Novel blown aluminum uniform temperature plate

It is a new type of temperature chamber, which is applied to electrical components, electrical solid devices, circuits, etc. It can solve the problems of large temperature difference between the upper and lower shells and poor heat dissipation performance, so as to reduce the temperature difference between the upper and lower sides, improve the heat dissipation performance, fast condensation and heat dissipation. Evaporation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

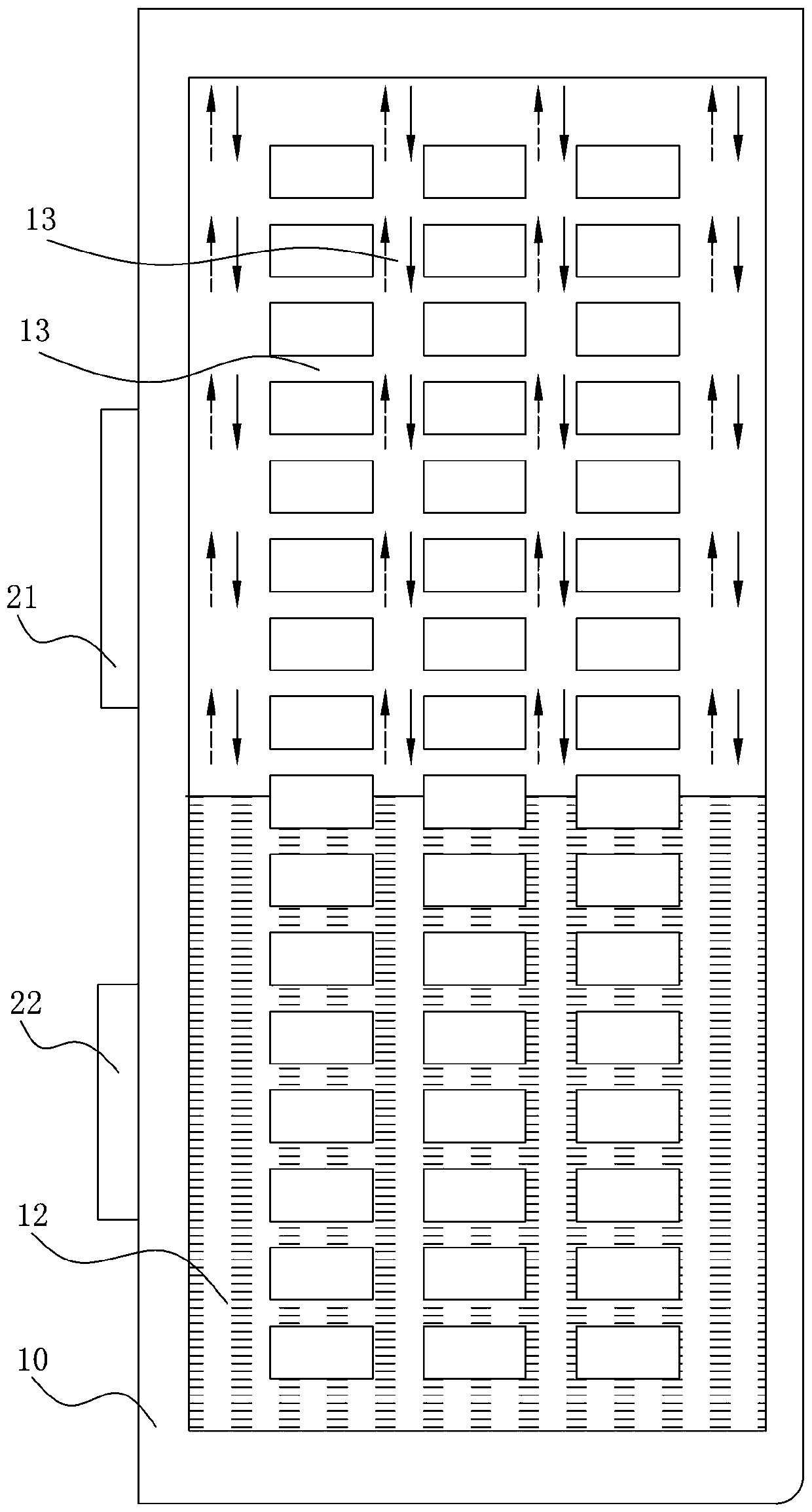

