Method for producing compound having N,N-bis(2-hydroxy-3-chloropropyl)amino group

A manufacturing method, the technology of chloropropyl, applied in the preparation of organic compounds, the preparation of amino hydroxyl compounds, organic chemical methods, etc., can solve the problems that the production efficiency and safety manufacturing methods have not been established, so as to avoid the risk of loss of control and improve productivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

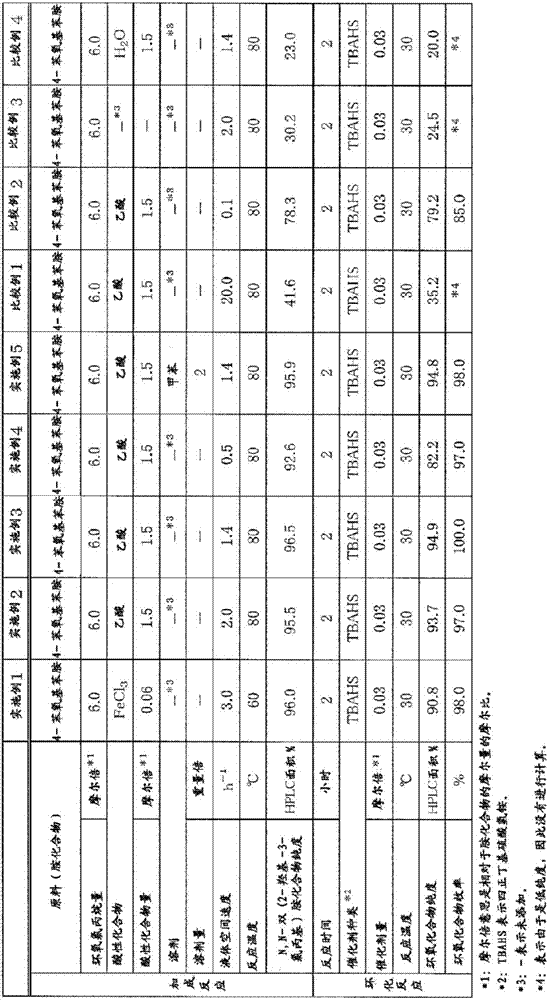

Embodiment 1

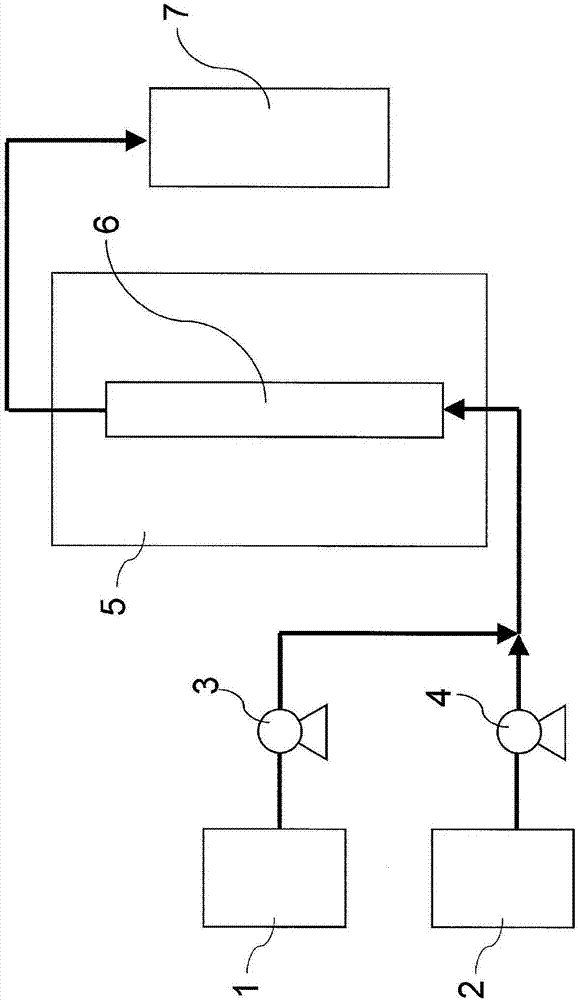

[0093] Addition reaction:

[0094] use figure 1 The device shown is used as a reaction raw material liquid to transfer 25% by weight (4-phenoxyaniline) / epichlorohydrin solution (4-phenoxyaniline:epichlorohydrin=1:6 (mol) ratio)), and 11% by weight (ferric chloride (III)) / isopropanol solution as an acidic compound solution were sent to a constant temperature of 60 °C at a supply speed of 1.10 g / min. and 0.14 g / min. A 5 / 8-inch SUS304 tubular reactor in the tank (inner diameter: 13.4 mm, length: 400 mm, space volume: 22 ml (filled with alumina balls of φ3 mm)) (the liquid space velocity in the reaction tube of the reaction solution at this time was 3.0 h -1 ). In addition, the supply amount of iron (III) chloride was 0.06 mole times with respect to the amine compound supplied to the tubular reactor. 150 g of the addition reaction liquid from the reactor outlet was obtained. Purity analysis of 4-phenoxy-N,N-bis(2-hydroxy-3-chloropropyl)aniline in the obtained reaction solutio...

Embodiment 2

[0099] Addition reaction:

[0100] As an acidic compound solution, instead of the 11 wt% (iron (III) chloride) / isopropanol solution in Example 1, acetic acid was fed at a rate of 0.13 g / min. The addition reaction was carried out in the same manner as in Example 1 except for a 5 / 8-inch SUS304 tubular reactor (inner diameter: 13.4 mm, length: 600 mm, space volume: 33 ml (filled with alumina balls of φ3 mm)). The liquid space velocity in the reaction tube of the reaction solution at this time was 2.0 h -1. In addition, the supply amount of acetic acid was 1.5 mole times with respect to the amine compound supplied to the tubular reactor. Analysis of the purity of 4-phenoxy-N,N-bis(2-hydroxy-3-chloropropyl)aniline in the obtained reaction liquid revealed a purity of 95.5% (HPLC area %).

[0101] Cyclization reaction:

[0102] The cyclization reaction was carried out in the same manner as in Example 1, except that 164 g (5.0 mole times / 4-phenoxyaniline) of 22% aqueous sodium hyd...

Embodiment 3

[0105] Addition reaction:

[0106] In Example 2, a 5 / 8-inch SUS304 tubular reactor (inner diameter: 13.4 mm, length: 400 mm, space volume 48 ml (manufactured by Shibata Chemical Co., Ltd., filled with SUS316L Helipack No. 1)) was used, except that , Addition reaction was carried out in the same manner as in Example 2. The liquid space velocity in the reaction tube of the reaction solution at this time is 1.4h -1 . The purity analysis of 4-phenoxy-N,N-bis(2-hydroxy-3-chloropropyl)aniline in the obtained reaction liquid was 96.5% (HPLC area %).

[0107] Cyclization reaction:

[0108] Cyclization reaction was carried out in the same manner as in Example 2 using the reaction solution obtained by the above addition reaction.

[0109] 53.9 g of 4-phenoxy-N,N-diglycidylaniline was obtained by this cyclization reaction (weight yield (4-phenoxyaniline basis): 100%). The chemical purity of the obtained 4-phenoxy-N,N-diglycidylaniline was 94.9% (HPLC area %).

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com