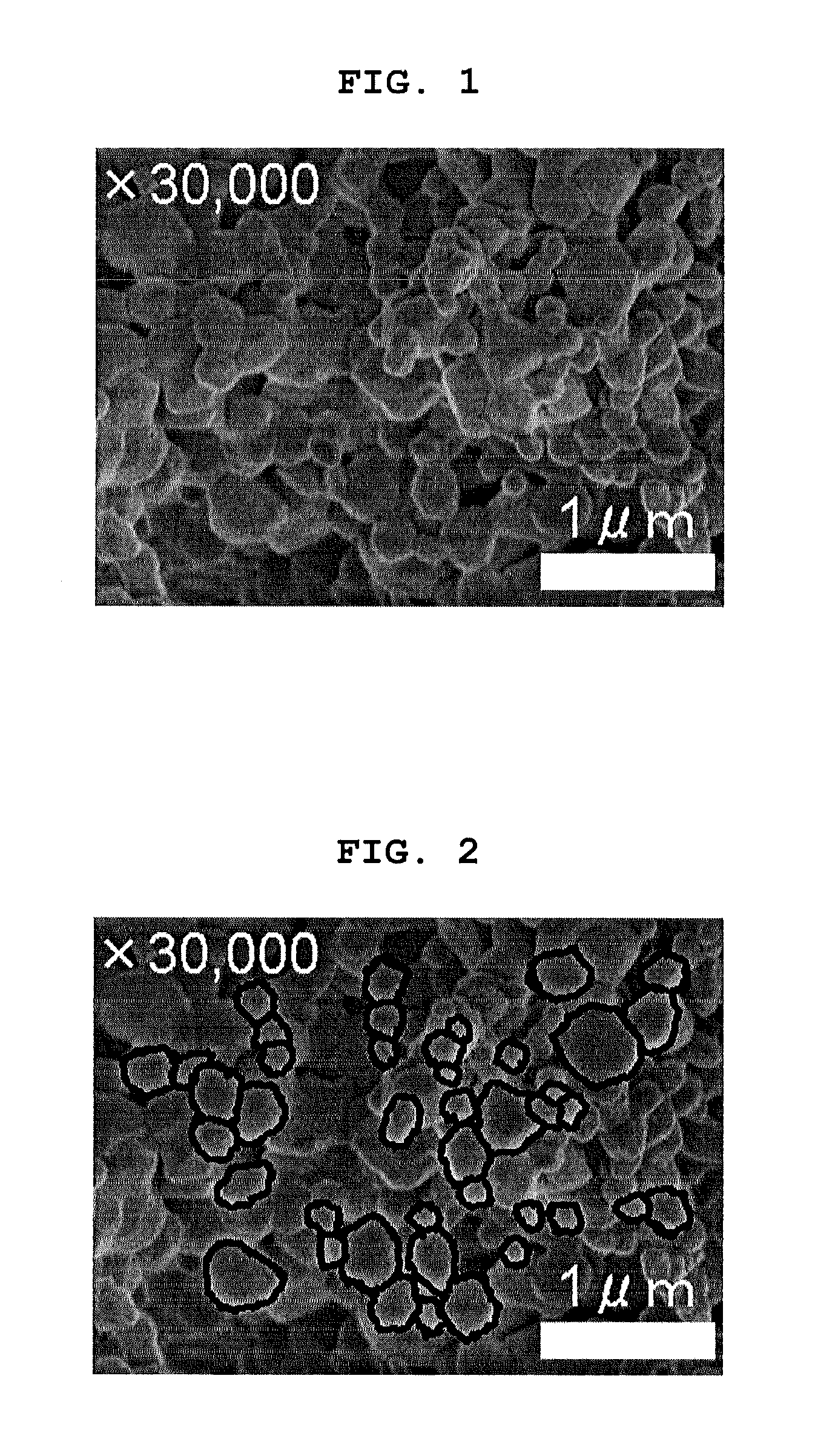

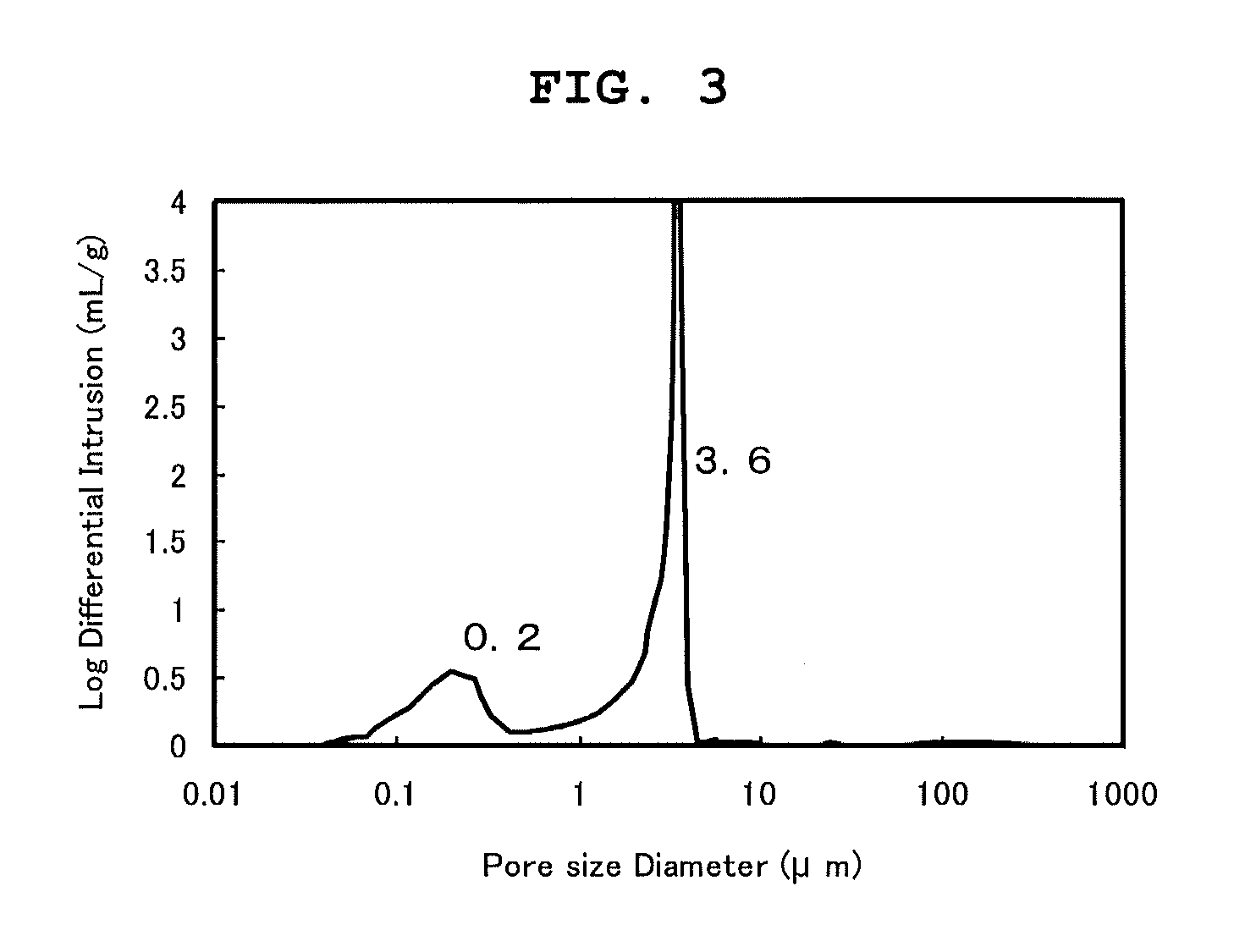

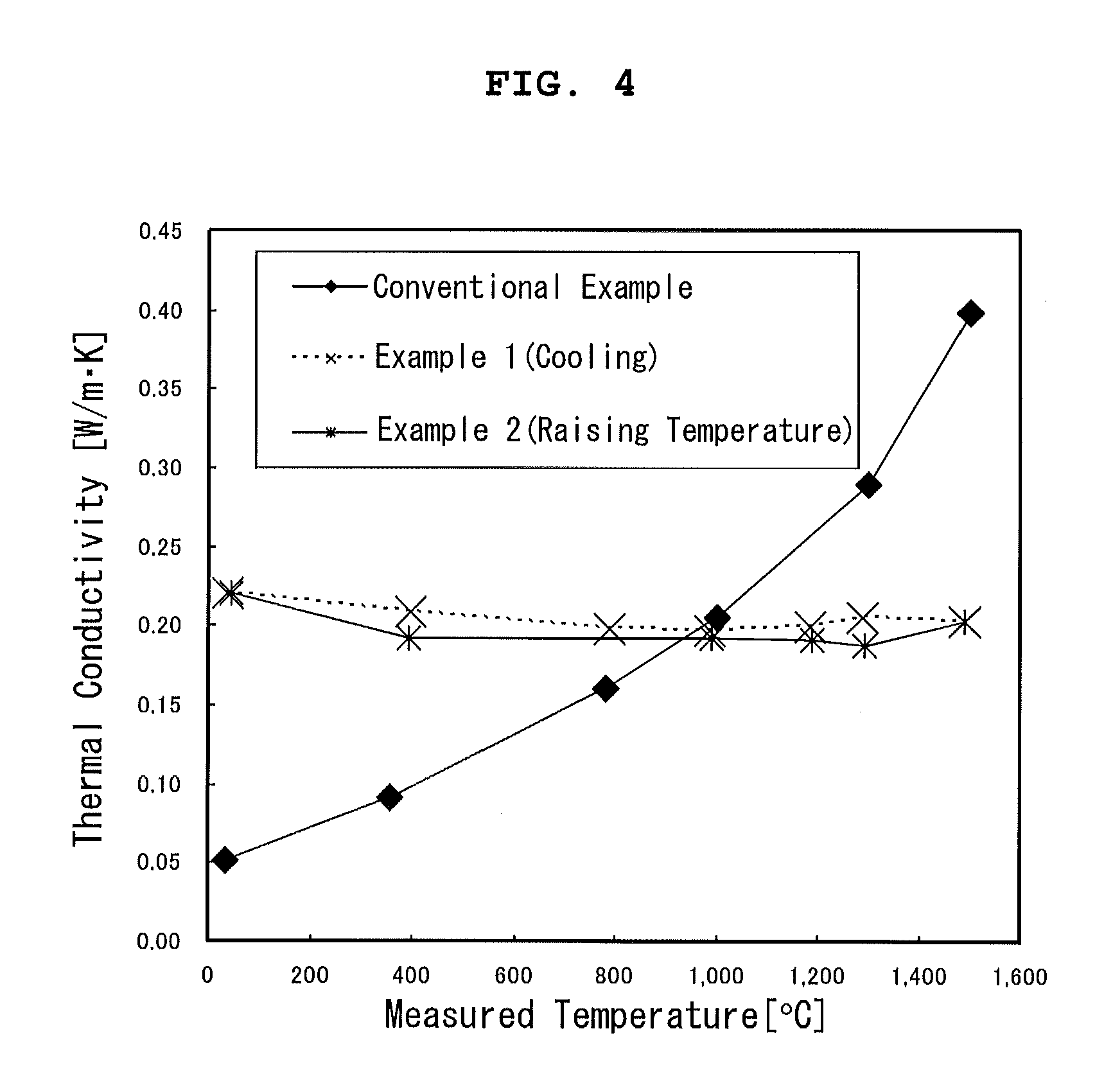

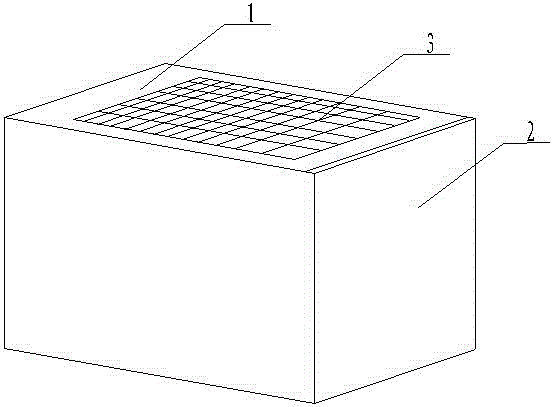

ActiveUS20140112861A1Reduce in quantityLess energy supplyMangesium aluminatesCeramicwareMetallurgyPore diameter

A heat-insulating material is provided in which thermal conductivity is controlled not to increase and good insulation properties are held even in a high temperature range. The heat-insulating material is formed of a spinel porous sintered body having a porosity of 65 to 90 vol. % and represented by a chemical formula XAl2O4 (X═Zn, Fe, Mg, Ni, or Mn) which is arranged such that large pores having a diameter of greater than 1000 μm occupy 25 vol. % or less of the total pore volume, fine pores having a diameter of 0.45 μm or less occupy 5 to 40 vol. % of the volume of the pores having a diameter of 1000 μm or less, at least one pore-diameter distribution peak is within a range of 0.14 to 10 μm, and is formed of sintered particles having a calculated average particle diameter of 0.04 to 1 μm.

