Patents

Literature

35results about How to "Uniform temperature up and down" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

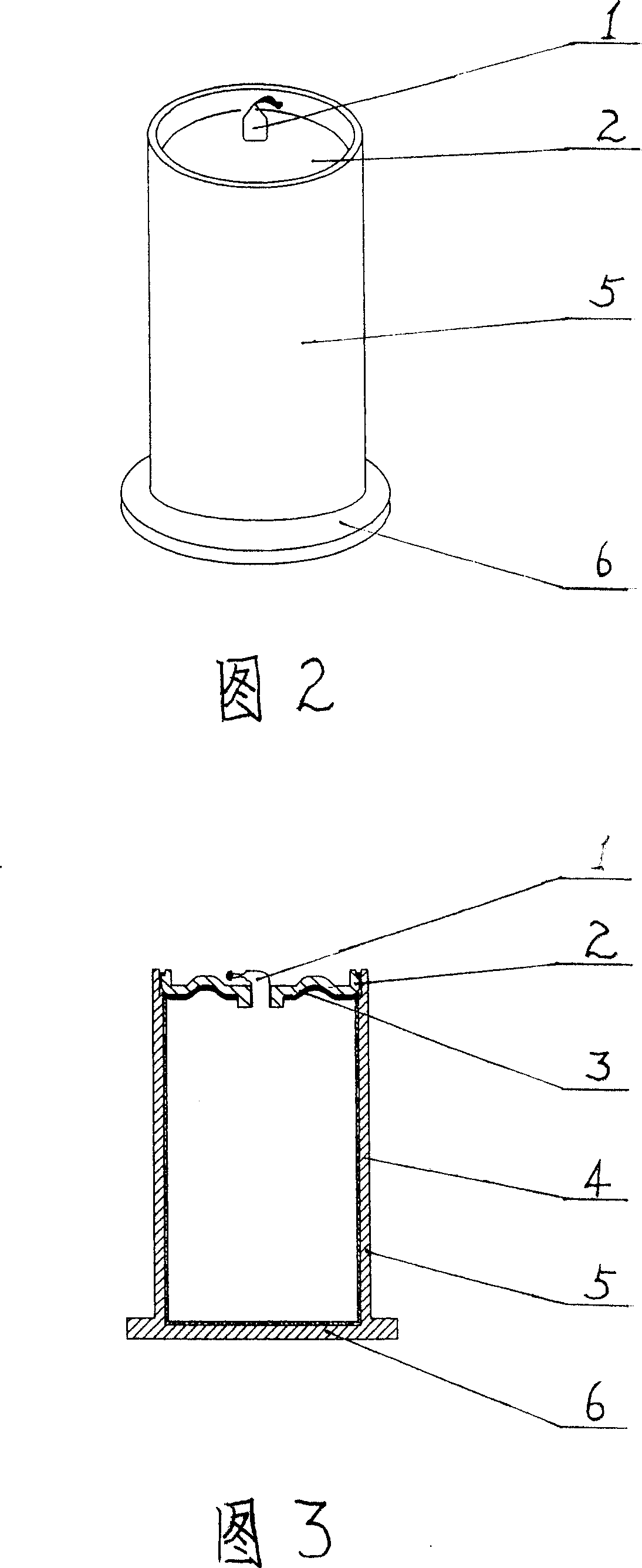

Refrigerated cabinet

InactiveCN101532763BUniform temperature up and downAvoid blockingLighting and heating apparatusDomestic refrigeratorsRefluxEngineering

