House constructed from finished product components and constructing method thereof

a finished product and construction method technology, applied in the field of houses, can solve the problems of large power consumption, long construction time, low construction efficiency, etc., and achieve the effects of reducing construction cost, facilitating convenient construction of bathrooms, and reliable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

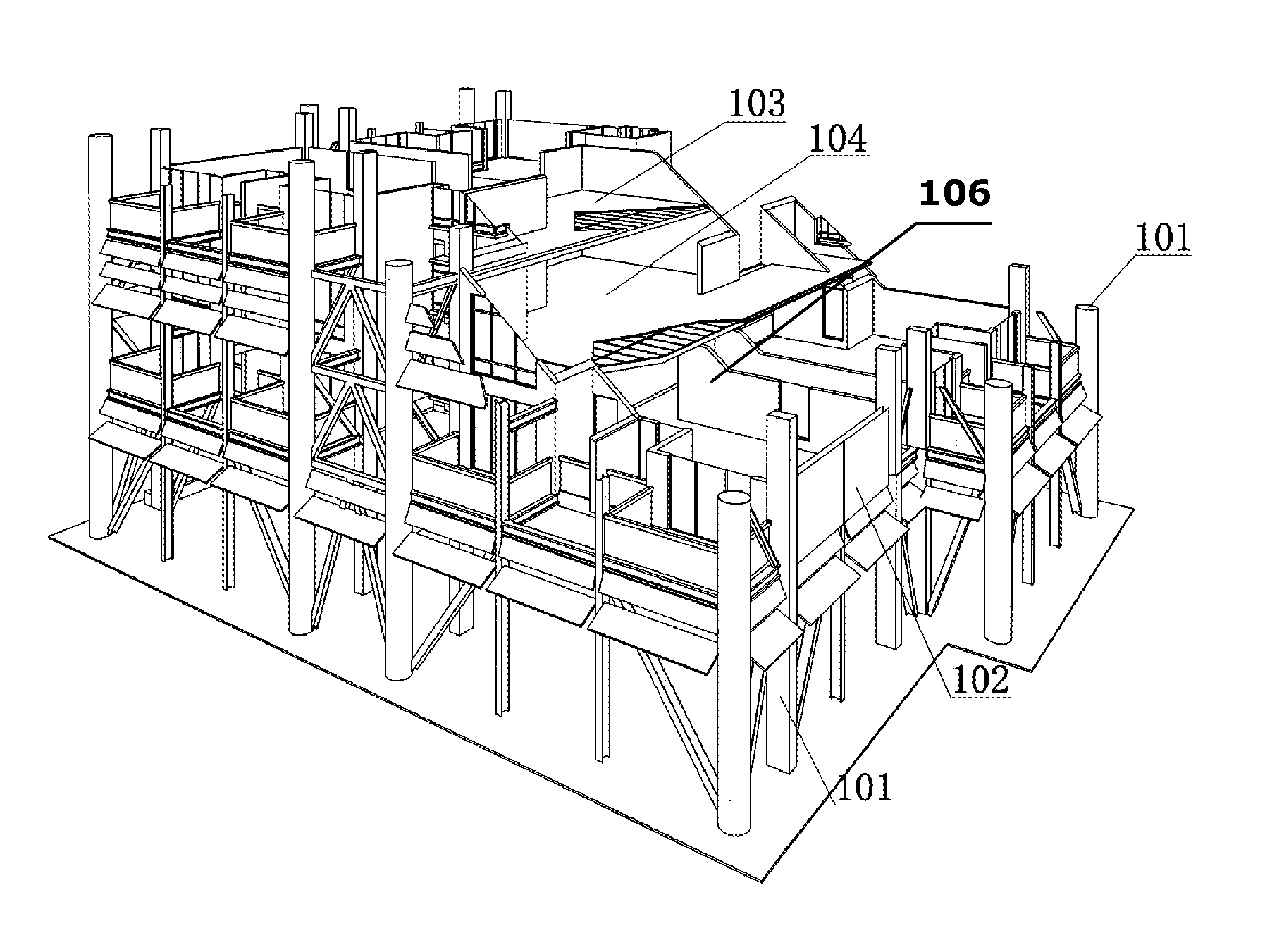

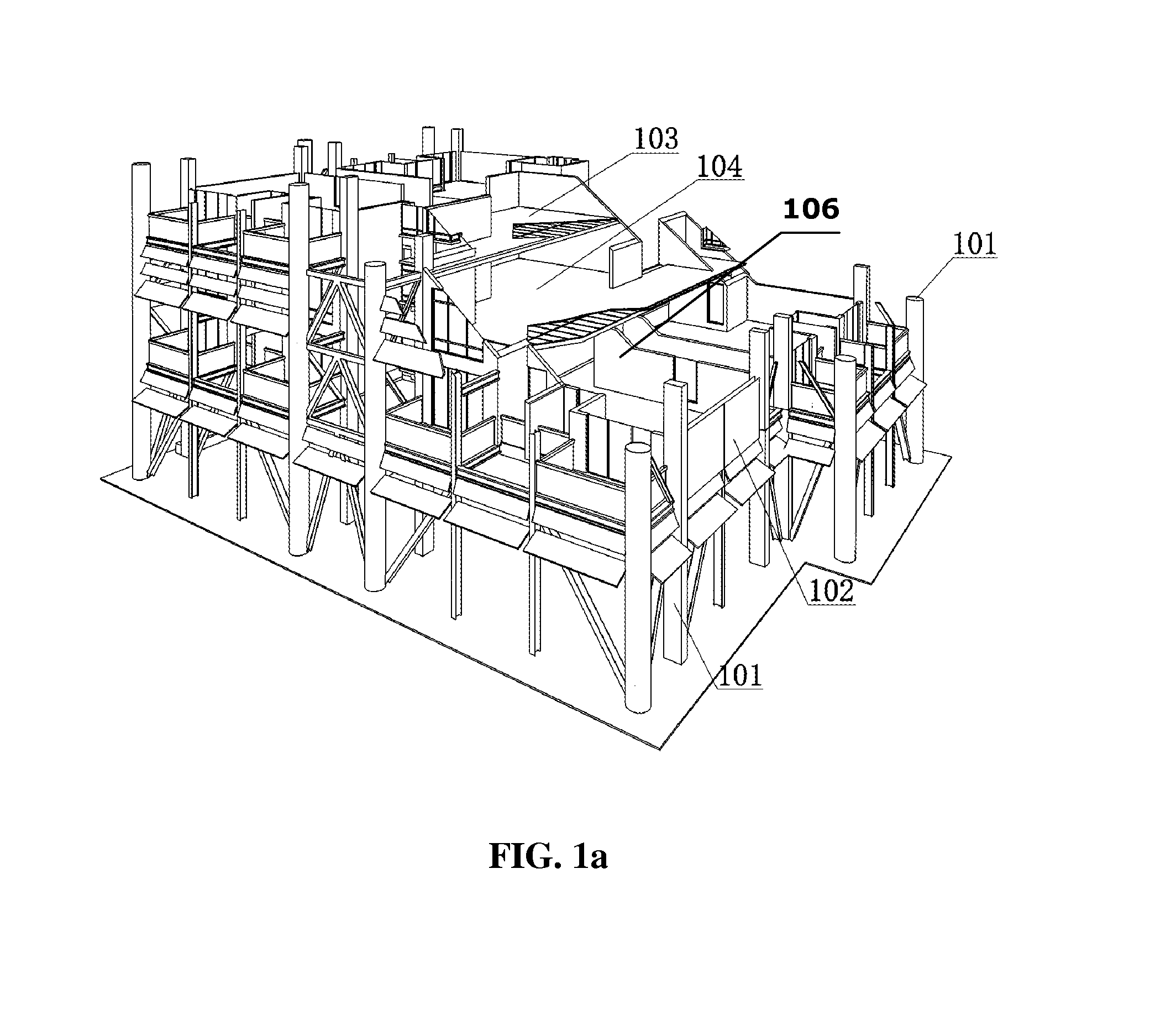

