Quenching hoisting tool for special-shaped flange forge piece

A technology for special-shaped flanges and forgings, which is applied in the field of hoisting tooling, and can solve the problems of affecting the quenching effect of the workpiece, increasing energy consumption, and large heat storage of the material tray.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0020] The "connection" in this manual can use common connection methods such as welding, bolts, and bolt connections.

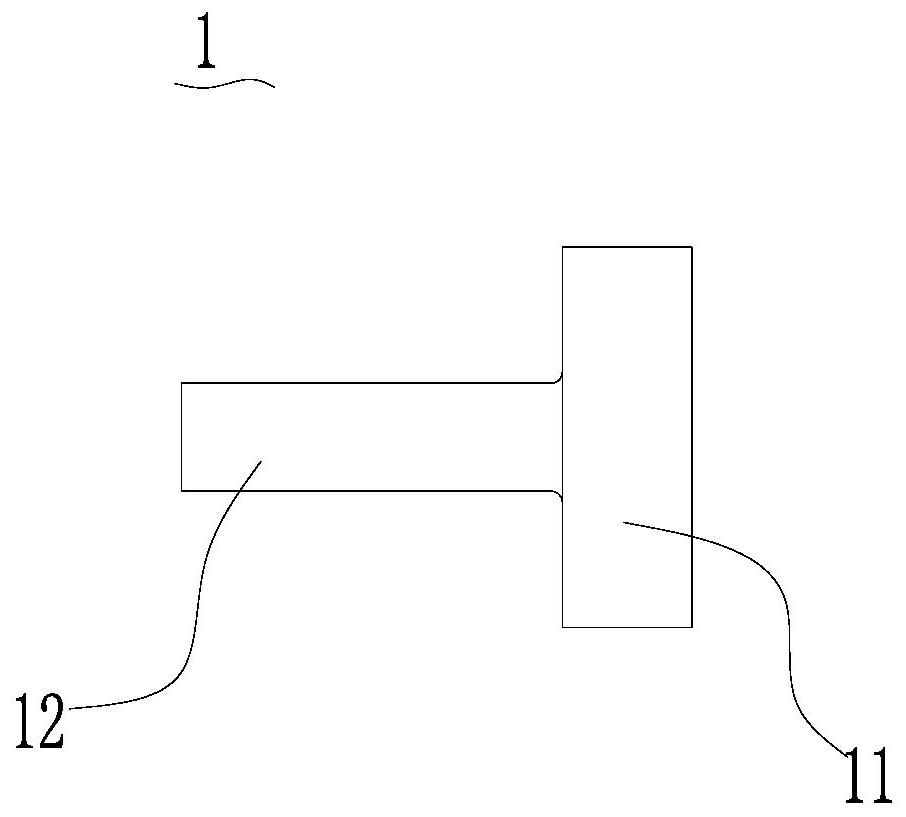

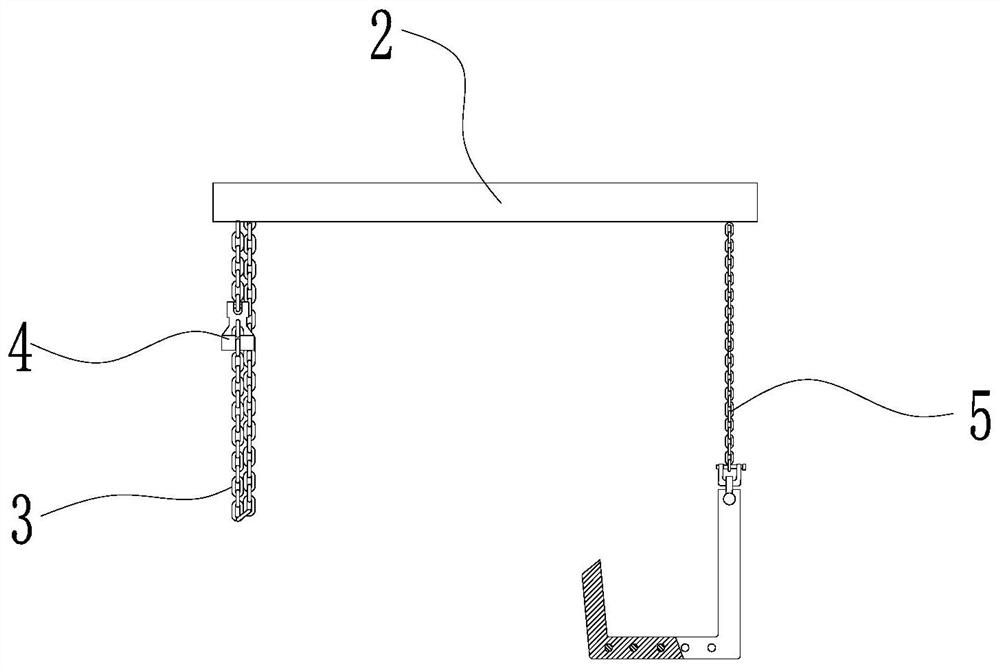

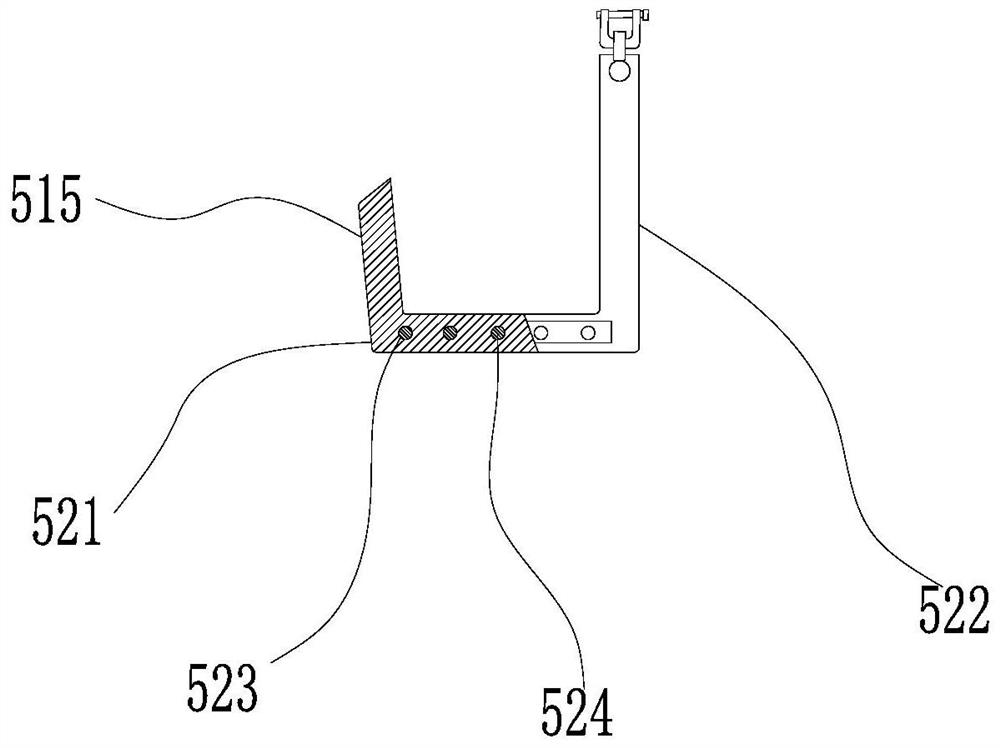

[0021] Such as Figure 2 to Figure 5 As shown, a kind of quenching and hoisting tool for special-shaped flange forgings of the present invention includes a hanging beam 2, one end of the hanging beam 2 is provided with a first hanging rope 3, and the other end is provided with a flange hanger 5, so The two ends of the first hanging rope 3 are bent and connected to the hanging beam 2 to form a pole hanger; the flange hanger 5 includes a first U-shaped hook 51, a second U-shaped hook 52, a second Hanging rope 53, third hanging rope 54 and tension member 55; the first U-shaped hook 51 is connected to the hanging beam 2 through the second hanging rope 53, and the second U-shaped hook 52 is connected through the third hanging rope 54 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com