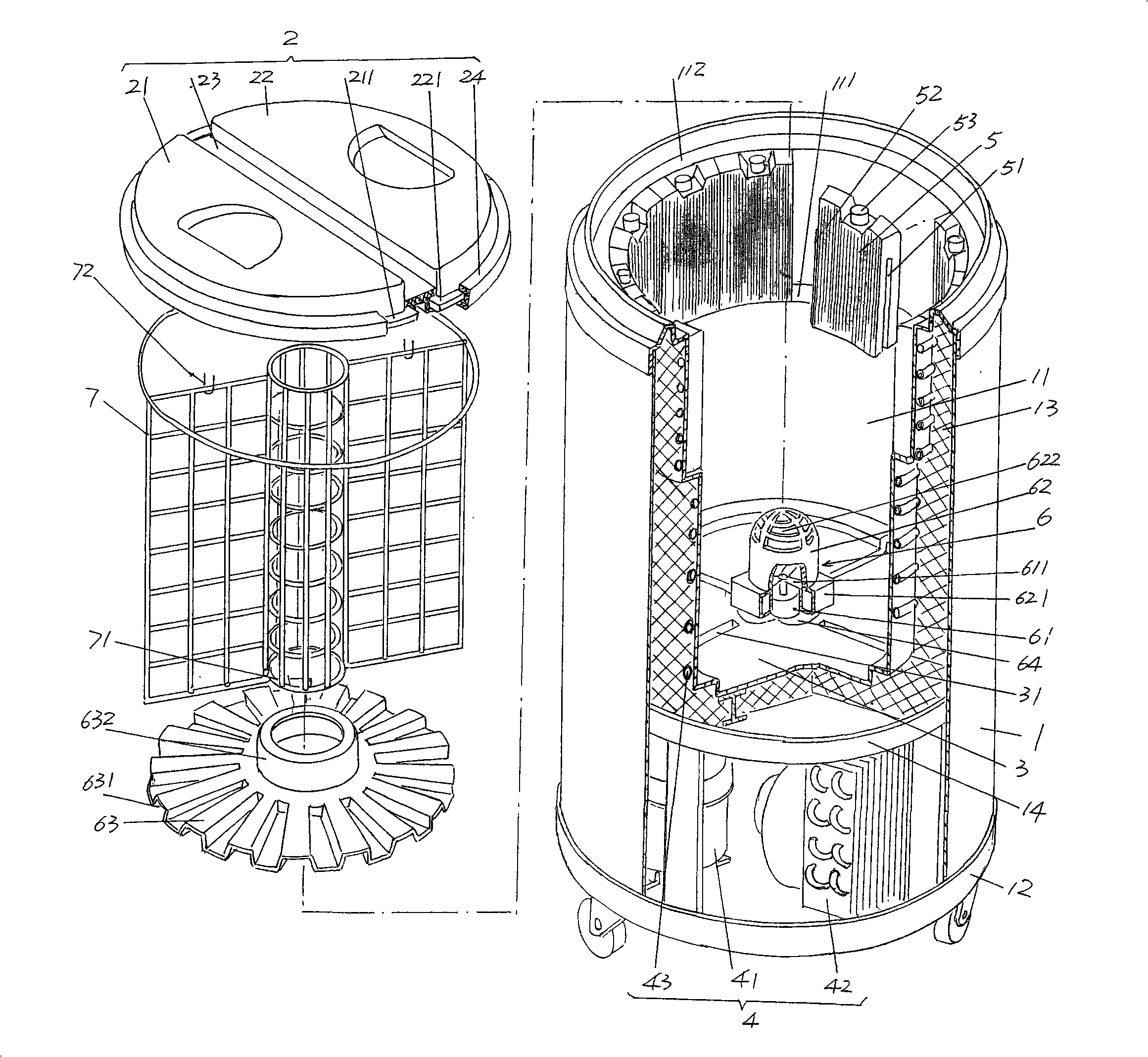

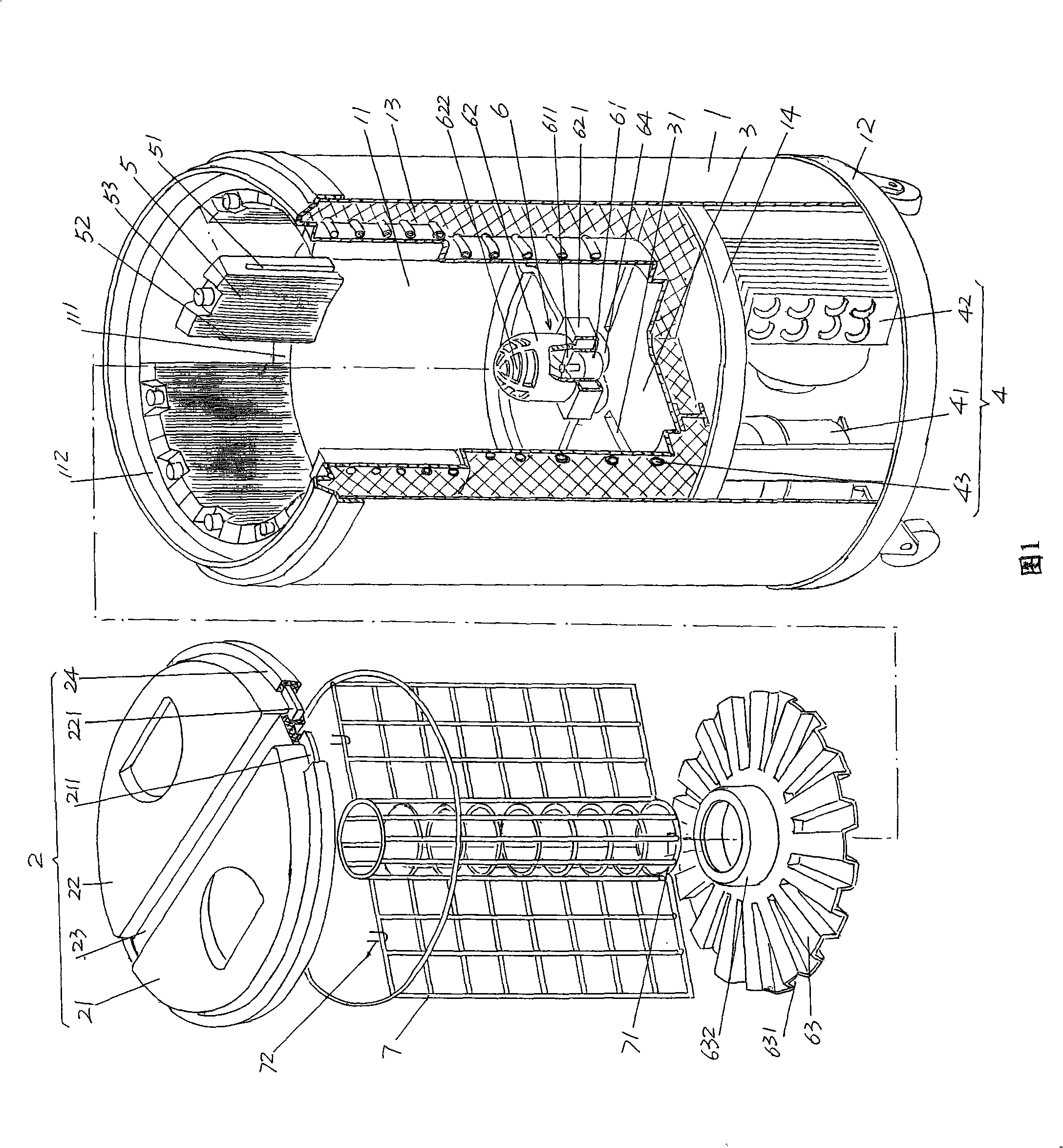

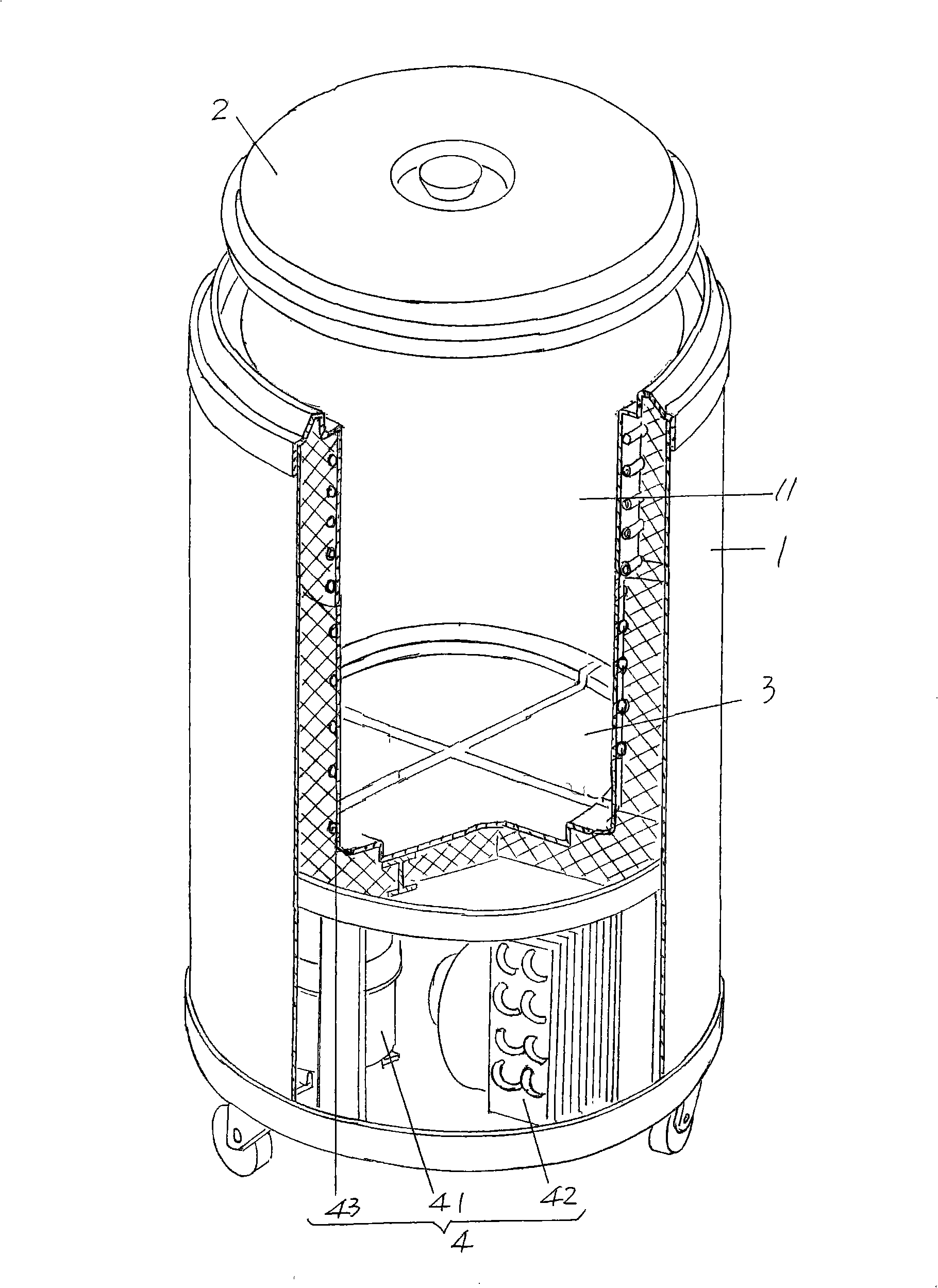

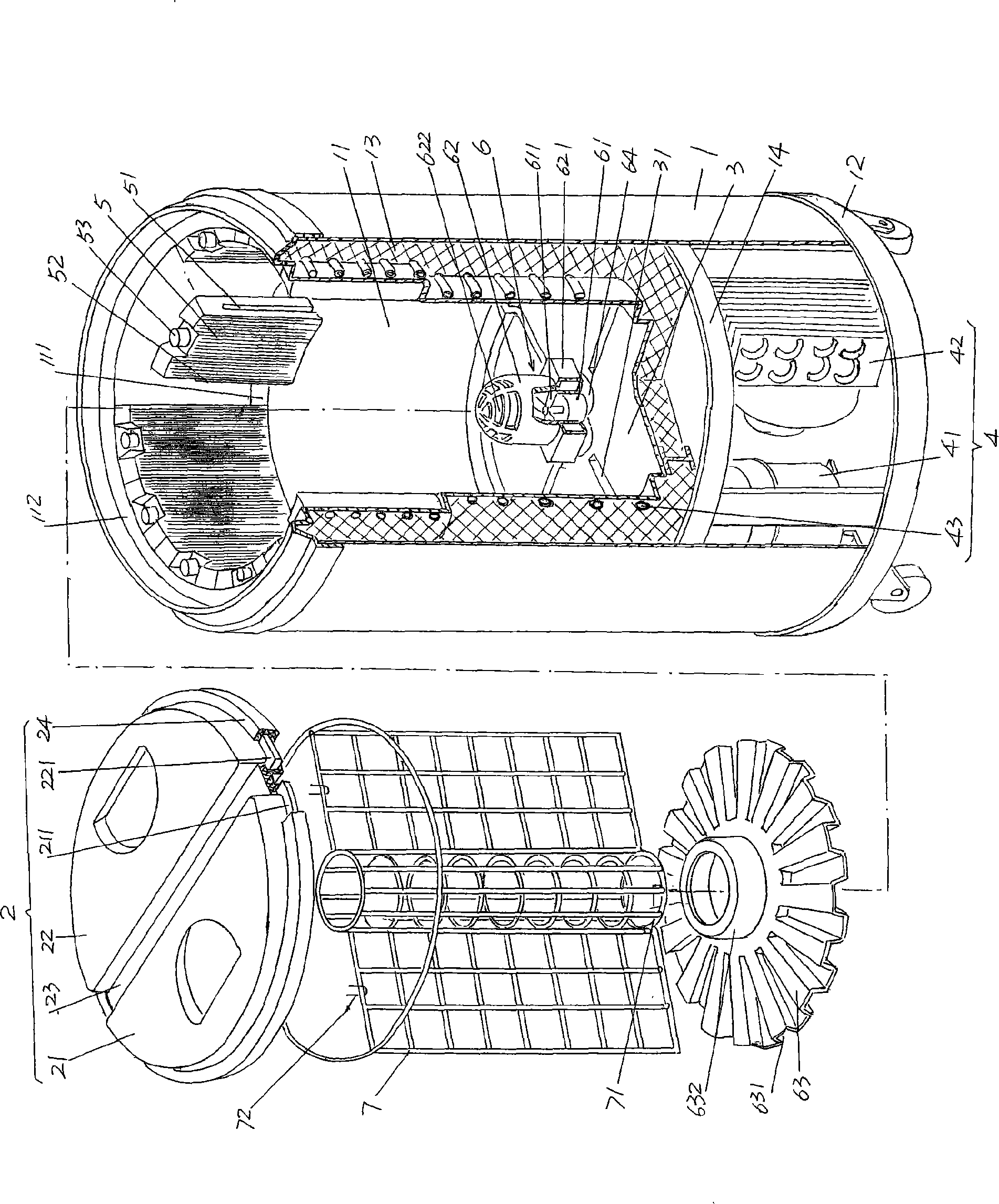

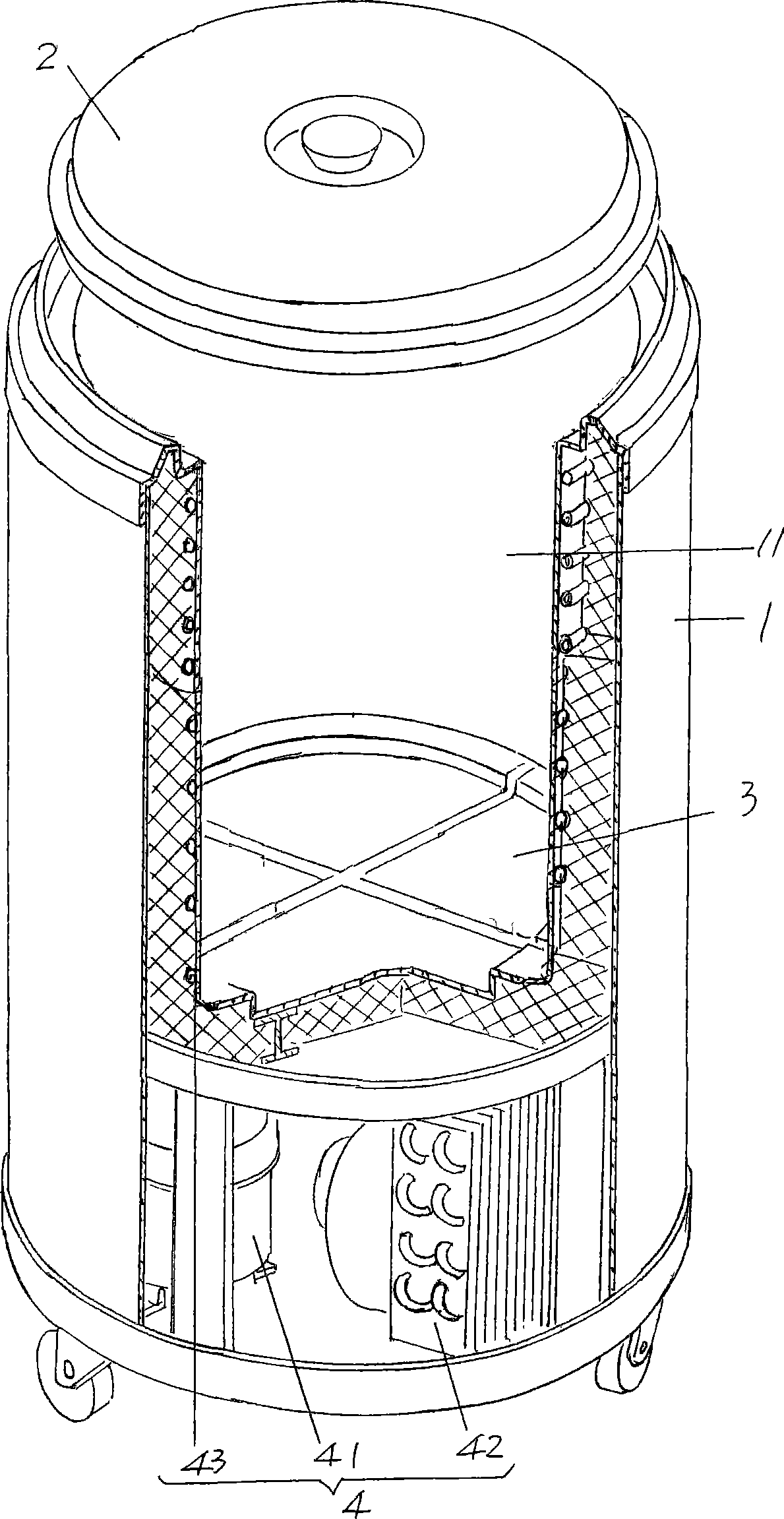

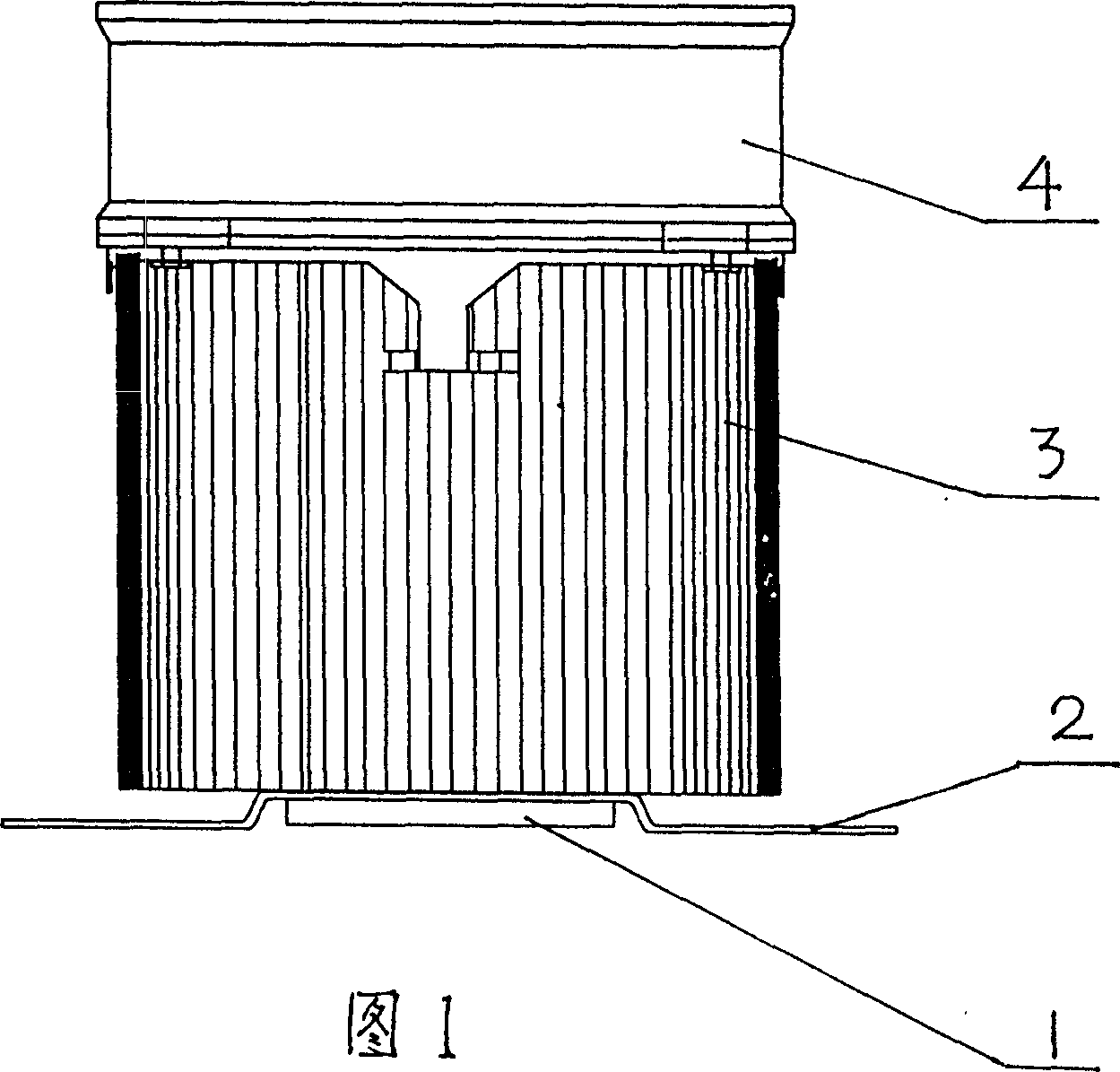

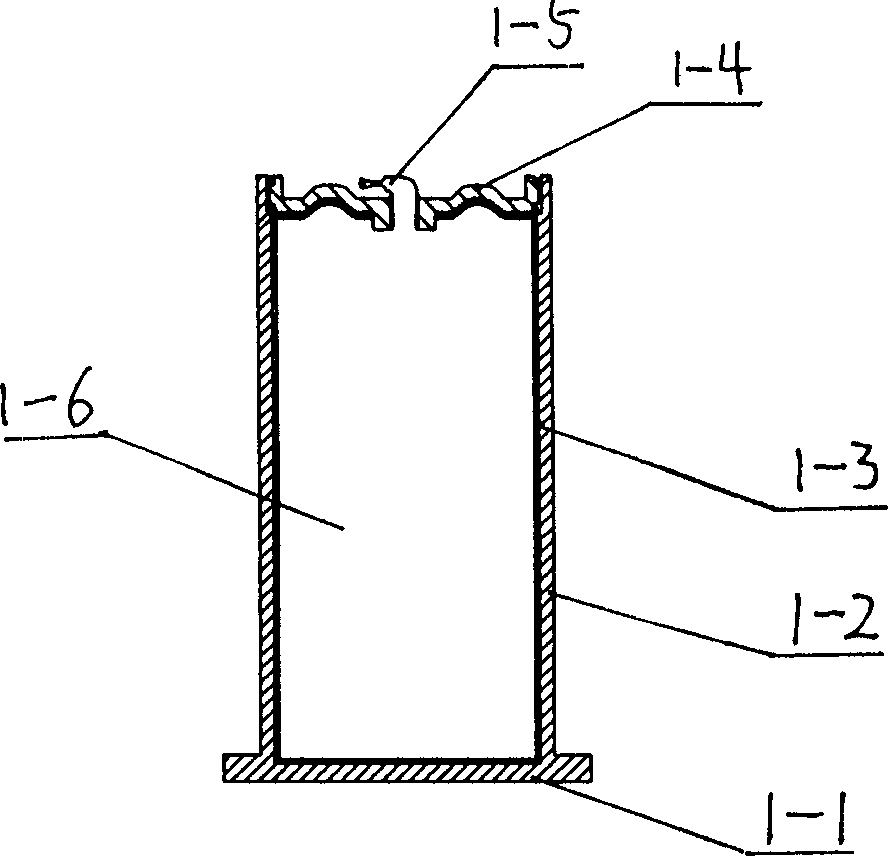

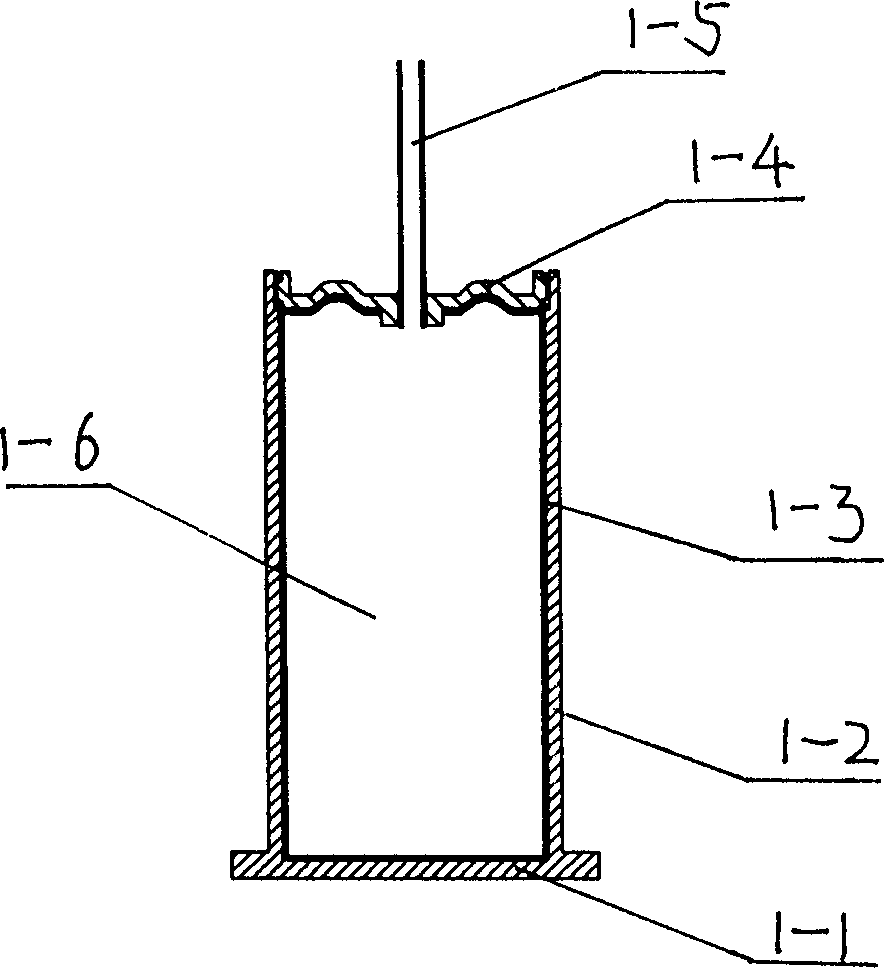

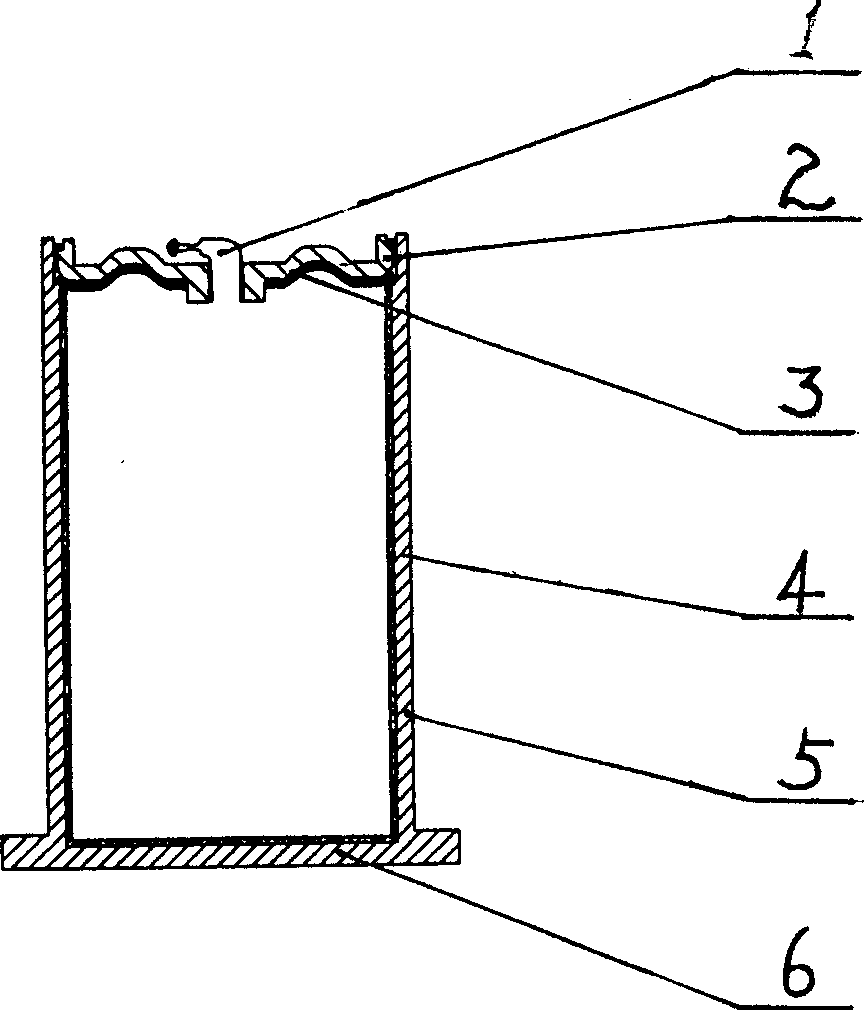

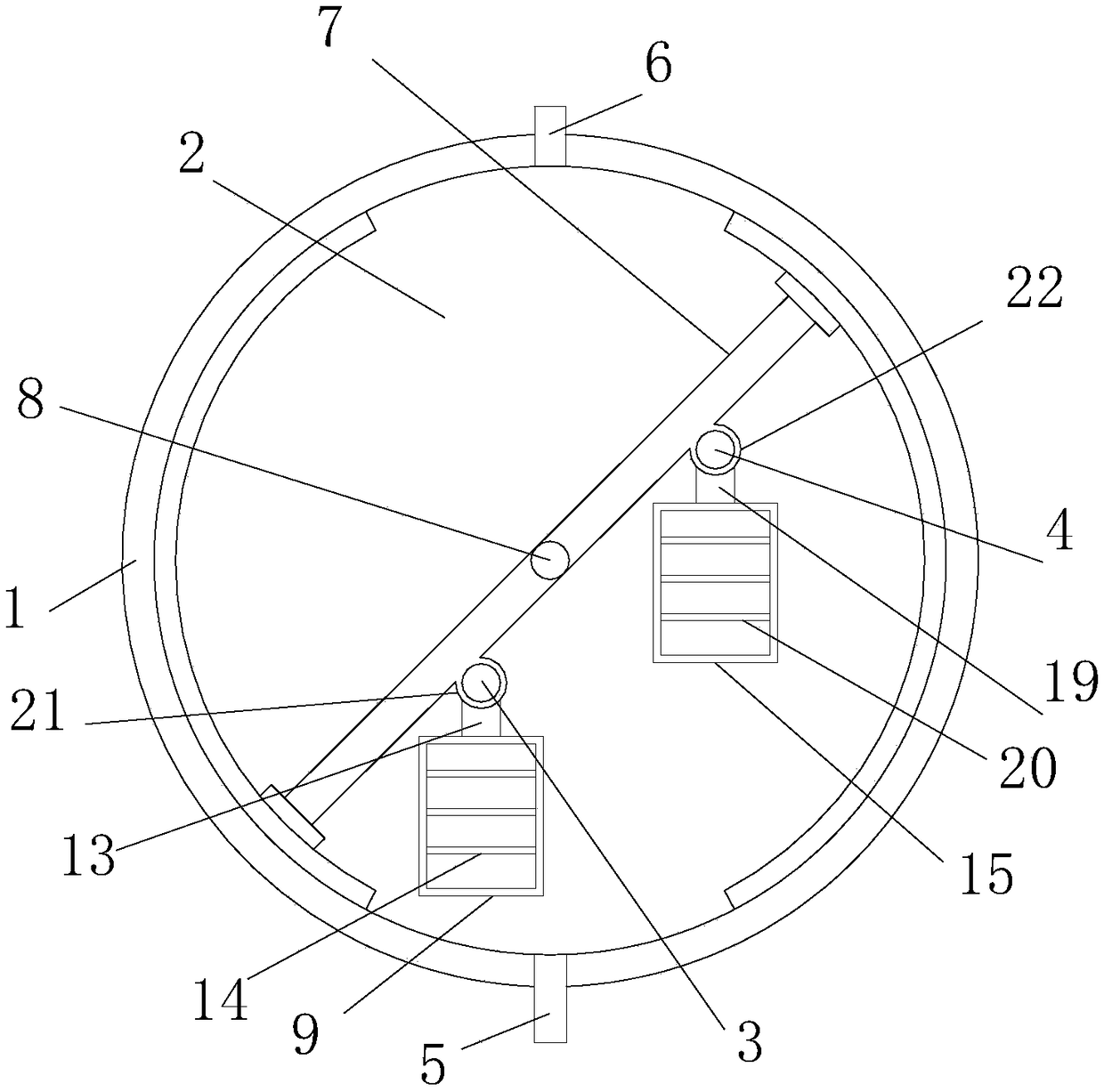

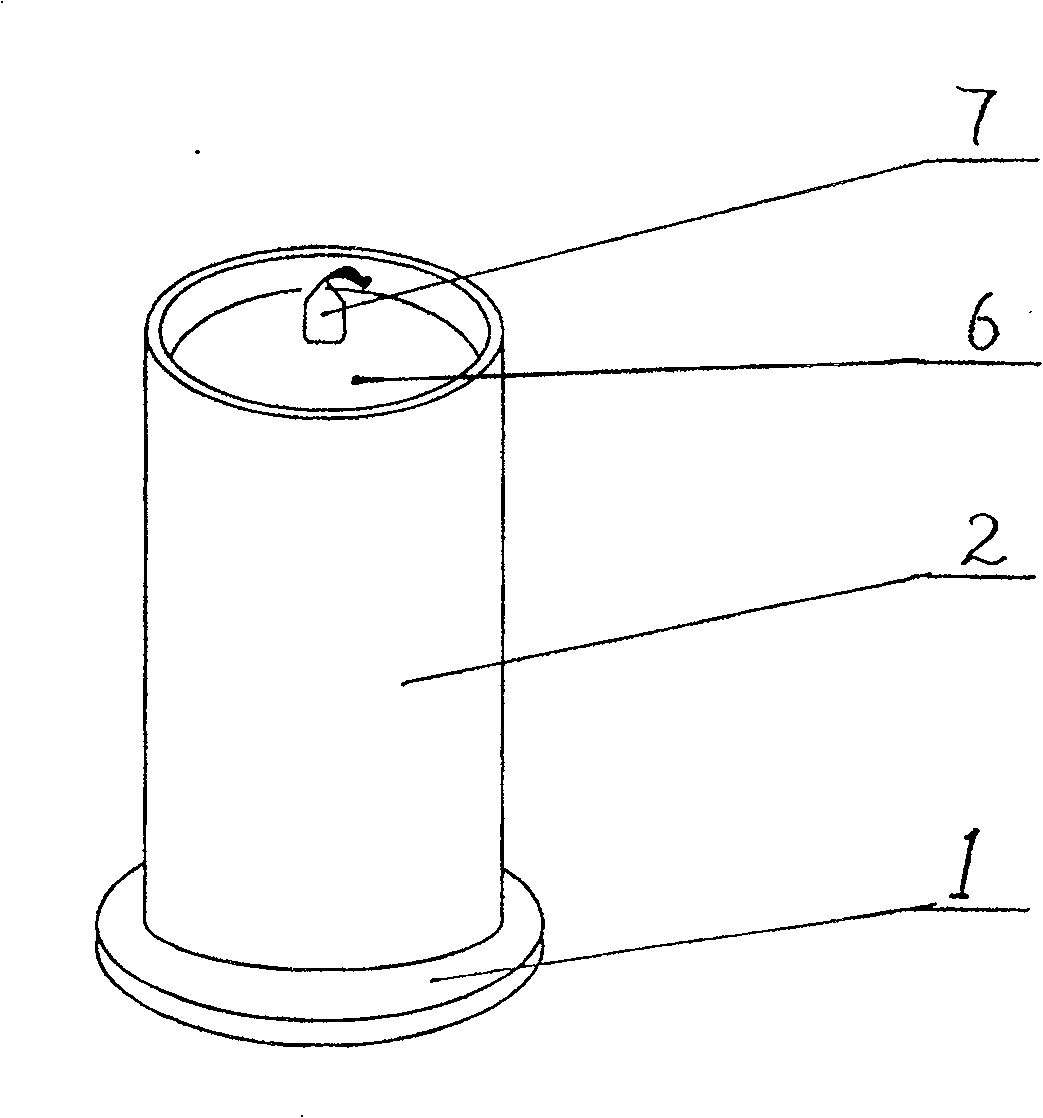

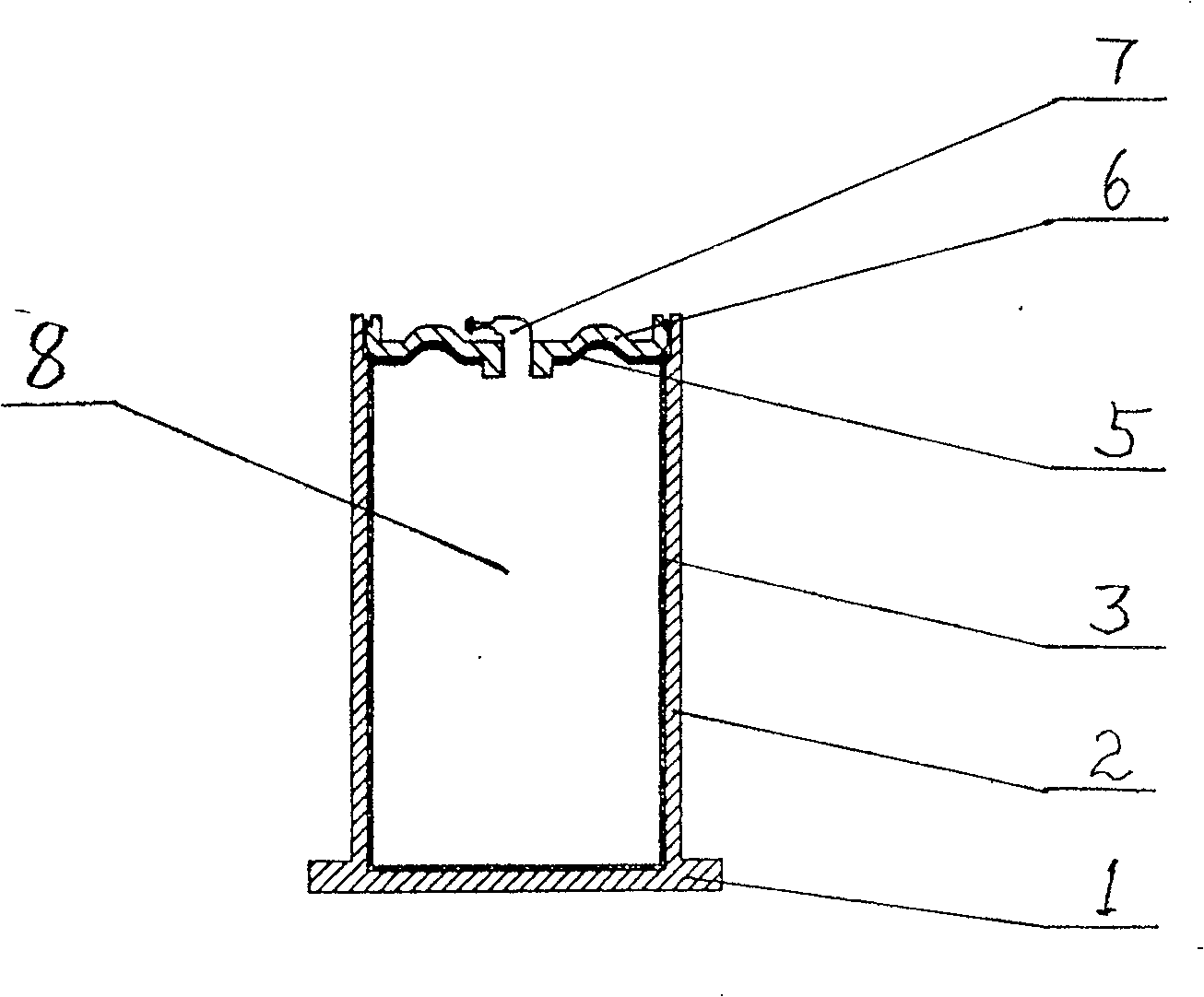

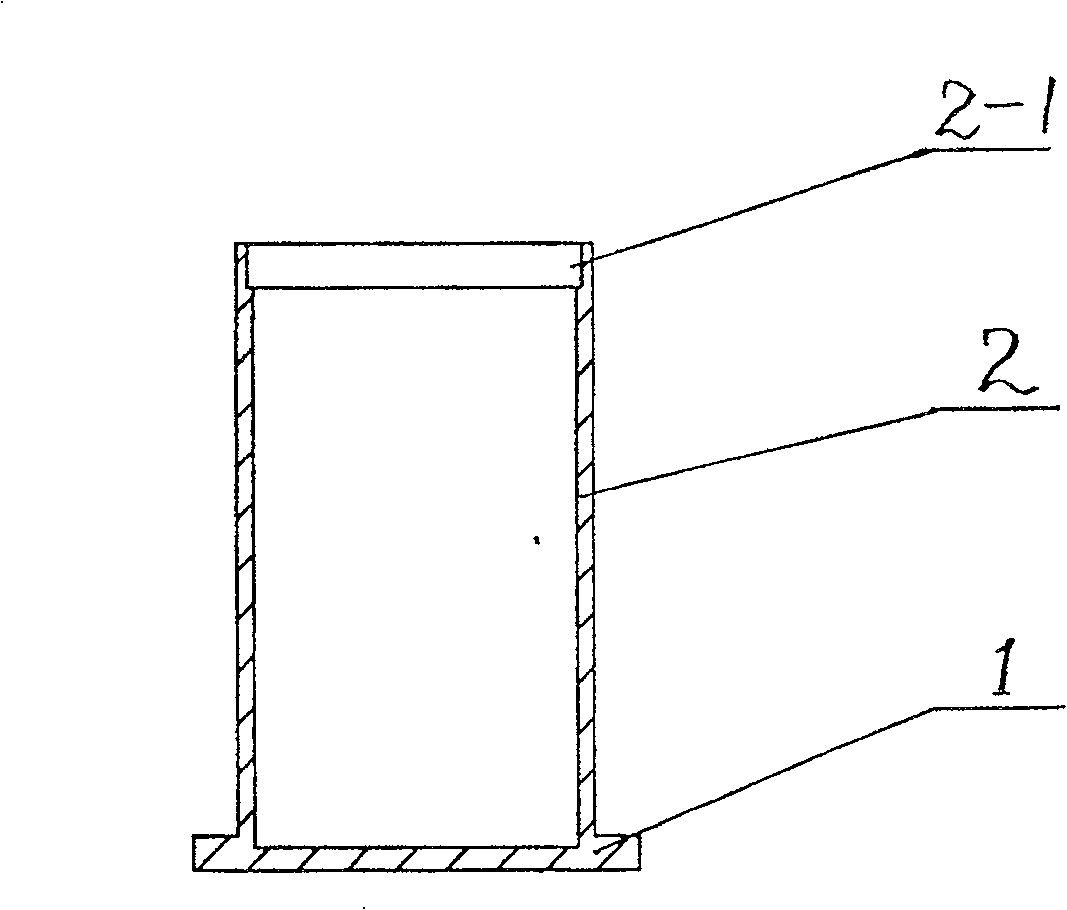

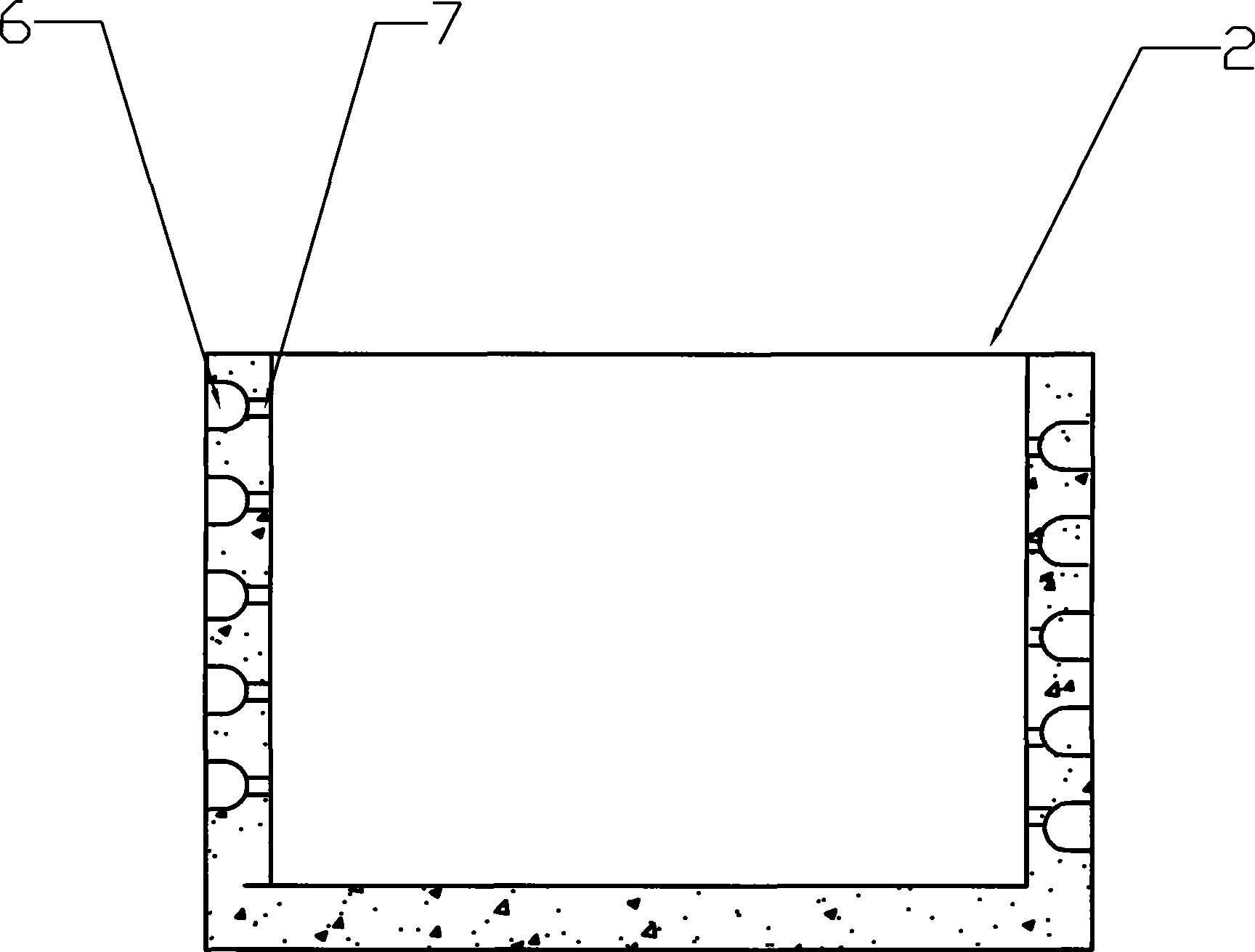

The invention relates to a refrigerated cabinet, and belongs to the technical field of refrigerating machinery. The refrigerated cabinet comprises a cylindrical cylinder, a cylinder cover which covers and matches on an opening part of the upper part of the cylinder, a water accumulating tray positioned on the bottom of a liner of the cylinder, and a refrigeration system which is arranged on a cylinder base on the bottom of the cylinder and consists of a compressor, a condenser and an evaporator, wherein the evaporator is arranged in an insulating layer between the liner and the wall body of the cylinder, and is attached to the outer wall of the liner; a cold accumulating tank base is formed along the peripheral direction on the upper part of the liner, and is provided with a group of coldaccumulating tanks; and cold accumulating liquid is filled in the cold accumulating tanks. The refrigerated cabinet has the advantages of having ideal energy-saving effect, contributing to improving the refrigeration speed while showing energy saving, effectively separating refrigerated products to provide convenience for taking the refrigerated products, and preventing the refrigerated products from blocking a bossing of a reflux mechanism.

Owner:JIANGSU BAIXUE ELECTRIC APPLIANCES

Refrigerated cabinet

InactiveCN101532763AUniform temperature up and downAvoid blockingLighting and heating apparatusDomestic refrigeratorsRefluxEngineering