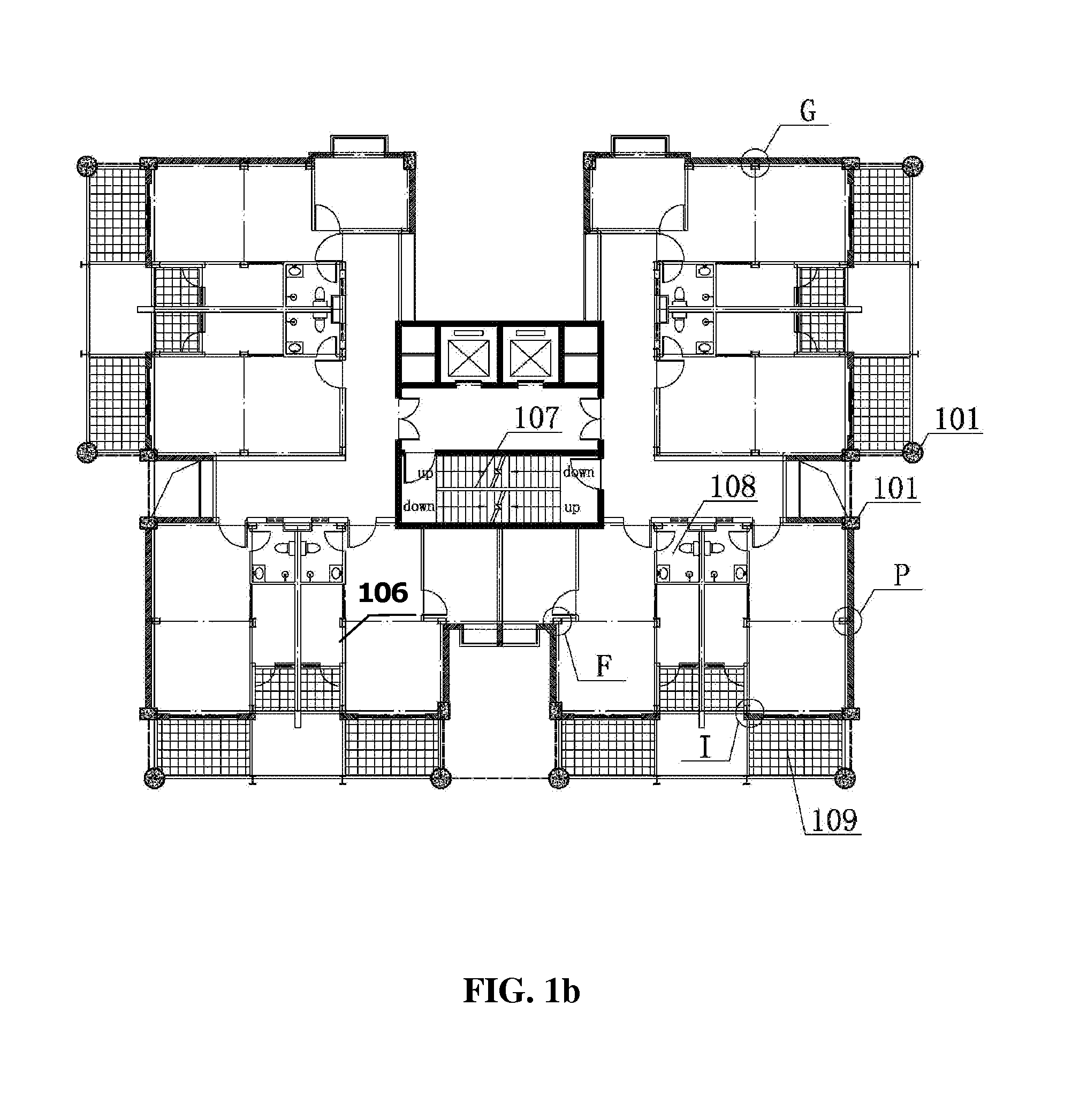

[0061]As shown in FIGS. 1a and 1b, an house of the invention comprises a finished product main frame 101, an enclosed wall 102, a finished product top cover plate 103, a finished product floor cover plate 104, a separation wall 106, a finished product stair 107, a bathroom 108, and a balcony 109. The enclosed wall is assembled by multiple finished product composite prefabricated external wallboards 202. The bathroom 108, the balcony 109, and the finished product stair 107 are respectively an integral prefabricated bathroom, an integral prefabricated balcony, and an integral prefabricated finished product stair which are hoisted to a designed position for installation. The finished product main frame 101 is a steel frame, and comprises steel columns and steel beams connected to each other via welding or high-strength bolts. The finished product main frame 101 can also be a steel frame.

[0062]The finished product composite prefabricated external wallboards and the finished product stai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com