Numerical control setting machine

A sizing machine and sizing mechanism technology, applied in the direction of sizing/elongation circular fabrics, textiles and papermaking, fabric surface trimming, etc., can solve problems such as not meeting high-quality sizing requirements, affecting sizing quality, and large sizing cavity length, etc. It achieves the effect of simple structure, small temperature difference in shaping and improvement of shaping quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

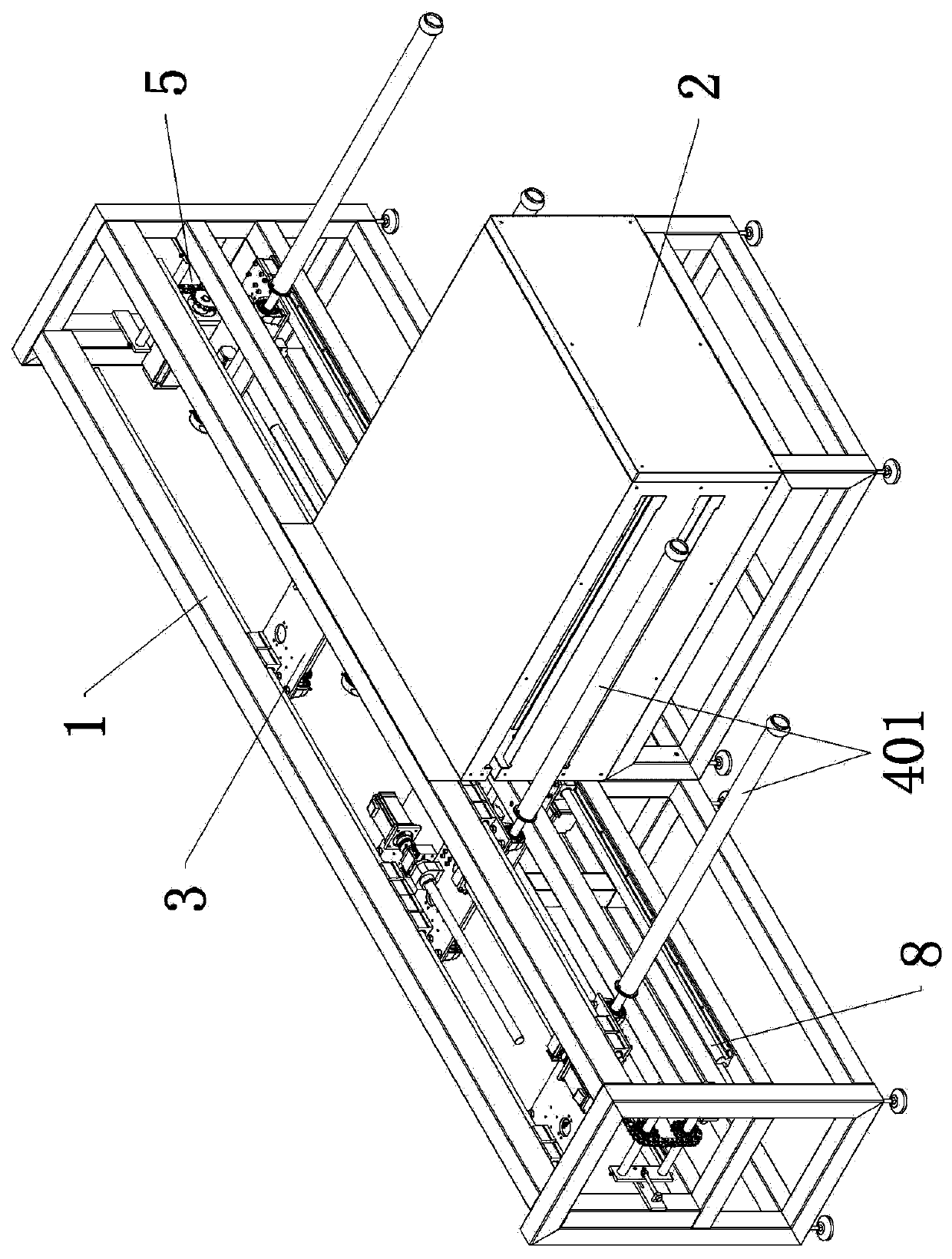

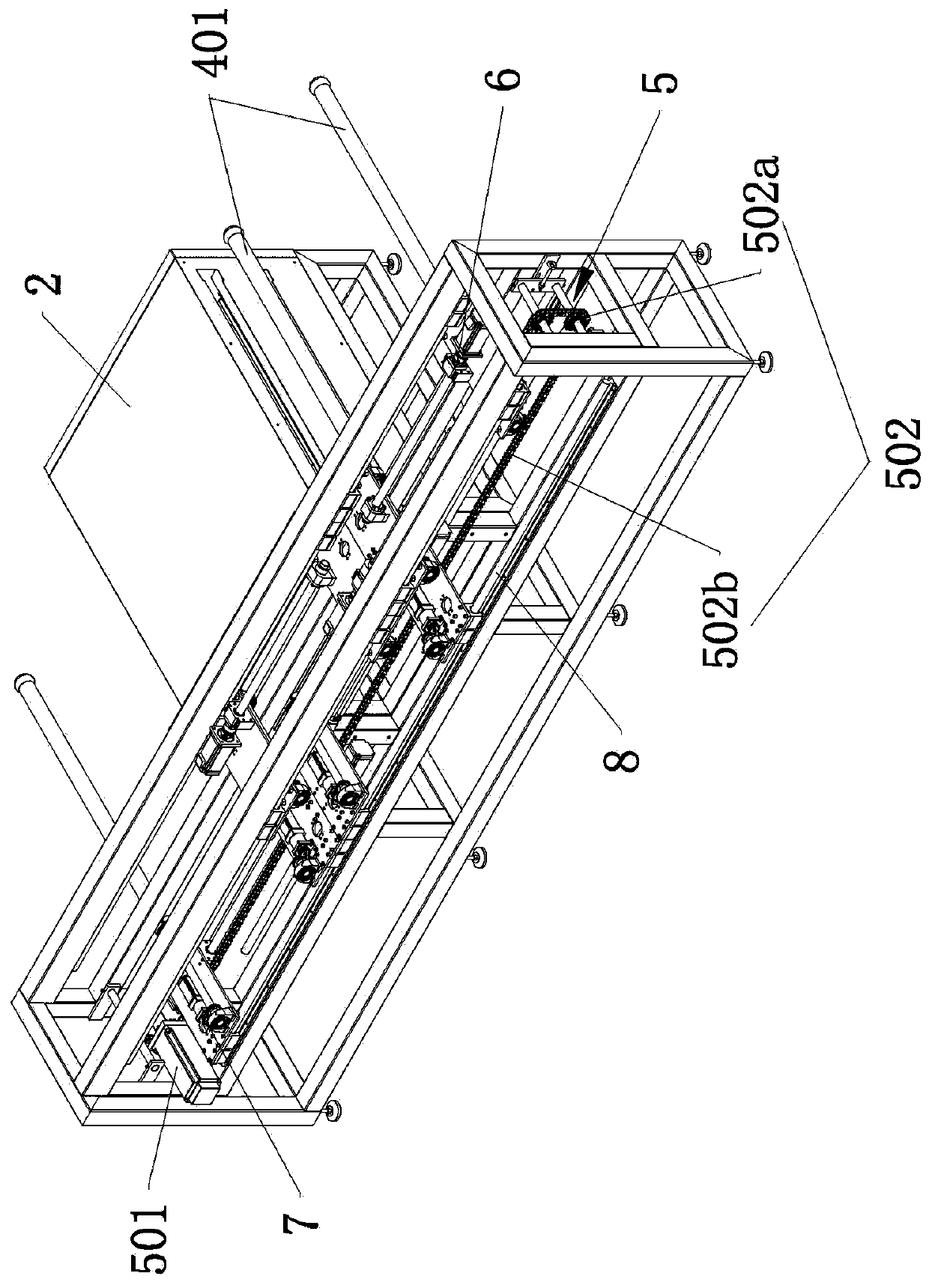

[0025] Example 1: Such as Figure 1 to Figure 5 As shown, a numerical control setting machine includes a setting frame 1, an oven 2 and a setting mechanism 4. The oven 2 is fixedly connected to one side of the setting frame 1, and the setting mechanism 4 and the oven 2 are located on the same side of the setting frame 1.

