Reinforced heat transfer high-temperature phase-change heat storage type electric boiler

A regenerative electric boiler and high-temperature phase change technology, which is applied in heat storage heaters, fluid heaters, lighting and heating equipment, etc., can solve problems such as waste of energy, insufficient power supply capacity, and potential safety hazards, and reduce safety hazards. Hidden dangers, improvement of heating efficiency, and the effect of ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

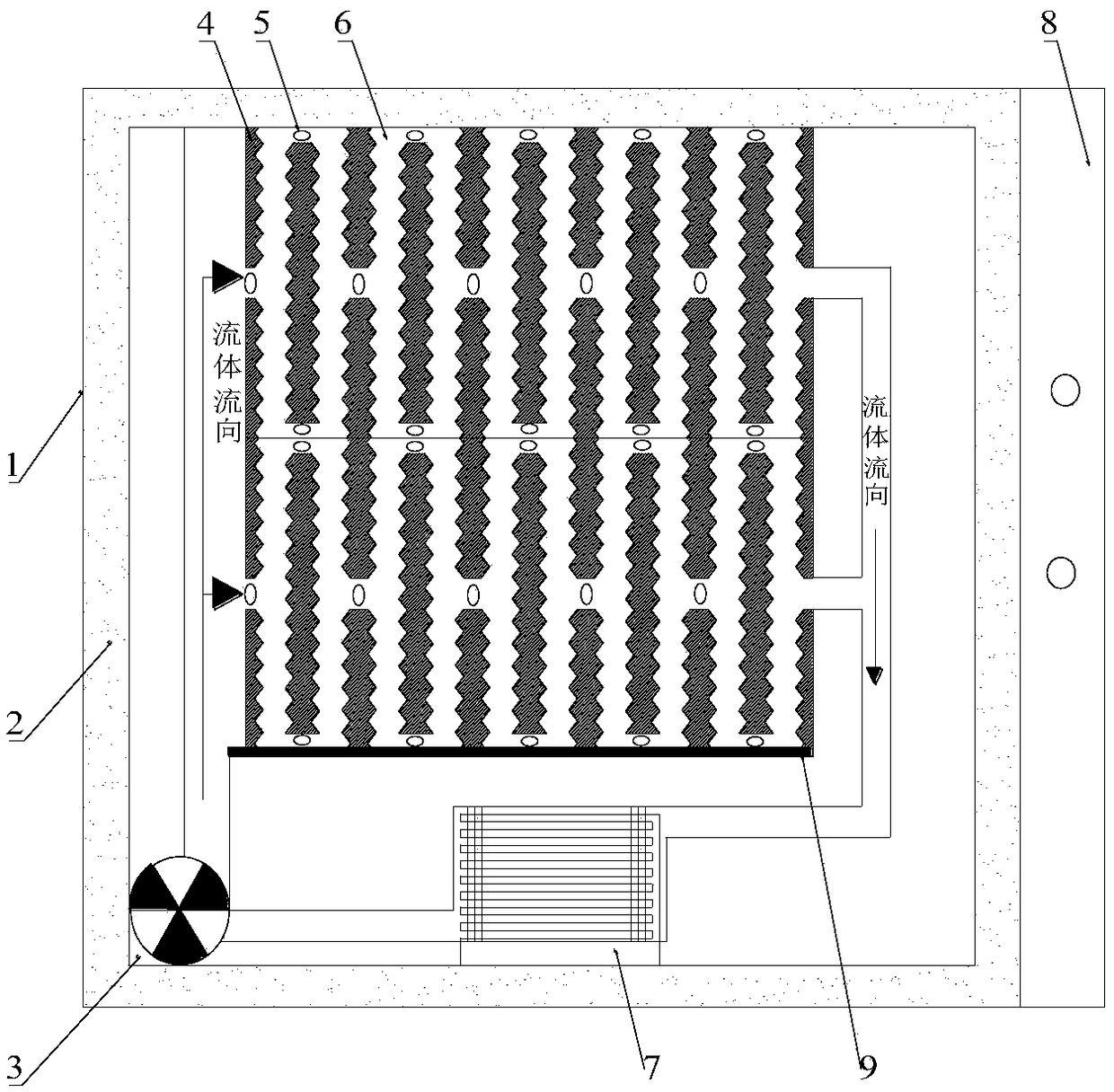

[0023] See attached figure 1 As shown, the present invention is an enhanced heat transfer high-temperature phase-change heat storage electric boiler, including a thermal insulation shell 2, a circulating fan 3, and a heat storage module 4 (the heat storage material is made into a zigzag heat exchange plate, which is made of high temperature resistant inorganic materials, heat conduction enhancement materials and phase change materials), electric heating element 5, air-water heat exchanger 7, automatic control system 8, and shell main body 1. in:

[0024] The heat preservation shell 2 of the high-temperature phase-change heat storage electric boiler is a cuboid shell, and the circulation fan 3, the heat storage module 4, the electric heating element 5, and the air-water heat exchanger 7 are installed inside it. .

[0025] The circulation fan 3 is installed at the bottom of the heat preservation shell 2 and is electrically connected with the automatic control system 8 to reali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com