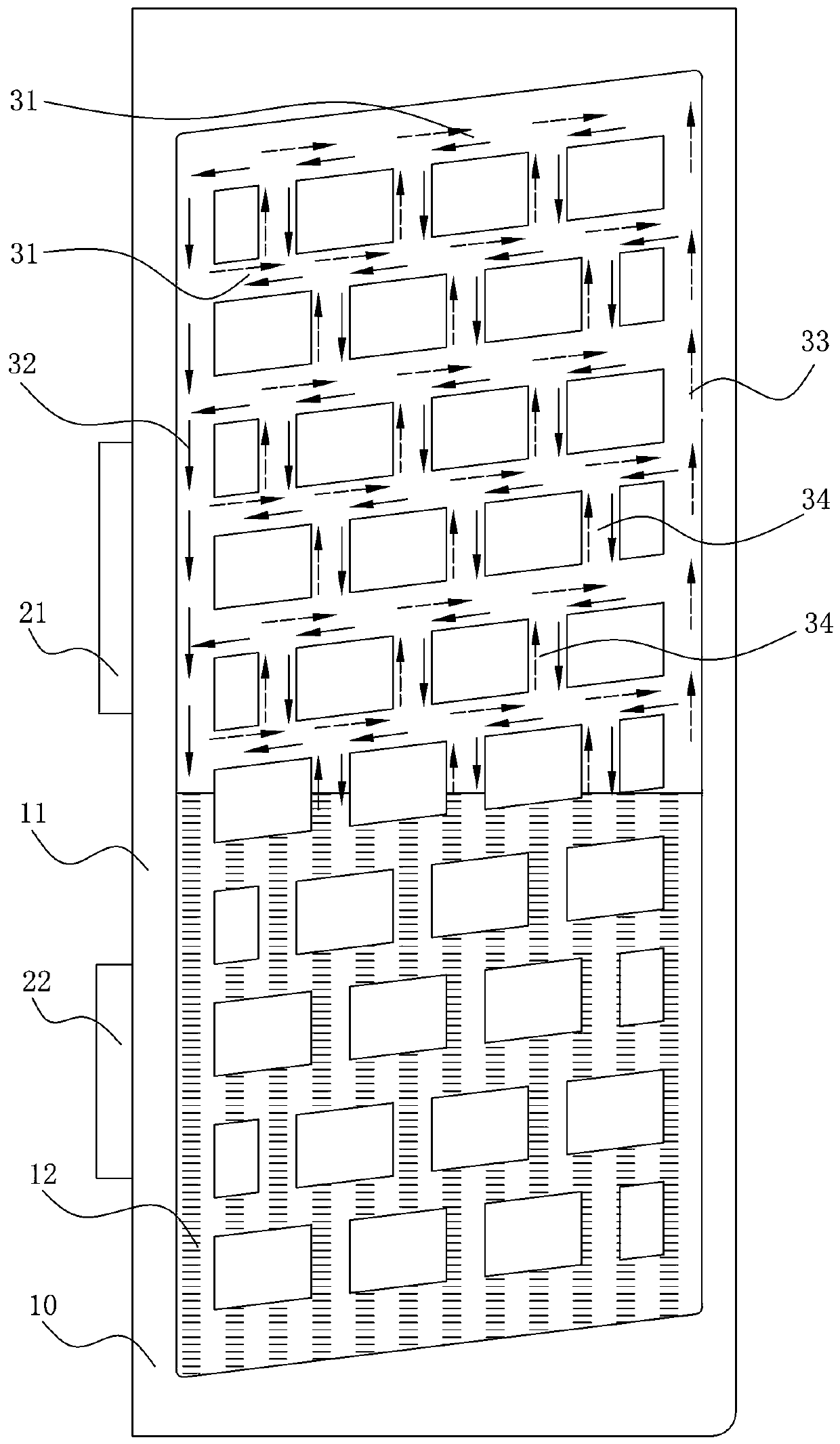

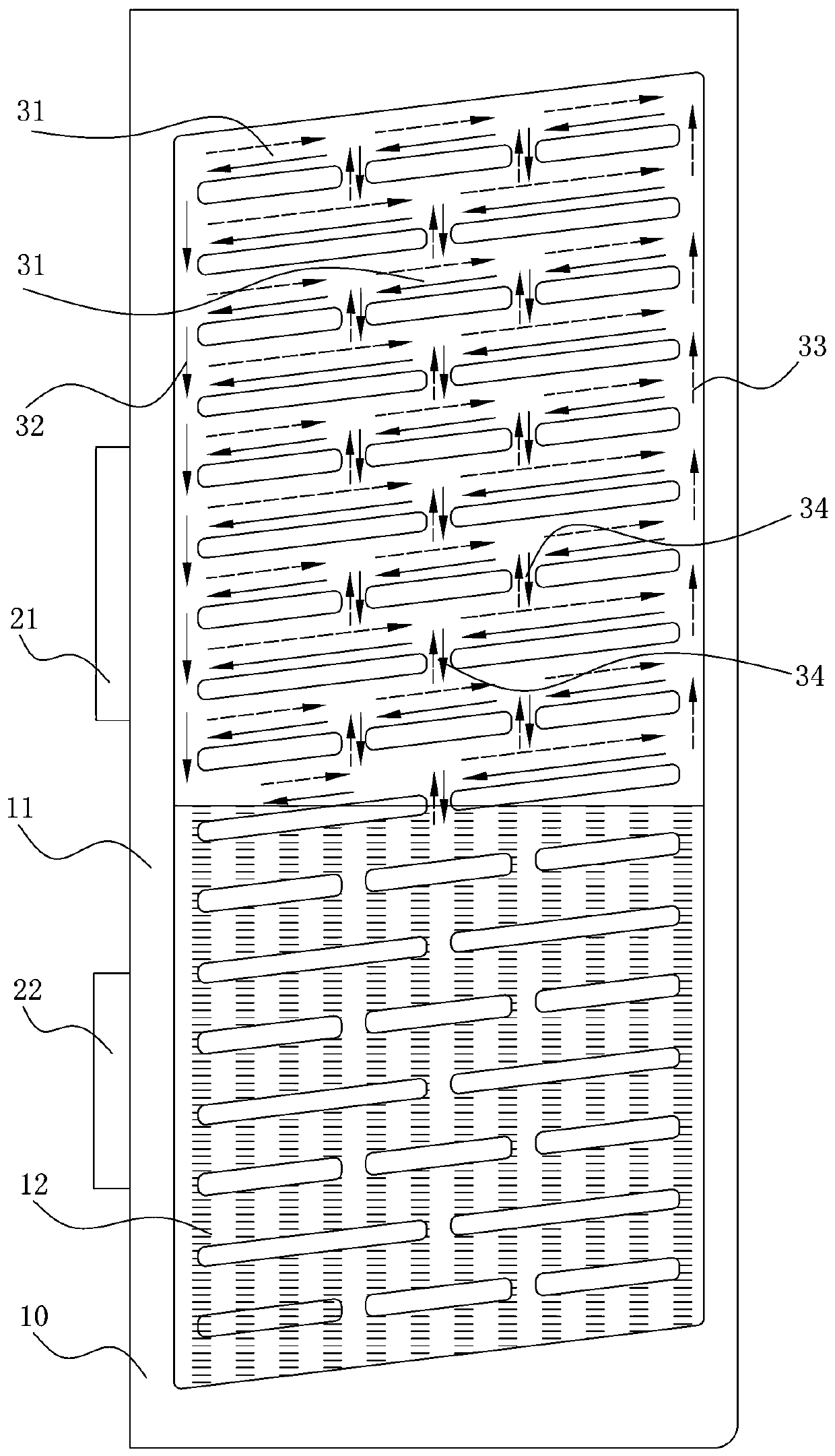

[0025] Such as figure 2 As shown, in the first embodiment provided by the present invention, a new type of inflatable aluminum vapor chamber includes a housing 10 , and one side of the housing 10 is a heat source end 11 . The external upper heat source 21 and the lower heat source 22 are mounted on the heat source end 11 up and down. The inside of the housing 10 is under negative pressure and injected with a working medium 12 , and a plurality of drainage channels 31 are arranged in the housing 10 .

[0026] The drainage channel 31 is arranged obliquely, and the inclination direction is from high to low to the heat source end 11; the condensed working fluid 12 flows along the drainage channel 31 to the heat source end 11 under the action of gravity; The channel 31 is away from the heat source end 11 . Furthermore, the temperature difference between the left and right sides of the casing 10 is reduced, and the heat dissipation performance is improved. At the same time, it i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com