[0026] The shaping mechanism 4 is divided into upper and lower layers, and each layer of the shaping mechanism 4 includes two sets of shaping components 401, and the two sets of shaping components 401 are arranged front and back. Each group of sizing components 401 includes two sizing rollers 401a, and a total of four sizing rollers 401a of the two groups of sizing components 401 are distributed back and forth along the length direction of the sizing frame 1.

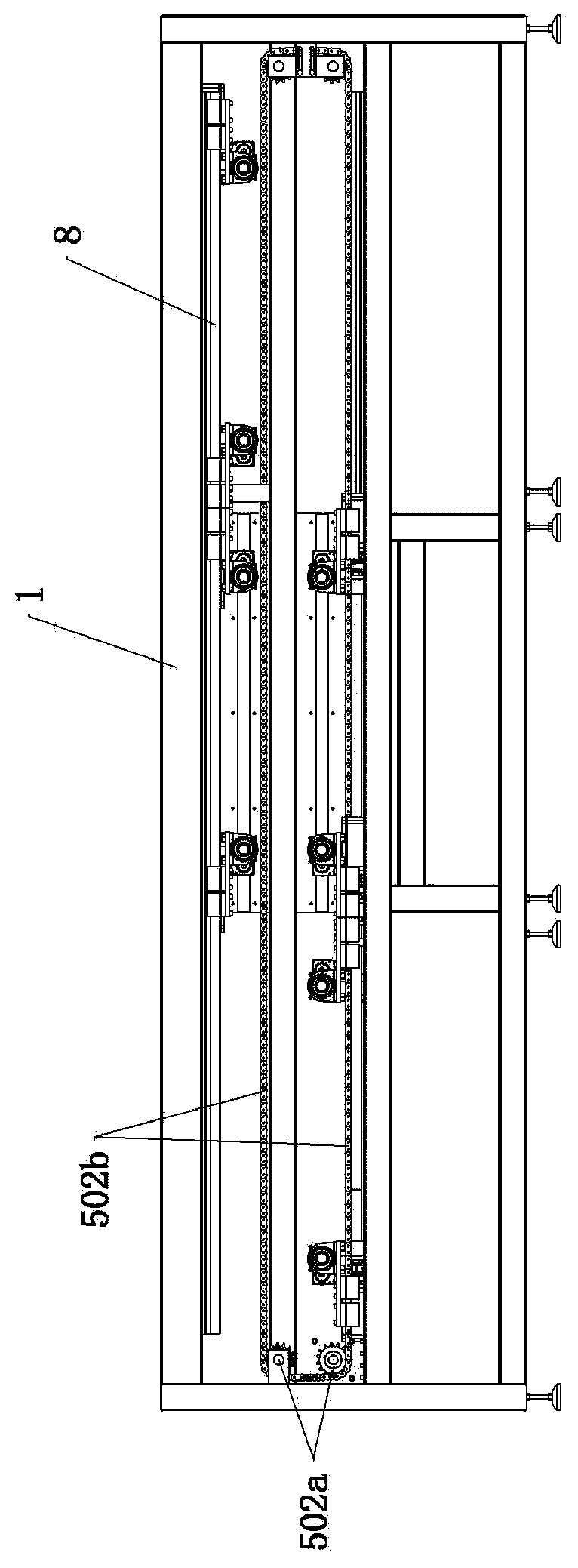

[0027] A movable seat 3 is installed on the sizing frame 1, and the movable seat 3 is installed on the sizing frame 1 through a slide 8 and can move back and forth along the chute 8 in the length direction...

Embodiment 2

[0036] Embodiment 2: The difference from Embodiment 1 is that each layer of the shaping mechanism 4 includes four sets of shaping components 401, and the four sets of shaping components 401 are symmetrically distributed on the left and right sides of the shaping frame 1, that is, the shaping frame 1 There are a total of four shaping rollers 401a for each layer on one side, and two left and right shaping rollers are installed on a movable seat 3. The oven 2 is arranged on the left and right sides of the shaping frame 1 and located in the middle of the shaping frame 1. When the driving assembly 5 is running, The two sets of sizing components 401 corresponding up and down on the same side of the sizing rack 1 alternately enter and exit the oven 2 on the corresponding side.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com