Owner:COORSTEK INC

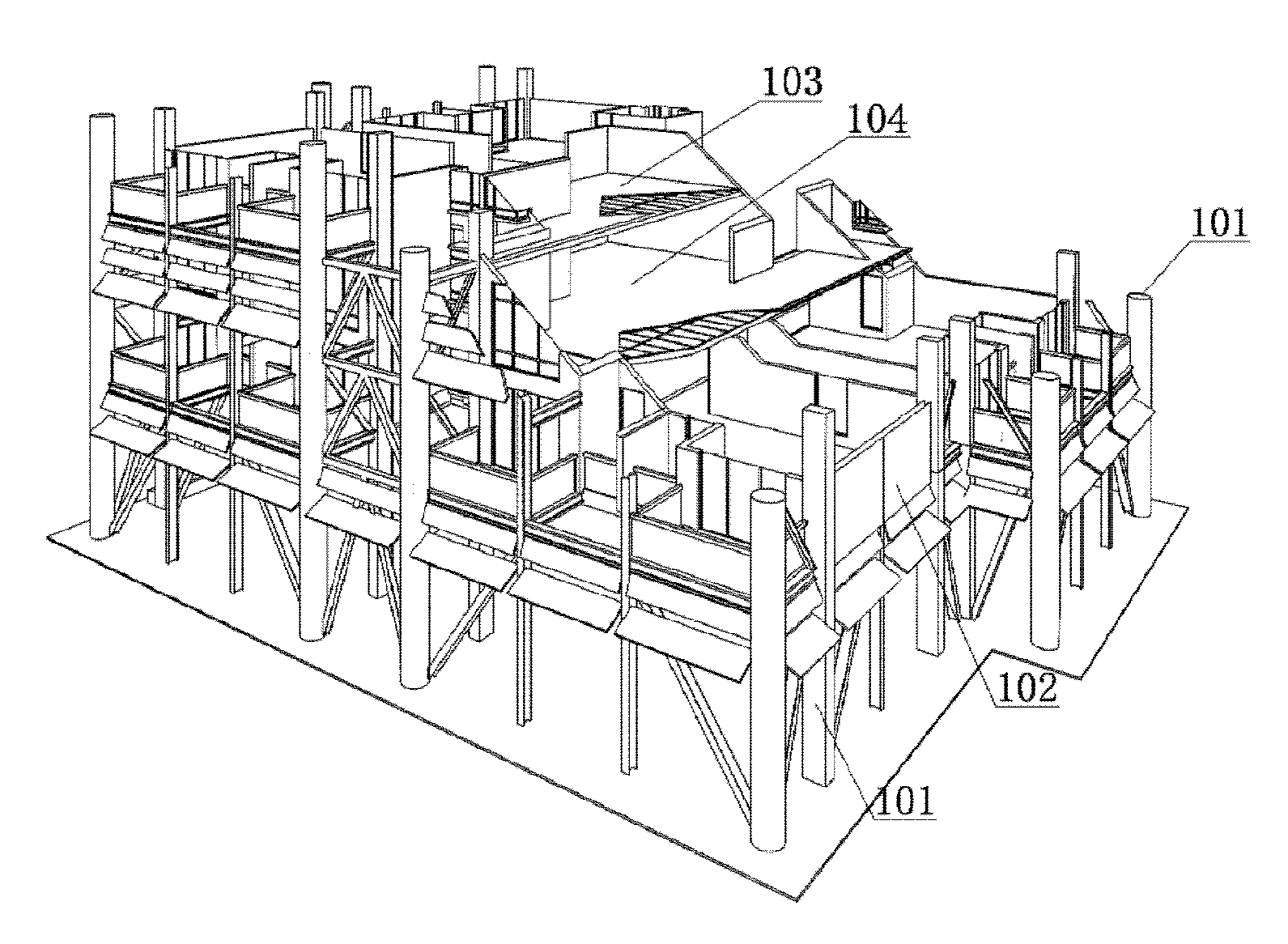

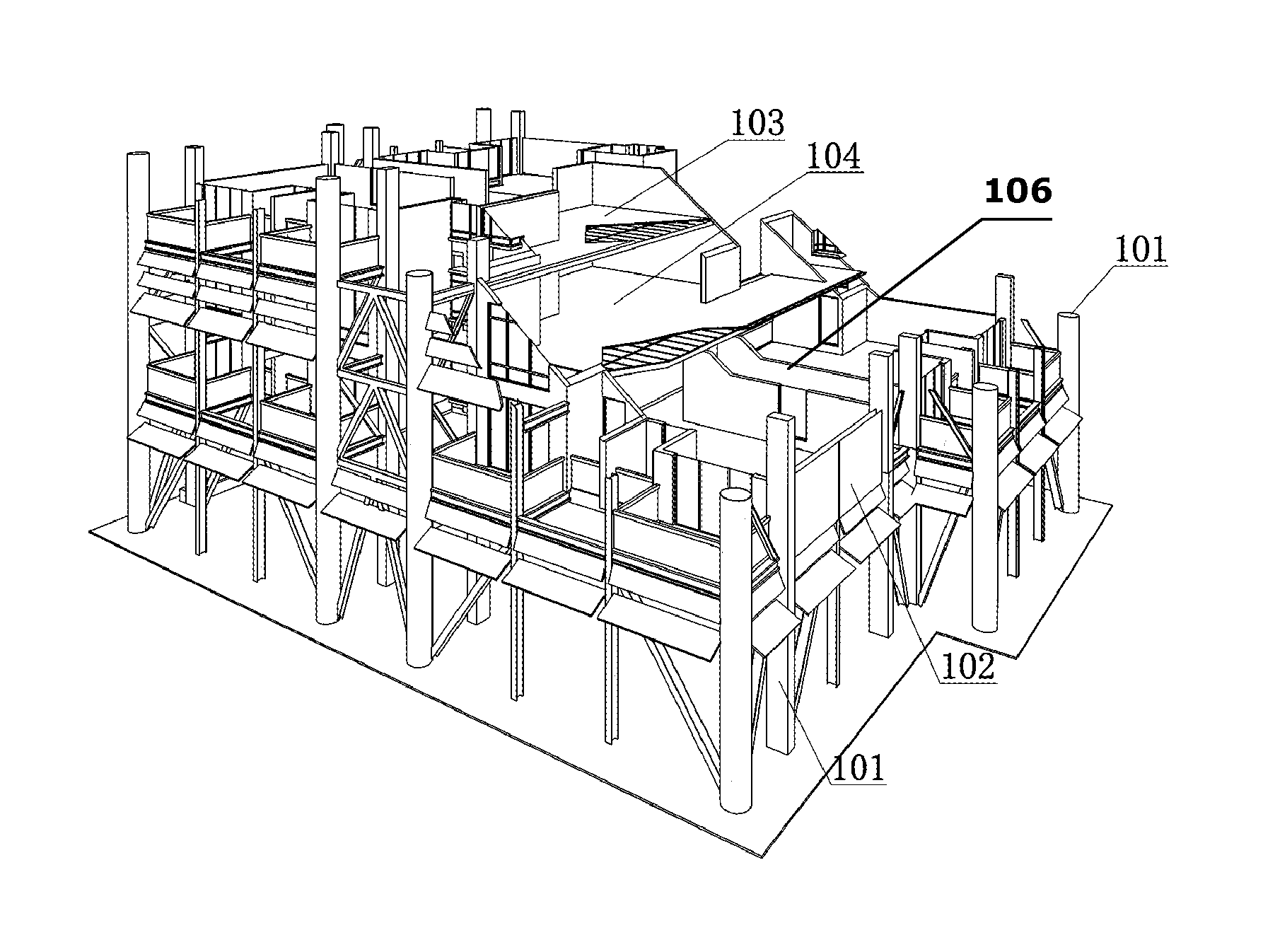

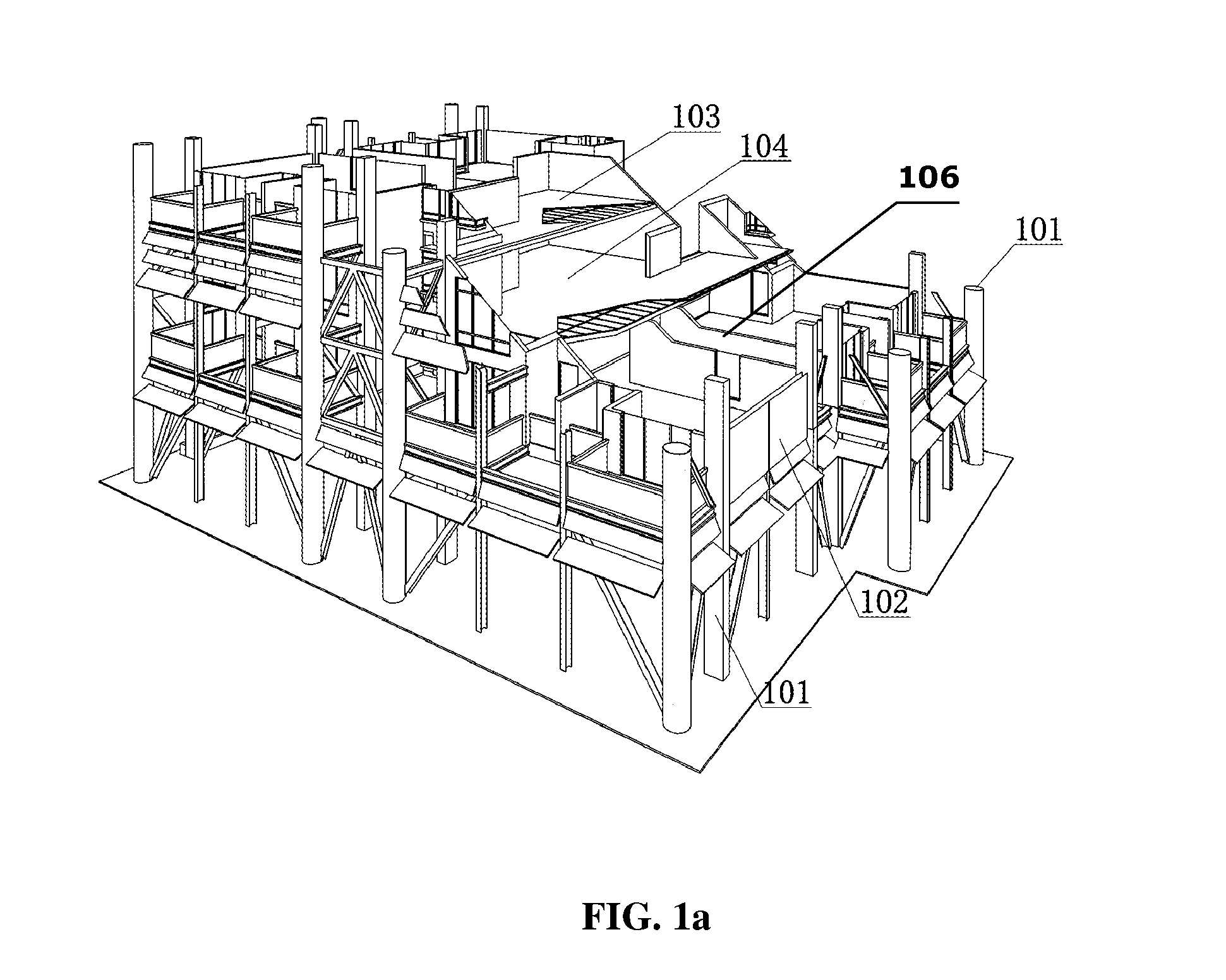

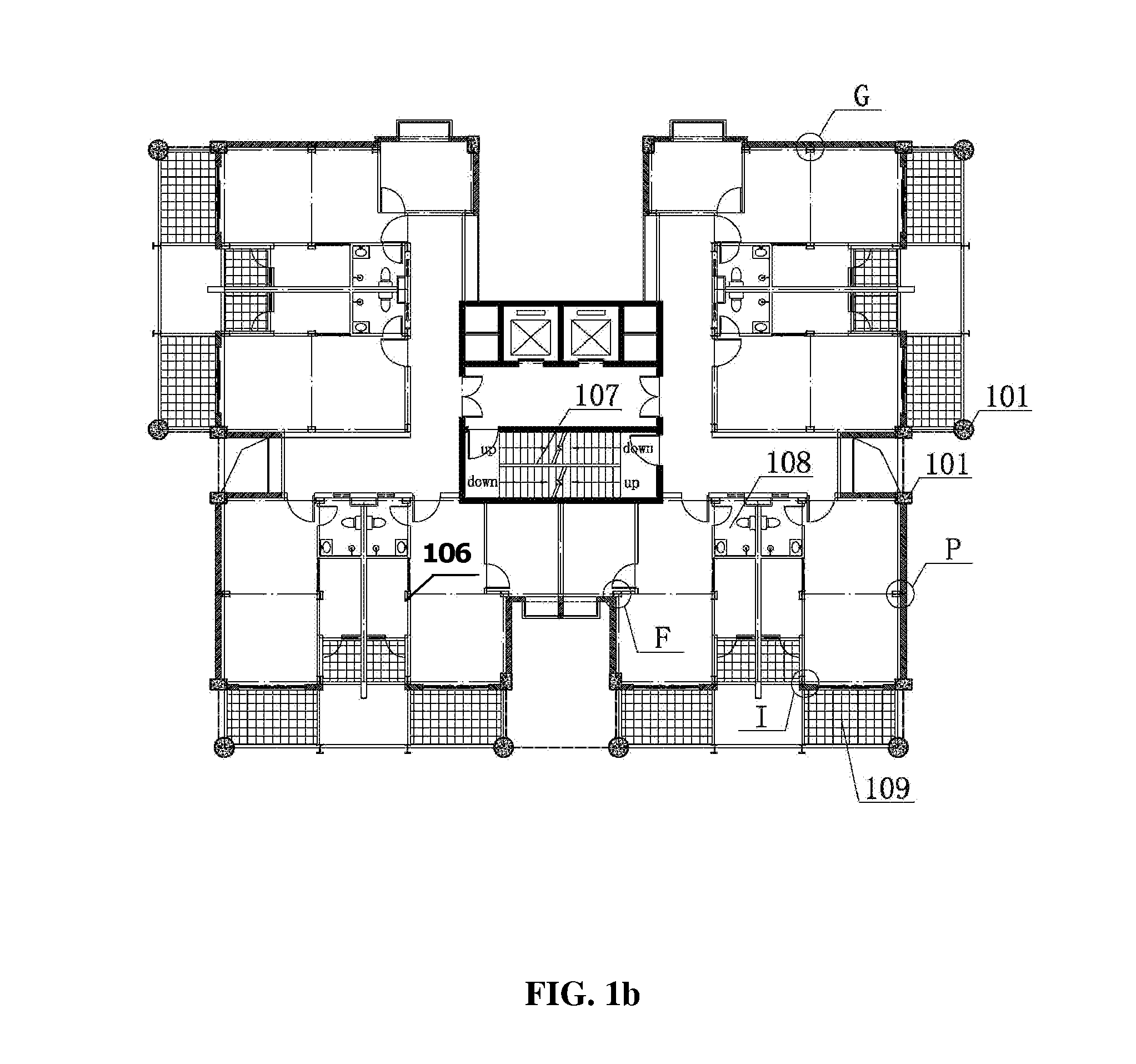

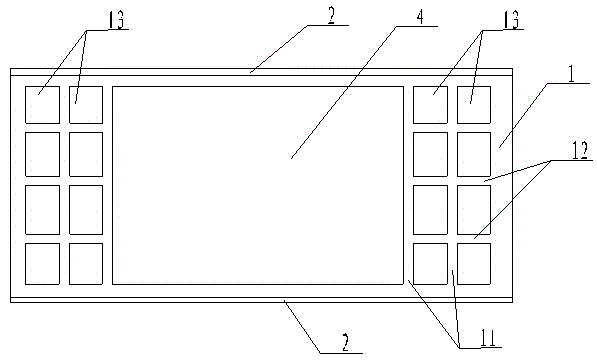

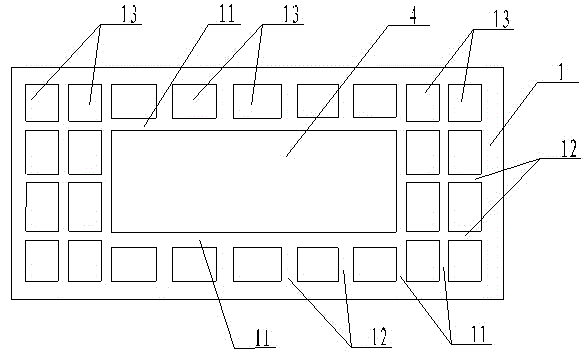

House constructed from finished product components and constructing method thereof

InactiveUS20130055653A1Easy constructionQuality improvementFloorsPublic buildingsMaterial consumptionBuilding construction

A house constructed from finished product components and a method for constructing such house are disclosed. The components of the house such as the finished product main frame, the finished product enclosed wall, the finished product floor cover plate, the finished product top cover plate and the finished product stair are finished product industrially constructed in different manufactories, and then transported to the constructing location respectively, and then assembled at the base of the house, so as to form a house constructed from finished product components. By using finished product components, the construction of the house has high efficiency, good quality, less material consumption and shorter construction period. Furthermore, comparing with traditional site operation, constructing house from finished product components is more environment-friendly.

Owner:HUANG ZHENXI +1

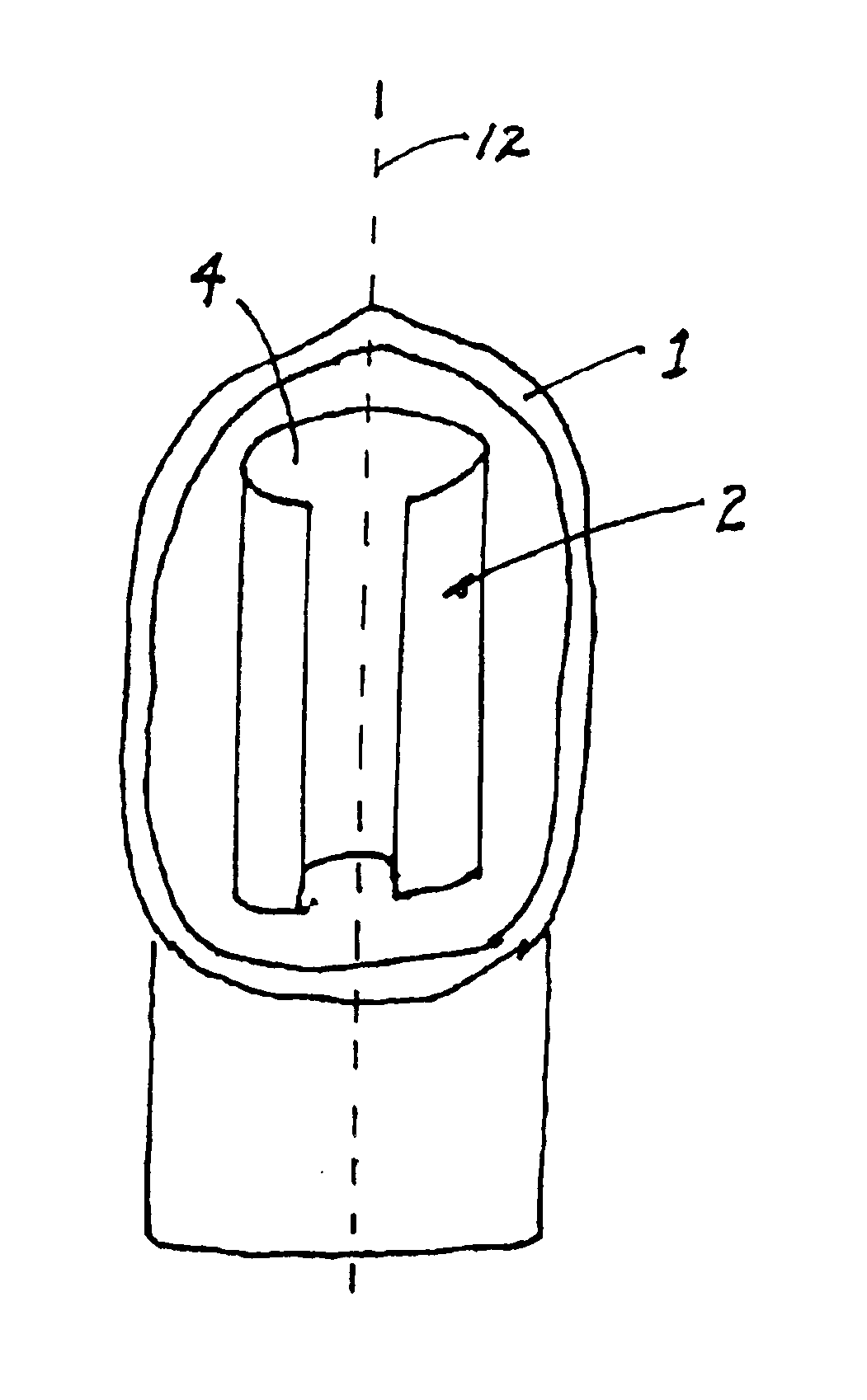

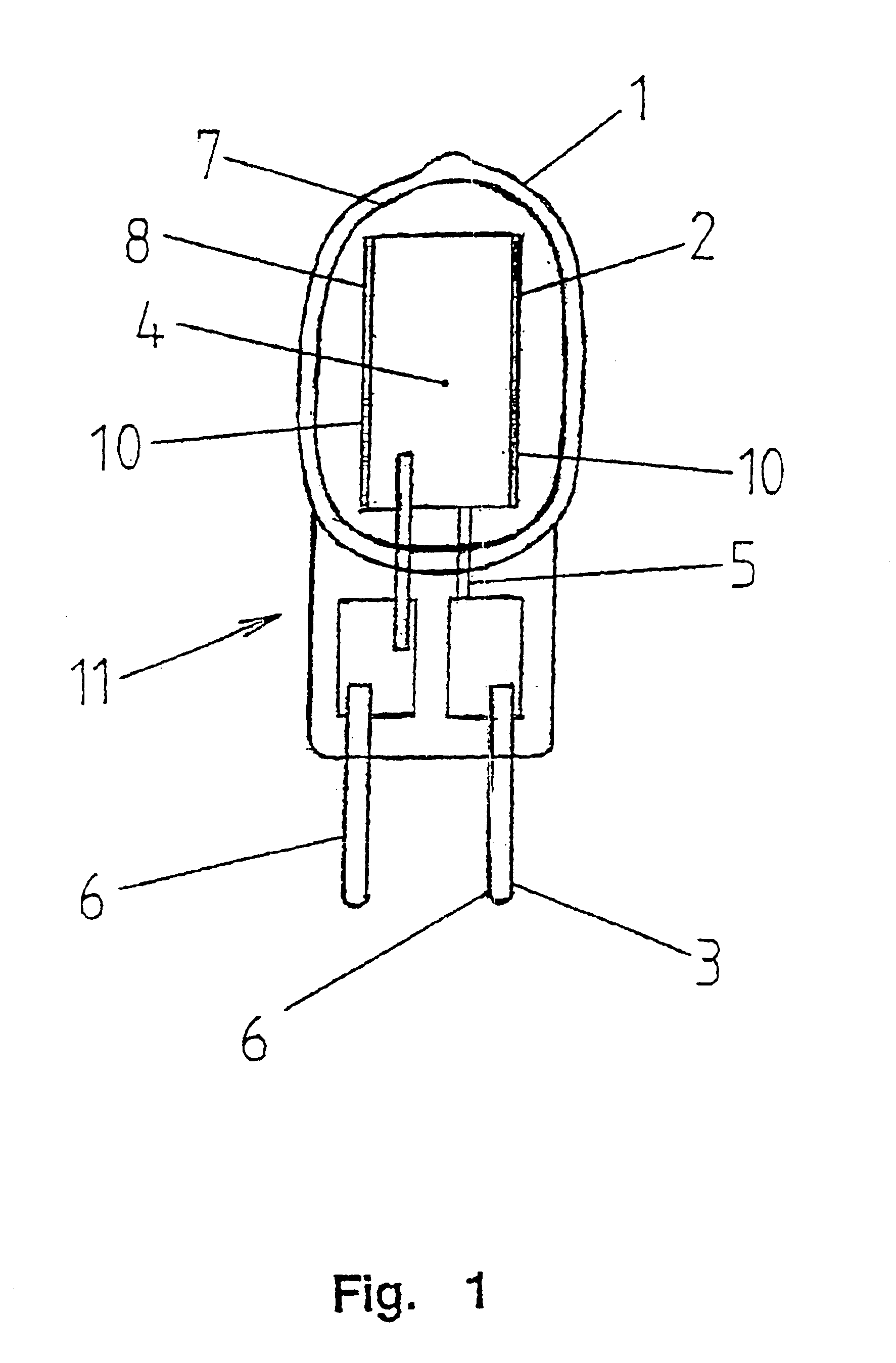

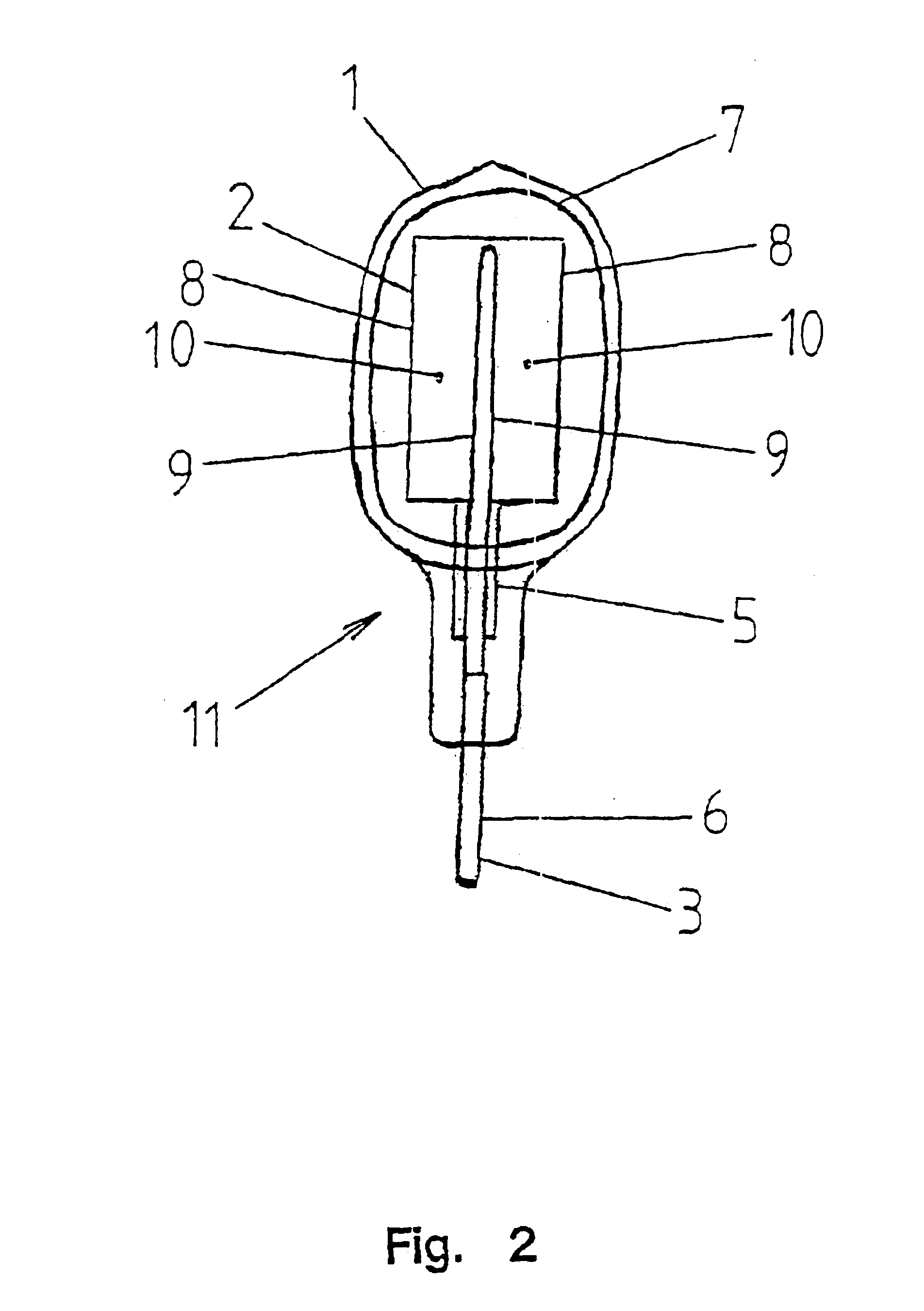

Light source and method for producing a light source

InactiveUS6903508B1Reliable productImprove conversion efficiencyDischarge tube luminescnet screensLamp incadescent bodiesCarbideThermal radiation

A light source, in particular incandescent lamp, with a bulb (1), a filament (2) arranged in the bulb (1), and a heating device (3) for the filament (2), the filament (2) emitting both visible light and heat radiation, is designed and constructed with respect to a high conversion efficiency between an electrical power input and emitted light output such that the filament (2) includes a flat section (4). A light source of this type may be produced by a method, wherein initially a filament (2) of a sintered metal powder is provided. Subsequently, the filament (2) is exposed to an atmosphere of carbon dioxide or of carbon dioxide and inert gas for forming a metal carbide. Finally, the filament (2) is sealed into the bulb (1).

