Hook commutator

A commutator, hook type technology, applied in the direction of rotating current collectors, current collectors, electrical components, etc., can solve the problems of reducing operating characteristics, reducing electrical characteristics, etc., to avoid excessive heat.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

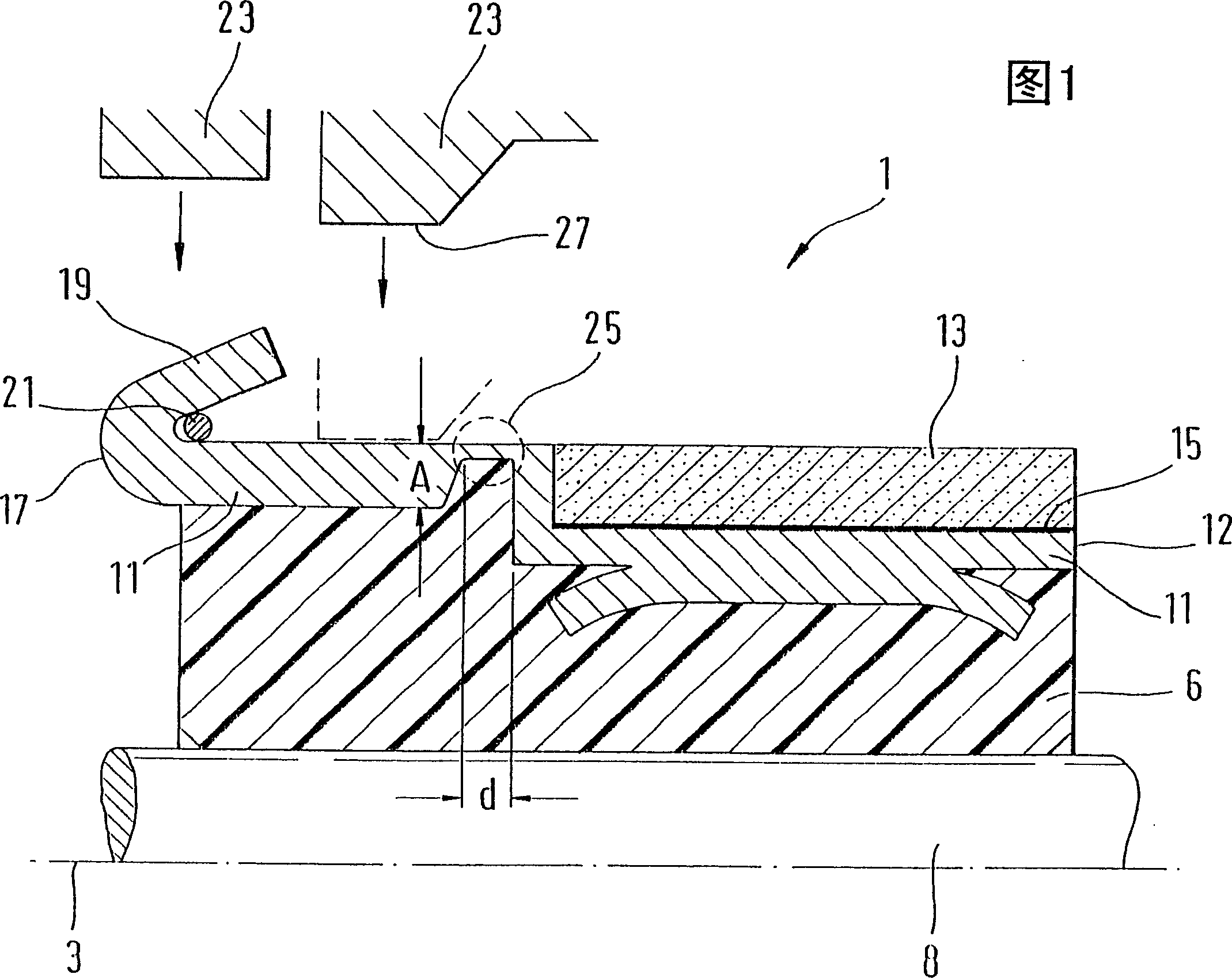

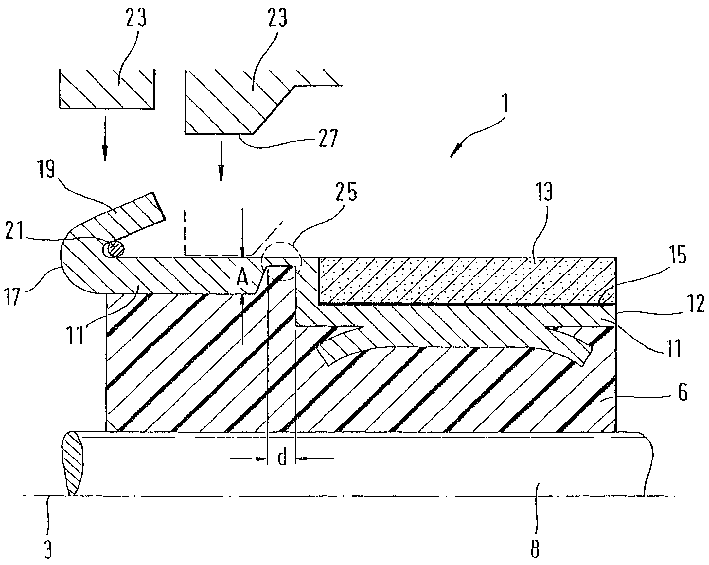

[0013] The drawing shows an otherwise known hook commutator 1 for an electric motor armature in axial cross-section. The hook commutator 1 has an axis of symmetry 3 . For example, a carrier 6 is mounted on the rotor shaft 8 of the motor armature. At least one commutator segment 11 made of electrically conductive material is fastened to the carrier 6 . This is done, for example, in that the commutator segments 11 are at least partially surrounded by injection molding of plastic, for example the material forming the carrier body 6 . However, the commutator segment 11 can also be fixed on the carrier 6 by other fixing methods.

[0014] Commutator segment 11 carries on one section at its one axial end 12 a carbon segment 13 which is fastened to commutator segment 11 via a soldered connection 15 . However, the invention is not restricted to the carbon segments 13 , but rather relates to all thermally sensitive segments connected to the commutator segments 11 . A commutator hook...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com