The invention relates to a refrigerated cabinet, and belongs to the technical field of refrigerating machinery. The refrigerated cabinet comprises a cylindrical cylinder, a cylinder cover which covers and matches on an opening part of the upper part of the cylinder, a water accumulating tray positioned on the bottom of a liner of the cylinder, and a refrigeration system which is arranged on a cylinder base on the bottom of the cylinder and consists of a compressor, a condenser and an evaporator, wherein the evaporator is arranged in an insulating layer between the liner and the wall body of the cylinder, and is attached to the outer wall of the liner; a cold accumulating tank base is formed along the peripheral direction on the upper part of the liner, and is provided with a group of cold accumulating tanks; and cold accumulating liquid is filled in the cold accumulating tanks. The refrigerated cabinet has the advantages of having ideal energy-saving effect, contributing to improving the refrigeration speed while showing energy saving, effectively separating refrigerated products to provide convenience for taking the refrigerated products, and preventing the refrigerated products from blocking a bossing of a reflux mechanism.

Owner:JIANGSU BAIXUE ELECTRIC APPLIANCES

Top-blown heat pipe radiator and its manufacturing method

InactiveCN1744806AReduce the temperature difference between upper and lowerImprove cooling efficiencyDigital data processing detailsSemiconductor/solid-state device detailsEvaporationEngineering

The radiator includes heat pipe, basal body of thermal fin, and fan. There are through holes inside basal body of thermal fin, and heat pipes are setup in through holes. Inner diameter of through hole is close fitted to external diameter of heat pipe. Multiple radial thermal fins are setup around. Being setup on top of basal body of thermal fin, fan is in use for forcing air to pass through radial thermal fins from upper to lower. Being in mode of evaporation condensed phase change, heat pipe conducts heat, providing features of quick conduction rate, large heat transfer power. Multiple radial thermal fins possess large area of dissipation. Forced air driven by fan passes through radial thermal fins in small wind resistance. Features of the invention are: large heat sinking capability, small thermal resistance, and lightweight.