Owner:IP2H AG

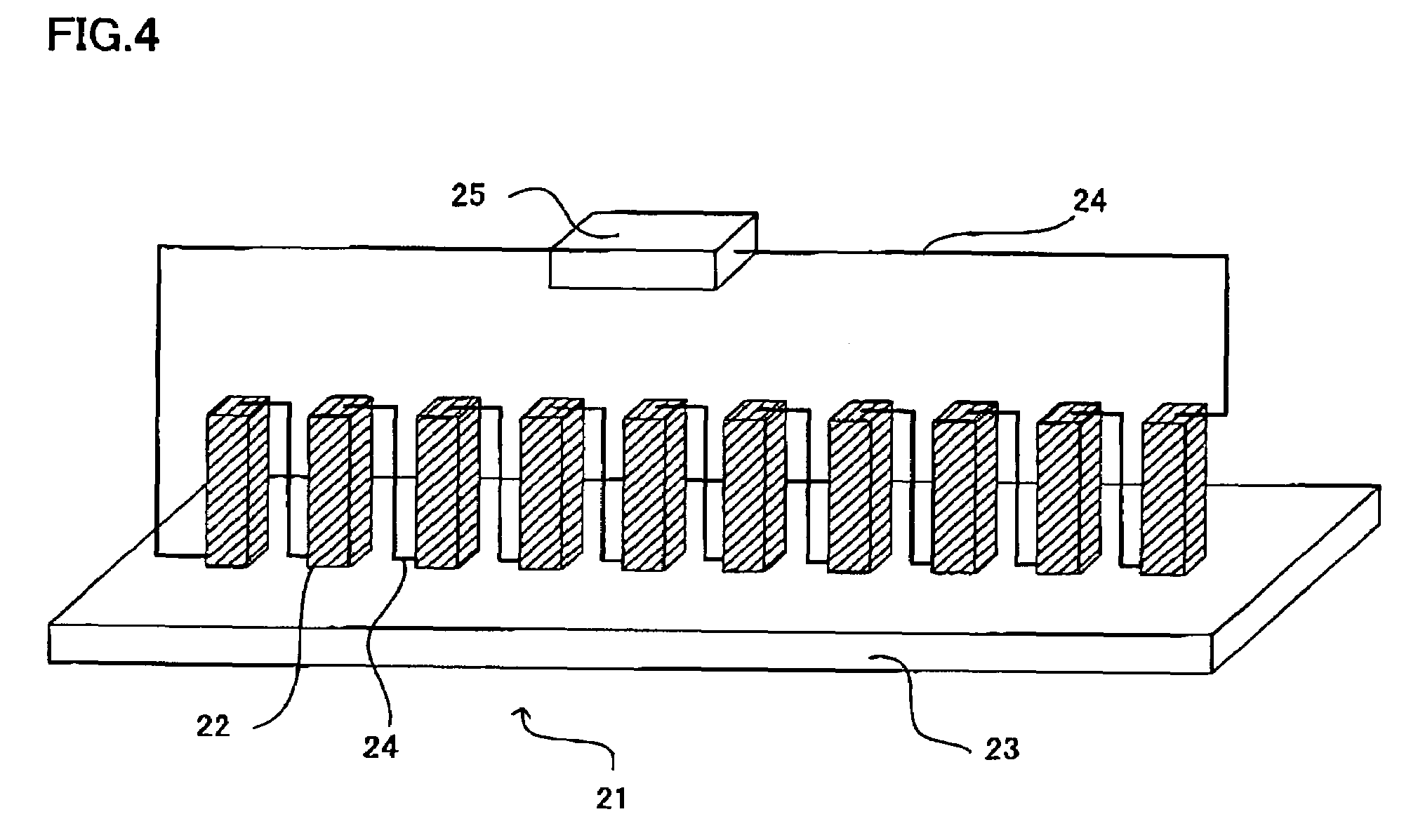

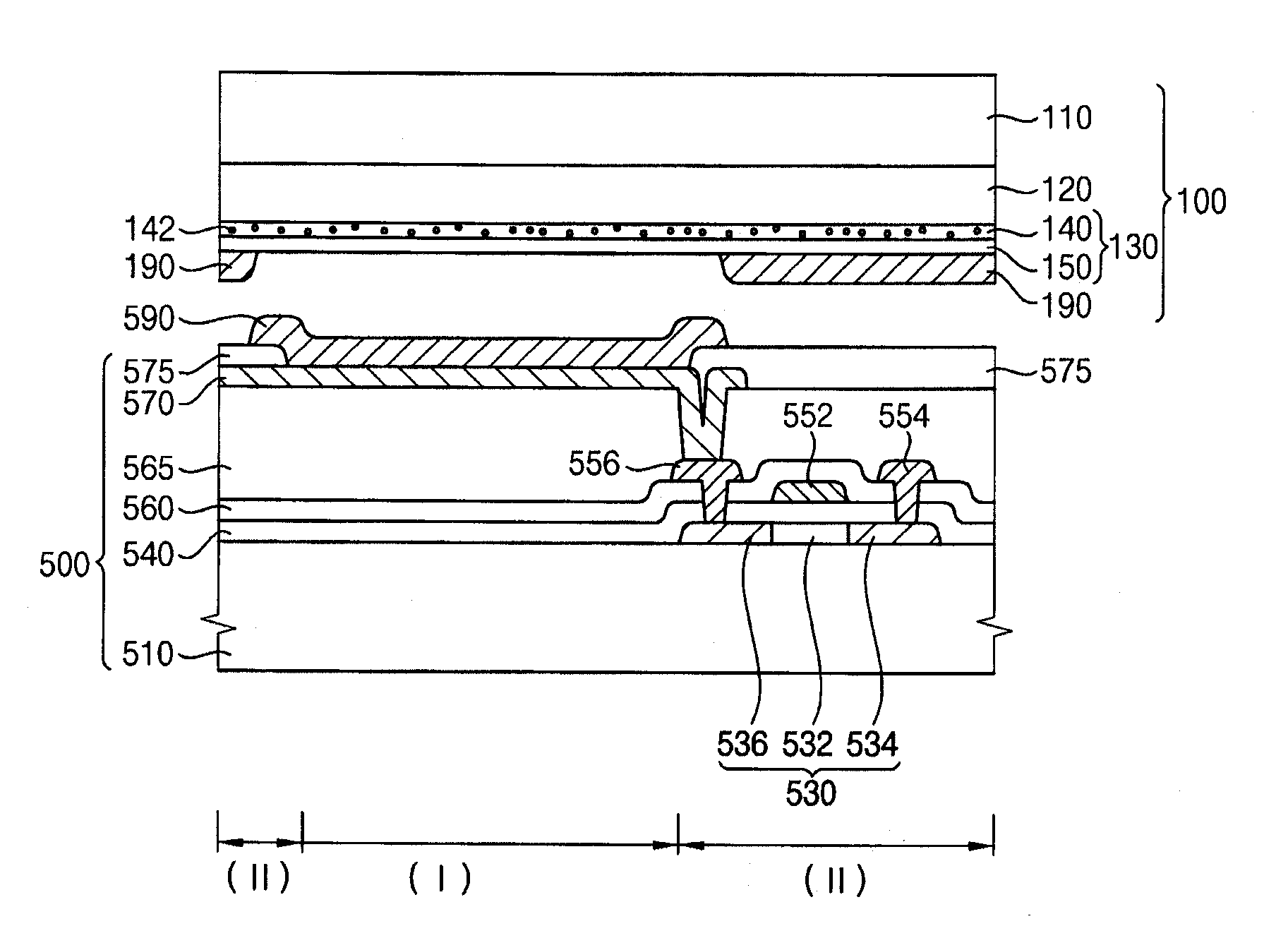

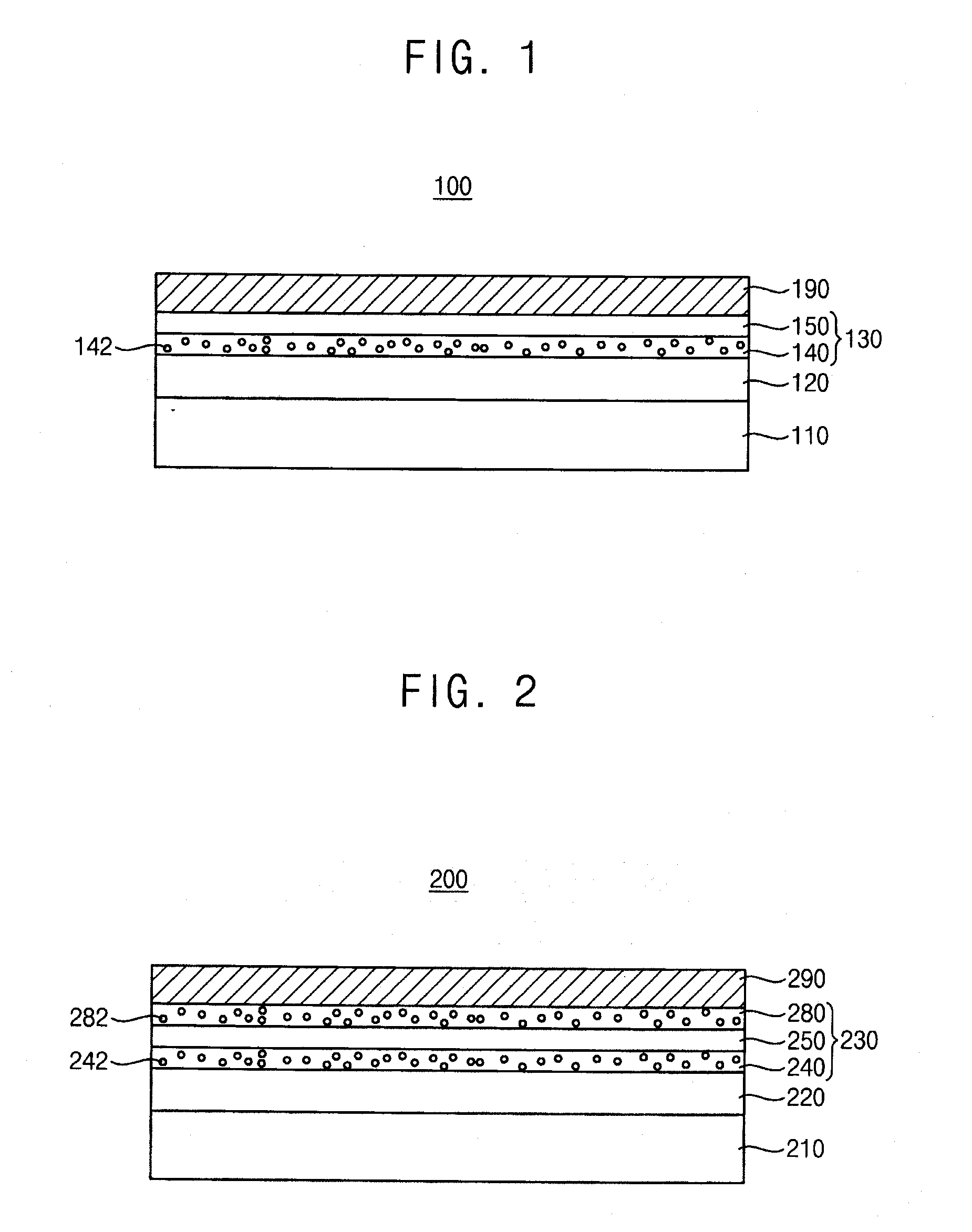

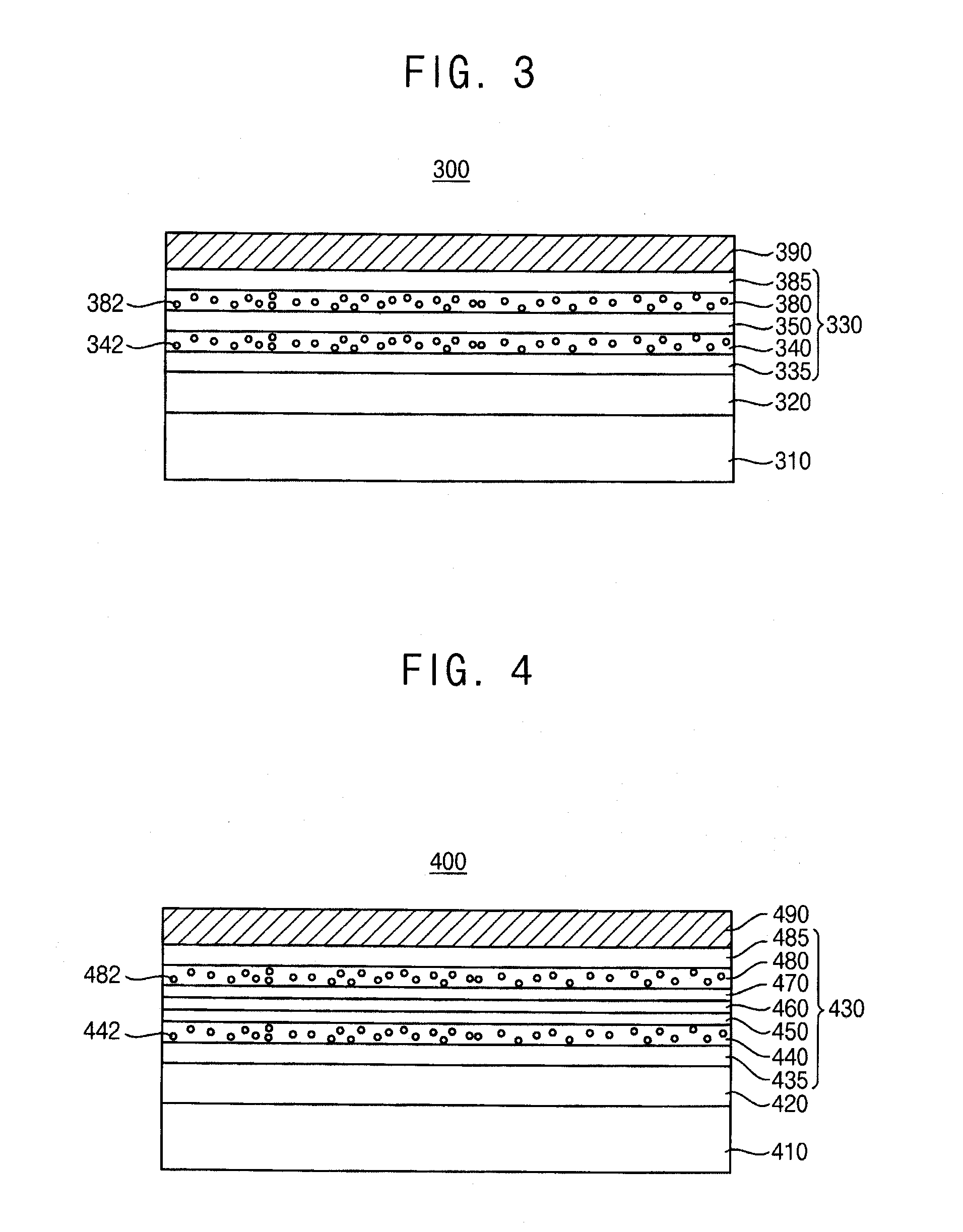

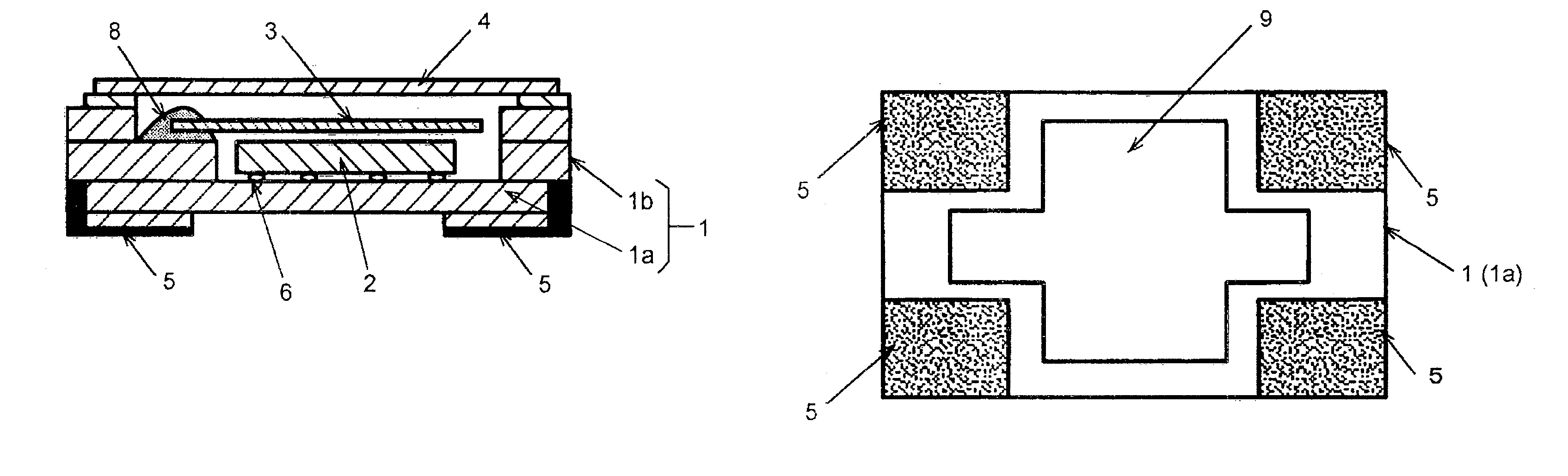

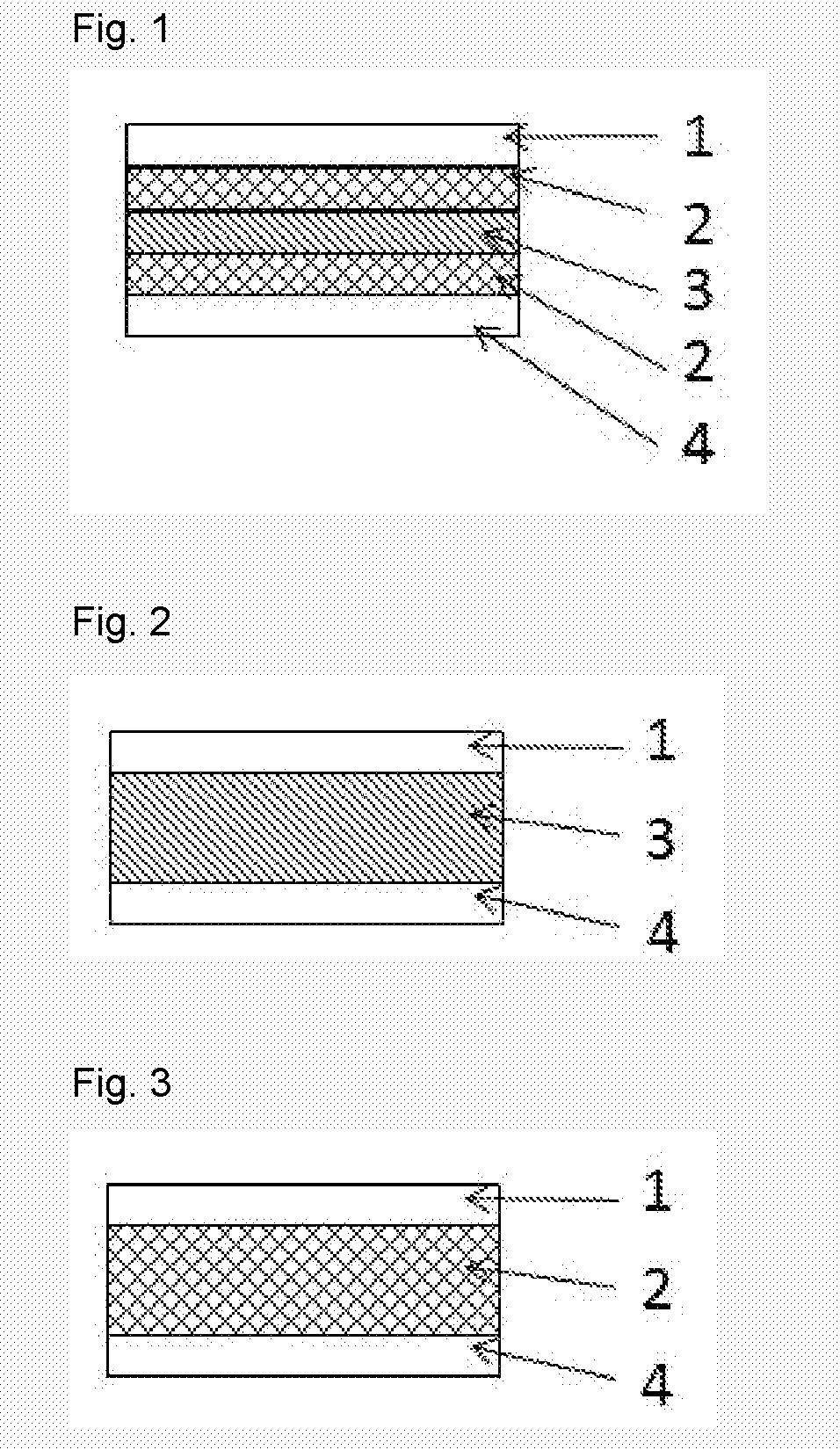

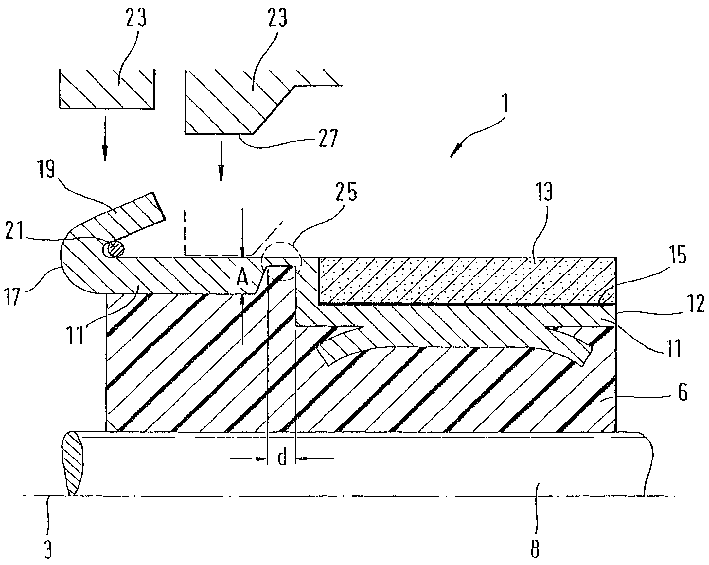

Donor substrates, laser induced thermal imaging methods using donor substrates and methods of manufacturing organic light emitting display devices using donor substrates

ActiveUS20130341601A1Reduce excess thermal transferSmall thermal conductivityFinal product manufactureSolid-state devicesPorous layerDisplay device

A donor substrate includes a base substrate, a light to heat conversion layer, a buffer layer and a transfer layer. The light to heat conversion layer may be disposed on the base substrate. The buffer layer may be disposed on the light to heat conversion layer. The buffer layer may include at least one porous layer having a plurality of pores. The transfer layer may be disposed on the buffer layer.

Owner:SAMSUNG DISPLAY CO LTD

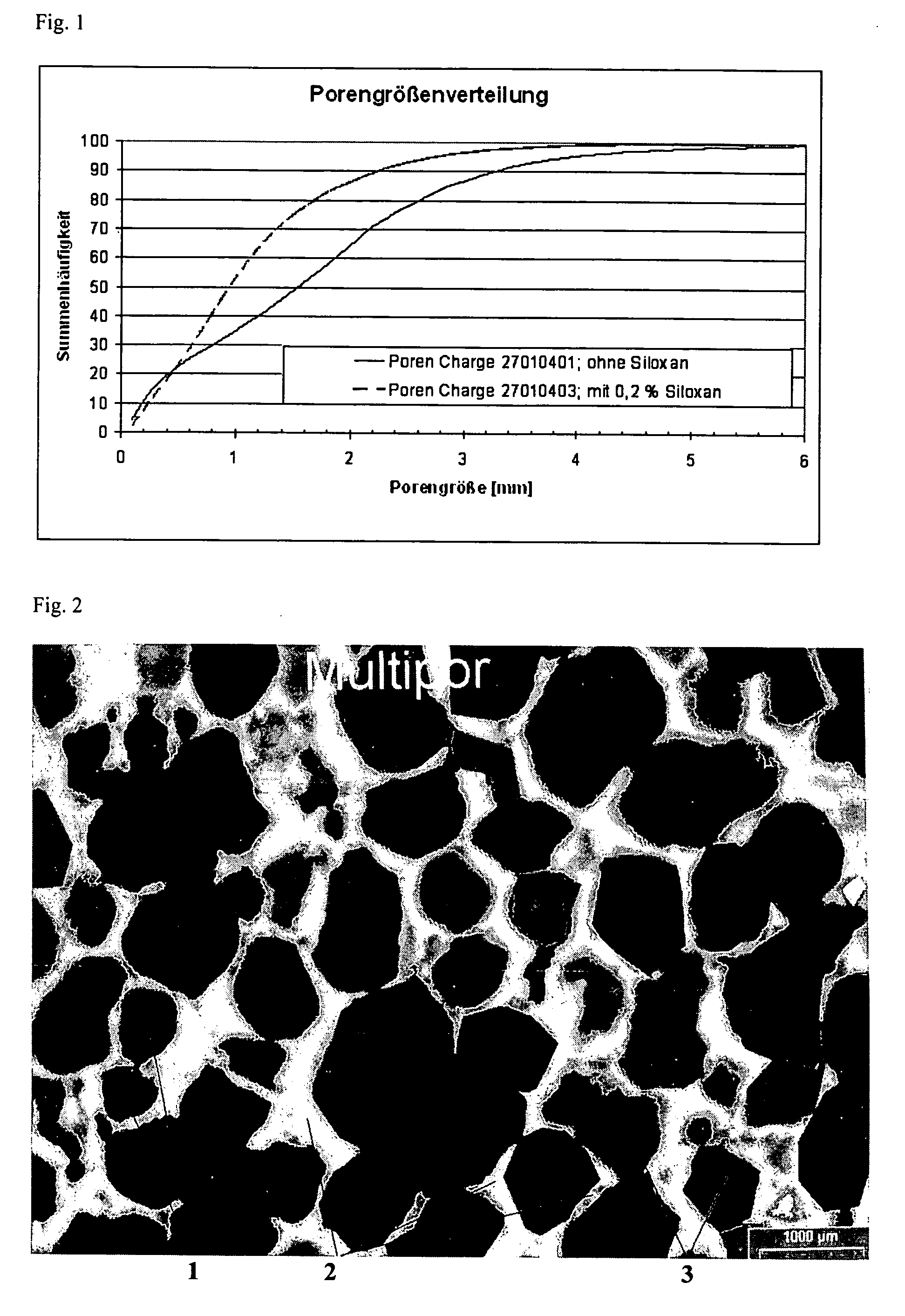

Mineral insulation element and process for producing it

ActiveUS20060177368A1Small thermal conductivitySmall bulk densitySolid waste managementLayered productsThermal conductivityAluminium

A mineral, aluminum-blown insulation element, in particular insulation slab, comprising calcium silicate hydrates as framework and blown pores surrounded by the framework, wherein more than 40% by volume, in particular more than 50% by volume, of the blown pores have a diameter of less than 1 mm and more than 75% by volume, in particular more than 85% by volume, of the blown pores have a diameter of less than 2 mm and the thermal conductivity λ10dr is preferably less than 0.045 W / mK.

Owner:XELLA DAMMSYSTEME GMBH

A method for preparing a heat-insulating coating material specially used for environmentally friendly packages

InactiveCN109111806AHigh compressive strengthHigh melting pointFireproof paintsReflecting/signal paintsFiberAcrylic resin

A method for preparing a heat-insulating coating material specially used for environmentally friendly packages is disclosed. The coating material includes following main raw materials by weight: 25-35parts of waterborne silicone acrylic resin, 5-10 parts of polyphenylene particles, 6-12 parts of hollow glass microbeads, 10-18 parts of zirconia ceramic fibers, 6-10 parts of mica, 6-10 parts of SiO2 aerogel, 50-60 parts of ethanol, 2-3 parts of a dispersant, 1.5-2.5 parts of a coupling agent, 2-3 parts of a thickener, 1-2 parts of a defoamer and a [Ag<46>Au<24>(SC2H4Ph)<32>](BPh4)2 cluster. Themethod includes S1) pretreating the hollow glass microbeads, S2) pretreating the SiO2 aerogel; S3) preparing a powder material mixture; S4) preparing slurry; and S5) mixing the powder material with the slurry. Through synergistic effects of the raw materials, the prepared coating material has excellent flame retardance, excellent heat insulation performance and a high thermal insulation efficiency. The method is simple, the raw materials are easily available and environmentally friendly, and the preparation cost is low.

Owner:葛惠惠 +2

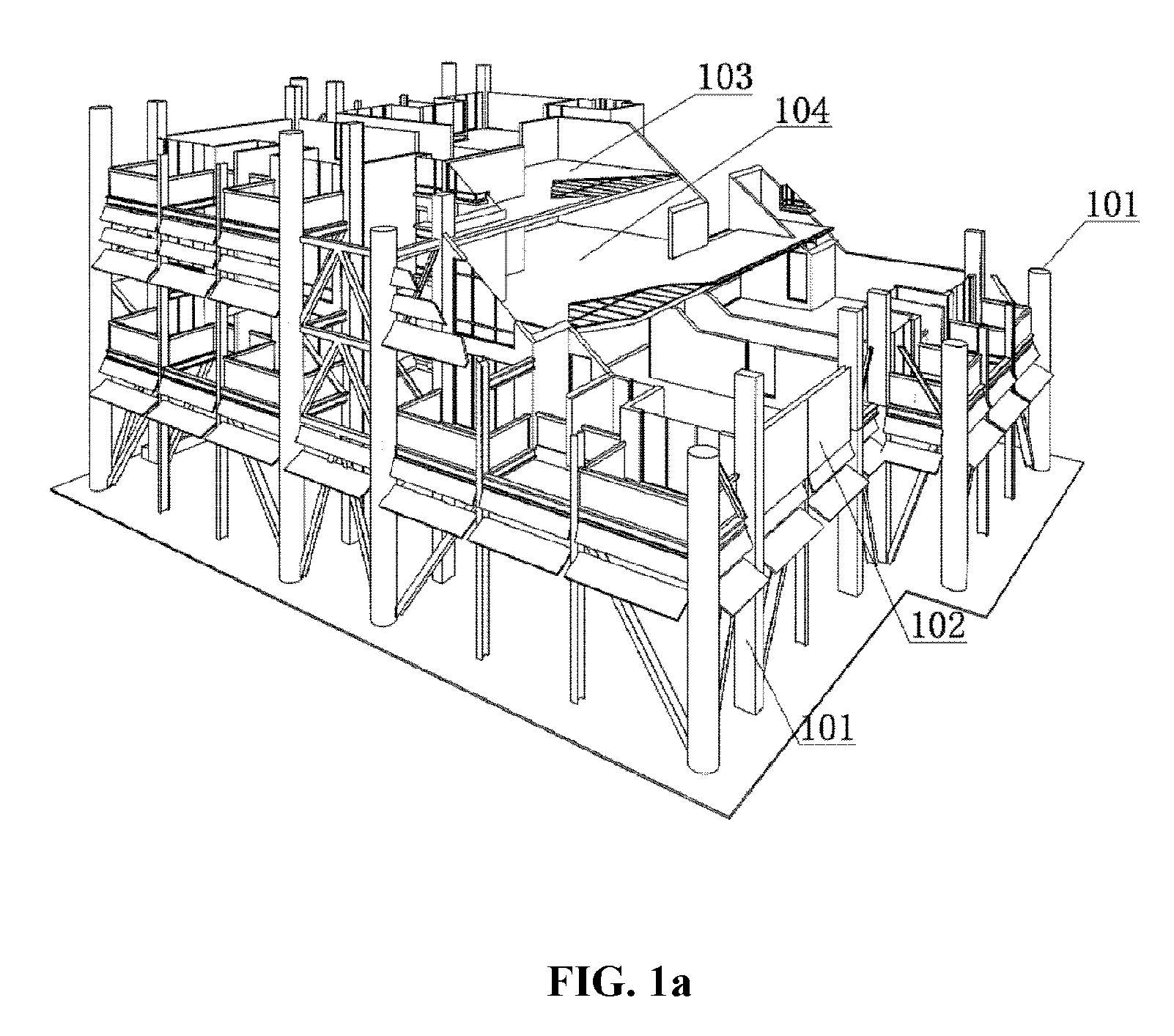

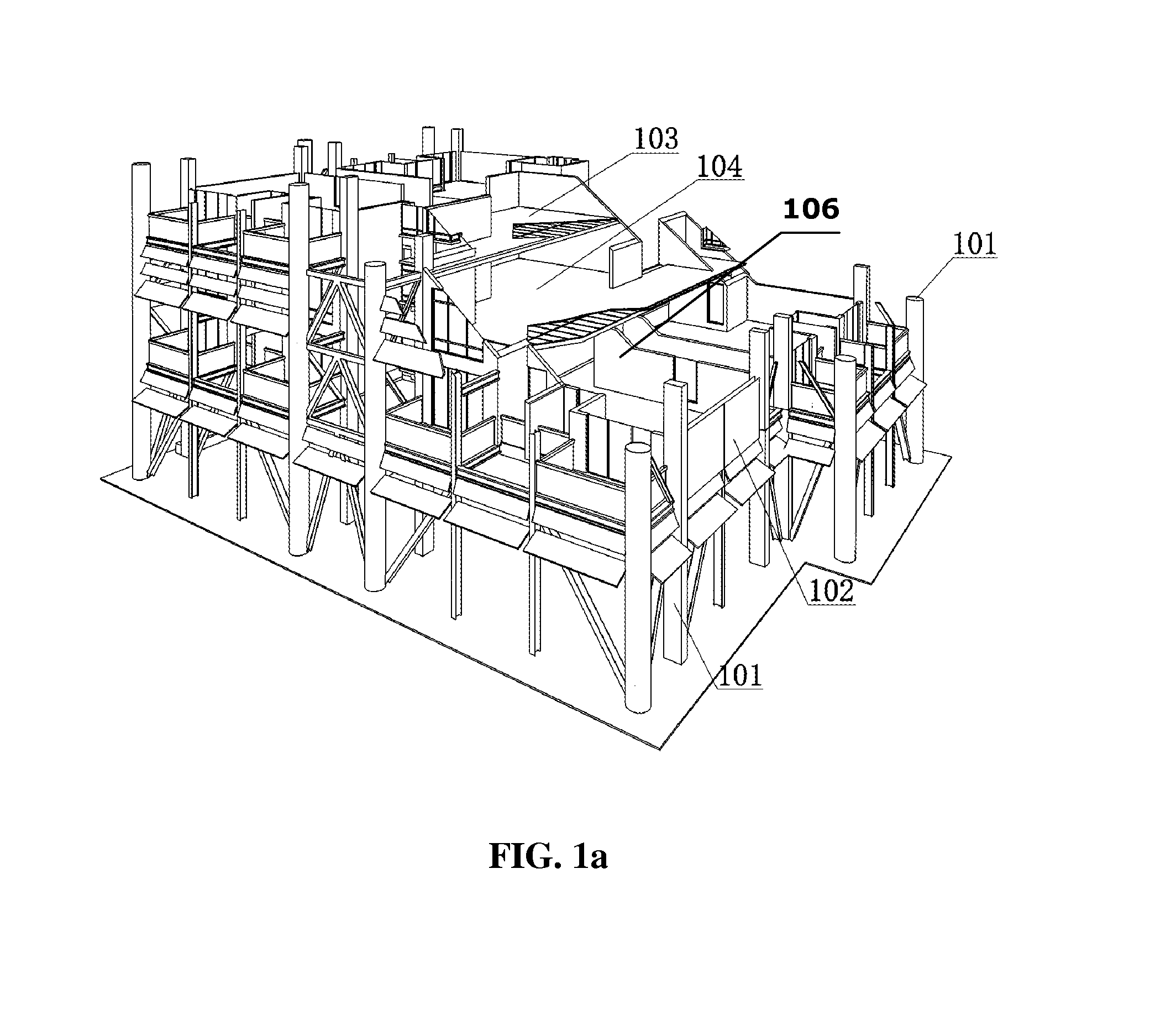

House constructed from finished product components and constructing method thereof

InactiveUS20140338283A1Reduce power consumptionImprove construction efficiencyFloorsBuilding repairsMaterial consumptionBuilding construction

A method for constructing such house is disclosed. The components of the house such as the finished product main frame, the finished product enclosed wall, the finished product floor cover plate, the finished product top cover plate and the finished product stair are finished product industrially constructed in different manufactories, and then transported to the constructing location respectively, and then assembled at the base of the house, so as to form a house constructed from finished product components. By using finished product components, the construction of the house has high efficiency, good quality, less material consumption and shorter construction period. Furthermore, comparing with traditional site operation, constructing house from finished product components is more environment-friendly.

