Sliding member

a sliding member and mating technology, applied in the field of sliding members, can solve the problems of reduced strength and hardness, to the base side, and inability to easily dissipate the heat generated in the sliding part with a mating member, and achieve the effect of high seizure resistan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015]Hereinafter, a specific embodiment of a sliding member will be described.

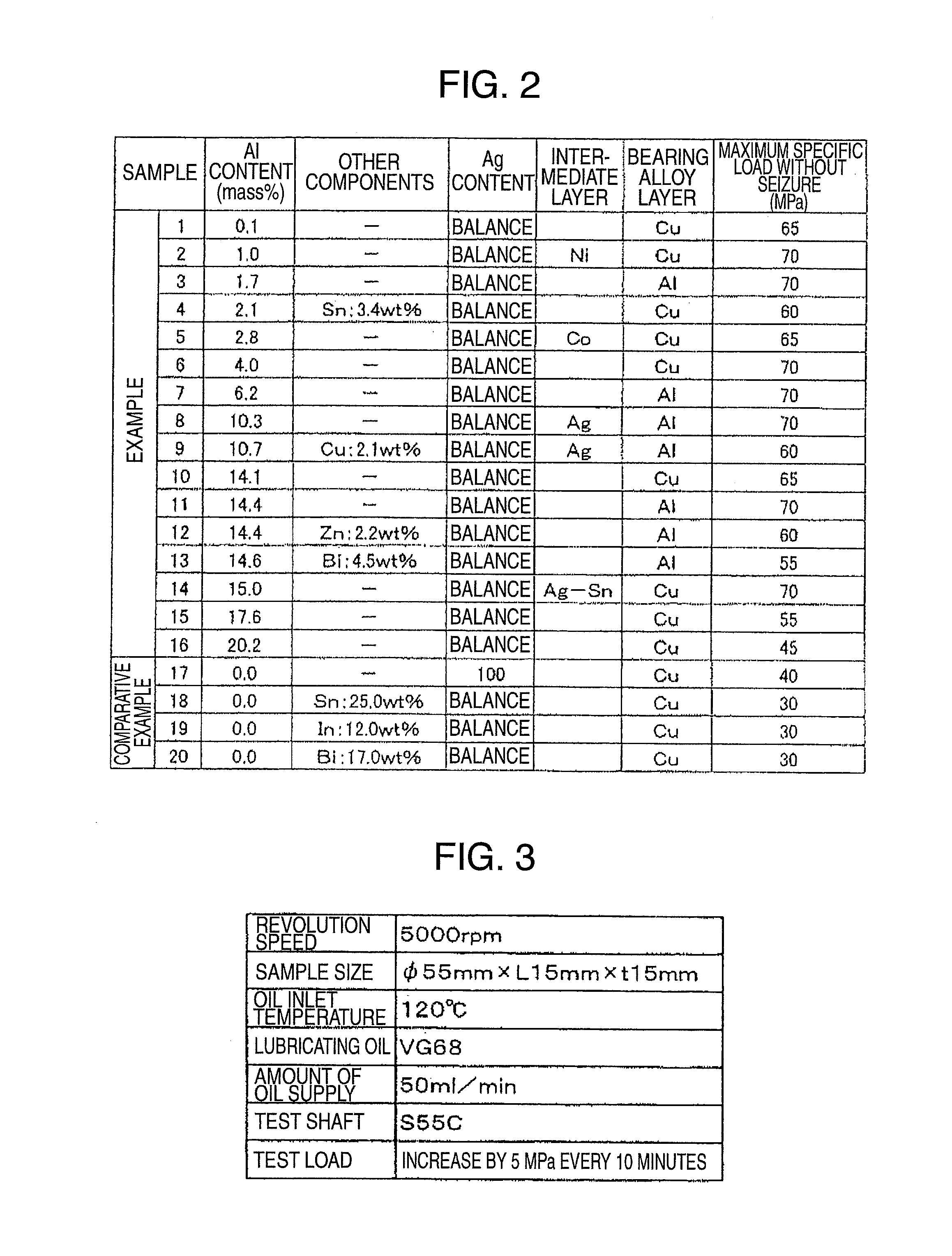

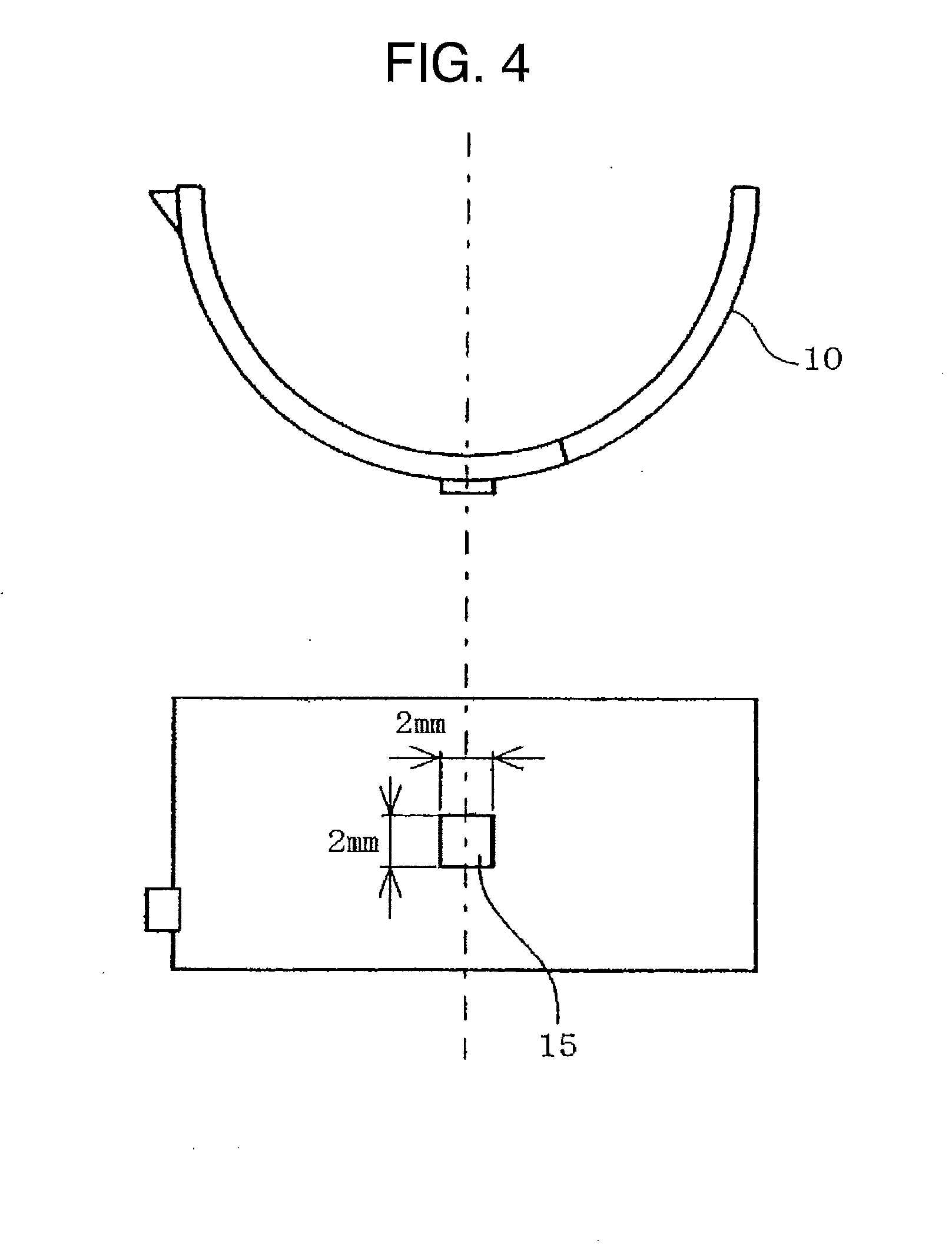

[0016]First, the procedures for producing a sliding member to be used as a sample in the present embodiment will be described.