Owner:嘉善华昇电子热传科技有限公司

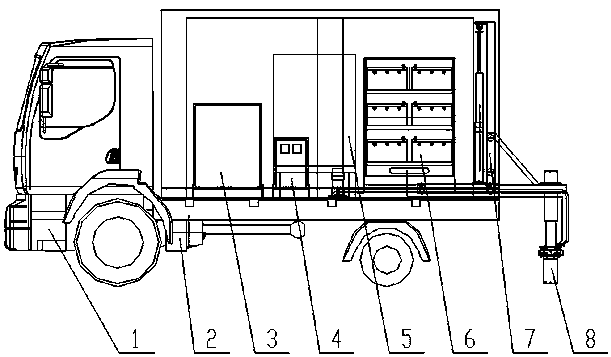

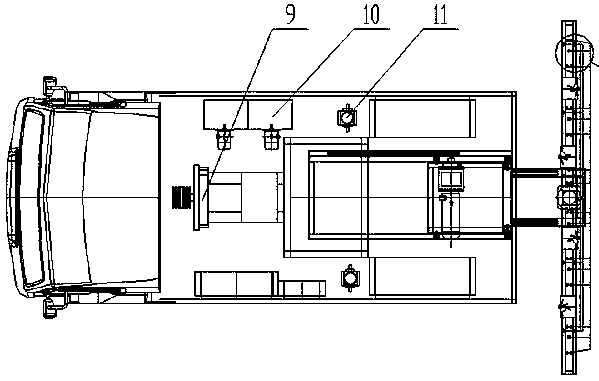

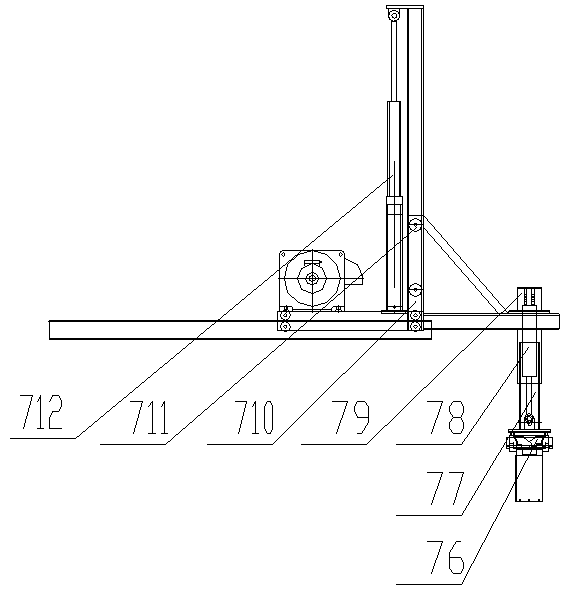

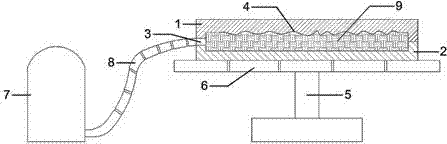

Microwave caulking maintenance vehicle for asphalt pavement repairing

PendingCN110241699AImprove viscous flowIncreased diffusion rateRoads maintainenceMicrowaveRoad surface

The invention relates to a microwave caulking maintenance vehicle for asphalt pavement repairing. The microwave caulking maintenance vehicle comprises a microwave caulking device, an adjusting mechanism and an accessory chain slot milling machine; the microwave caulking device comprises a microwave heater and a power supply; the adjusting mechanism is used for adjusting positions of the microwave heater in the X-axis direction, the Y-axis direction and the Z-axis direction of the microwave maintenance vehicle; and the chain slot milling machine drives a cutting tool bit through a rotating chain to thermally cut an asphalt heating area, and the cutting depth is adjusted by adjusting a lifting oil cylinder, wherein the cutting tool bit is mounted on the chain slot milling machine. Through a microwave heating technique, the speed of viscous flowing and molecule diffusion of asphalt and an asphalt regenerating agent in asphalt concrete can be increased, compared with infrared heating, the advantages that the heating depth is large, and the temperatures of the upper part and the lower part of a material layer are uniform are achieved better, and the microwave caulking maintenance vehicle is particularly suitable for treating reflection cracks from the lower layer of the pavement; and the pavement microwave caulking vehicle sufficiently utilizes unique advantages of microwave heating in the aspect of engineering maintenance, the asphalt pavement cracks are repaired really from inside to outside, and the service life of the pavement is prolonged.