Owner:HUANG TAO +1

Safe explosion-proof membrane and preparation method thereof

InactiveCN107325311AImprove uniformityNot easy to fadePolyester coatingsTectorial membraneThermal insulation

The invention discloses a safe explosion-proof membrane and a preparation method thereof. The explosion-proof membrane comprises a PET carrier layer, wherein a first functional layer is arranged on one surface of the PET carrier layer, a second functional layer is arranged on the other surface of the PET carrier layer, and protecting membrane layers are arranged on the outer surfaces of the first functional layer and the second functional layer. The preparation method of the explosion-proof membrane comprises the steps of preparing the first functional layer, preparing the second functional layer, preparing materials of the protecting membrane layers, and carrying out coating. The safe explosion-proof membrane is unlikely to fade and warp, has thermal-insulation, ultraviolet ray-blocking, anti-hitting and explosion-proof functions and is simple in preparation process, relatively low in cost and suitable for being taken as an outer-layer explosion-proof membrane of mobile phones and digital products.

Owner:HEFEI FANTENG ENVIRONMENTAL PROTECTION TECH CO LTD

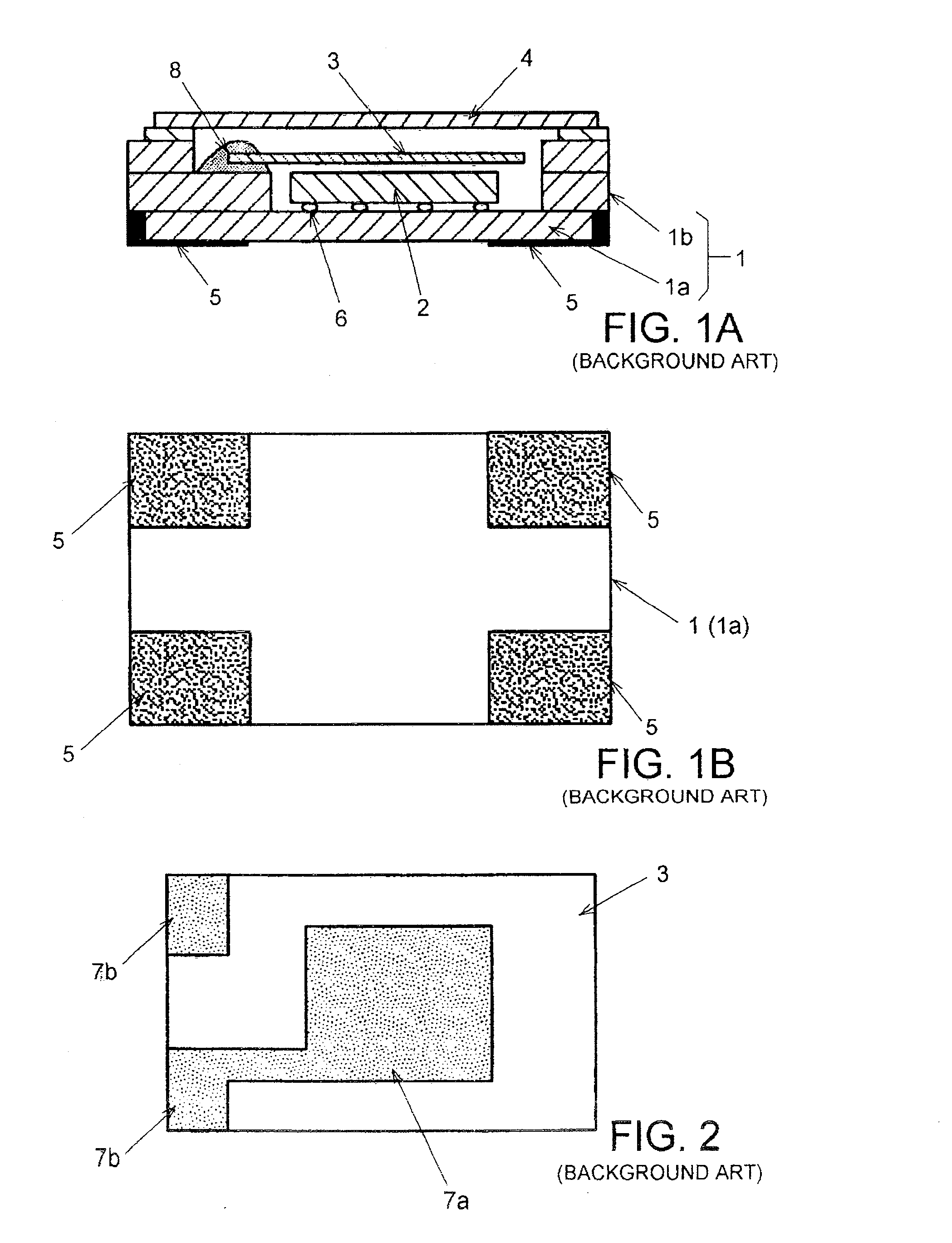

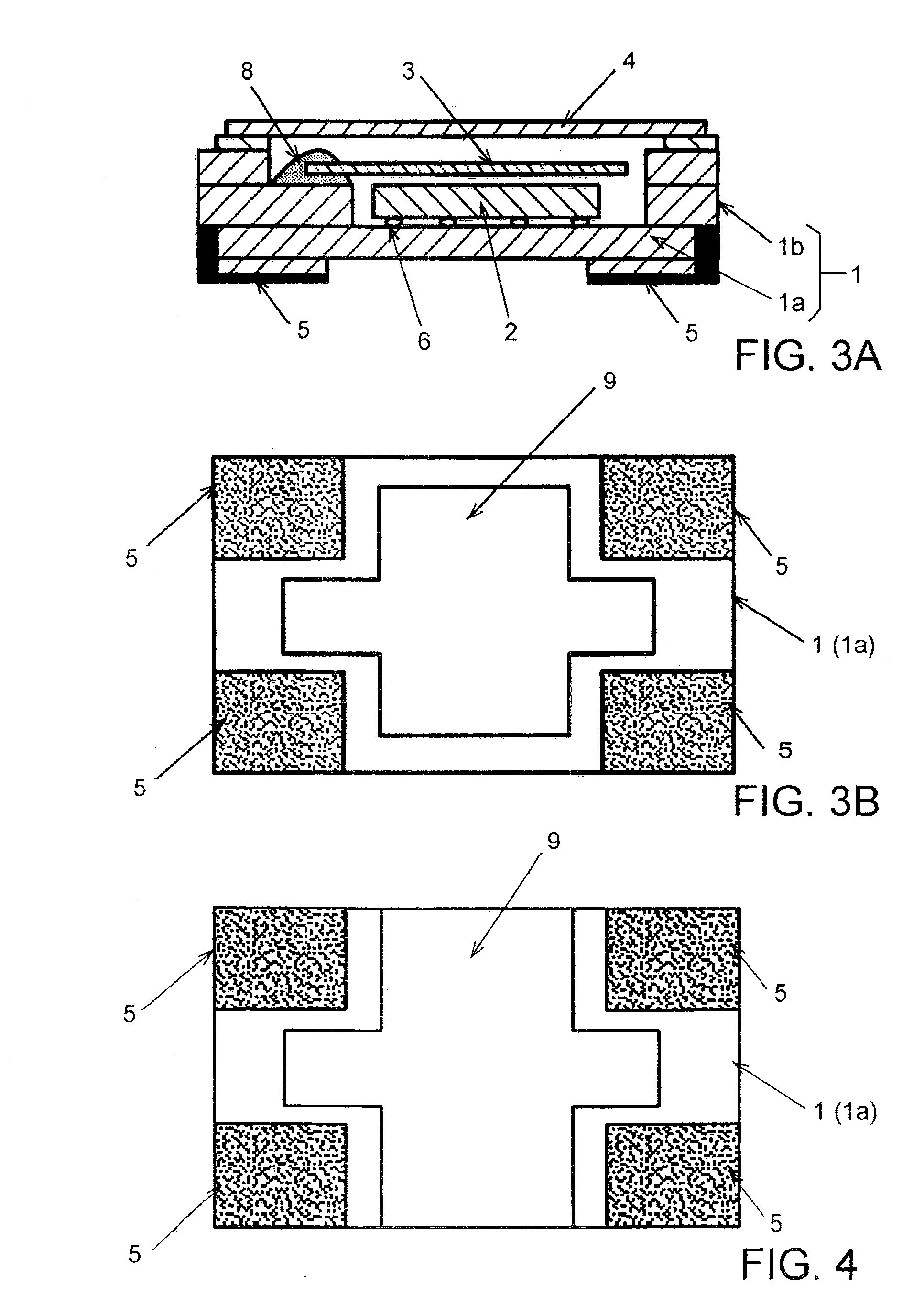

Surface mount crystal oscillator

InactiveUS20070241827A1Enhance heat radiation effectTemperature differenceOscillations generatorsSurface mountingEngineering

A crystal oscillator for surface-mounting on a circuit board comprises a package body which includes a bottom wall layer, and a frame wall layer having an opening and laminated on the bottom wall layer, where the opening defines a recess in the package body, a crystal blank contained in the recess, an IC chip contained in the recess, and mounting terminals disposed at four corners on an outer bottom surface of the package body for use in mounting the crystal oscillator. An oscillation circuit using the crystal blank is integrated in the IC chip. The package body is formed with a cavity in at least a central region of the outer bottom surface thereof, and no electrode layer is disposed in the cavity.

Owner:NIHON DEMPA KOGYO CO LTD

Method and pavement structure for protecting highway subgrade in frozen soil area

ActiveUS8303211B2Lean structureLow costMaterial nanotechnologyIn situ pavingsEngineeringRoad surface

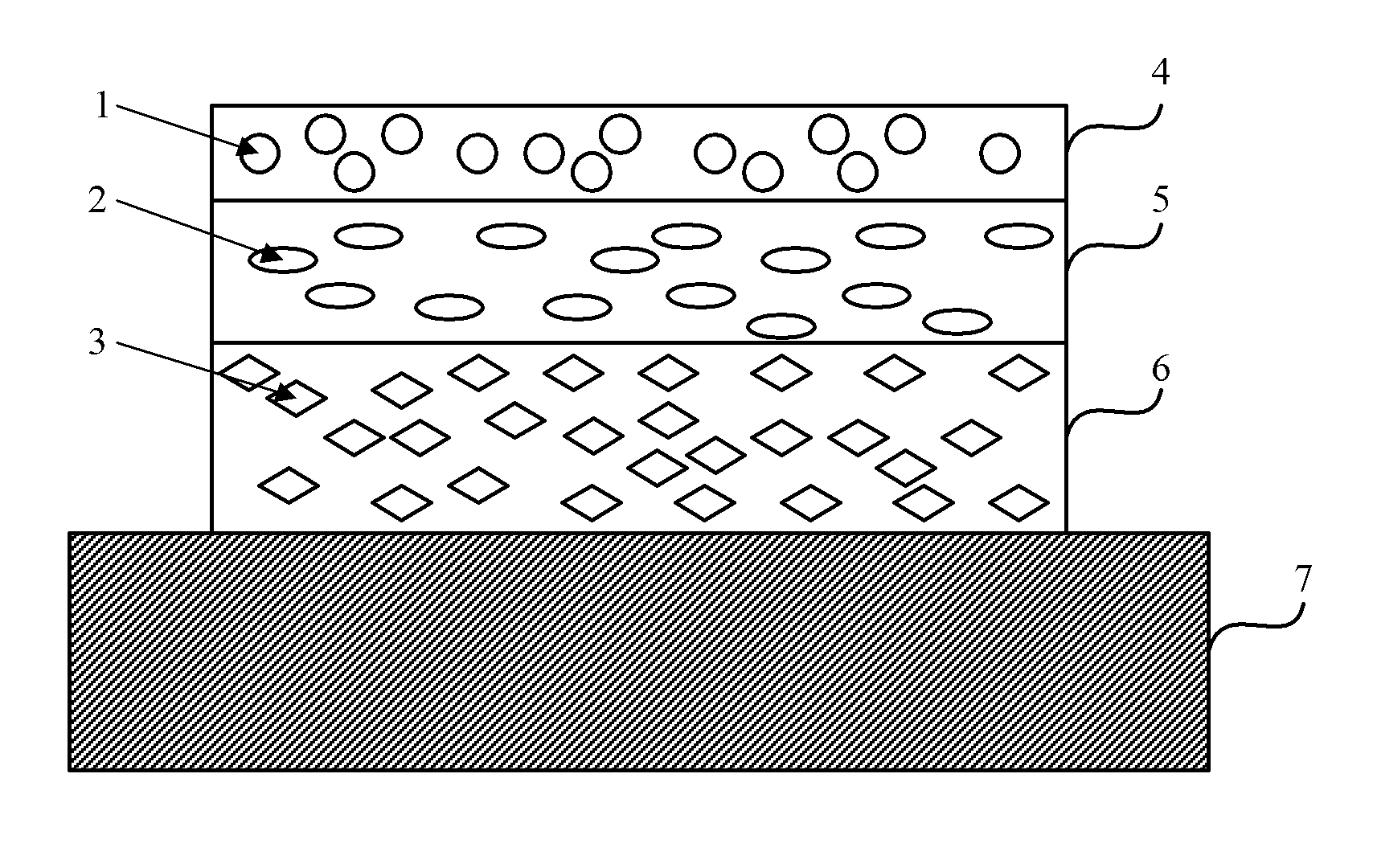

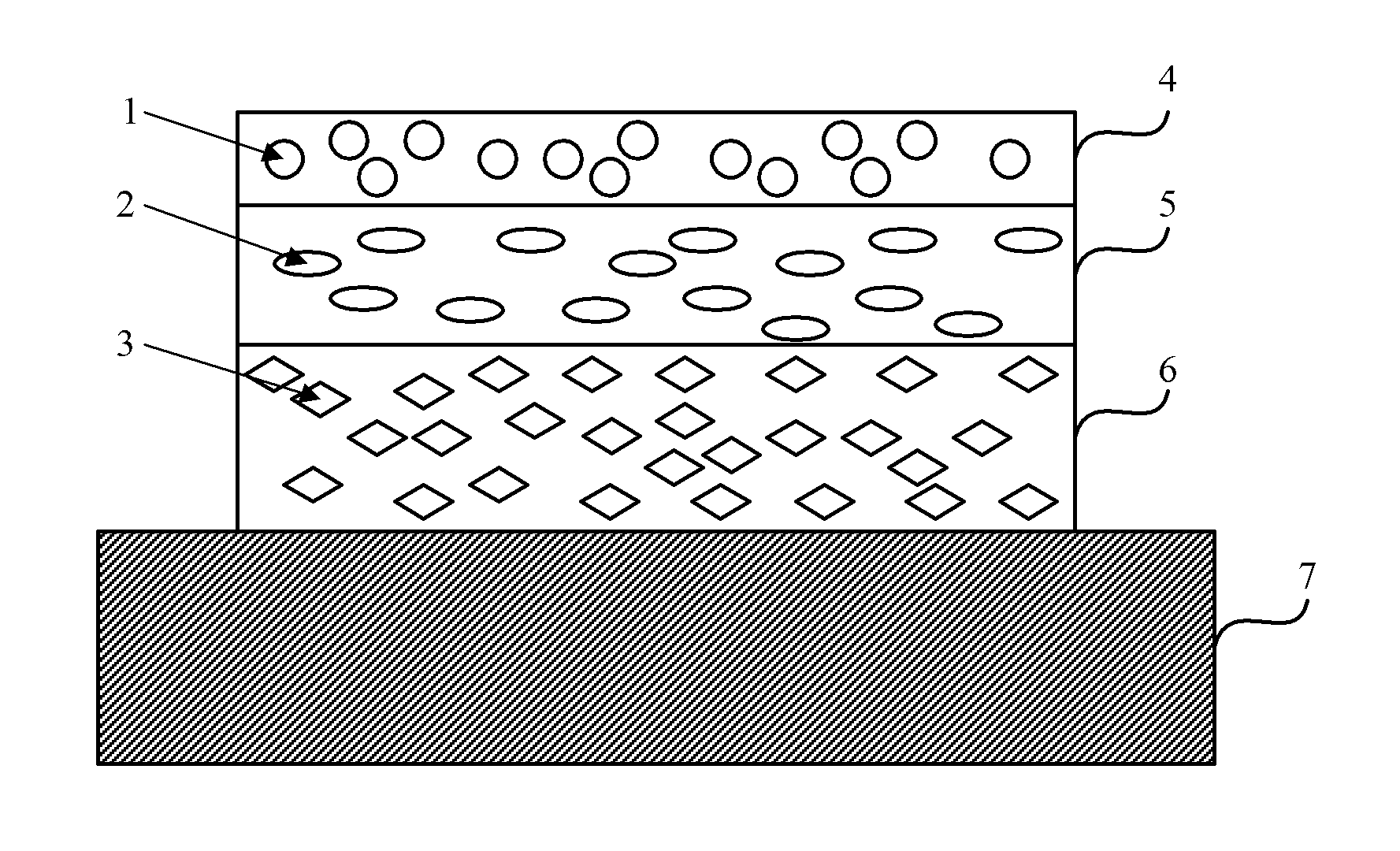

The present invention provides a method and pavement structure for protecting highway subgrade in frozen soil areas. The pavement structure has two or more pavement layers having gradient thermal conductivity; the thermal conductivity is layered among the pavement layers and is lowered from top to bottom, so that the pavement forms a uni-directional thermal conducting tunnel from the subgrade to the air. Heat can be easily released from the subgrade into the air, and is prevented from being transferred from the air to the subgrade. In this way, the frozen soil layer beneath the subgrade is cooled, so that the frozen soil table is made stable, and the highway subgrade in frozen soil areas is protected.

Owner:CCCC FIRST HIGHWAY CONSULTANTS +1

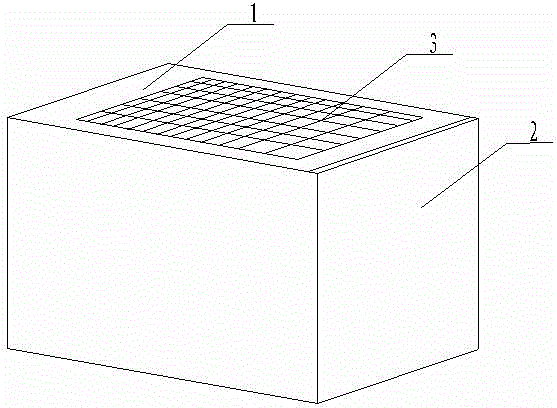

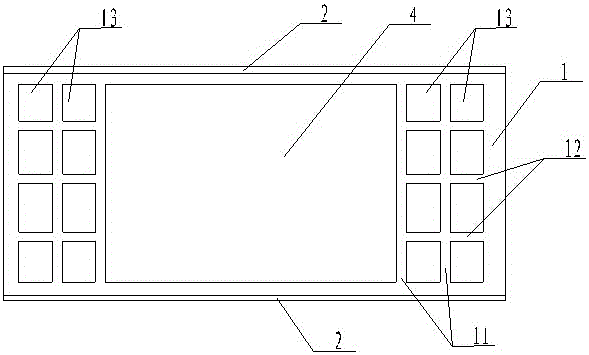

Production method of sintered-filled self-insulation building block or wallboard

ActiveCN104446212AImprove insulation effectGood energy saving and emission reduction effectSolid waste managementCelluloseFoaming agent

The invention discloses a production method of a sintered-filled self-insulation building block or wallboard. The production method comprises the following steps: adding cement and water into crushed construction waste or coal ash, uniformly mixing, then adding cellulose and a foaming agent, with the added amount of cellulose being 0.5-3% of the total mass and the added amount of the foaming agent being 1-5% the total mass, and uniformly mixing to obtain an insulation filling material; filling up the cavity of the building block or the wallboard with the insulation filling material, and naturally curing or curing by heating, thus obtaining the filled self-insulation building block or wallboard. According to the production method disclosed by the invention, the construction waste is used for resource utilization, thus turning waste into wealth; a wall body has an excellent insulation performance, is a real green and energy-saving building block, plays good energy-saving and emission-reducing roles, and meets the need of building energy conservation; the thickness of the wall body is reduced, sand rubbing does not need to be carried out at the outer side and the inner side of the wall body, the glaze surface of the wall body is directly used as an outer wall surface, and an inner cavity coating is directly brushed on the inner side surface of the wall body, thus furthest reducing working procedures and saving various building materials.

