Ceramic solar modular phase change heat storage sunlight greenhouse and phase change solution thereof

A technology of solar modules and ceramic solar panels, which can be used in greenhouse cultivation, climate change adaptation, heat exchange materials, etc., and can solve the problems of little improvement in greenhouse heat storage performance, increased greenhouse footprint, and insufficient heat storage in greenhouses, etc. , to achieve the effect of easy long-term stable operation, lower construction cost, and lower construction difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

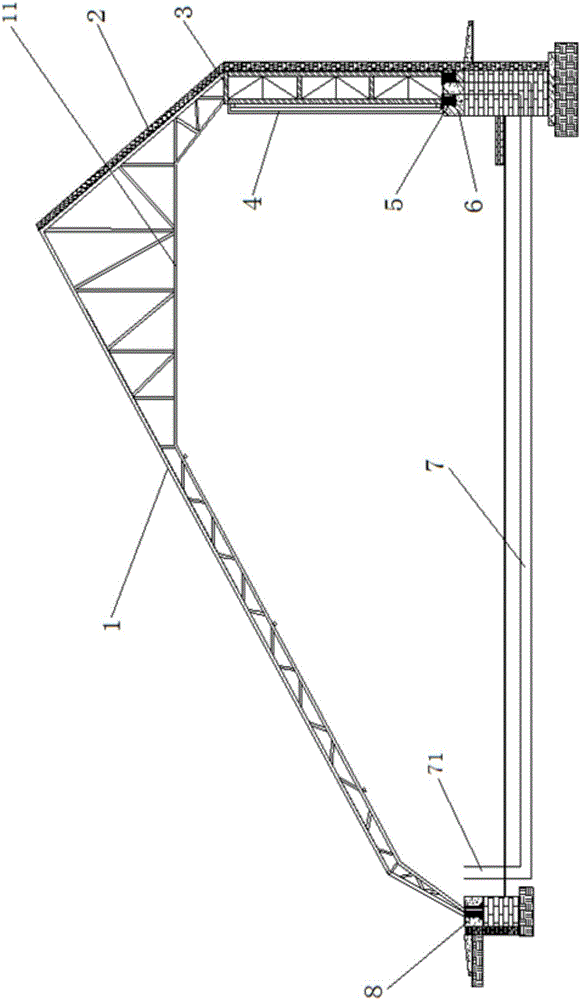

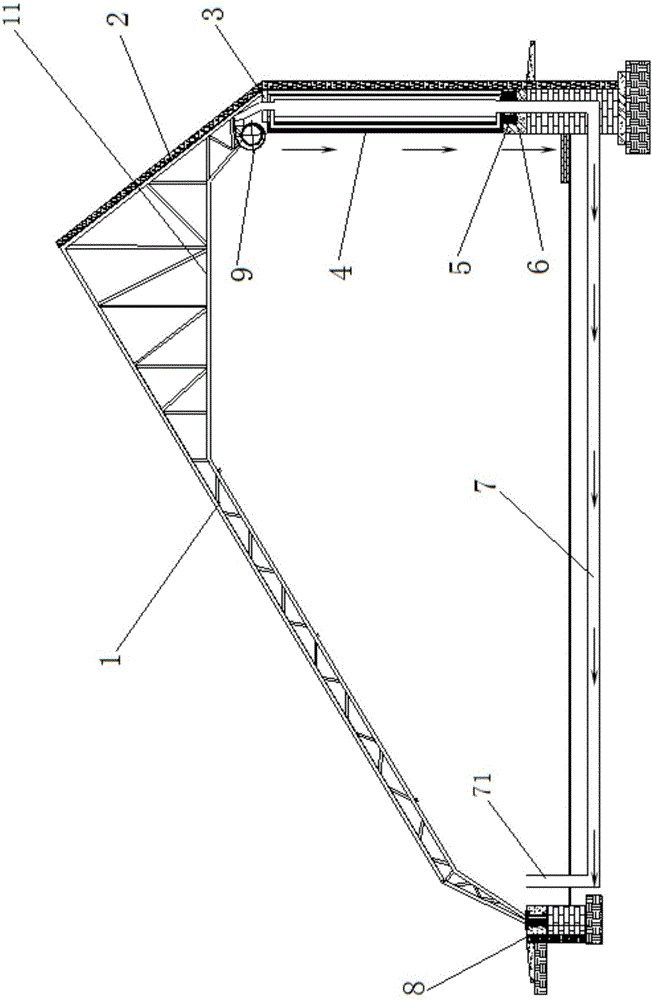

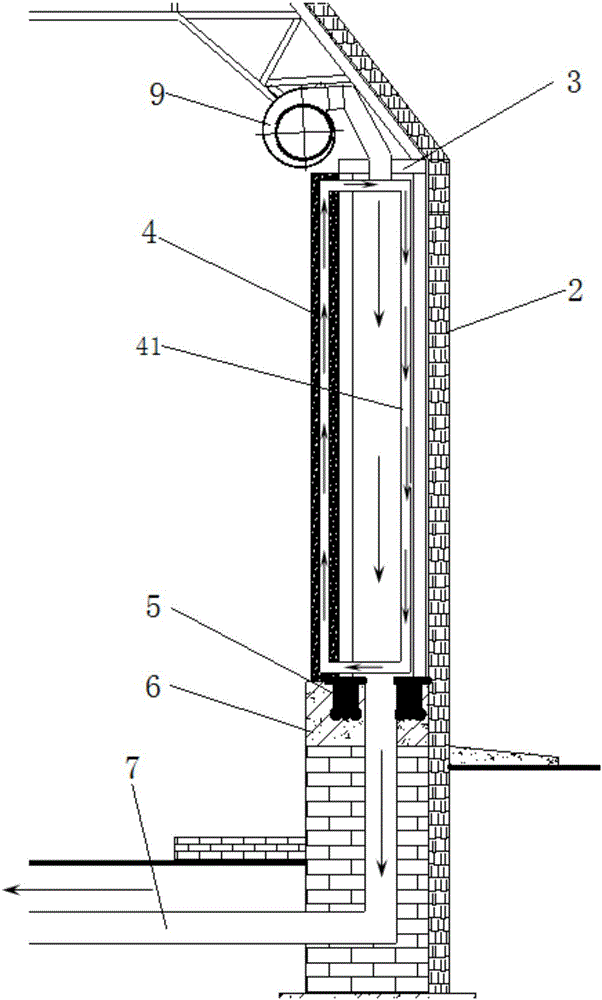

[0037] refer to figure 1 , 2 And 3, the specific structure of the ceramic solar modularized phase change heat storage solar greenhouse of this embodiment, including the greenhouse skeleton 1, the thermal insulation component 2, the steel structure component 3 of the greenhouse back wall, the solar ceramic phase change component 4, and the embedded parts 5 , the concrete ring beam 6 of the back wall of the greenhouse, the underground heat storage air duct 7 of the greenhouse and the front wall of the greenhouse 8;

[0038] When this greenhouse structure is built, first construct the foundation of the greenhouse front wall 7 front house foot ring beams and the greenhouse rear wall of the greenhouse civil engineering, then pour the greenhouse rear wall concrete ring beam 6 on the foundation of the greenhouse rear wall, and pour the concrete ring beam 6 At the same time, the embedded part 5 is cast in place; then the steel structure component 3 of the greenhouse rear wall is inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com