Owner:JIANGSU AOXIN SCI & TECH

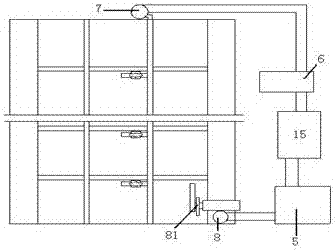

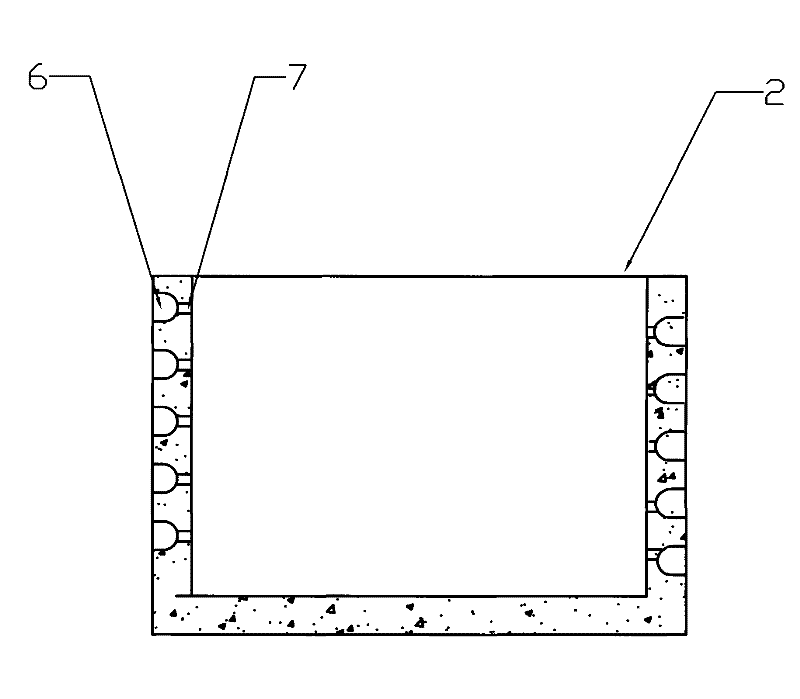

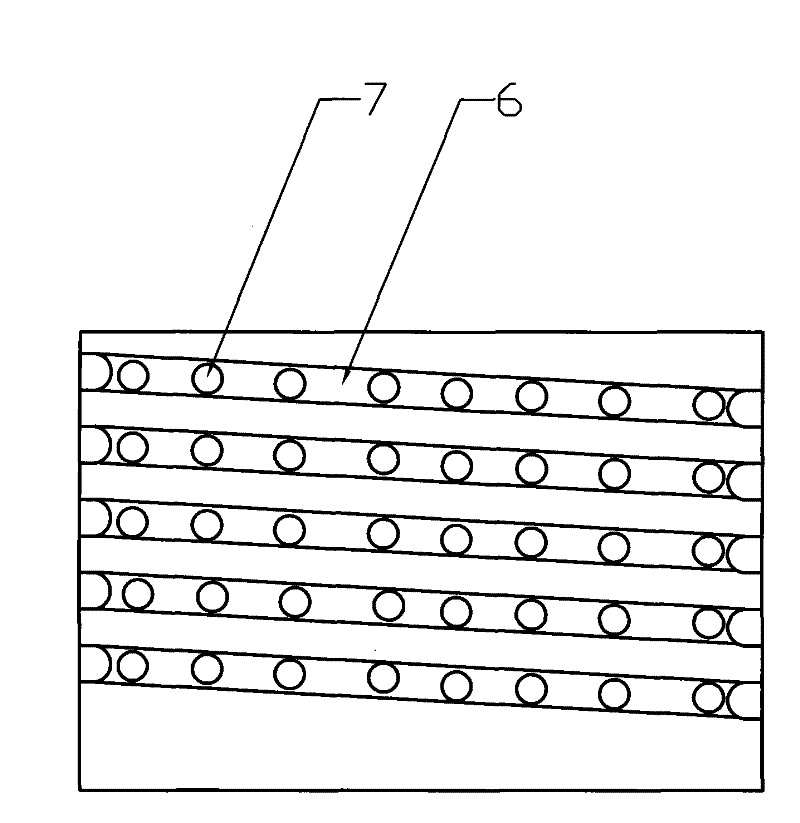

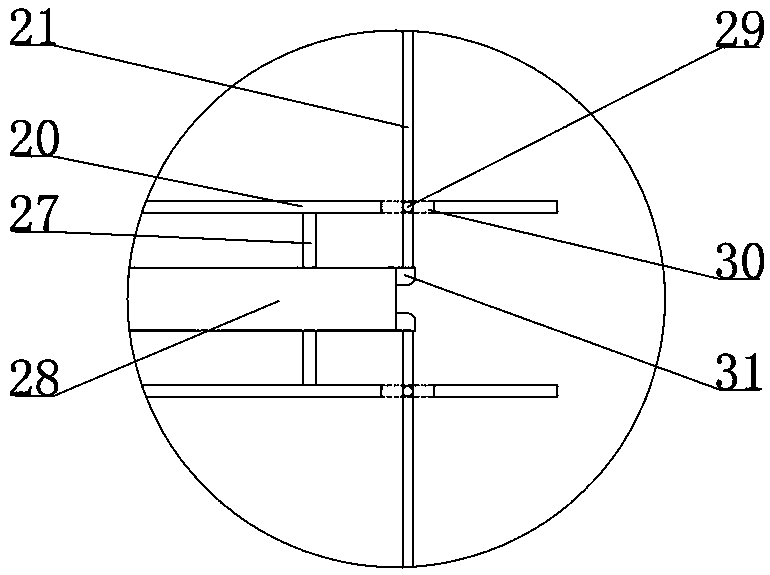

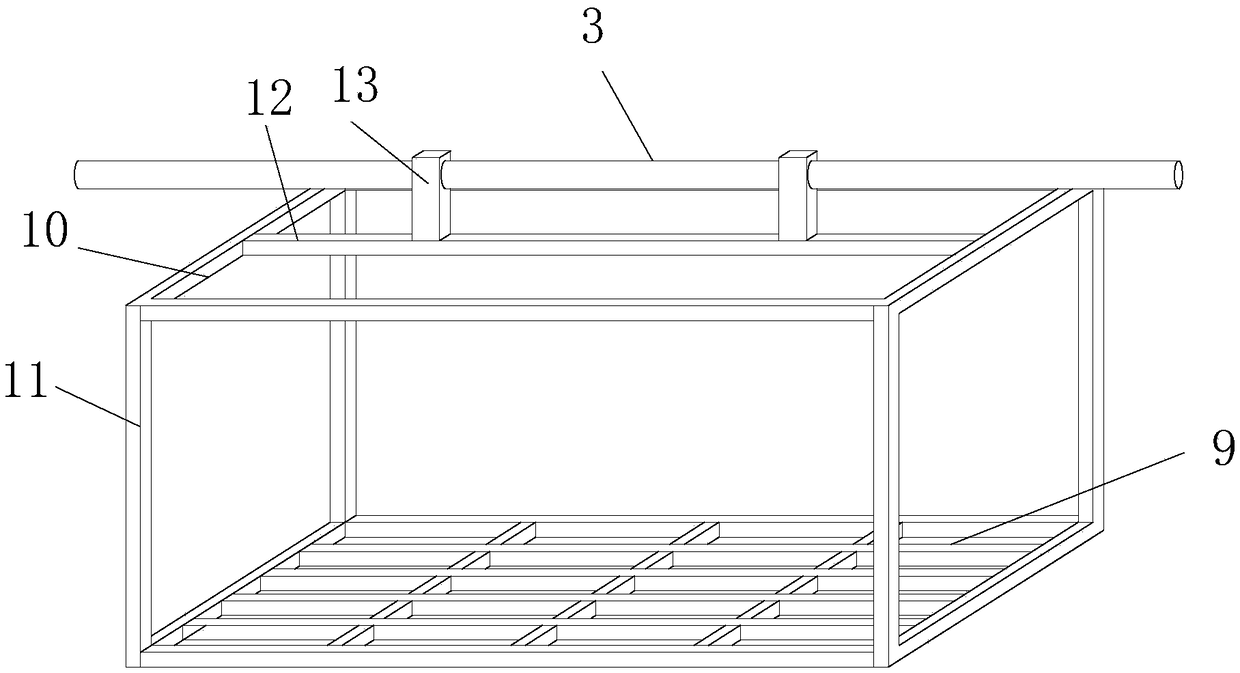

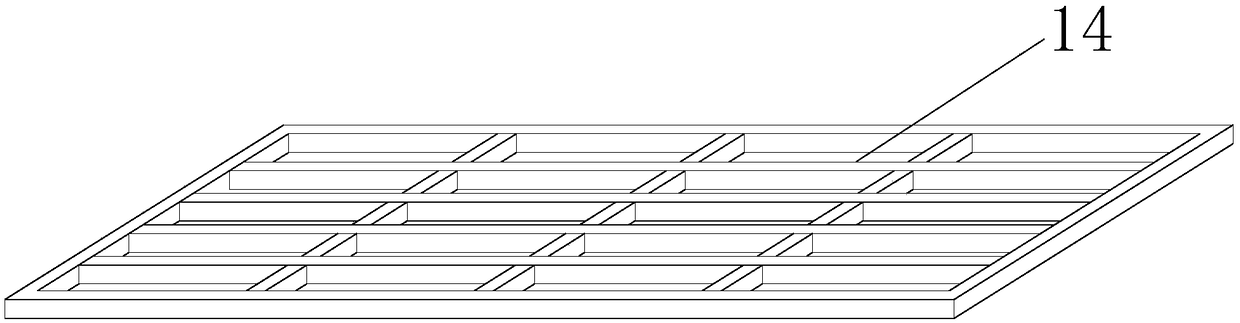

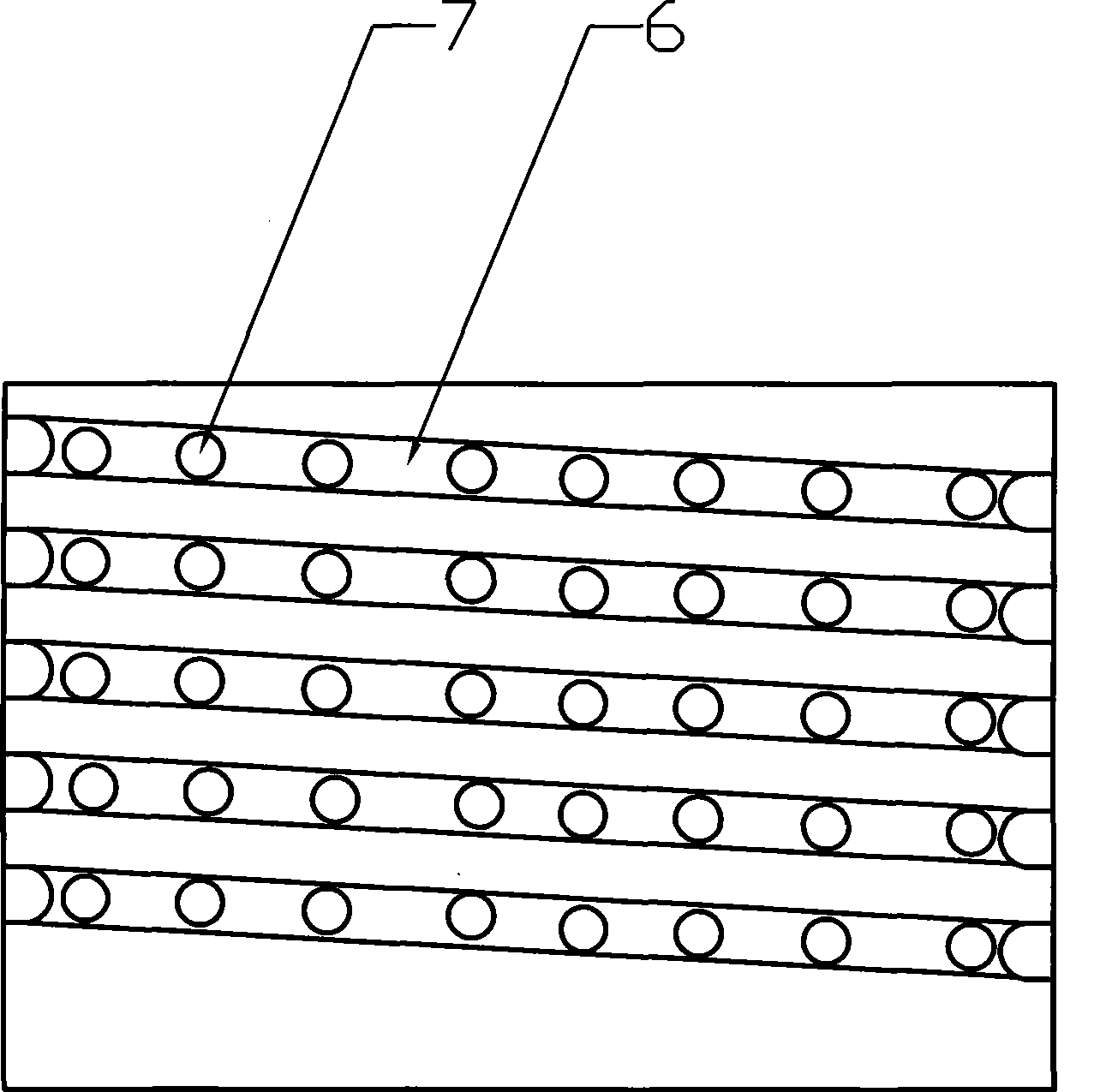

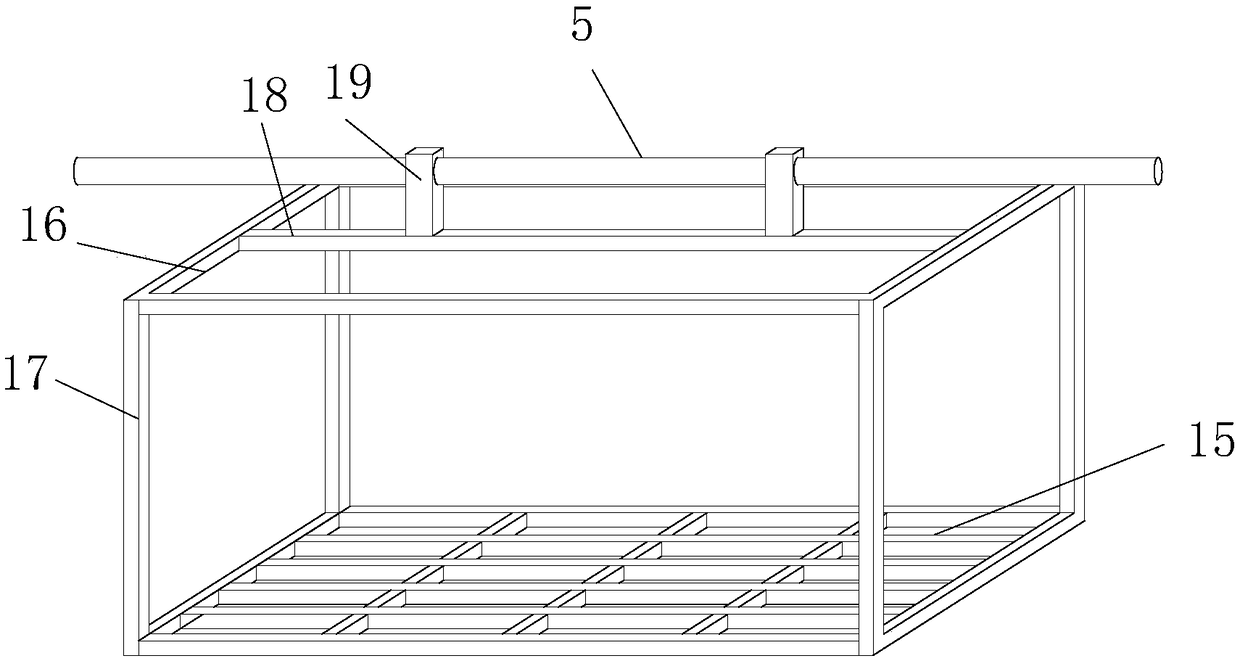

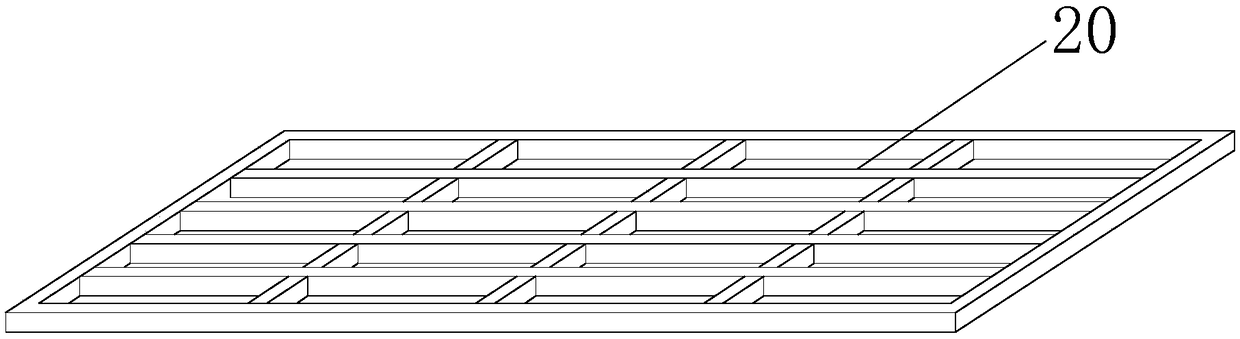

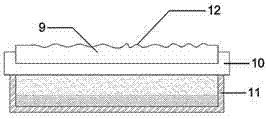

Energy-saving, stereo, multi-layer and intelligent plant factory

ActiveCN107197714AUniform temperature up and downReduce running timeDispersed particle filtrationClimate change adaptationPlant factoryPlant cell

The invention discloses an energy-saving, stereo, multi-layer and intelligent plant factory which comprises a workshop, a planting bed and a temperature rising, sterilization, disinfection and automatic lifting light supplementing device. Four layers of solar panels are used at the top of the workshop, a heat preservation curtain is laid on the solar panels, the solar panel thickness is 10 mm, the temperature rising curtain is black and absorbs light, a temperature rising chamber is formed between the solar panels and the temperature rising curtain, holes are formed in the temperature rising curtain, and the temperature rising curtain corresponds to a circulation fan in size and position. Multiple layers of planting grooves and an automatic nutrient solution circulating system are arranged on a planting bed main frame, galvanized steel pipes are arranged below each layer of planting grooves, upper and lower layers of parallel galvanized steel pipes are connected through one longitudinal water feeding pipe and one longitudinal water return pipe, and vertical indoor-temperature balance is achieved through same-way circulation. Planting cell plates are arranged above easy layer, automatic light supplementing lamp adjusting and lifting frames are installed on the planting cell plates, and light supplementing lamp tubes are installed at the bottoms of the lifting frames. The plant factory is small in earlier stage investment, low in operation cost and low in energy consumption.