Owner:晏兴洪

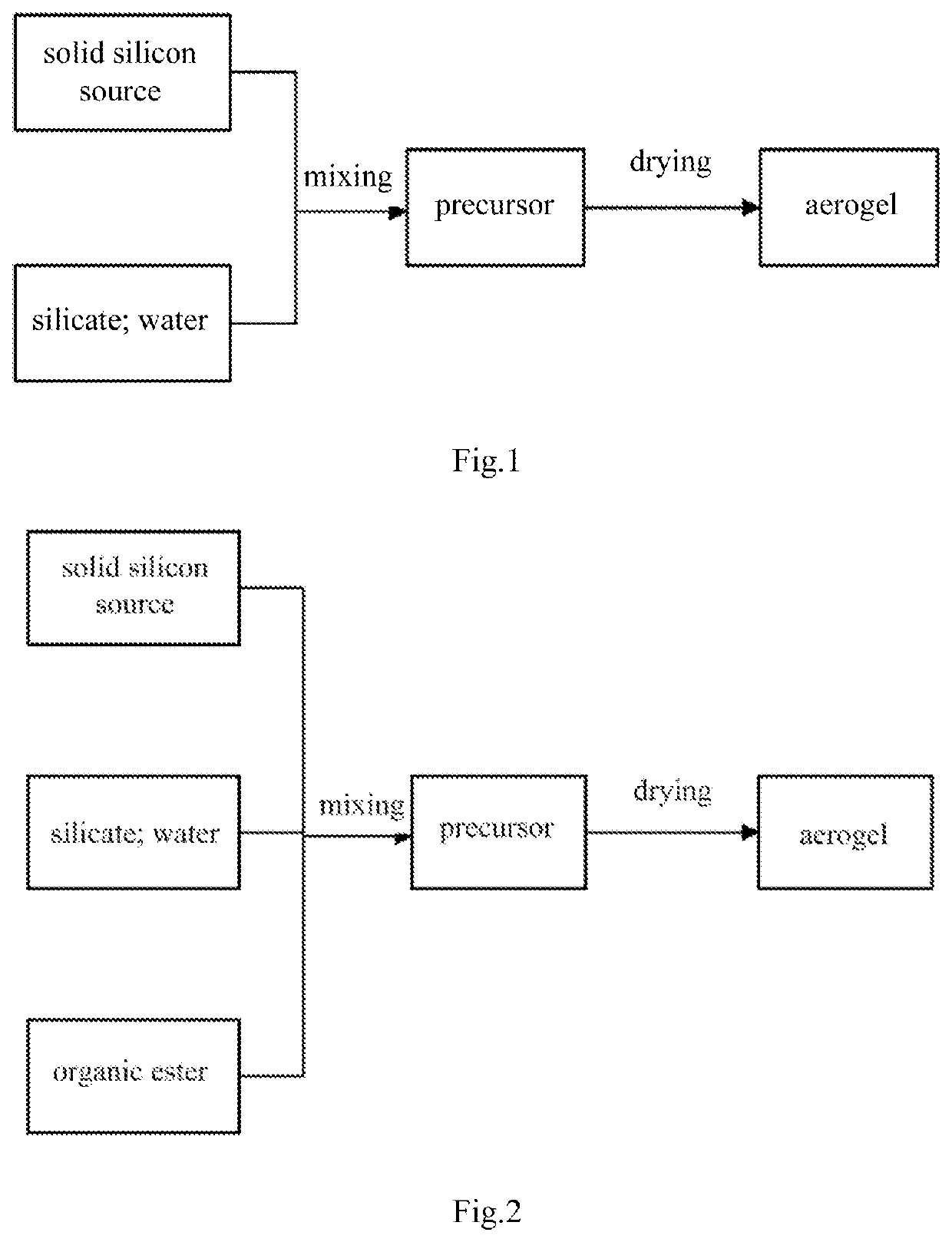

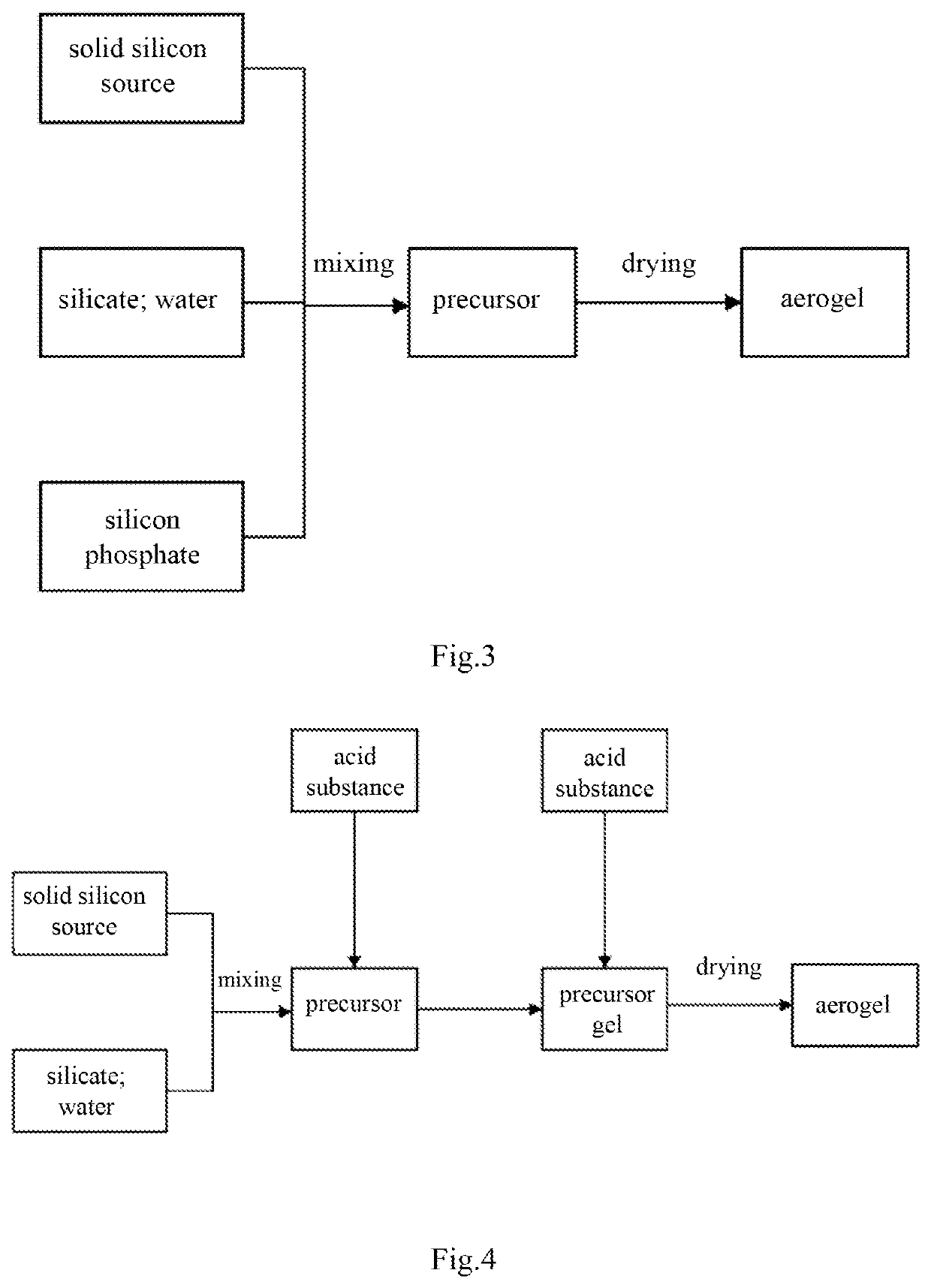

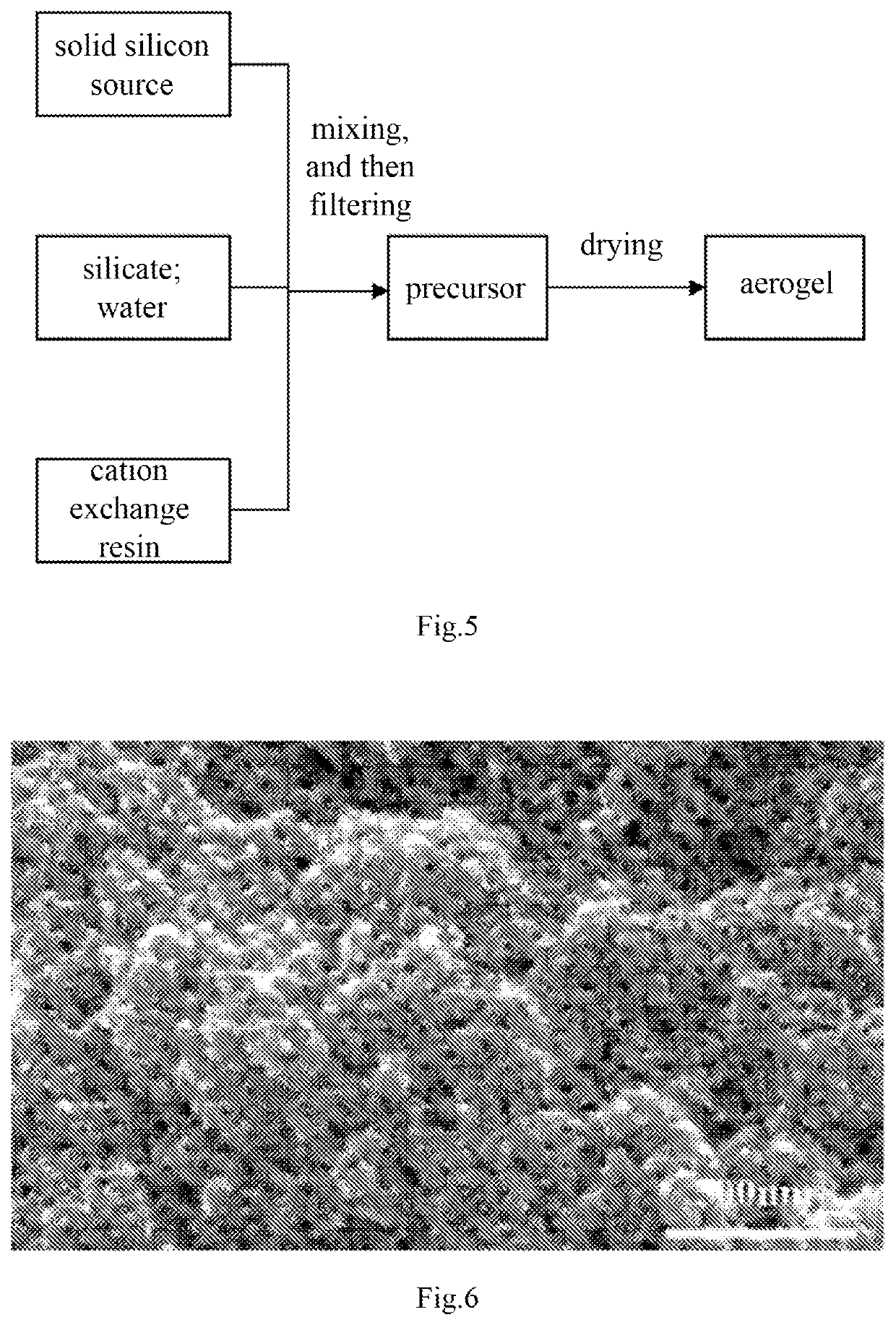

Silica aerogel preparation method and aerogel prepared using said method

PendingUS20210246038A1Increase opportunitiesIncreased formationAerogel preparationSilicon compoundsPhysical chemistrySilicon dioxide

A preparation method for a silica aerogel, comprising the following steps: A) raw material containing a solid silicon source and an alkaline solution is used to produce an aerogel precursor after mixing; and B) the aerogel precursor is dried to obtain a silica aerogel. An improved silica aerogel preparation method, comprising the following steps: A) a cation exchange resin and a silicate solution are used as raw materials and mixed; B) the mixed material is allowed to stand to obtain an aerogel precursor; and C) the aerogel precursor is dried to obtain a silica aerogel.

Owner:TIANJIN MROGAN KUNDOM HI TECH DEV

Heat-insulating material

ActiveUS9139448B2Small thermal conductivityImprove insulation performanceMangesium aluminatesCeramicwareMetallurgyPore diameter

A heat-insulating material is provided in which thermal conductivity is controlled not to increase and good insulation properties are held even in a high temperature range. The heat-insulating material is formed of a spinel porous sintered body having a porosity of 65 to 90 vol. % and represented by a chemical formula XAl2O4 (X=Zn, Fe, Mg, Ni, or Mn) which is arranged such that large pores having a diameter of greater than 1000 μm occupy 25 vol. % or less of the total pore volume, fine pores having a diameter of 0.45 μm or less occupy 5 to 40 vol. % of the volume of the pores having a diameter of 1000 μm or less, at least one pore-diameter distribution peak is within a range of 0.14 to 10 μm, and is formed of sintered particles having a calculated average particle diameter of 0.04 to 1 μm.

Owner:COORSTEK INC

Waterproof material for toilet and preparation method of waterproof material

The invention discloses a waterproof material for a toilet and a preparation method of the waterproof material and relates to the technical field of waterproof materials. The waterproof material comprises the following raw materials in parts: 70-80 parts of modified starch, 55-65 parts of inorganic powder fillers, 45-50 parts of cis-1,4-polyisoprene rubber, 35-40 parts of aluminum stearate, 30-35 parts of fly ash, 25-30 parts of nano particles, 15-25 parts of organic fibers, 15-20 parts of dimethyl silicone, 10-15 parts of aids, 5-10 parts of pigments and 120-150 parts of water. The waterproof material disclosed by the invention has excellent waterproof, anti-permeability and antibacterial and anti-mold properties, the raw materials are environmental-friendly and high in affinity, water leakage in the toilet can be effectively prevented, and the waterproof material is difficult to age.

Owner:HEFEI FENGTENG ENERGY SAVING TECH CO LTD

Method for making sintered filled self-insulating block or wallboard

ActiveCN104446212BImprove insulation effectGood energy saving and emission reduction effectSolid waste managementCelluloseFoaming agent

The invention discloses a production method of a sintered-filled self-insulation building block or wallboard. The production method comprises the following steps: adding cement and water into crushed construction waste or coal ash, uniformly mixing, then adding cellulose and a foaming agent, with the added amount of cellulose being 0.5-3% of the total mass and the added amount of the foaming agent being 1-5% the total mass, and uniformly mixing to obtain an insulation filling material; filling up the cavity of the building block or the wallboard with the insulation filling material, and naturally curing or curing by heating, thus obtaining the filled self-insulation building block or wallboard. According to the production method disclosed by the invention, the construction waste is used for resource utilization, thus turning waste into wealth; a wall body has an excellent insulation performance, is a real green and energy-saving building block, plays good energy-saving and emission-reducing roles, and meets the need of building energy conservation; the thickness of the wall body is reduced, sand rubbing does not need to be carried out at the outer side and the inner side of the wall body, the glaze surface of the wall body is directly used as an outer wall surface, and an inner cavity coating is directly brushed on the inner side surface of the wall body, thus furthest reducing working procedures and saving various building materials.