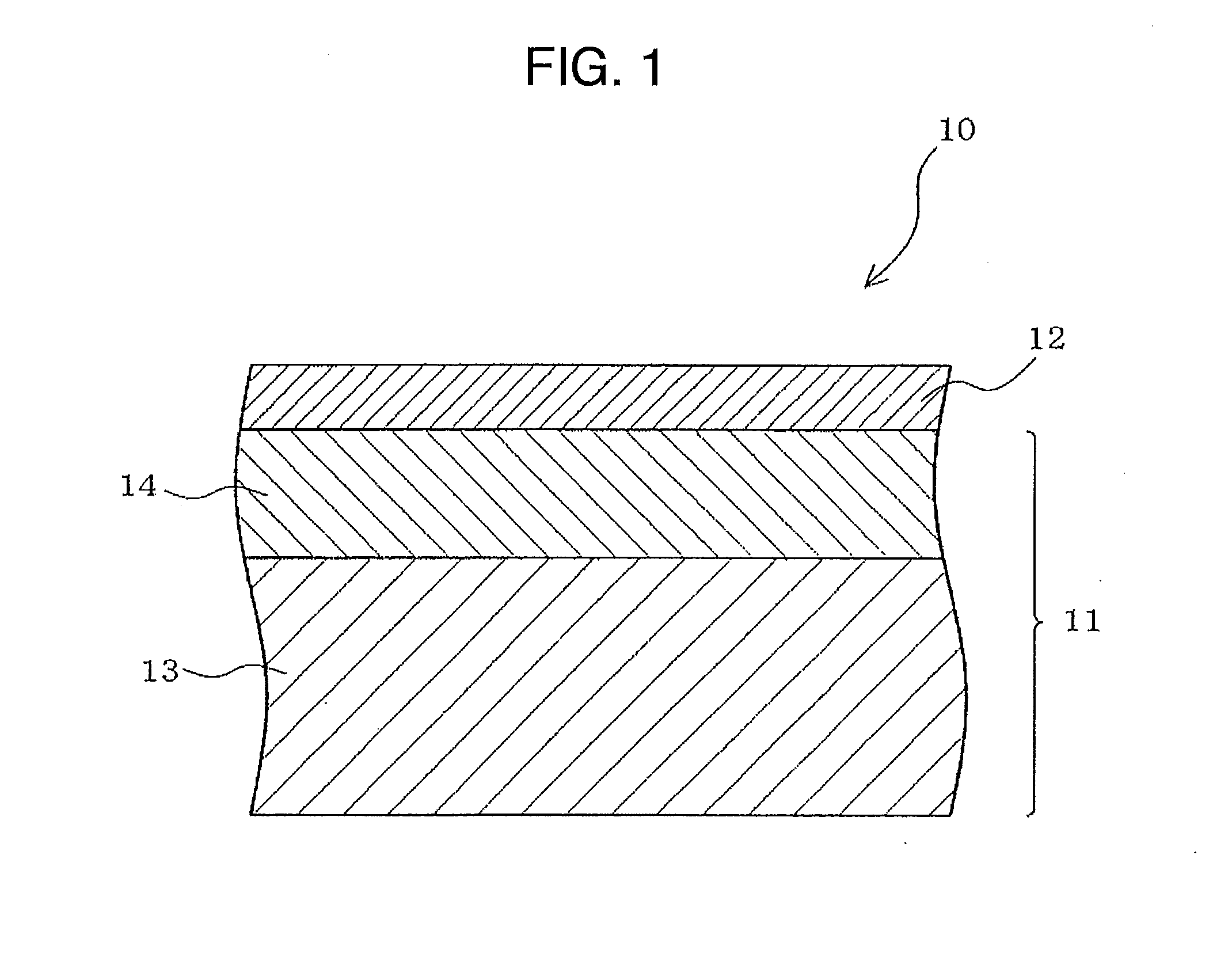

[0017]As shown in FIG. 1, a sliding member 10 comprises a base 11 and an overlay layer 12. The base 11 has a back plate layer 13 and a Cu-based or Al-based bearing alloy layer 14. The back plate layer 13 is formed from steel. Thus, the base 11 is a so-called bimetal comprising the steel back plate layer 13 and the Cu-based or Al-based bearing alloy layer 14. The base 11 formed from the back plate layer 13 and the bearing alloy layer 14 is shaped into a semicylindrical or cylindrical shape. The surface of the shaped base 11 on the side of the bearing alloy layer 14 is subjected to surface machining such as boring. The surface of the base 11 subjected to surface machining is washed by electrolytic degreasing and with acid. Thus, after the surface of the base 11 is washed, an Ag-based...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bias voltage | aaaaa | aaaaa |

| current | aaaaa | aaaaa |

| current | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com