Owner:南宫市新创现代农业开发有限公司

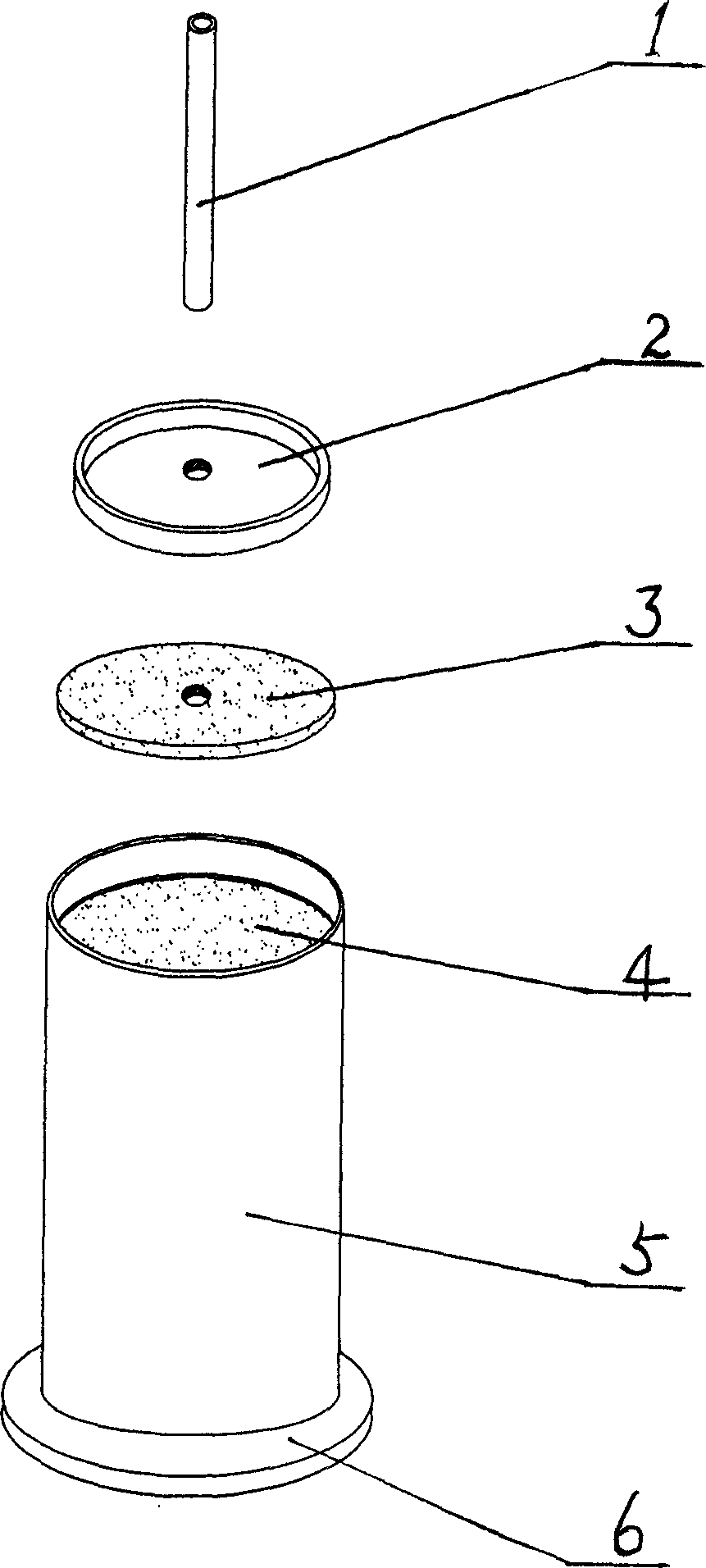

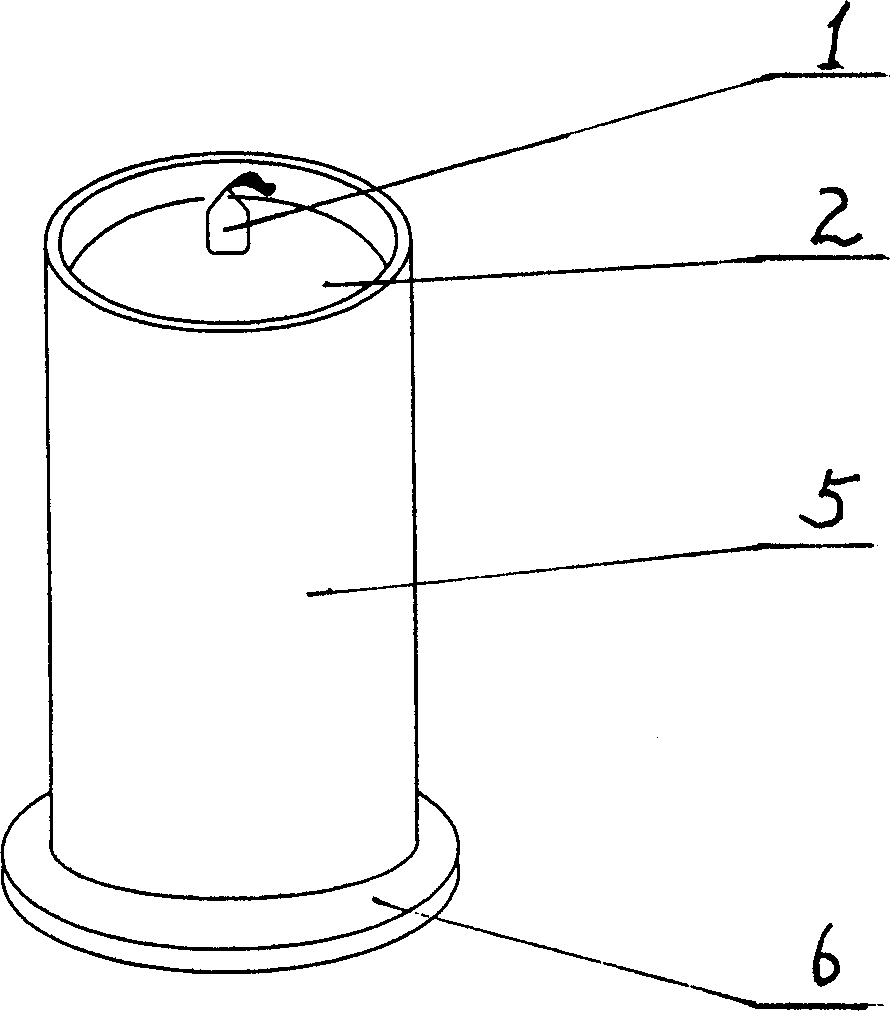

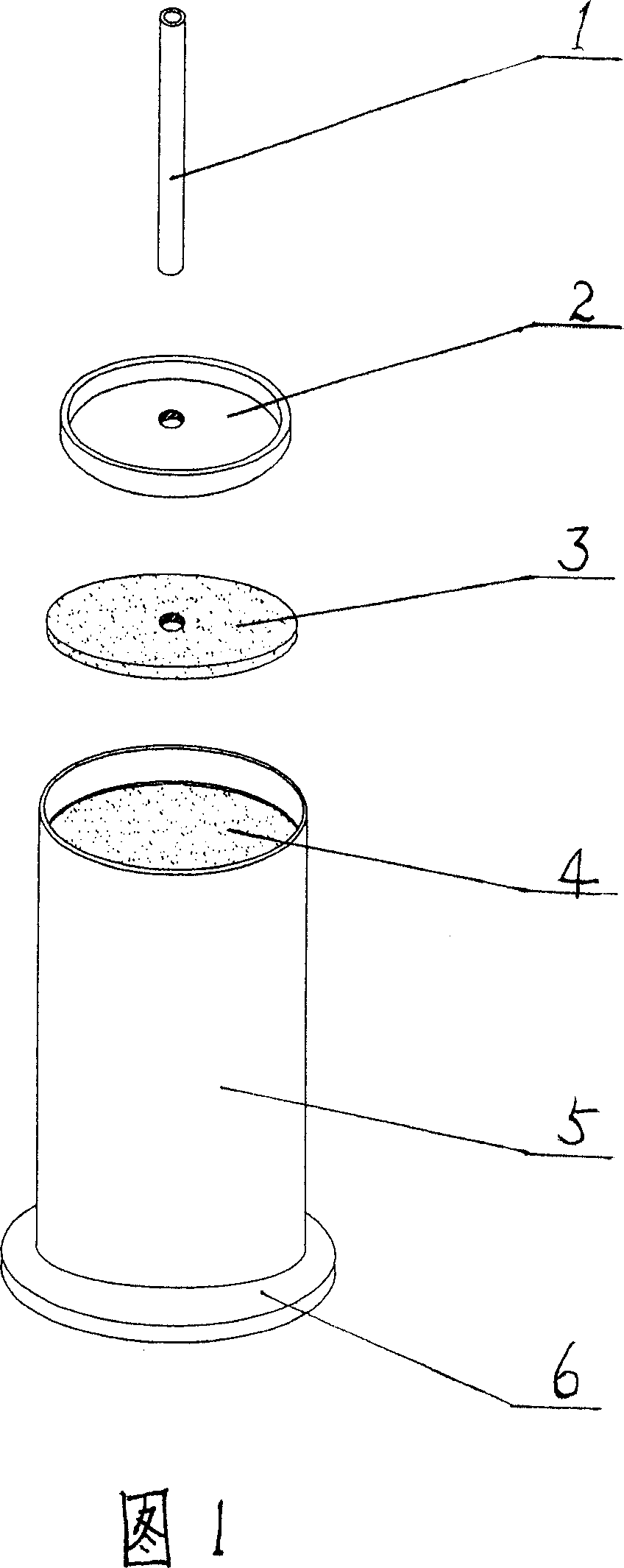

Cylindrical heat pipe

InactiveCN1731065ASmall fluctuationUniform temperature up and downIndirect heat exchangersWorking fluidEvaporation

The columnar heat pipe has sealed vacuum cavity comprising gas exhaust pipe, top cover, tube and bottom board; and has bottom board below the tube, step in the upper end of the tube, capillary cover mounted in the step, top cover on the capillary cover, sealed gas exhaust pipe on the top cover, sintered porous capillary layer in the inner wall of the tube and the inner surface of the bottom board to form work liquid circulating passage together with the capillary cover and work liquid adsorbed to the sintered layer and the capillary cover. The present invention has the beneficial effects caused by the phase change heat transfer of the evaporation and condesation of work fluid inside the columnar heat pipe, including fast heat transfer rate, great heat transfer capacity, homogeneous temperature, high stability, etc.