Owner:晏兴洪

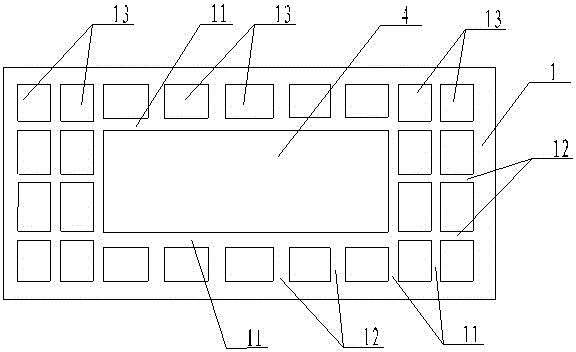

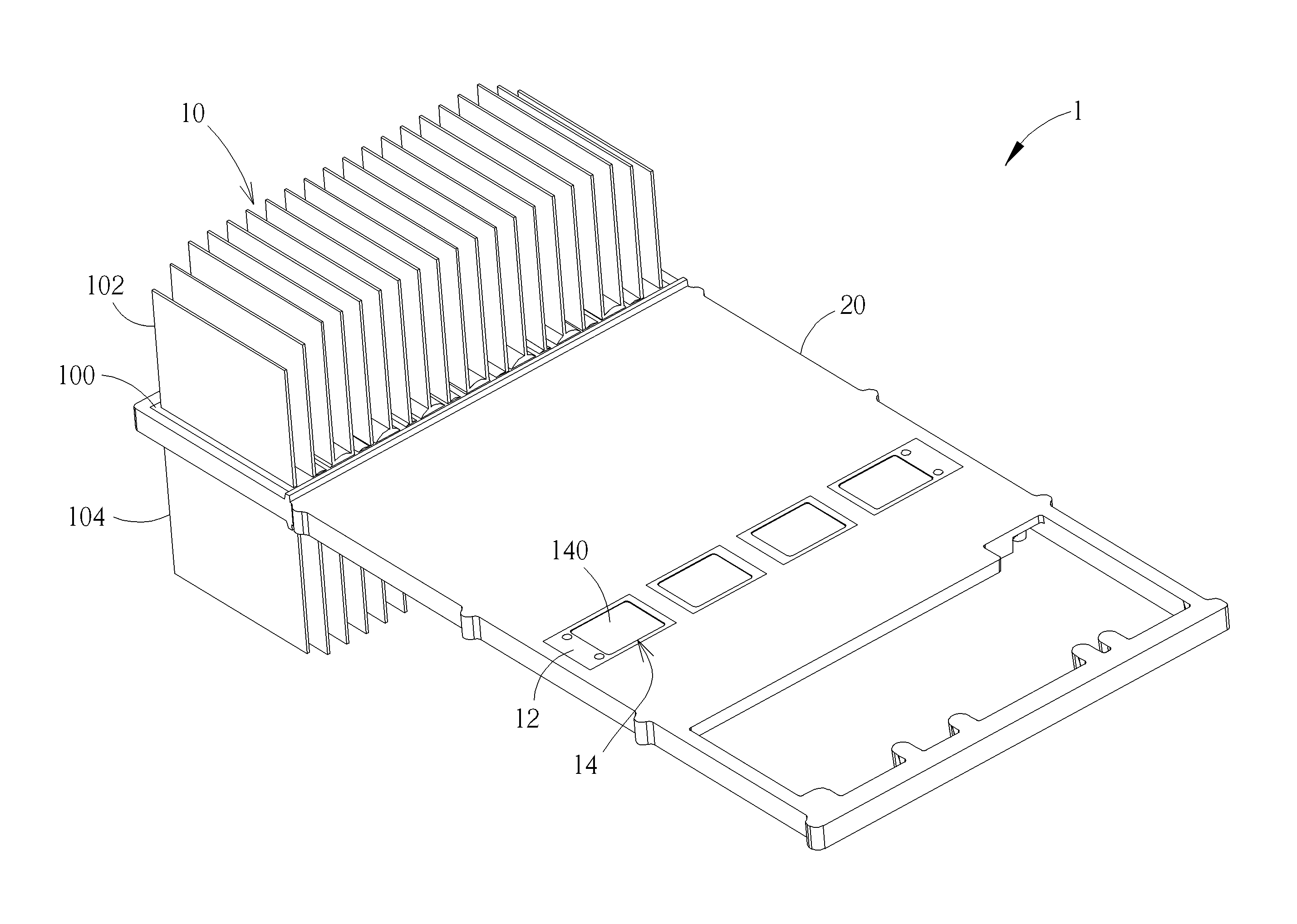

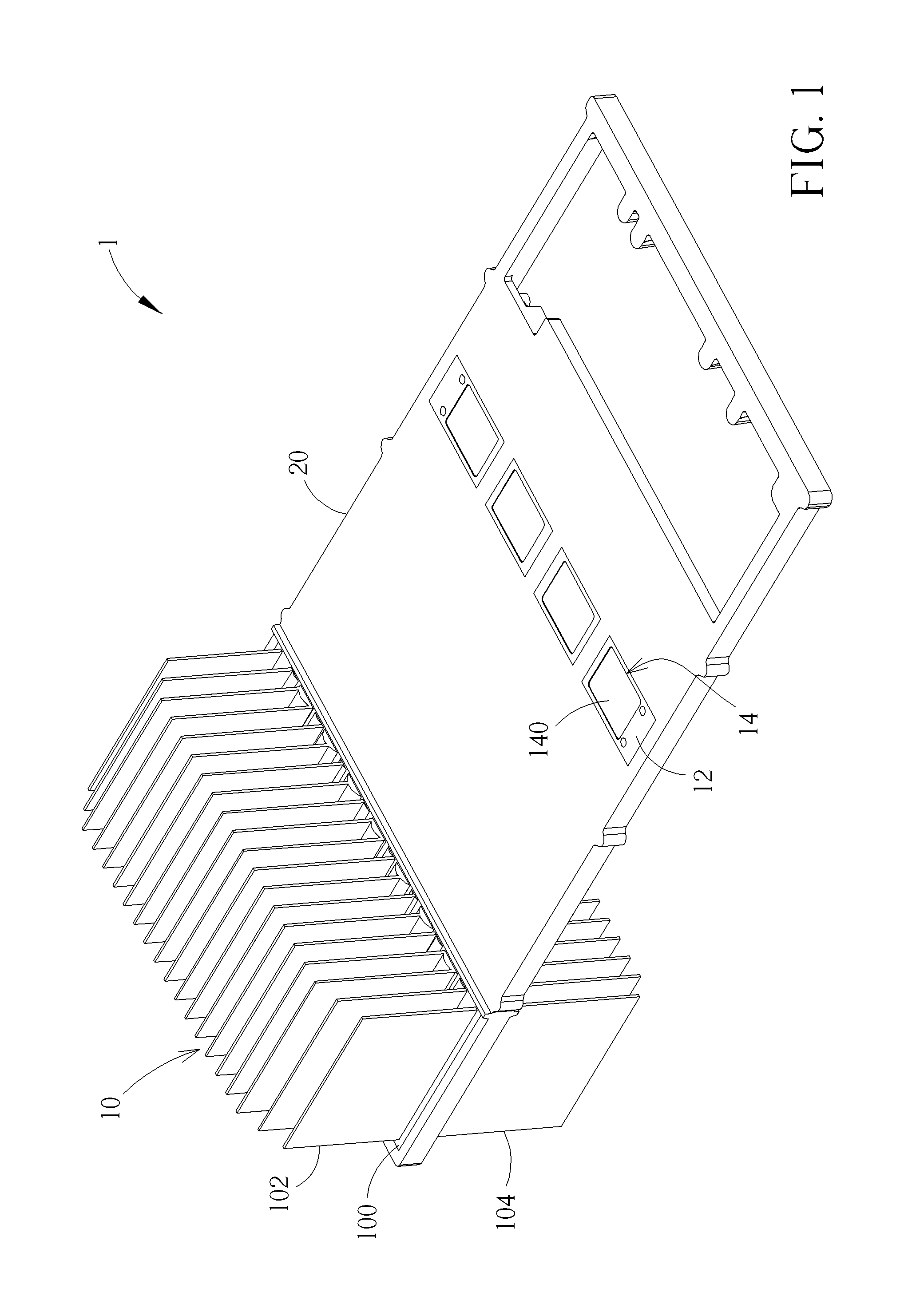

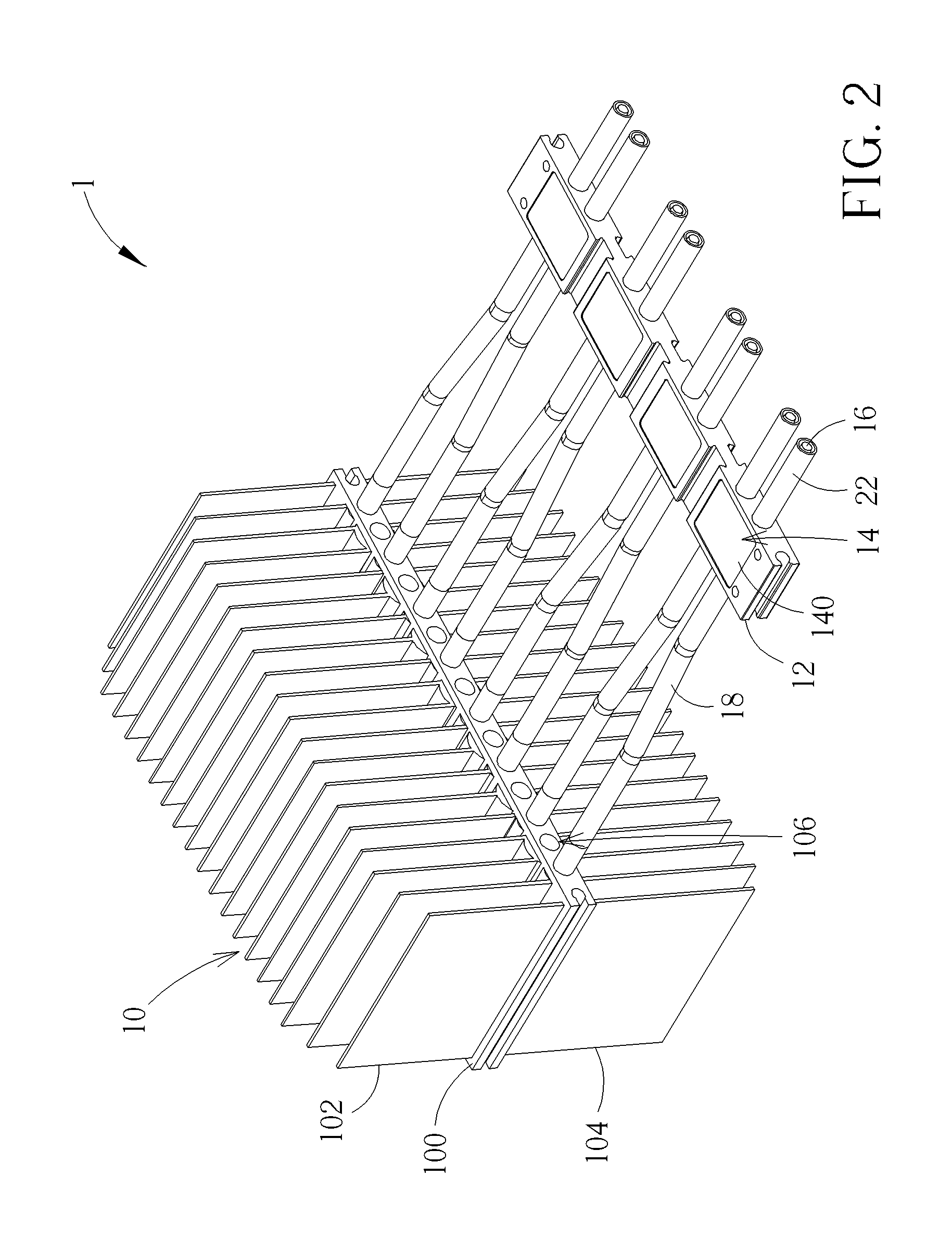

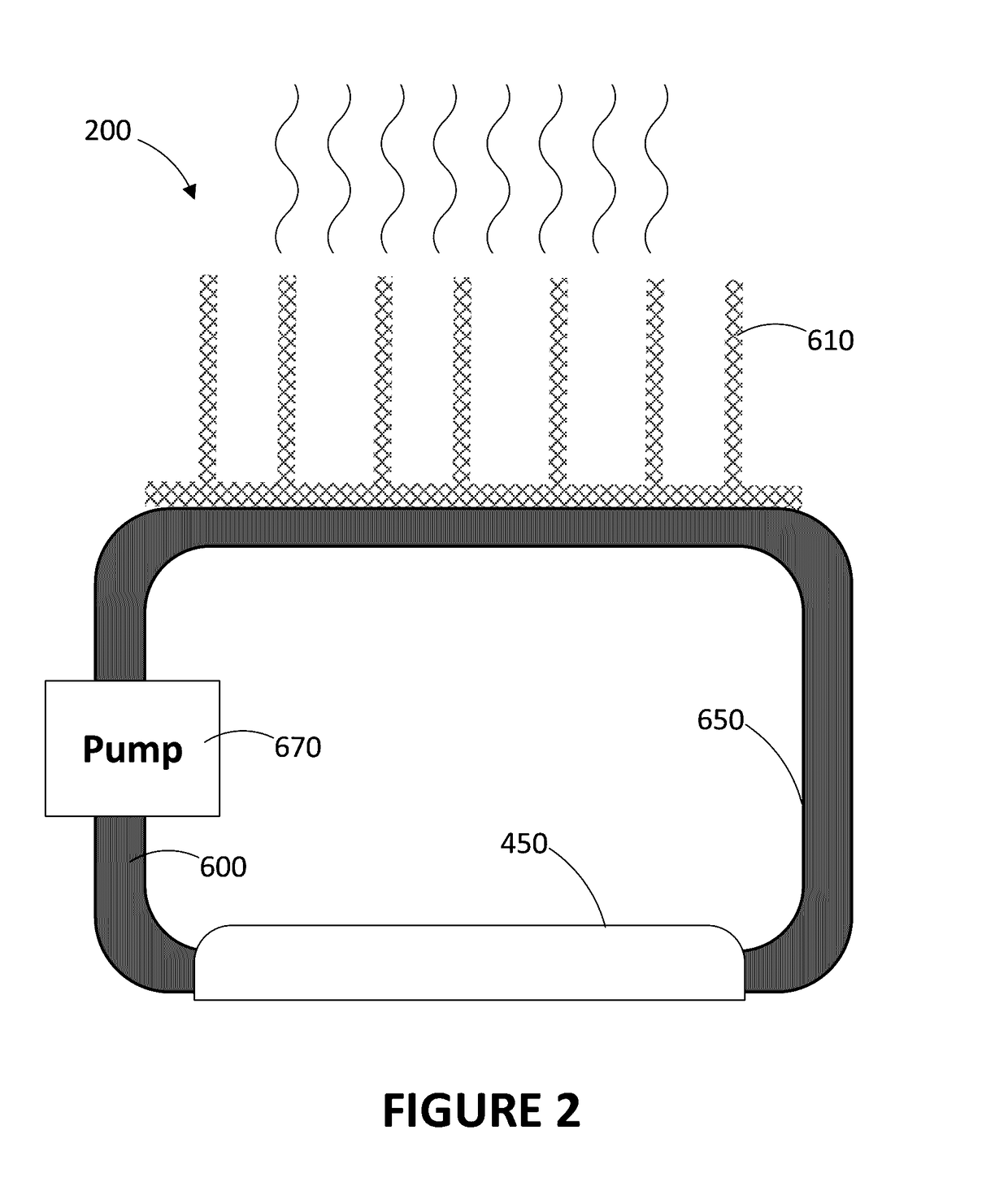

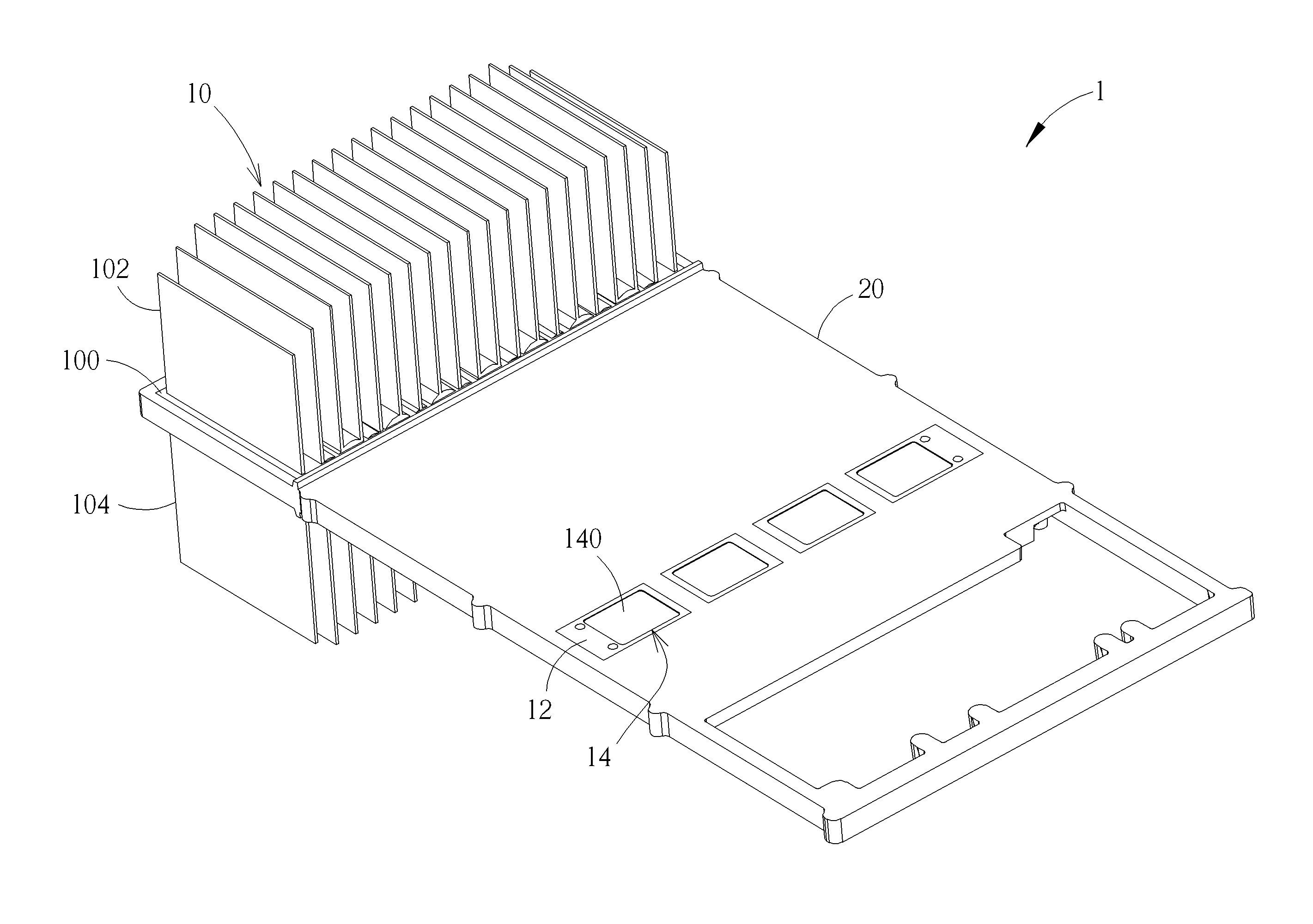

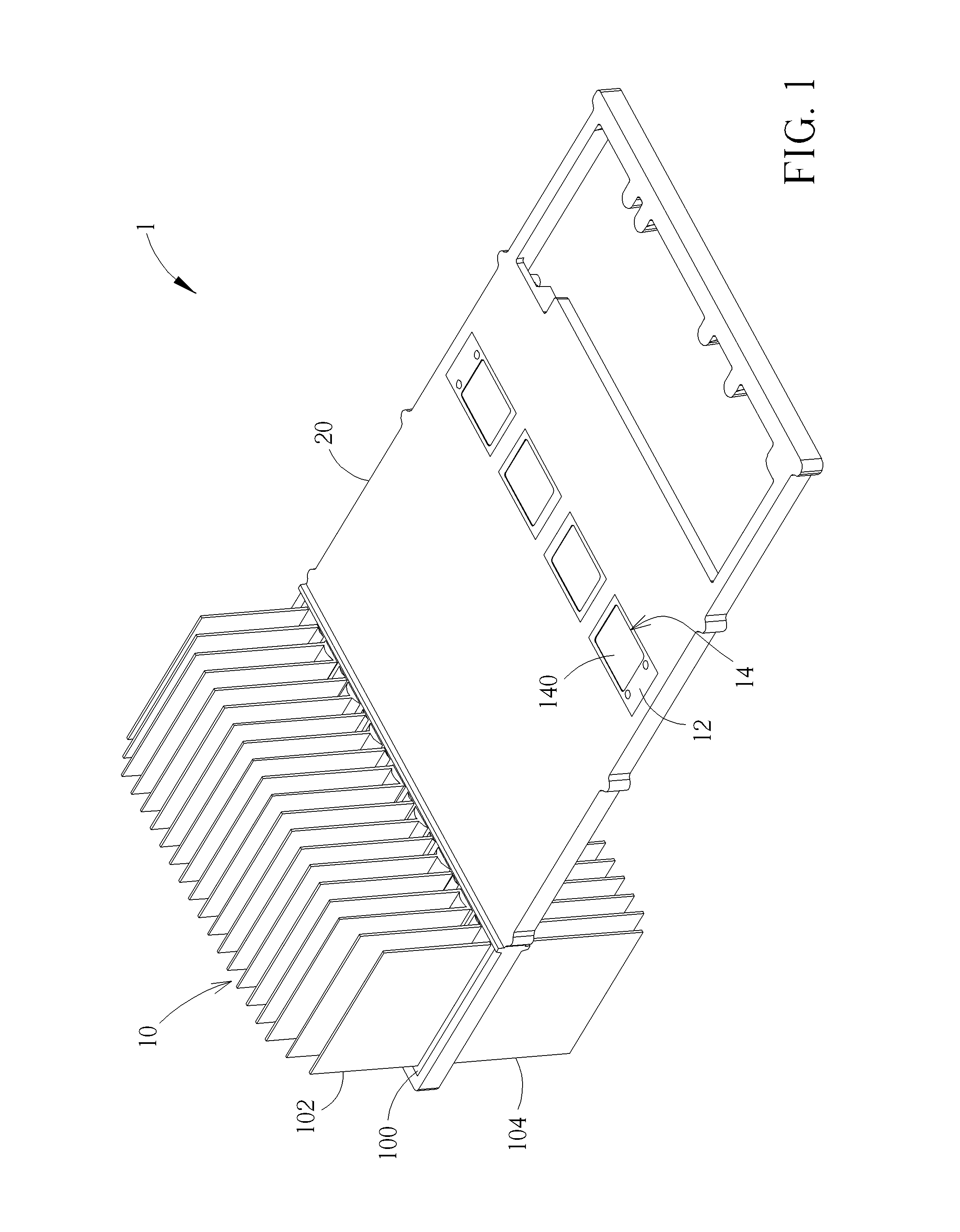

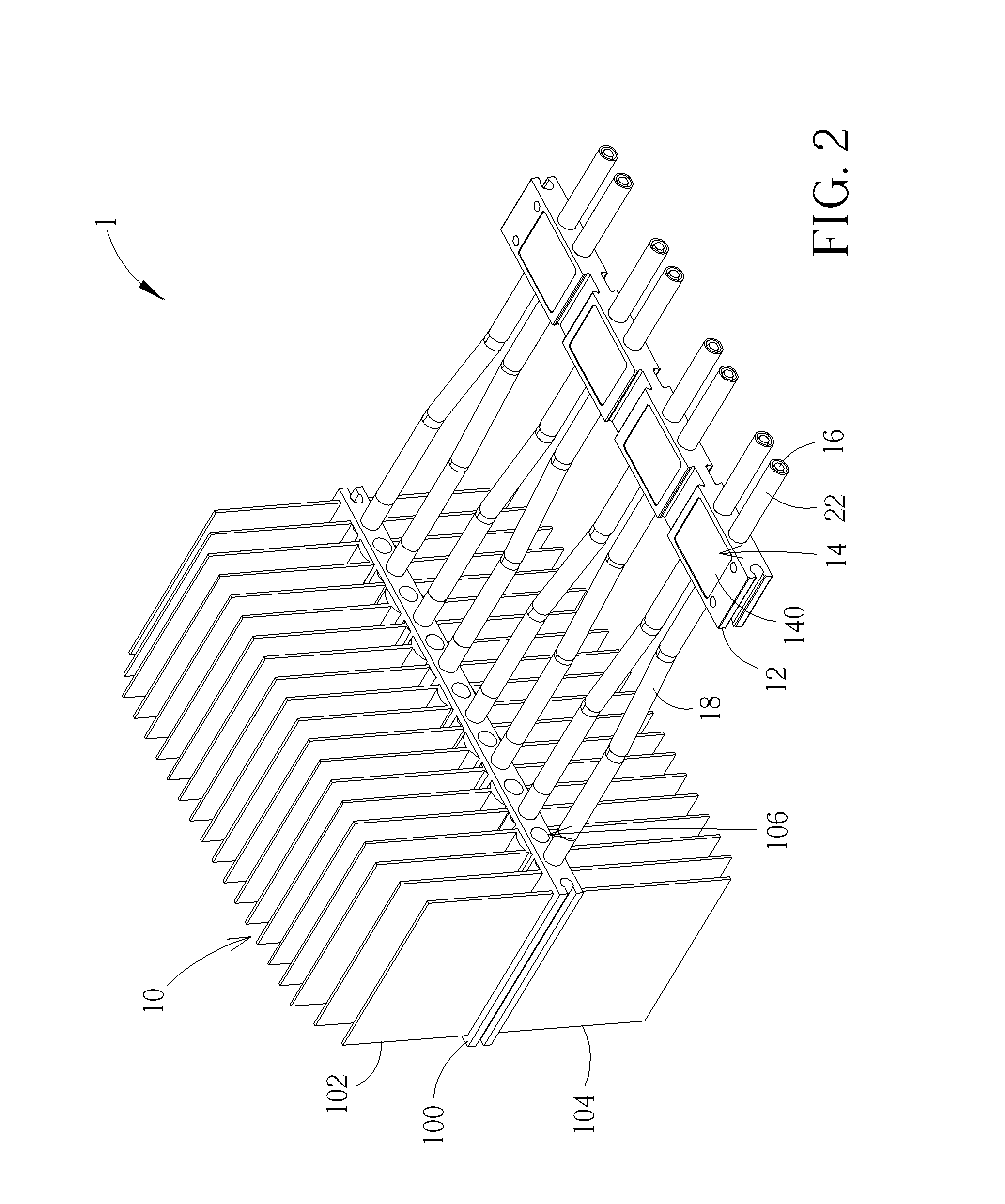

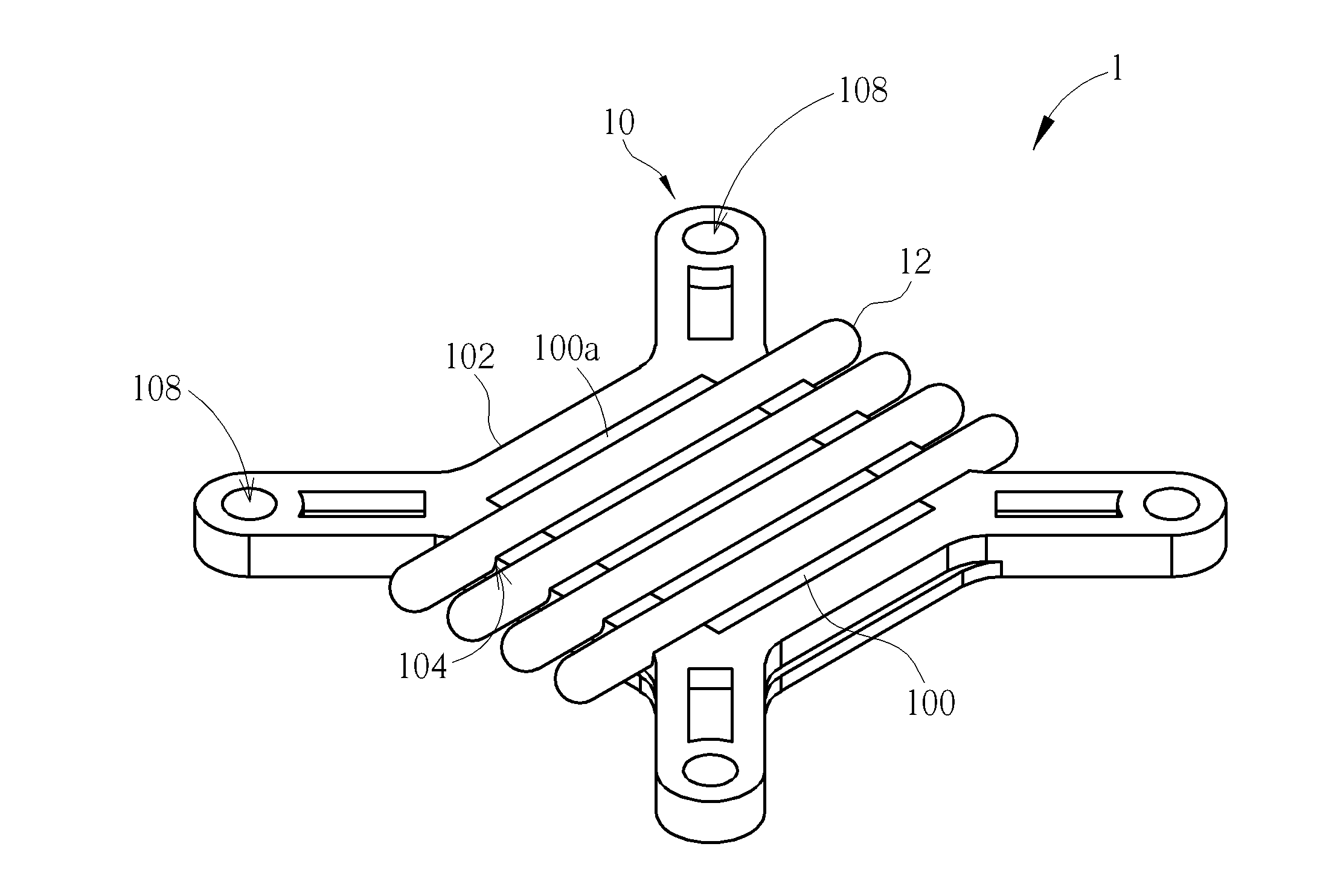

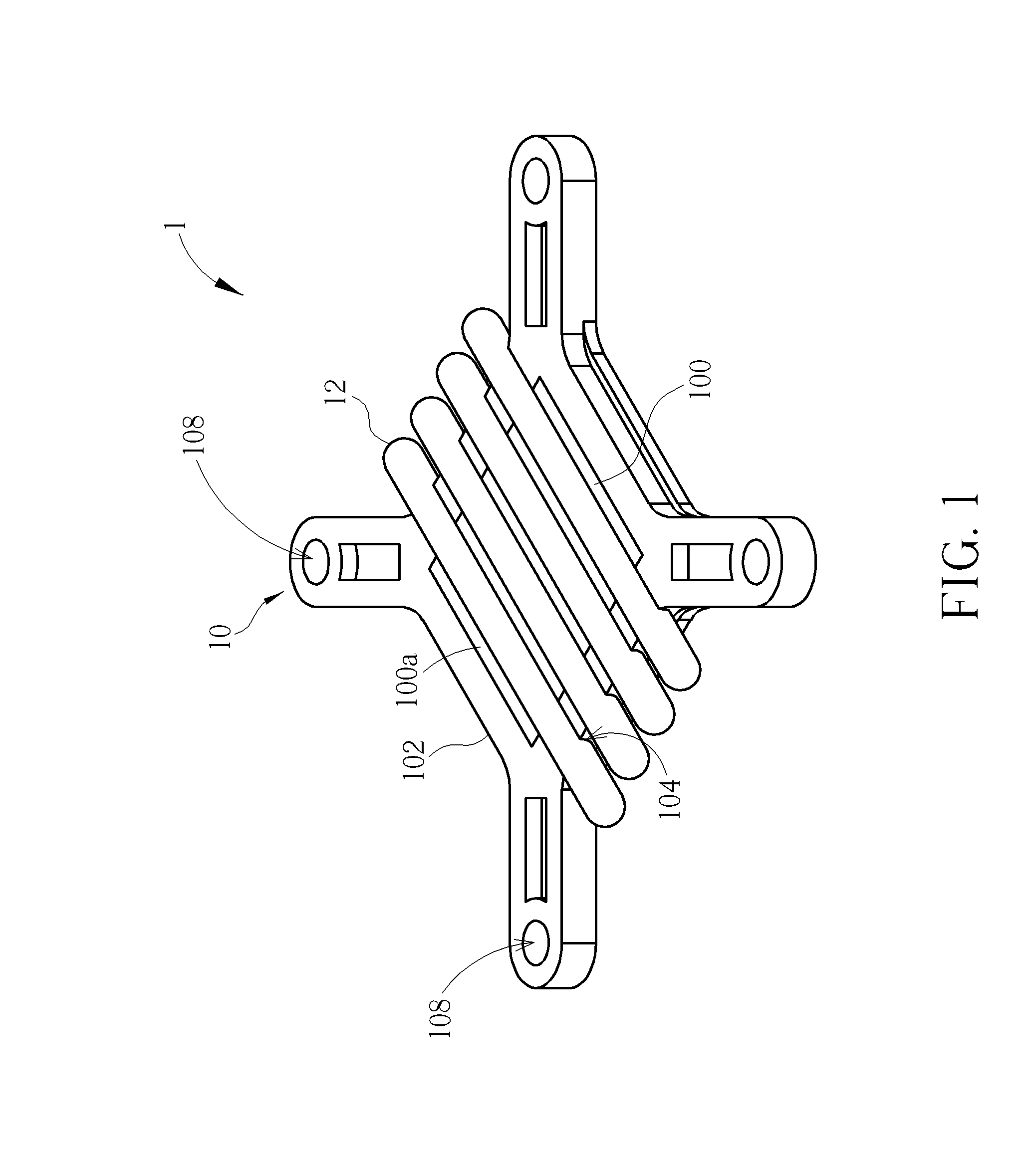

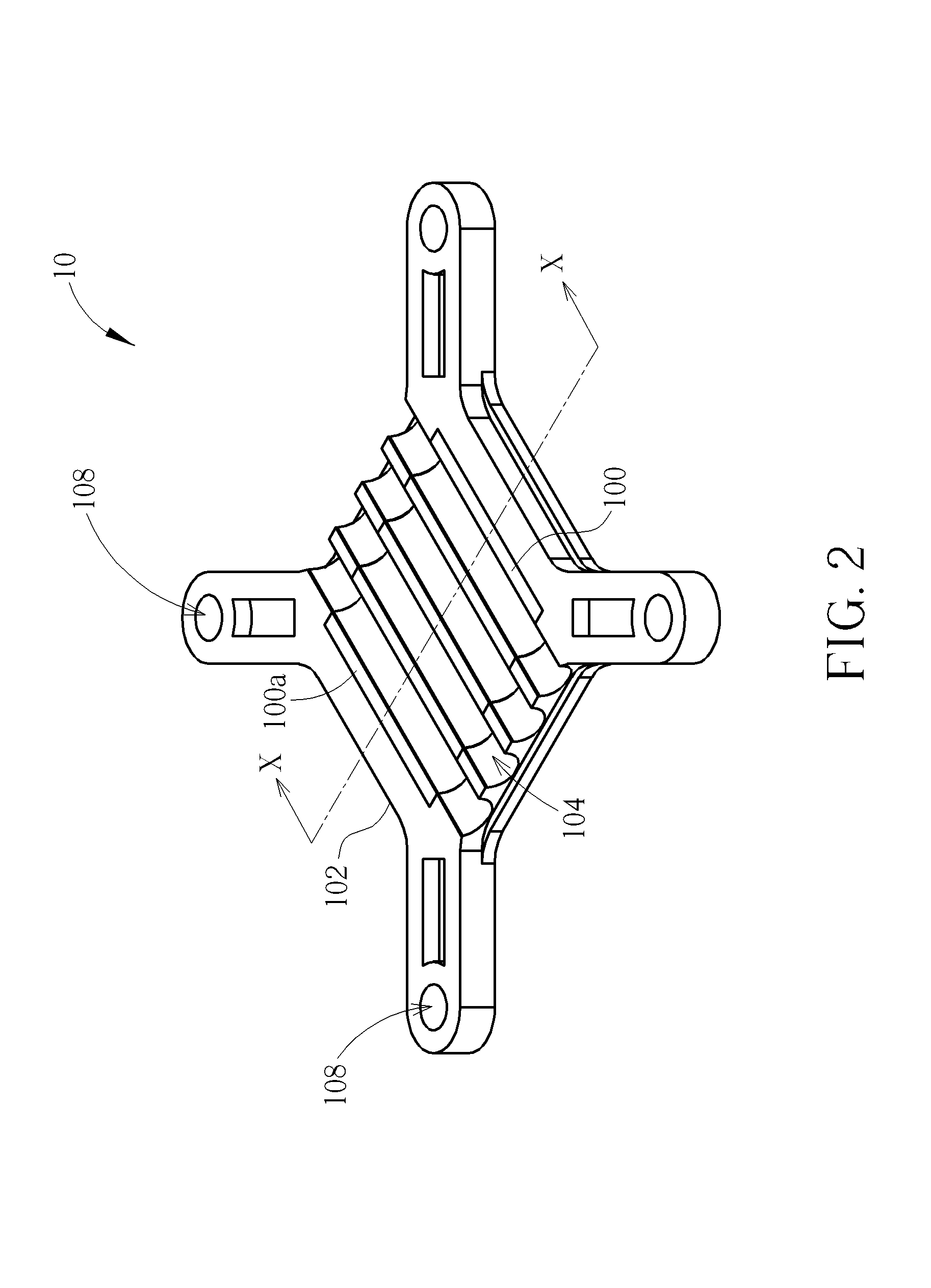

Heat dissipating device

ActiveUS9347712B2Improve cooling efficiencyAvoid increasing copper in the melted aluminumSemiconductor/solid-state device detailsSolid-state devicesDie castingEngineering

A heat dissipating device includes a heat dissipating fin module, a second base, a third base, a heat pipe, a first sleeve and a fourth base. The heat dissipating fin module includes a first base and a plurality of first heat dissipating fins. A recess is formed on the second base. The third base is disposed in the recess. The heat pipe includes a heat dissipating segment, a heat absorbing segment and a connecting segment connecting the heat dissipating segment and the heat absorbing segment. The heat dissipating segment is disposed in the first base. The heat absorbing segment is disposed in the second and third bases and contacts the third base directly. The first sleeve at least covers the connecting segment. The fourth base is formed by a die casting process and covers peripheries of the first and second bases and the first sleeve.

