Fiber-reinforced foam cement insulation board surface waterproof modification method

A technology of foamed cement and fiber reinforcement, applied in coatings, polyurea/polyurethane coatings, etc., can solve the problems of reducing the thermal conductivity of the board, increasing the foaming strength, and increasing the board, so as to reduce the water absorption of the system and improve the tensile strength. Tensile strength, coating surface smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

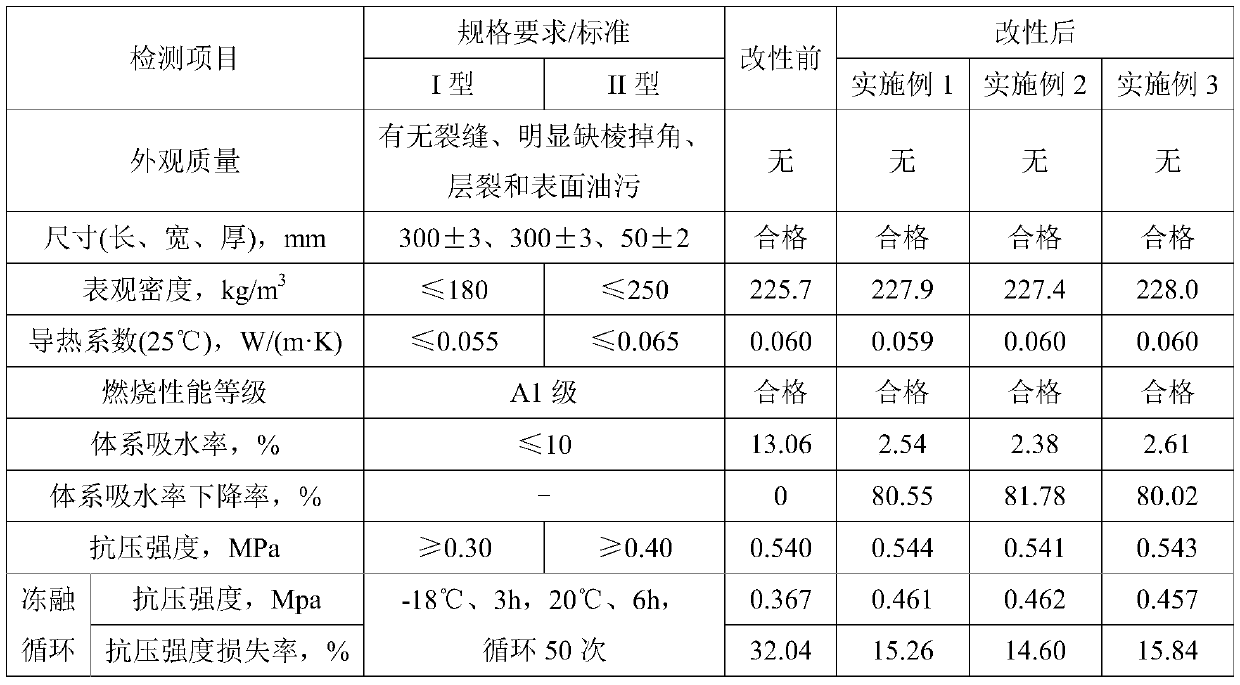

Embodiment 1

[0032] The surface waterproof modification method of the fiber-reinforced foamed cement insulation board in this embodiment is to apply a composite waterproof paint on the surface of the fiber-reinforced foamed cement insulation board to form a composite waterproof layer with a thickness of 1.0mm;

[0033] Specifically: apply the surface of the fiber-reinforced foamed cement insulation board (including the front and back sides and sides) with a wet roller brush to make it wet, and then apply the composite waterproof coating, and dry naturally to form a composite waterproof coating with a thickness of 1.0mm. layer.

[0034] The composite waterproof coating used is made of 4,4'-diphenylmethane diisocyanate and the following raw materials in parts by weight: 100 parts of polyether polyol, 0.50 parts of dispersant, 20 parts of plasticizer dibutyl phthalate, 39 parts of superfine cement, 6 parts of silica fume, 10 parts of talcum powder, 0.6 parts of hydrogenated castor oil, 0.10 p...

Embodiment 2

[0039] The surface waterproof modification method of the fiber-reinforced foamed cement insulation board in this embodiment is to apply a composite waterproof paint on the surface of the fiber-reinforced foamed cement insulation board to form a composite waterproof layer with a thickness of 1.0 mm;

[0040] Specifically: apply the surface of the fiber-reinforced foamed cement insulation board (including the front and back sides and sides) with a wet roller brush to make it wet, and then apply the composite waterproof coating, and dry naturally to form a composite waterproof coating with a thickness of 1.0mm. layer.

[0041] The composite waterproof coating used is made of 4,4'-diphenylmethane diisocyanate and the following raw materials in parts by weight: 100 parts of polyether polyol, 0.55 parts of dispersant, 18 parts of plasticizer dibutyl phthalate, 40 parts of superfine cement, 5 parts of silica fume, 11 parts of talcum powder, 0.55 parts of hydrogenated castor oil, 0.15...

Embodiment 3

[0046] The surface waterproof modification method of the fiber-reinforced foamed cement insulation board in this embodiment is to apply a composite waterproof paint on the surface of the fiber-reinforced foamed cement insulation board to form a composite waterproof layer with a thickness of 1.0mm;

[0047] Specifically: apply the surface of the fiber-reinforced foamed cement insulation board (including the front and back sides and sides) with a wet roller brush to make it wet, and then apply the composite waterproof coating, and dry naturally to form a composite waterproof coating with a thickness of 1.0mm. layer.

[0048] The composite waterproof coating used is made of 4,4'-diphenylmethane diisocyanate and the following raw materials in parts by weight: 100 parts of polyether polyol, 0.60 parts of dispersant, and 18 parts of plasticizer dibutyl phthalate , 41 parts of superfine cement, 6 parts of silica fume, 12 parts of talcum powder, 0.5 parts of hydrogenated castor oil, 0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com