Owner:嘉善华昇电子热传科技有限公司

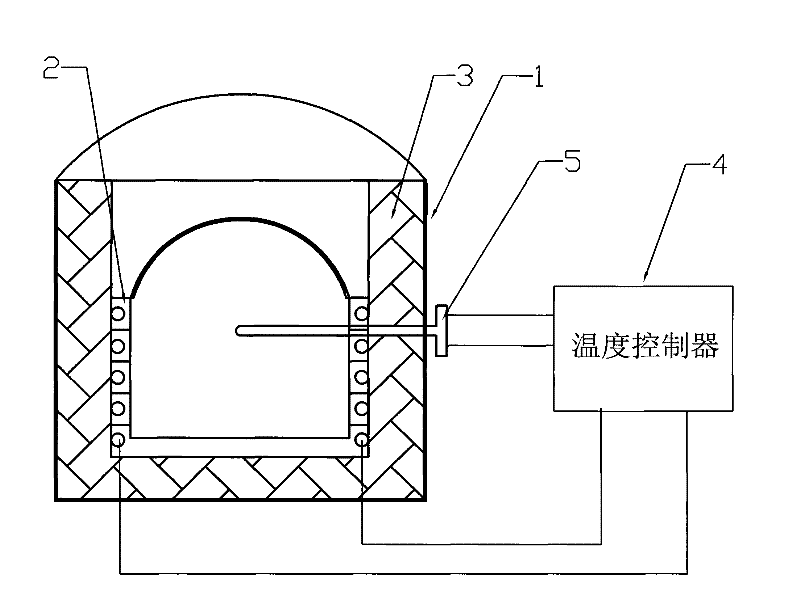

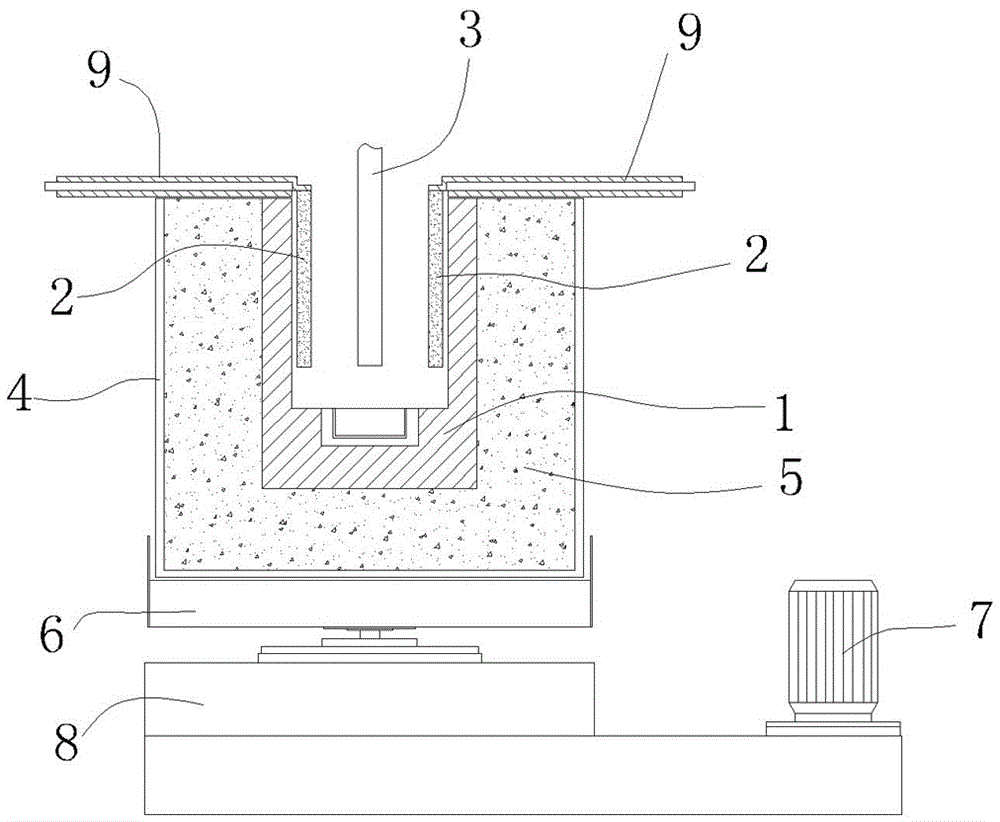

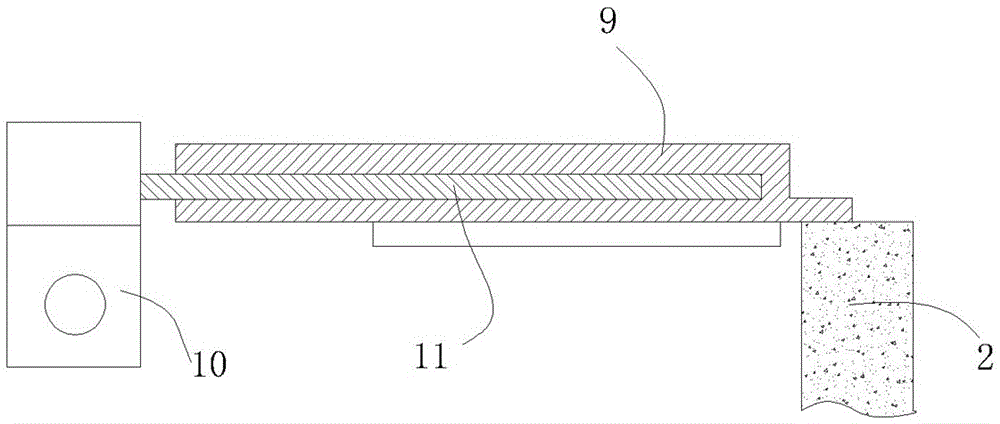

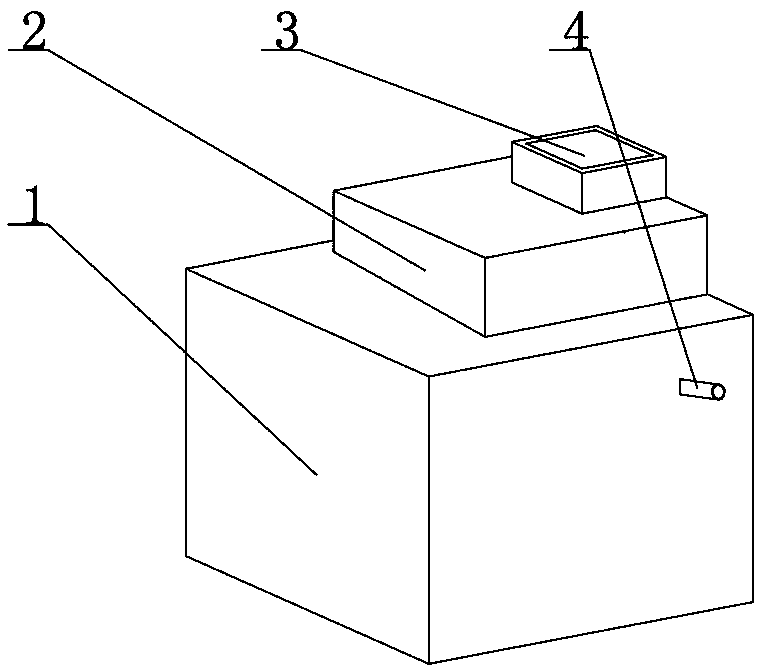

Aluminizing furnace

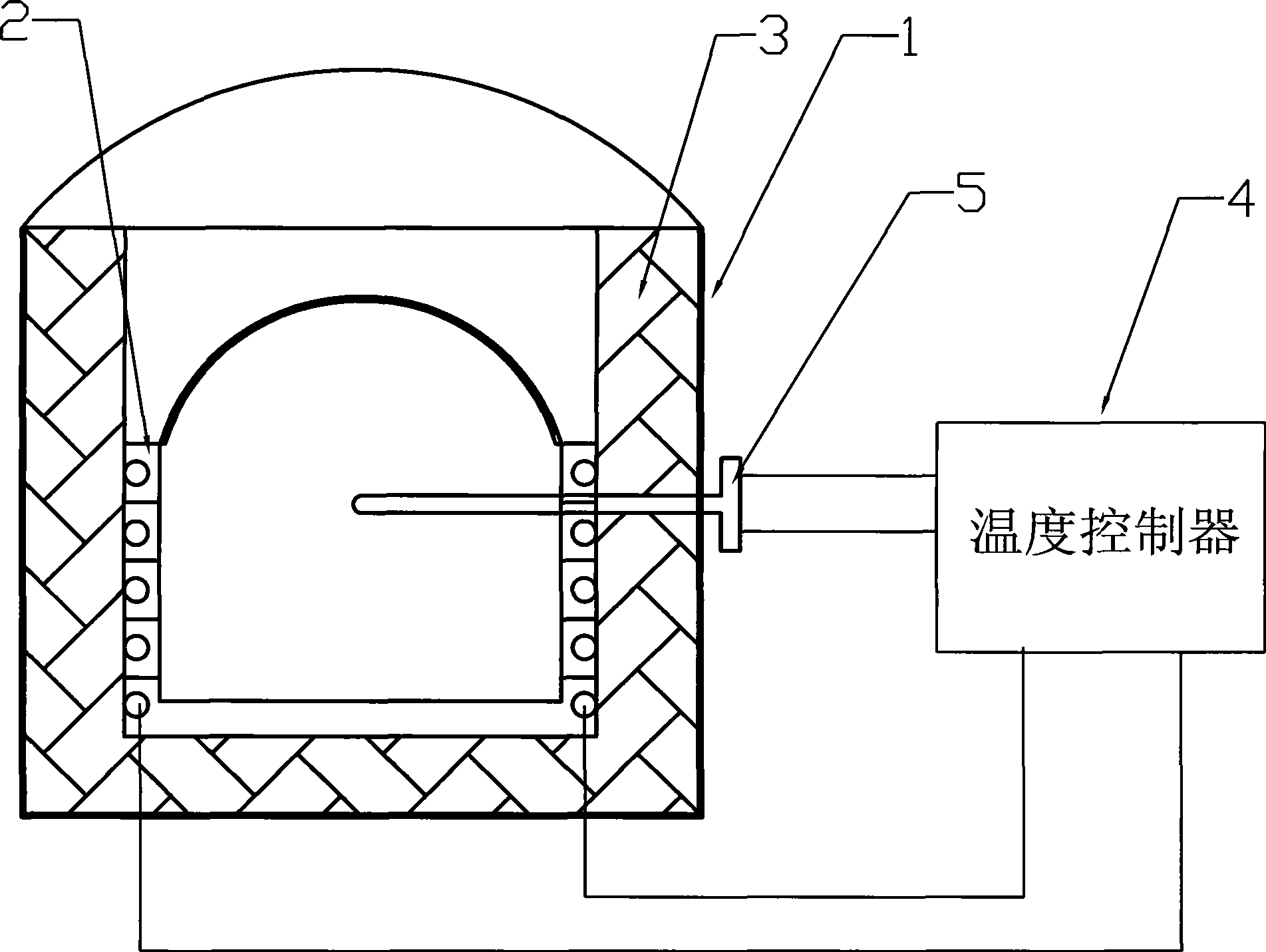

InactiveCN101463459BUniform temperature up and downStrong self-controlSolid state diffusion coatingAutomatic controlElectric arc furnace

The invention relates to an electric furnace, in particular to an alumetized furnace which is specially used for iron pan alumetized compound bottom. In order to solve the technical problems, the invention adopts the technical proposal that the alumetized furnace is specially used for iron pan alumetized compound bottom, and is characterized by comprising an external body, an electric furnace flue arranged inside the external body, an electric furnace wire groove positioned on the outer wall of the electric furnace flue, electric furnace wires wound inside the electric furnace wire groove, a plurality of heat transferring holes which are evenly distributed in the electric furnace wire groove, and a temperature controller connected with connectors of the electric furnace wires by electric wires. The alumetized furnace has the advantages of high temperature resistance, uniform temperature between the top and bottom of the flue, strong automatic control and humanized operation.

Owner:王新田

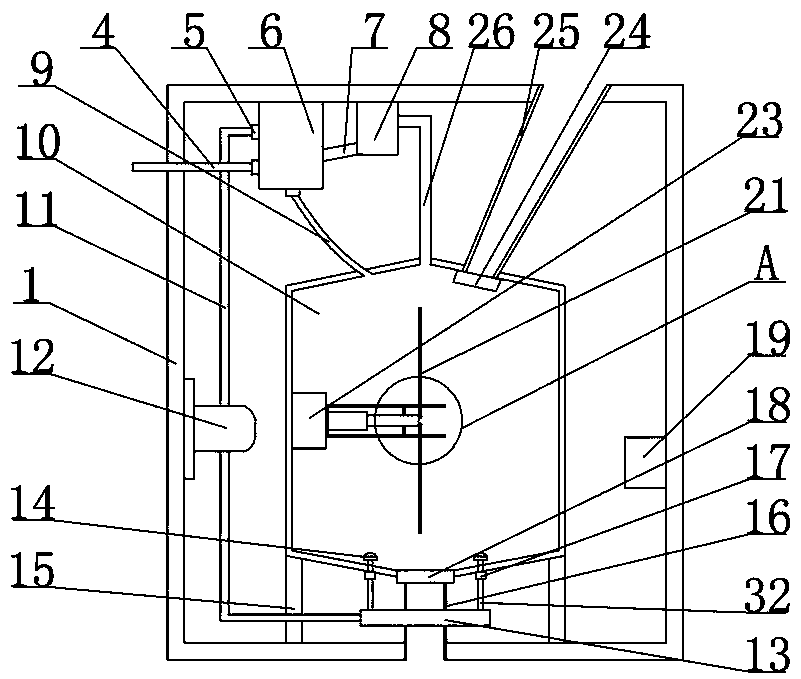

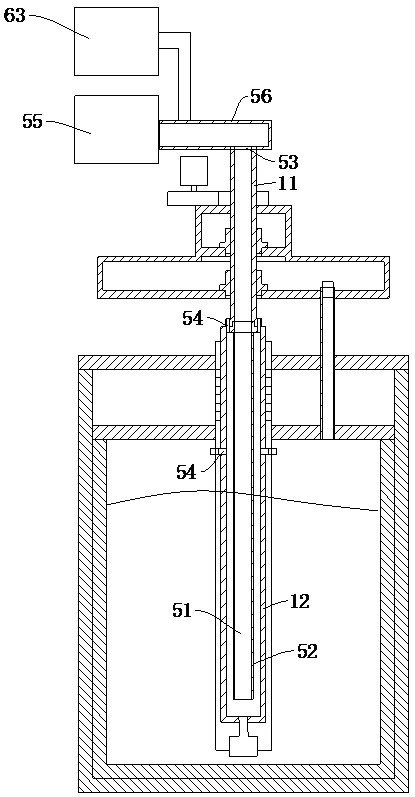

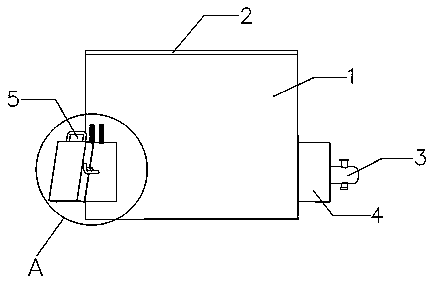

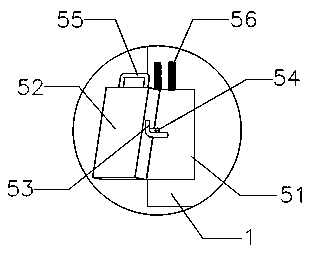

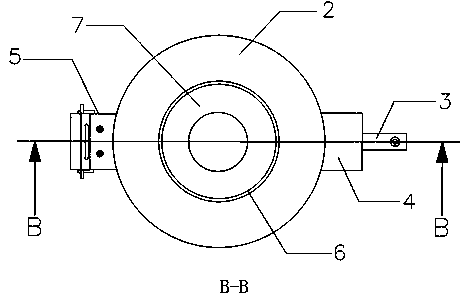

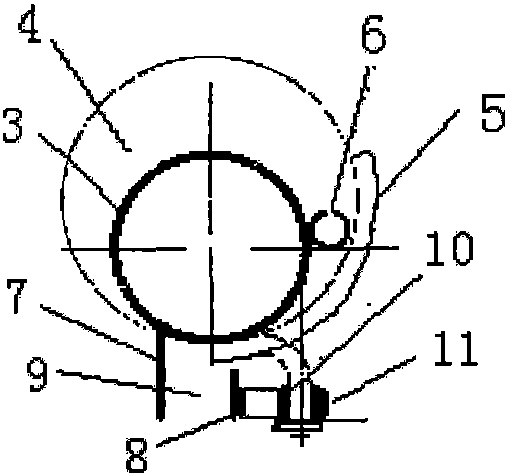

Electrolytic production device for rare earth alloy

InactiveCN105951128AReduce abnormal production lossExtended service lifeElectrodesThermal insulationSlag

The invention discloses an electrolytic production device for a rare earth alloy. The electrolytic production device comprises a graphite electrolytic bath, graphite anodes stretching into the graphite electrolytic bath, and a cathode stretching into the graphite electrolytic bath, and further comprises a protective jacket and a rotating driving mechanism, wherein a thermal insulation layer is arranged between the protective jacket and the graphite electrolytic bath; and the rotating driving mechanism is in transmission connection with the graphite electrolytic bath, so that the rotating driving mechanism can drive the graphite electrolytic bath to rotate. According to the electrolytic production device, during the electrolytic process, the rotating driving mechanism drives the graphite electrolytic bath to rotate, an electrolyte in the graphite electrolytic bath is dynamic, carbide slag is not liable to generate on the back surfaces of the graphite anodes, the direct voltage and current transmission of the graphite anodes to the graphite electrolytic bath is obstructed, the reactive current consumption is reduced, and the purpose of energy consumption is achieved; and the direct voltage and current transmission of the graphite anodes to the graphite electrolytic bath is obstructed, so that the service life of the graphite electrolytic bath is further prolonged.

Owner:NINGBO FUNENG NEW MATERIAL

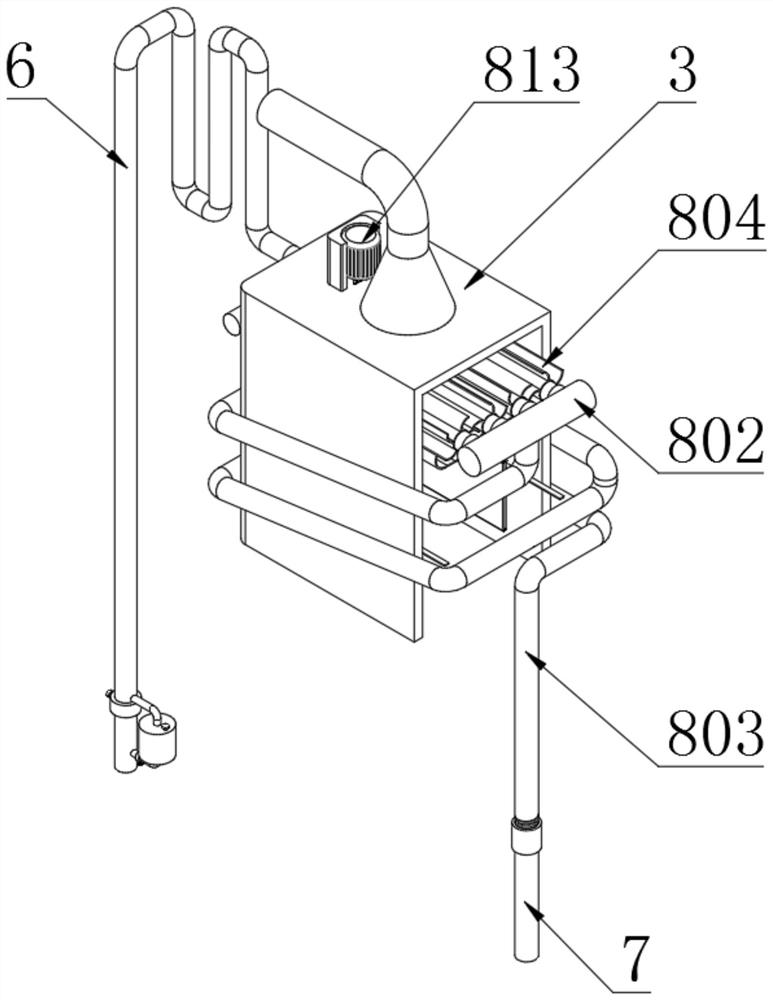

Rose essential oil extraction device

PendingCN110846135AAccelerate evaporationEvenly heatedEssential-oils/perfumesThermodynamicsEngineering

The invention discloses a rose essential oil extraction device. The rose essential oil extraction device comprises a distillation box, wherein a mixing box is arranged at the upper side of the top plate of the distillation box; a distillation kettle is arranged at the middle part of the interior of the distillation box; a motor box is arranged on the inner wall of the side plate of the distillation kettle; a fixed cylinder is arranged on the output shaft of one side, far away from the side plate, of the motor box; a stirring rod is arranged at one side, far away from the motor box, of the fixed cylinder; a sixth guide pipe located at the upper end of the distillation kettle is connected with a condenser; a second guide pipe located at the left side of the condenser is connected with an oil-water separator; a booster pump is connected with and arranged below the oil-water separator through a fourth guide pipe; a fourth guide pipe located below the booster pump is connected with a gas distribution valve; and the upper side of the gas distribution valve is connected with an eighth guide pipe which penetrates through the bottom plate of the distillation kettle and is connected with a spray head. According to the invention, during extraction of rose essential oil, raw materials are put into the mixing box through a feeding inlet and stirred in the mixing box; stirred raw materials enter the distillation kettle through the sixth guide pipe and are heated through a heating unit; steam enters the oil-water separator through the condenser; and gas enters the distillation kettle through the spray head.