Owner:COOLER MASTER DEVELOPMENT CORP

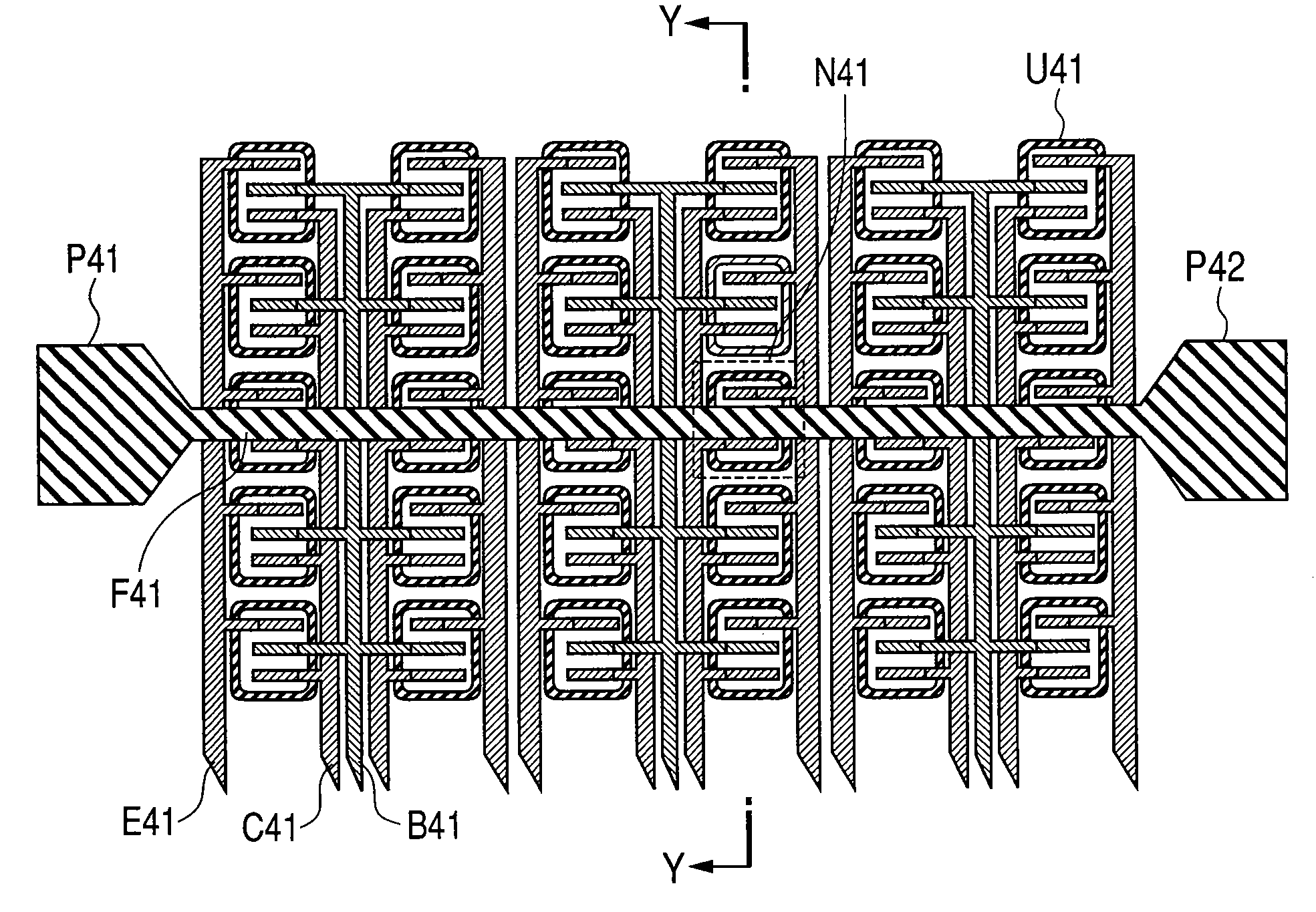

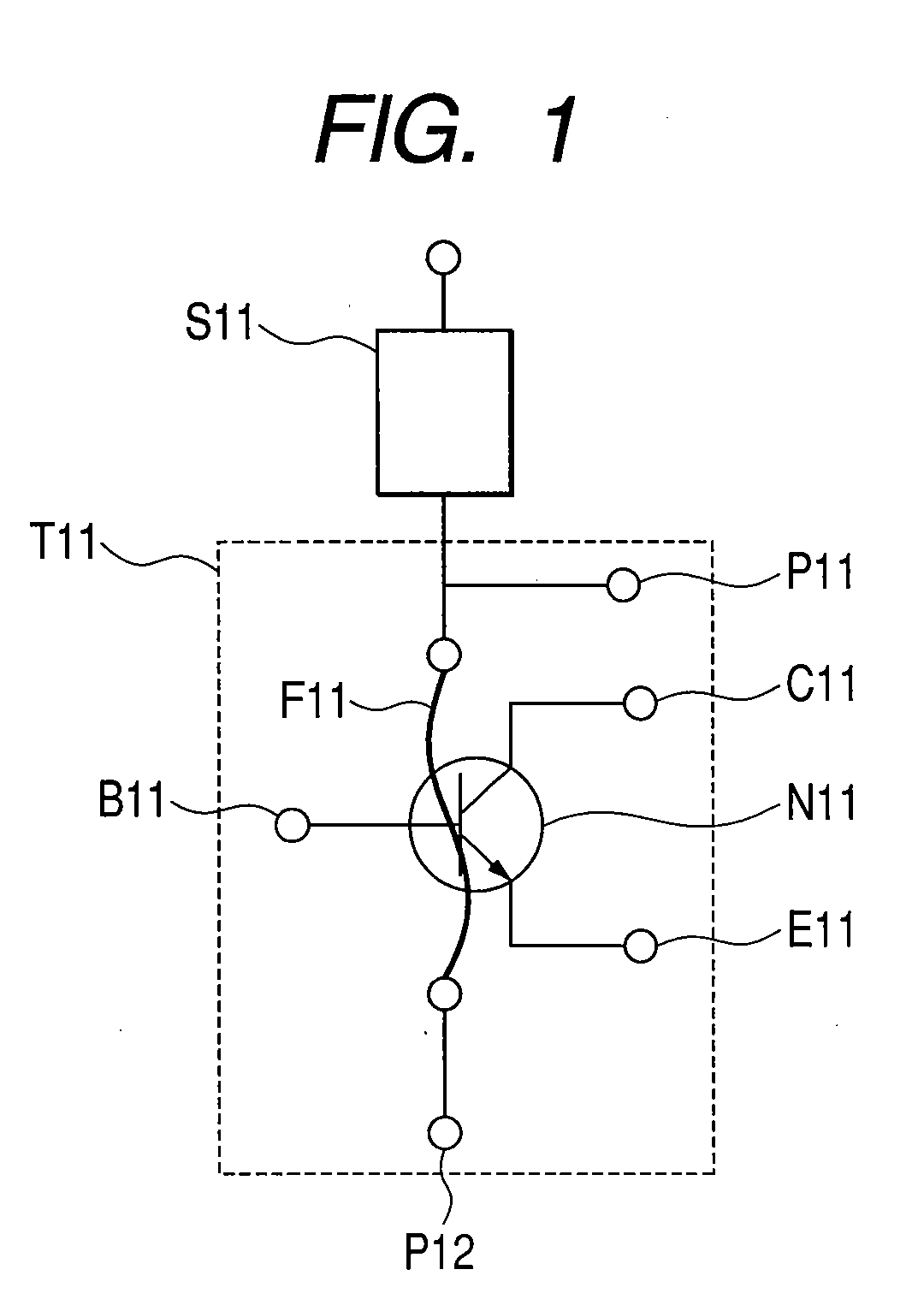

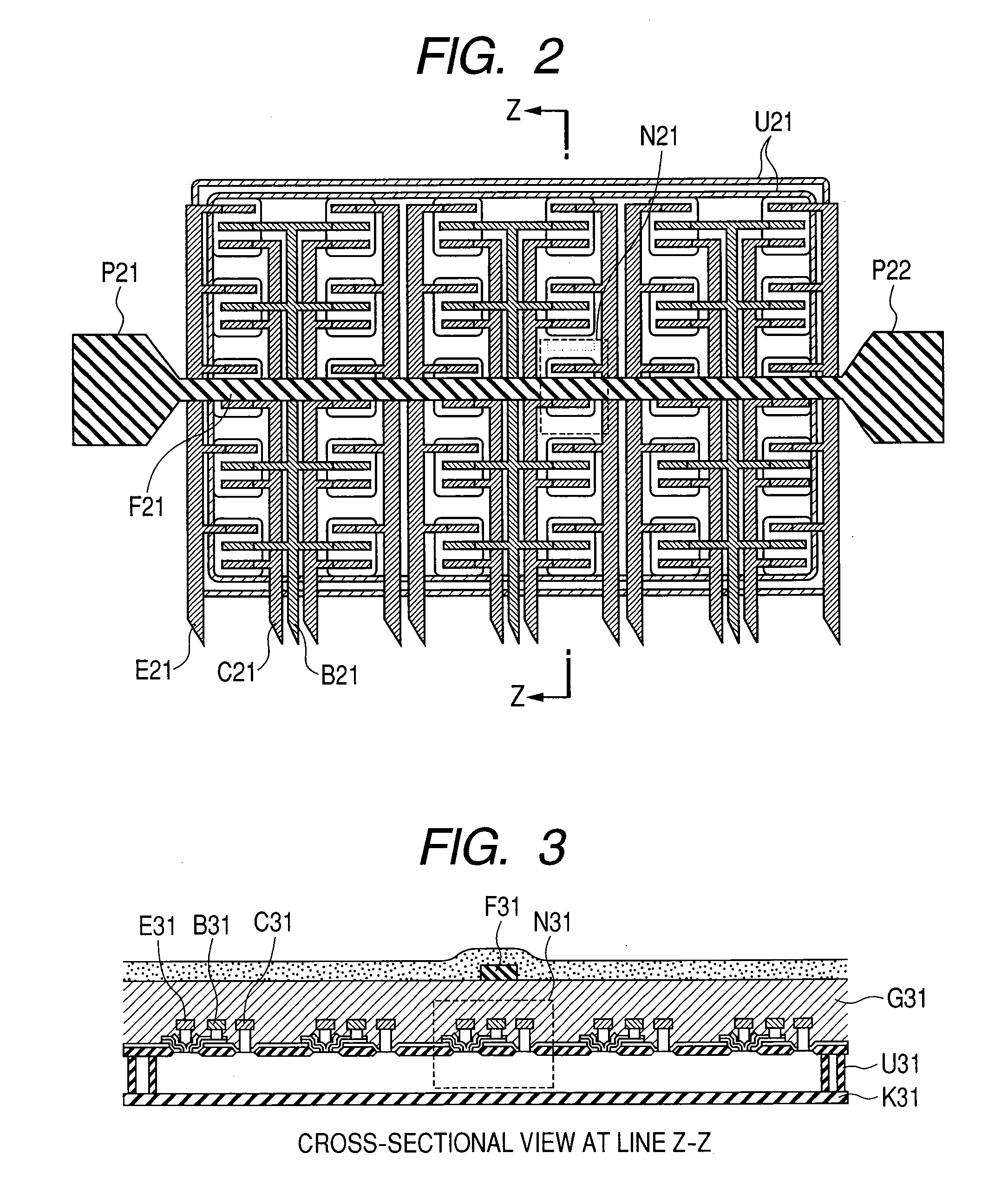

Semiconductor device

InactiveUS20080036032A1Exothermic efficiency be improveSmall thermal conductivitySemiconductor/solid-state device detailsSolid-state devicesEngineeringSemiconductor

A trimming element for trimming a redundant circuit and a high-accuracy resistance in consideration of the stability and the ease of fuse cutting, and more specifically a trimming element which is easily formed by an existing process. An SOI substrate, a heater connected to the SOI substrate, and a fuse connected to the heater are formed.

Owner:HITACHI LTD

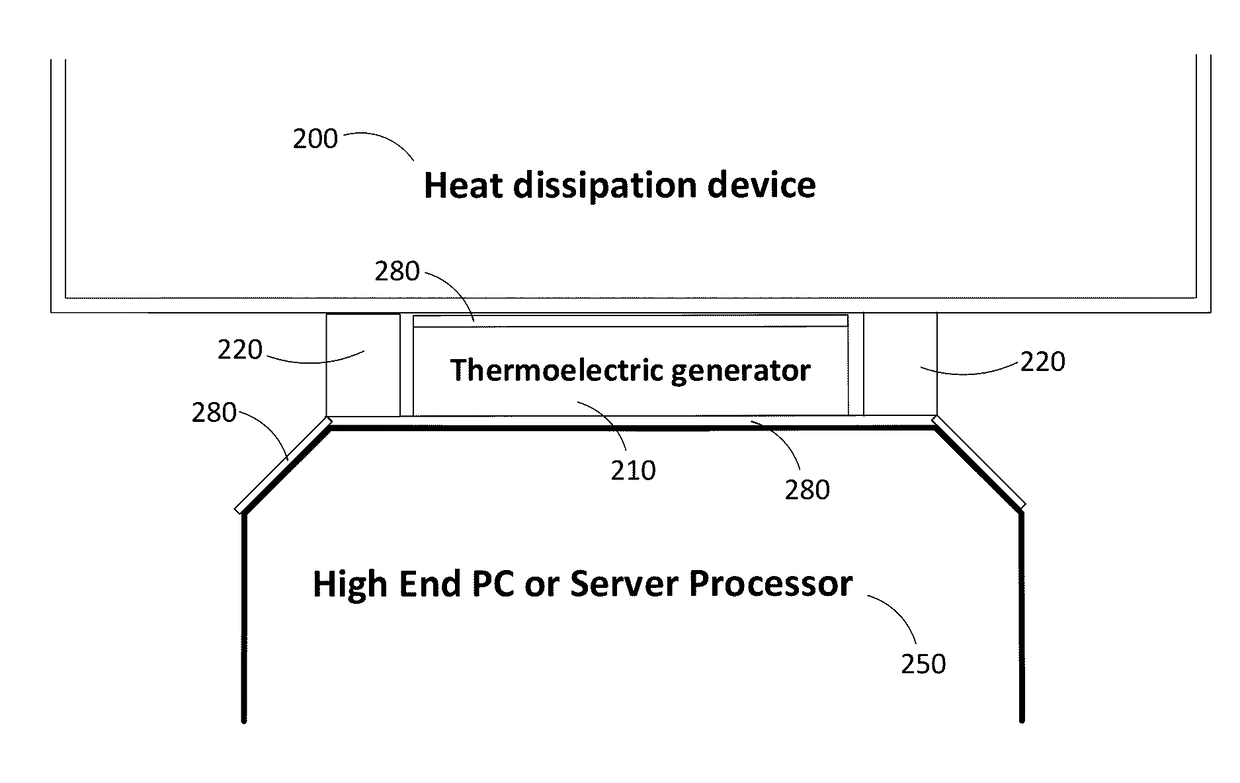

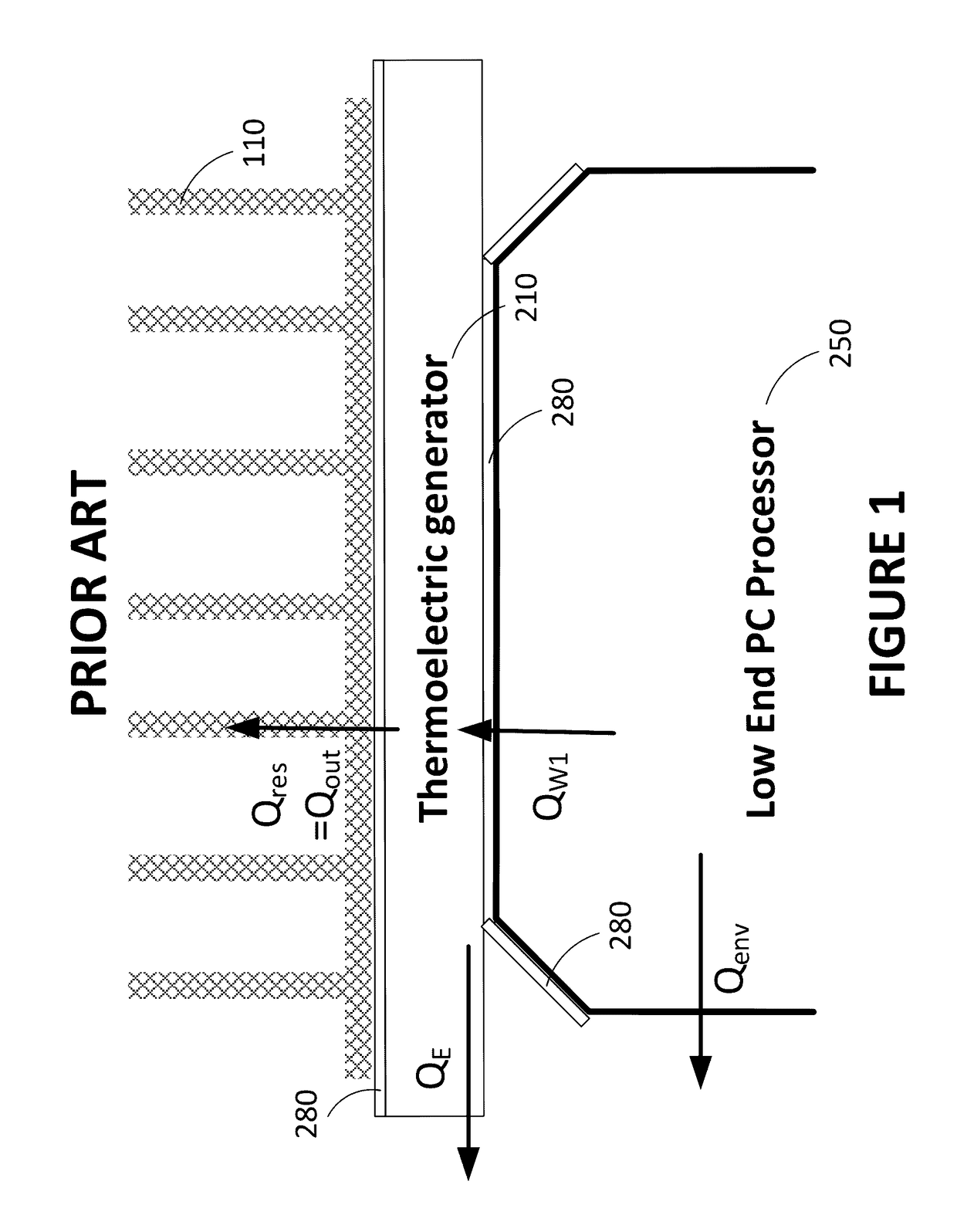

Apparatus for thermoelectric recovery of electronic waste heat

ActiveUS20170162774A1Avoid componentsSmall thermal conductivityThermoelectric device with peltier/seeback effectSemiconductor/solid-state device detailsCold sideEngineering

The present document describes an apparatus for recovering heat from an electronic component to generate electric energy. The apparatus comprises a thermoelectric generator having a cold side and a hot side, the hot side being in thermal communication with the electronic component. The apparatus further comprises a heat dissipation device in thermal communication with the cold side of the thermoelectric generator for dissipate heat it receives, and a heat transfer device with a thermal conductivity greater than 200 W(m·K) for directly transferring the heat from the electronic component to the heat dissipation device.

Owner:HYPERTECH CIARA INC

Organosilicon microemulsion antisticking agent and preparation method thereof

InactiveCN101406928BSolution to short lifeHigh particleFoundry mouldsFoundry coresSilanesFatty alcohol

Owner:武汉亿强科技开发股份有限公司

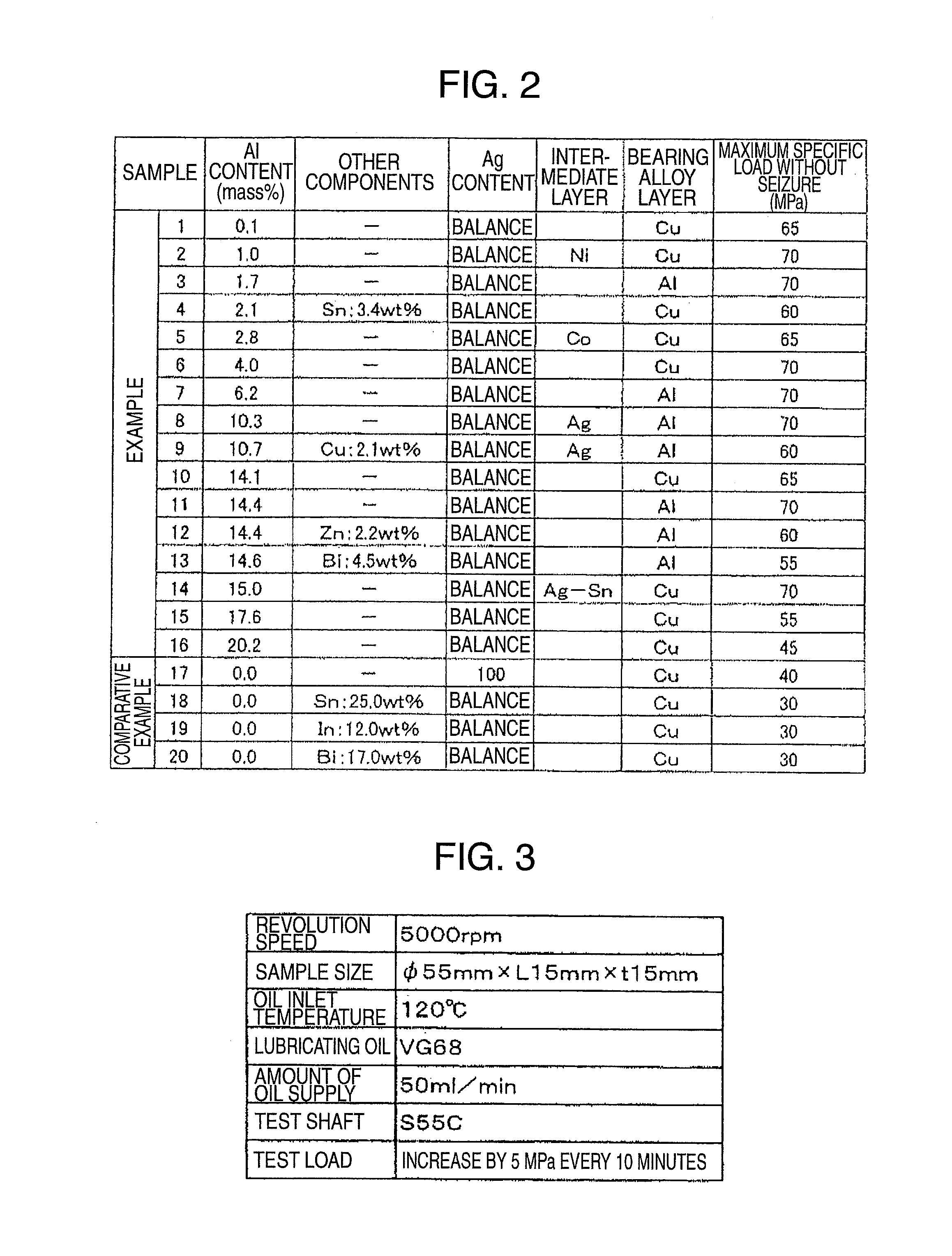

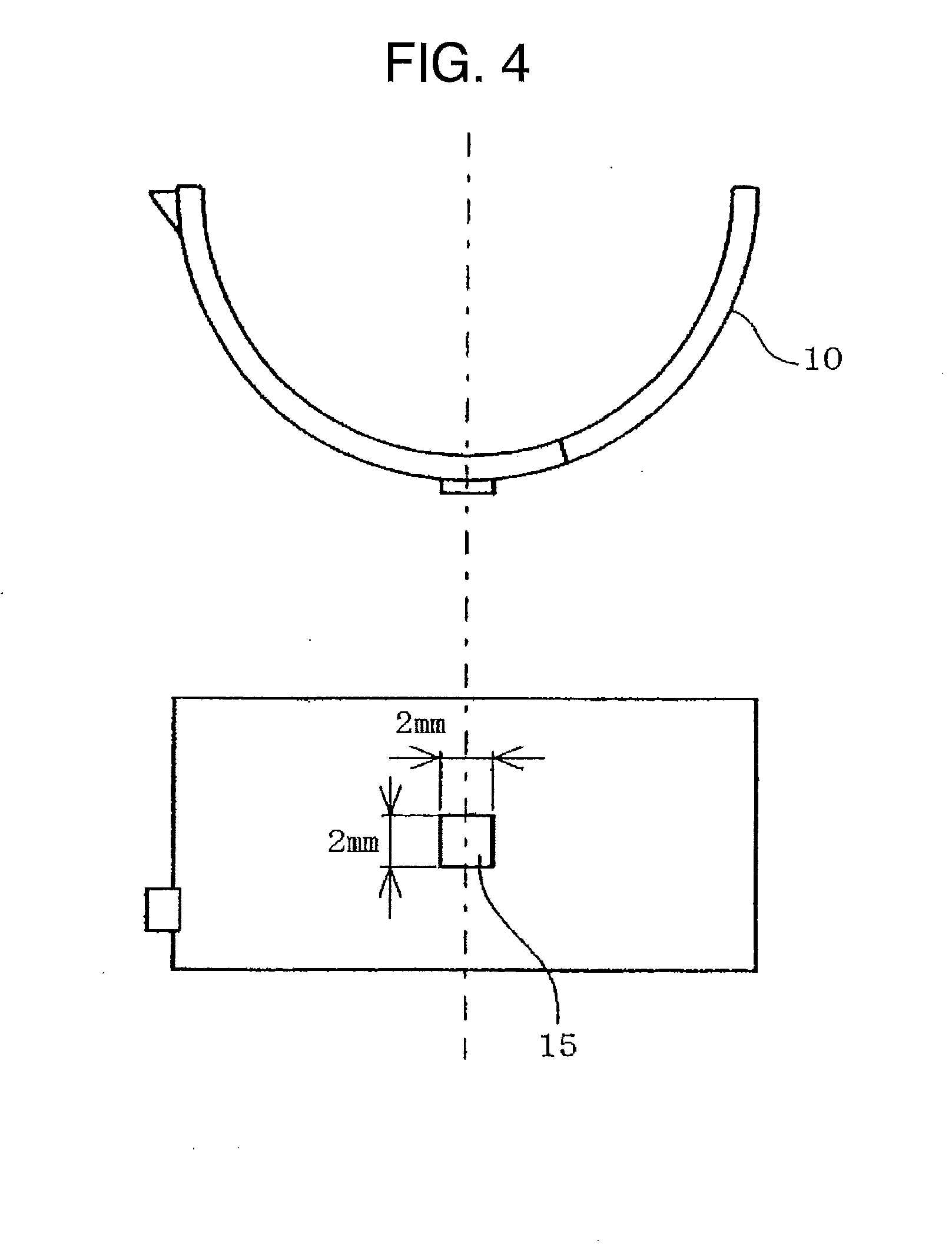

Sliding member

InactiveUS20150291904A1High seizure resistanceImprove thermal conductivityShaftsBearing componentsMetallurgyThermal conductivity

Provided is a sliding member which has high seizure resistance though an overlay layer comprising Ag as the main component is used therein. The sliding member of an embodiment comprises a base and an overlay layer which is disposed on the sliding-side surface of the base and which comprises Ag as the main component and contains Al. The overlay layer comprising Ag as the main component is relatively soft. Due to this, the overlay layer comprising Ag as the main component can ensure high seizure resistance even when the use of Pb is avoided. Furthermore, the overlay layer comprising Ag as the main component has excellent thermal conductivity. Due to this, frictional heat generating at the sliding part rapidly dissipates to the base side.

