Top-blown heat pipe radiator and its manufacturing method

A heat pipe radiator, top-blown technology, applied in the direction of cooling/ventilation/heating transformation, equipment, instrument cooling, etc., can solve the problem of not meeting the heat dissipation performance of the radiator, large temperature difference of the radiator, and low heat dissipation efficiency and other issues, to achieve the effect of light weight, large heat dissipation capacity, and improved heat dissipation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further explained below in conjunction with the drawings:

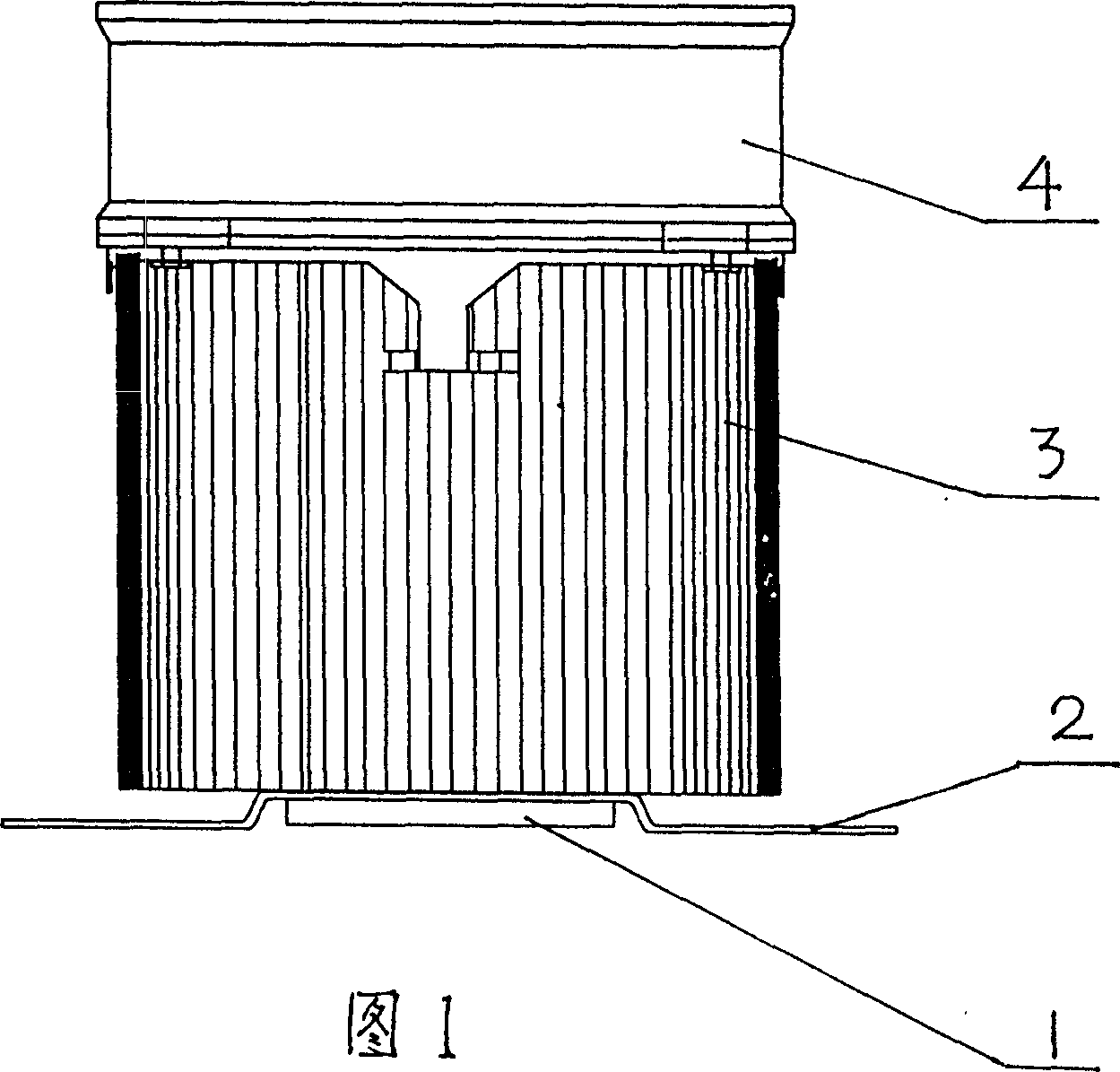

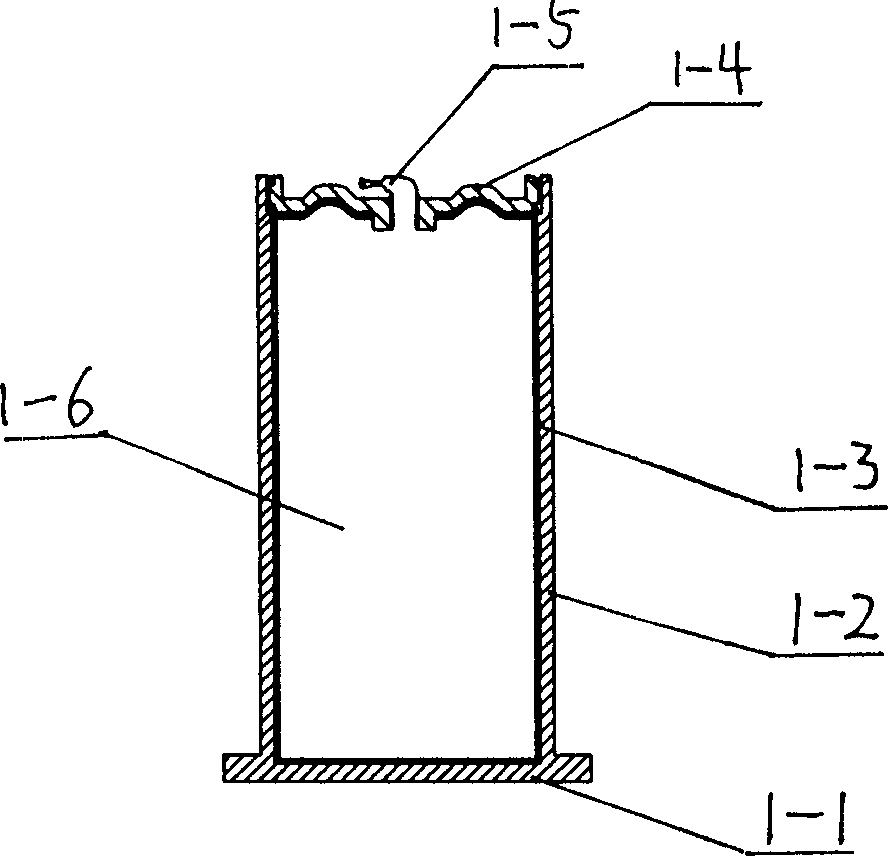

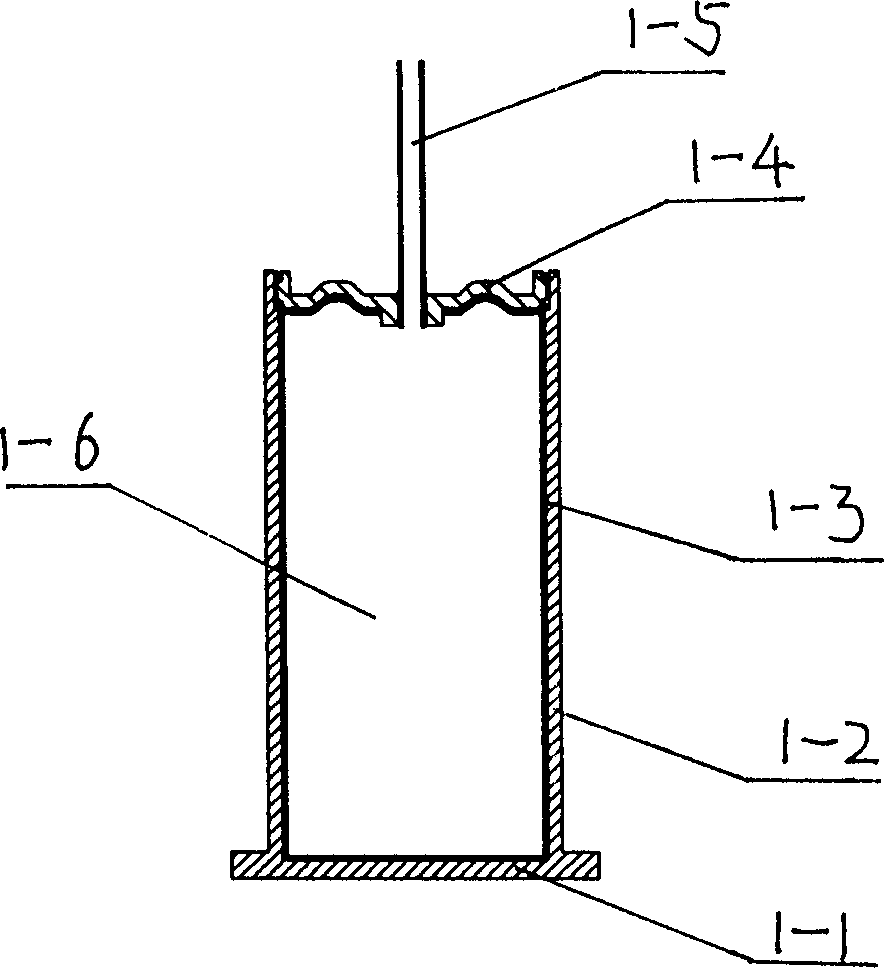

[0020] Refer to Figure 1, Figure 6 , Figure 8 , This top-blowing heat pipe radiator includes a heat pipe 1, a fastener 2, a heat sink base 3 and a fan 4. The heat sink base 3 has a through hole 3-1 penetrating up and down and a plurality of radiating fins 3-2. The heat pipe 1 is composed of a bottom plate 1-1, a pipe body 1-2, a top cover 1-4, and an exhaust pipe 1-5 to form a sealed cavity 1-6, and the inside is vacuum. The inner surface of the sealed cavity 1-6 is provided with a sintered layer 1-3 with a porous capillary structure. The sintered layer 1-3 is made by sintering copper powder at a high temperature, and the sintered layer 1-3 adsorbs working fluid; the bottom plate 1-1 Set at the lower end of the tube body 1-2, the upper end of the tube body 1-2 is provided with a top cover 1-4, and the top cover 1-4 is provided with an exhaust pipe 1-5, through the exhaust pipe 1-5 to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com