Owner:DAIDO METAL CO LTD

Heat dissipating device

ActiveUS20140131014A1Improve cooling efficiencyAvoid increasing copper in the melted aluminumSemiconductor/solid-state device detailsSolid-state devicesEngineeringHeat sink

A heat dissipating device includes a heat dissipating fin module, a second base, a third base, a heat pipe, a first sleeve and a fourth base. The heat dissipating fin module includes a first base and a plurality of first heat dissipating fins. A recess is formed on the second base. The third base is disposed in the recess. The heat pipe includes a heat dissipating segment, a heat absorbing segment and a connecting segment connecting the heat dissipating segment and the heat absorbing segment. The heat dissipating segment is disposed in the first base. The heat absorbing segment is disposed in the second and third bases and contacts the third base directly. The first sleeve at least covers the connecting segment. The fourth base is formed by a die casting process and covers peripheries of the first and second bases and the first sleeve.

Owner:COOLER MASTER DEVELOPMENT CORP

Thermal conductive member and heat dissipation structure including the same

ActiveUS20200031723A1Improve cooling effectSmall thermal conductivitySemiconductor/solid-state device detailsSolid-state devicesBoron nitrideCeramic materials

A thermal conductive member includes: first and second surface layers including an insulating material A, and an intermediate layer including an insulating material B. The insulating material A includes a first boron nitride sintered body having an orientation degree of hexagonal boron nitride primary particles of 0.6 to 1.4, and a first heat curable resin composition impregnating in the first boron nitride sintered body. The insulating material B includes a second boron nitride sintered body having an orientation degree of hexagonal boron nitride primary particles of 0.01 to 0.05, and a second heat curable resin composition impregnating in the second boron nitride sintered body.

Owner:DENKA CO LTD

Method of manufacturing heat dissipating base, heat dissipating base and heat dissipating device

InactiveUS20140069623A1Small thermal conductivityLower heating costsSemiconductor/solid-state device detailsSolid-state devicesHeat conductingDie casting

A method of manufacturing a heat dissipating base includes steps of providing a first base, wherein the first base is made of a first heat conducting material; putting the first base into a mold; pouring a second heat conducting material, which is melted, into the mold, wherein a thermal conductivity of the first heat conducting material is larger than that of the second heat conducting material; and processing the second heat conducting material by a die casting process, so as to form a second base, wherein the second base covers a periphery of the first base and an upper surface and a lower face of the first base are exposed.

Owner:COOLER MASTER DEVELOPMENT CORP

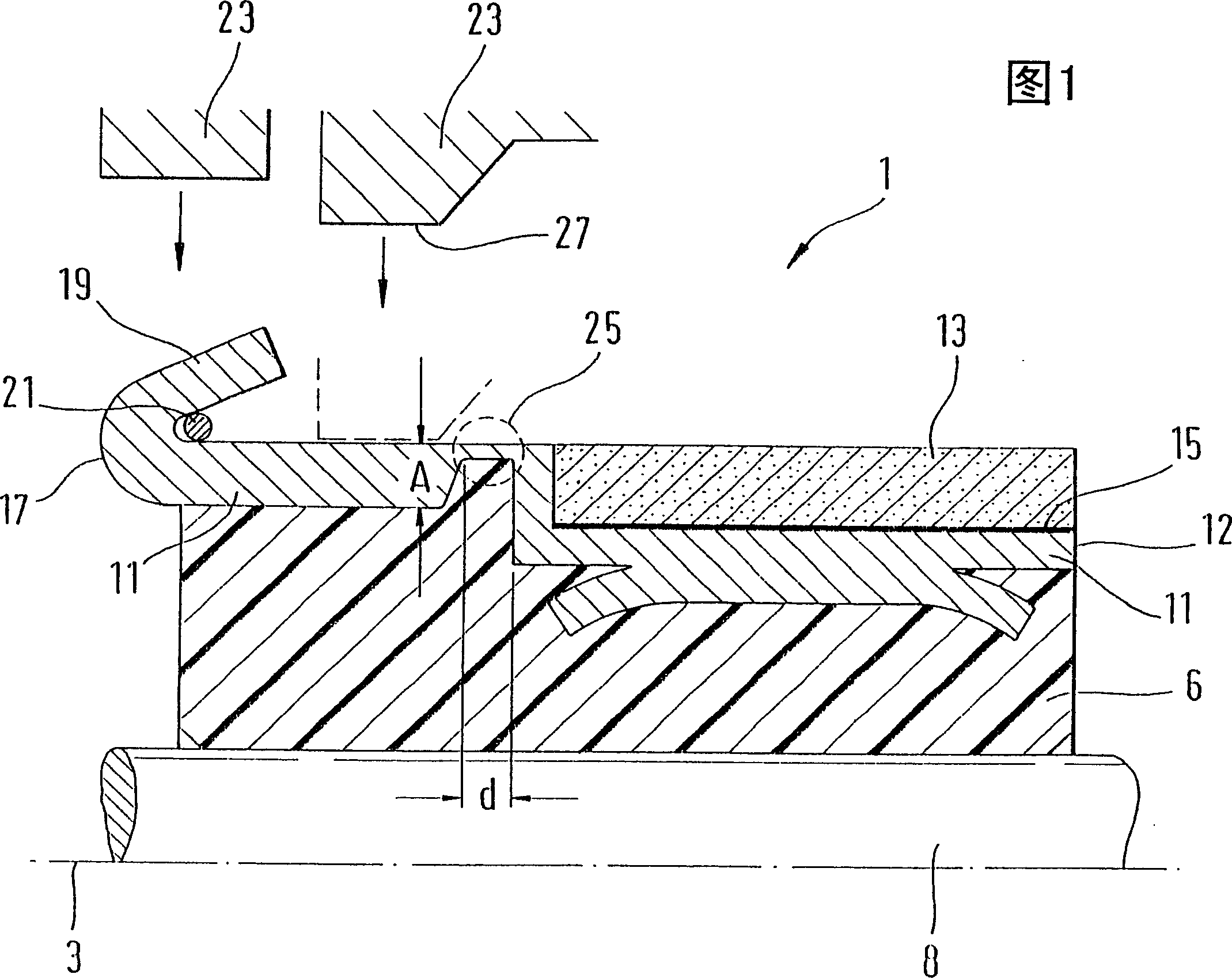

Hook commutator

InactiveCN1200488CWill not be affected by soldered connectionsReduce the cross-sectional areaRotary current collectorDynamo-electric machinesEngineeringConductor Coil

In prior art hook commutators, the brazed connection (15) used to connect the carbon segments (13) to the segments (11) would become disengaged because during the thermal bonding used to secure the winding wires generate heat. The hook commutator (1) according to the invention has a low thermal conductivity between the commutator hook (19) and the carbon segment (13), thereby protecting the soldered connection (15) from overheating.

Owner:ROBERT BOSCH GMBH

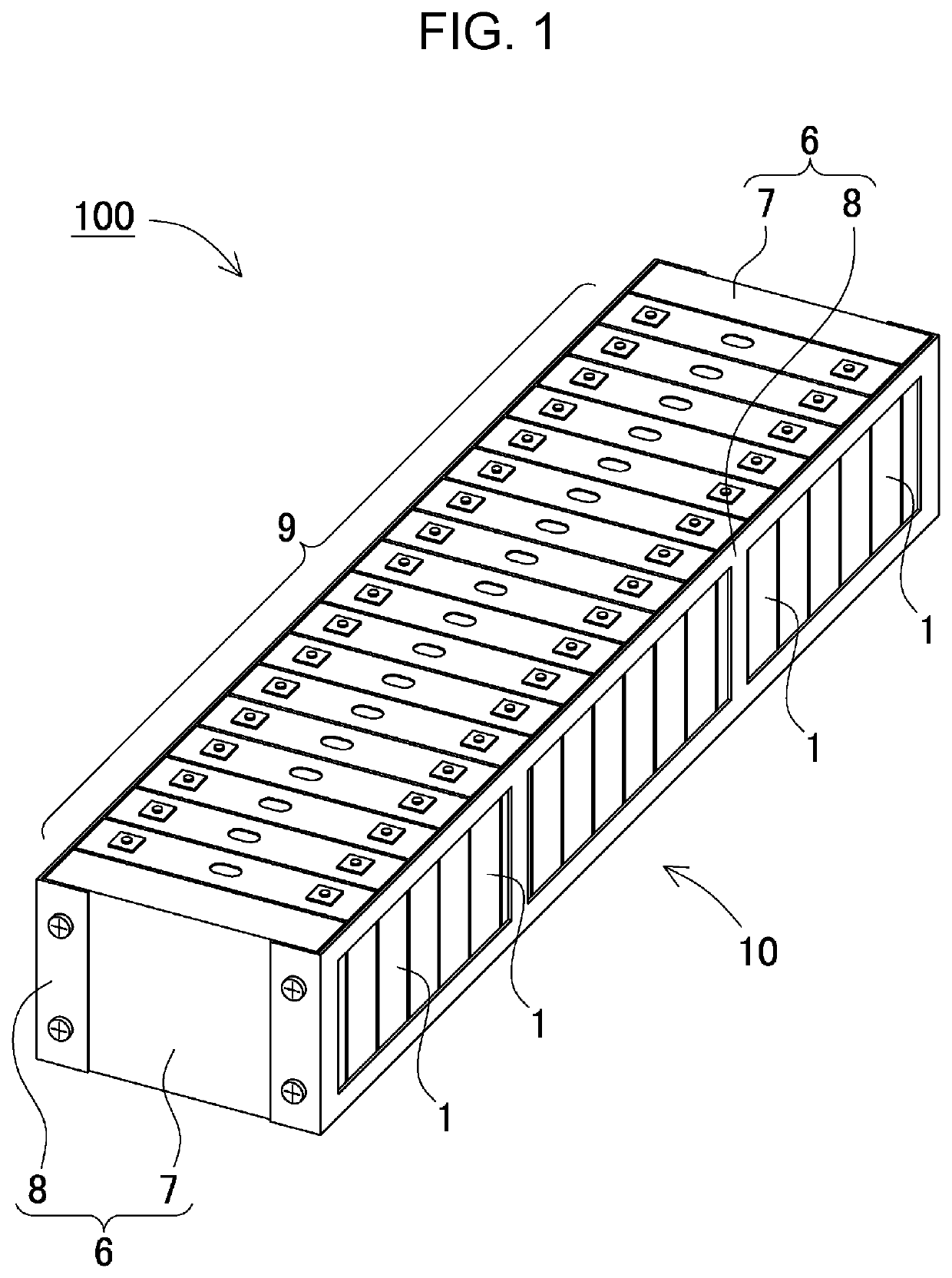

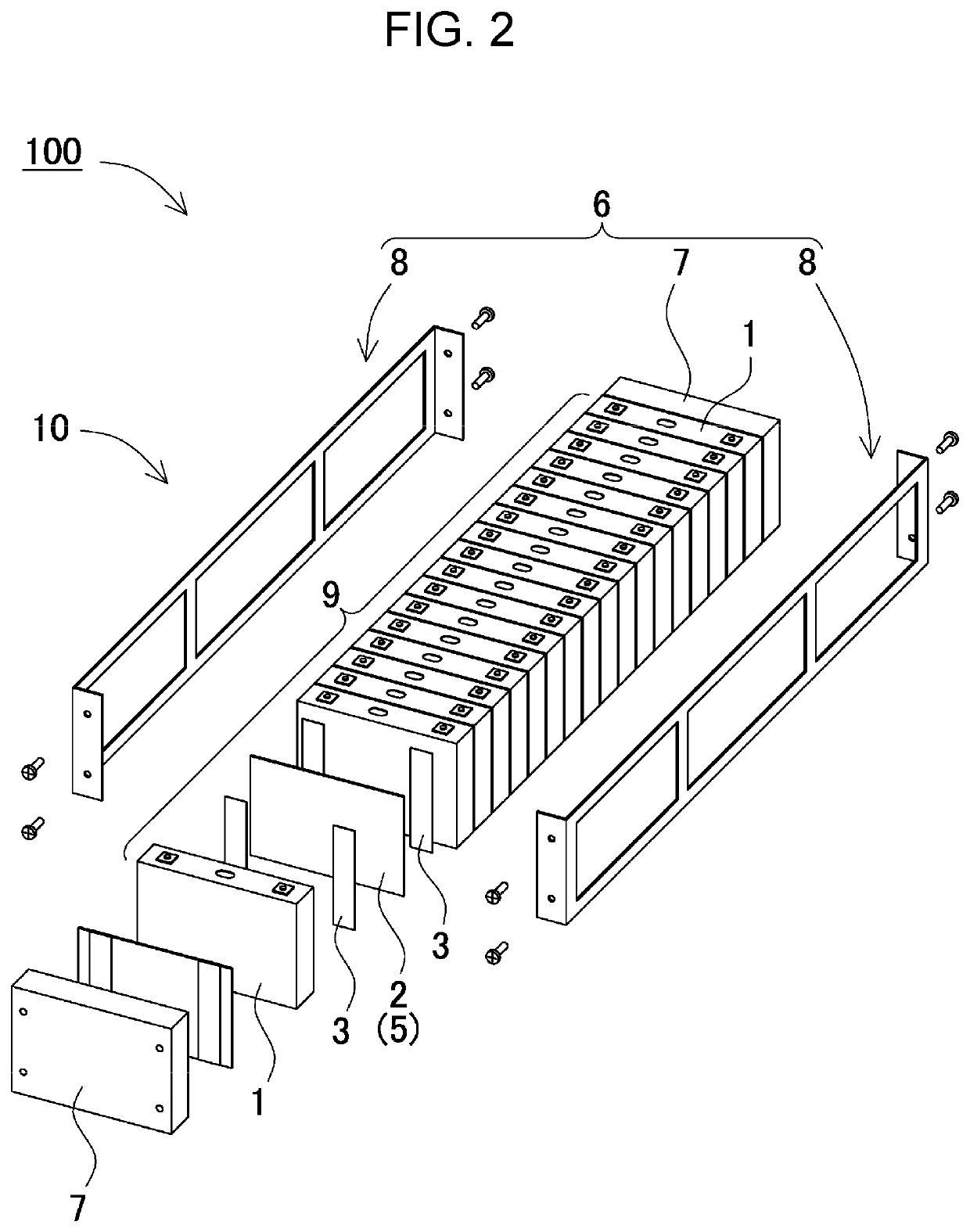

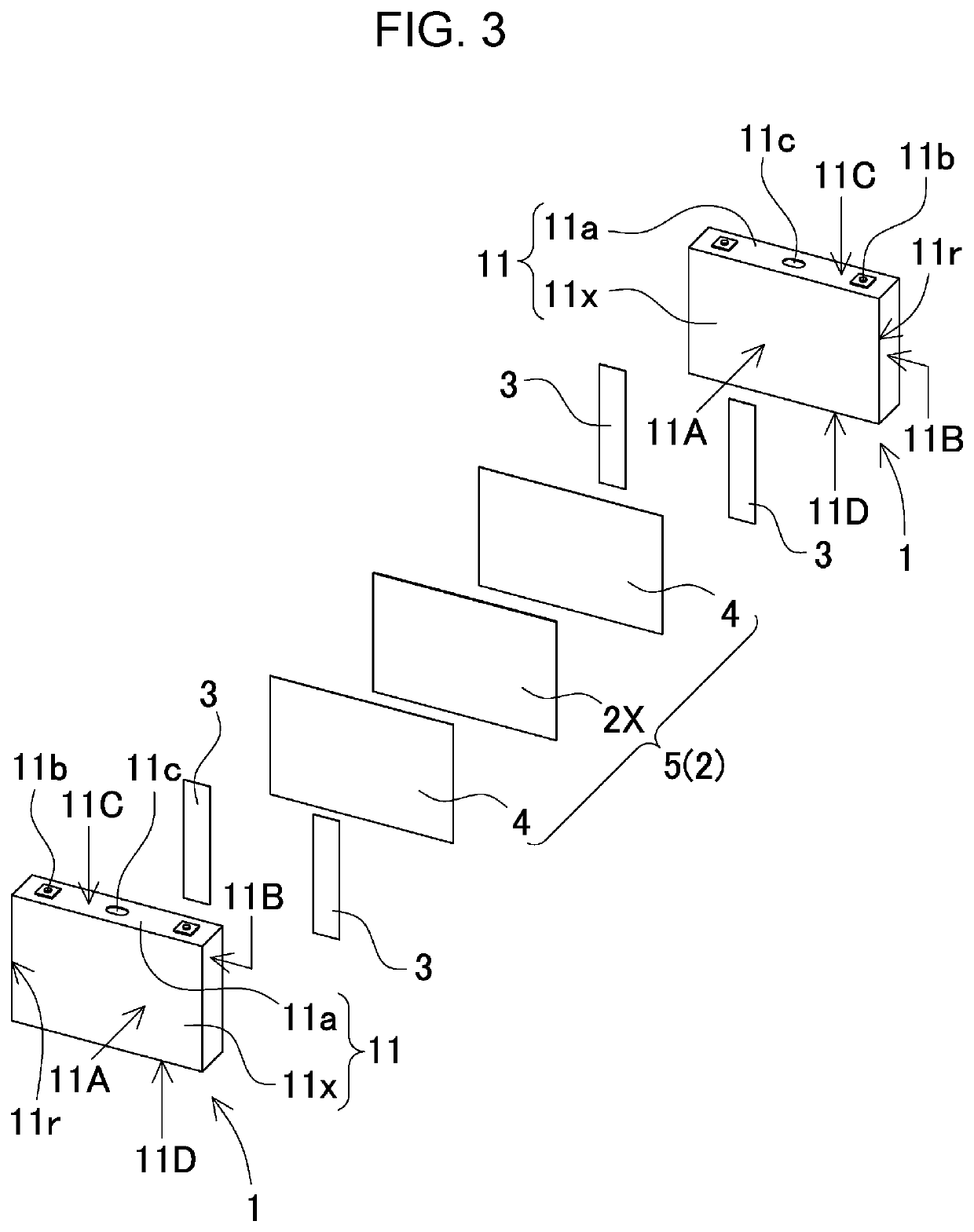

Power supply device, electric vehicle provided with said power supply device, and electricity-storage device

ActiveUS20210091428A1Effective preventionSimple structureBattery isolationSecondary cellsFiberThermal insulation

A plurality of battery cells each having a prismatic shape, a fixing member that fixes the plurality of battery cells in a stacked state, and a thermal insulation sheet that is sandwiched between stacking surfaces of battery cells and thermally insulates the adjacent battery cells, wherein thermal insulation sheet is an inorganic fiber sheet in which inorganic fibers are aggregated in a three-dimensionally non-directional manner and fine voids are provided between the inorganic fibers.

Owner:SANYO ELECTRIC CO LTD

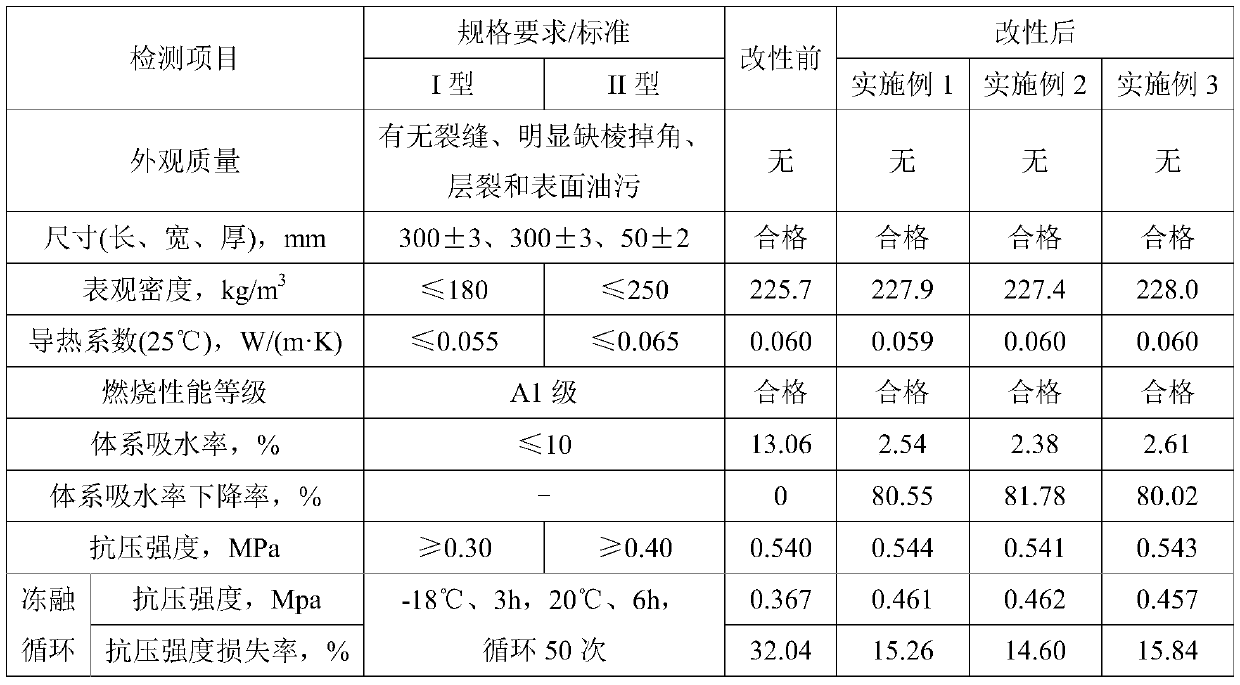

Fiber-reinforced foam cement insulation board surface waterproof modification method

InactiveCN111285706AReduce the water absorption of the systemIncrease crosslink densityPolyurea/polyurethane coatingsSilica fumePlasticizer

The invention relates to a surface waterproof modification method for a fiber-reinforced foamed cement insulation board. The method comprises the steps: coating the surface of the fiber-reinforced foamed cement insulation board with a composite waterproof coating to form a composite waterproof layer, wherein the composite waterproof coating is mainly prepared from polyisocyanates and the followingraw materials in parts by weight: 100 parts of polyether polyol, 0.5-0.6 part of a dispersing agent, 15-20 parts of a plasticizer, 39-41 parts of superfine cement, 4-6 parts of silica fume, 10-12 parts of talcum powder, 0.5-0.6 part of hydrogenated castor oil, 0.1-0.2 part of a defoaming agent, 0.3-0.4 part of a catalyst, 1.0-1.5 parts of a latent curing agent and 10-12 parts of solvent oil. According to the waterproof modification method, a composite waterproof layer with the thickness of 0.5-5.0 mm is formed on the surface of the fiber-reinforced foamed cement insulation board, the volume water absorption rate of the board is greatly reduced, the reduction rate reaches 80% or above, the freeze-thaw cycle resistance and durability of the board are improved, and the service life of the board is prolonged.

Owner:郑州知淘信息科技有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com