Owner:SHANGQIU NORMAL UNIVERSITY

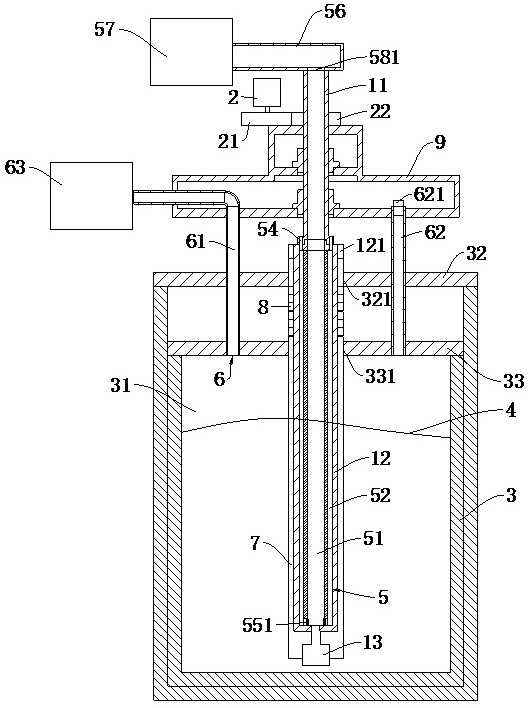

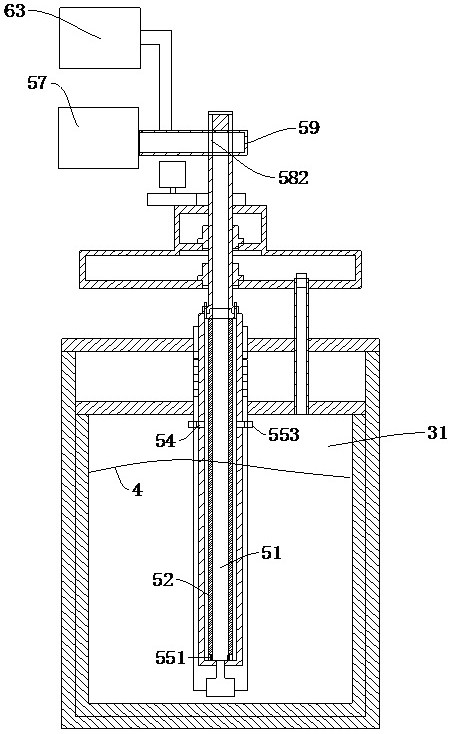

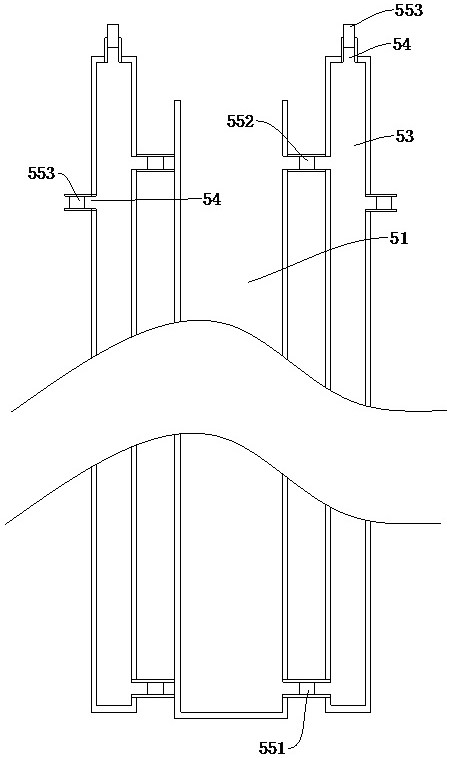

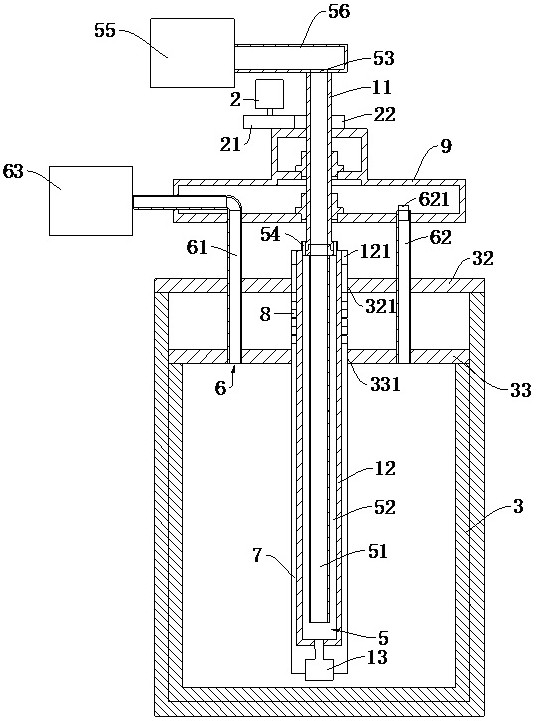

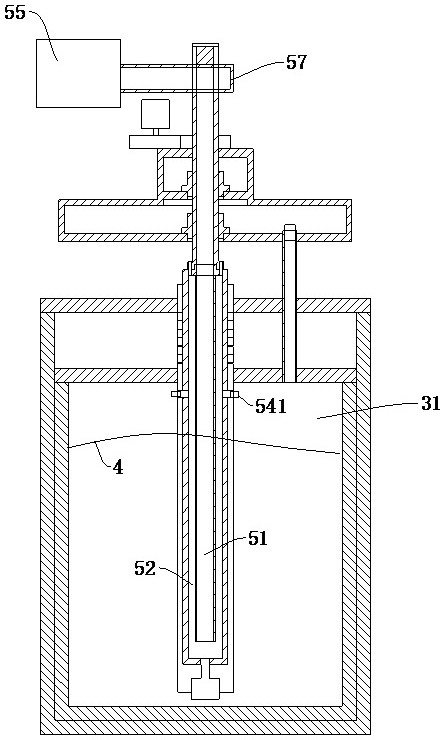

Ultrahigh-purity aluminum crystallization method

ActiveCN113106267AHigh purityAchieve purificationProcess efficiency improvementPhysical chemistryMaterials science

The invention discloses an ultrahigh-purity aluminum crystallization method. The ultrahigh-purity aluminum crystallization method comprises the following steps of: selecting a high-purity aluminum raw material and melting the high-purity aluminum raw material into aluminum liquid in a graphite crucible; inserting a crystallization device into the graphite crucible; driving a graphite pipe sleeve to rotate synchronously by a rotary device; continuously introducing cooling gas into a gas cooling system in the graphite pipe sleeve to start crystallization; keeping a constant rotary speed of a crystallization machine in a crystallization process; adjusting the flowing direction of the cooling gas in a cooling gas path so that the surface of the graphite pipe sleeve, which is in contact with the aluminum liquid, is directionally solidified and an inverted mushroom type high-purity crystal substance with a certain thickness is separated out; when crystallization set time is reached, stopping the crystallization device from rotating and then stopping introducing the cooling gas into a rotary body; lifting the crystallization device out from the graphite crucible and picking off the crystal substance on the graphite pipe sleeve below the crystallization machine to obtain the high-purity crystal substance; and pouring out the residual aluminum liquid in the crucible and putting the high-purity crystal substance into the crucible again to be repeatedly crystallized to obtain the crystal substance with higher purity. By adopting the method disclosed by the invention, the problems in the prior art that the purification cost is high and the purification effect is not good are solved.

Owner:宁波锦越新材料有限公司

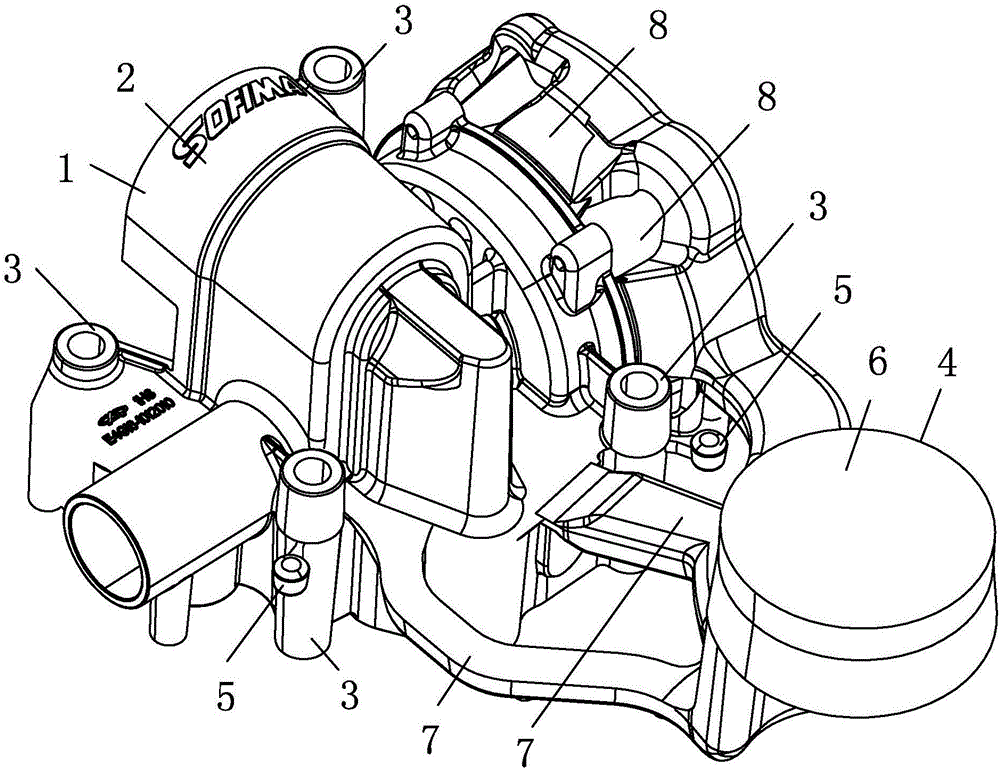

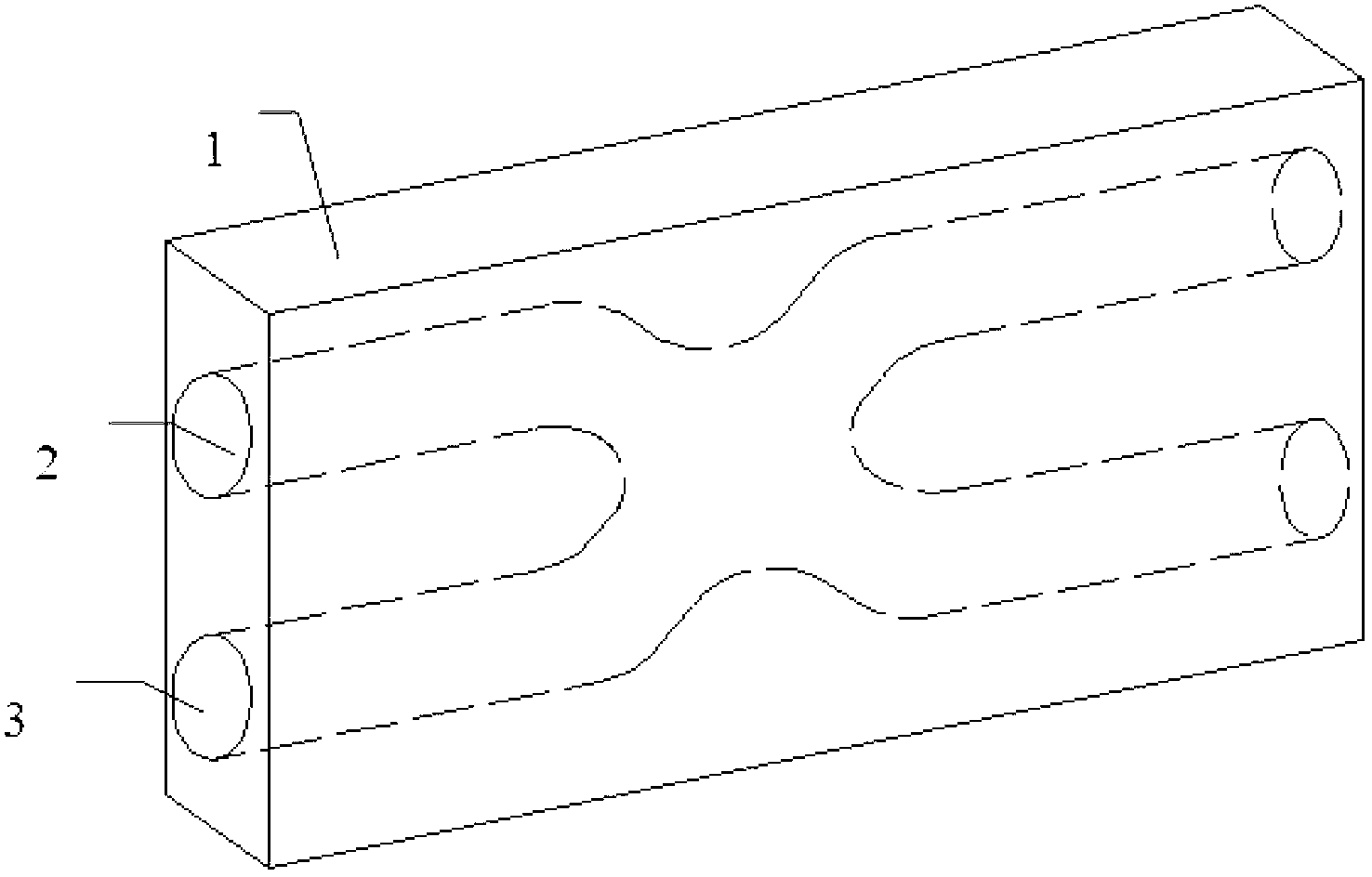

Die-casting method for automobile engine cylinder cover

The invention relates to the casting field and provides a die-casting method for an automobile engine cylinder cover. According to the die-casting method for the automobile engine cylinder cover, the automobile engine cylinder cover is provided with an upper convex cover and four side pipes. A die-casting mould of the automobile engine cylinder cover is provided with a casting system, slag collecting bags and a mold cavity provided with four side pipe cavities and an upper convex cover cavity. The die-casting method comprises the following steps that firstly, the die-casting mould with the mold cavity being evenly sprayed with mould release agents is fixed on a die-casting machine and preheated to the set temperature; secondly, smelted alloy liquid is quantificationally input into a charging chamber of the die-casting machine; and thirdly, a pressure head of the die-casting machine presses the alloy liquid into the mold cavity in an injecting mode for forming through the casting system, and the forming process comprises the initial low-speed press-injecting stage and the high-speed press-injecting stage. According to the die-casting method for the automobile engine cylinder cover, the casting defects of air holes and included slag are not produced in the automobile engine cylinder cover.

Owner:宁波环亚机械制造有限公司

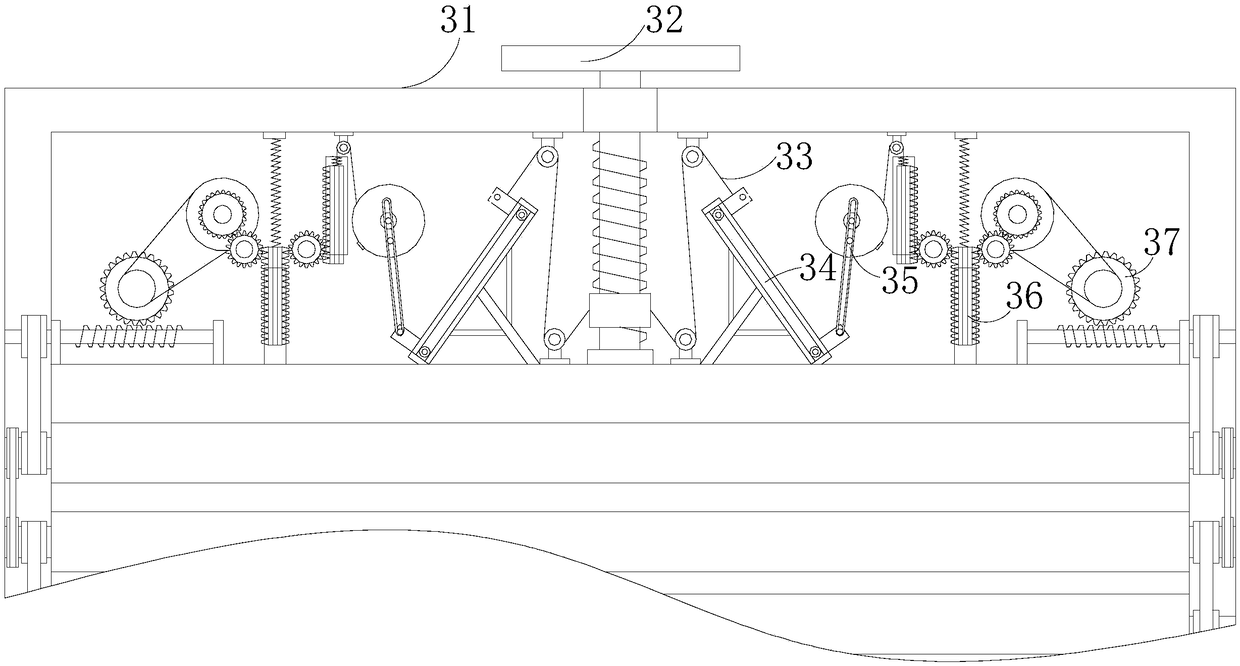

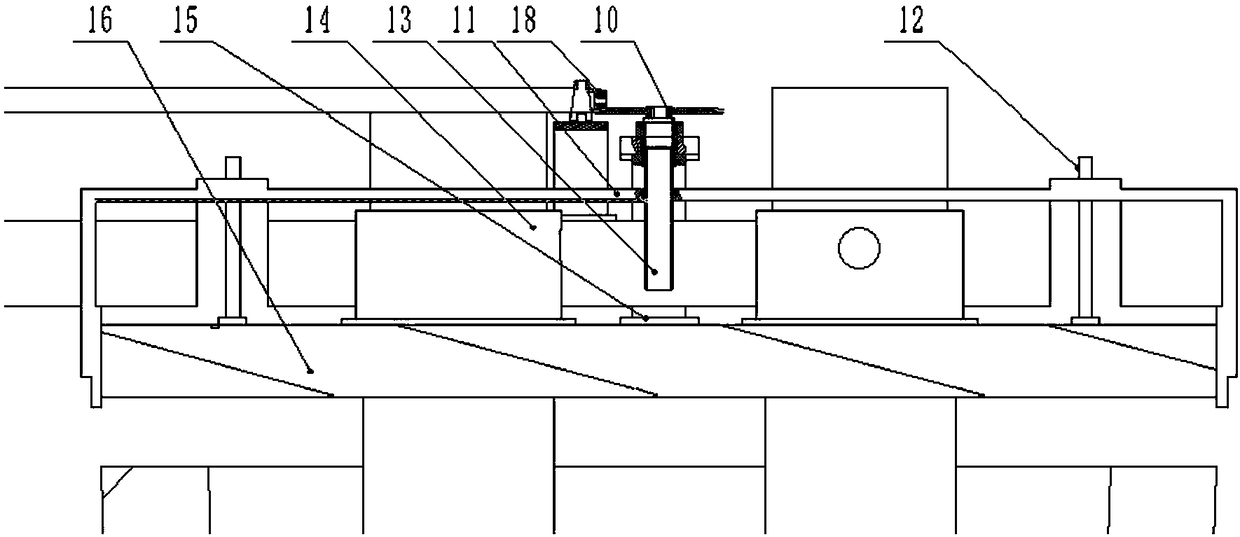

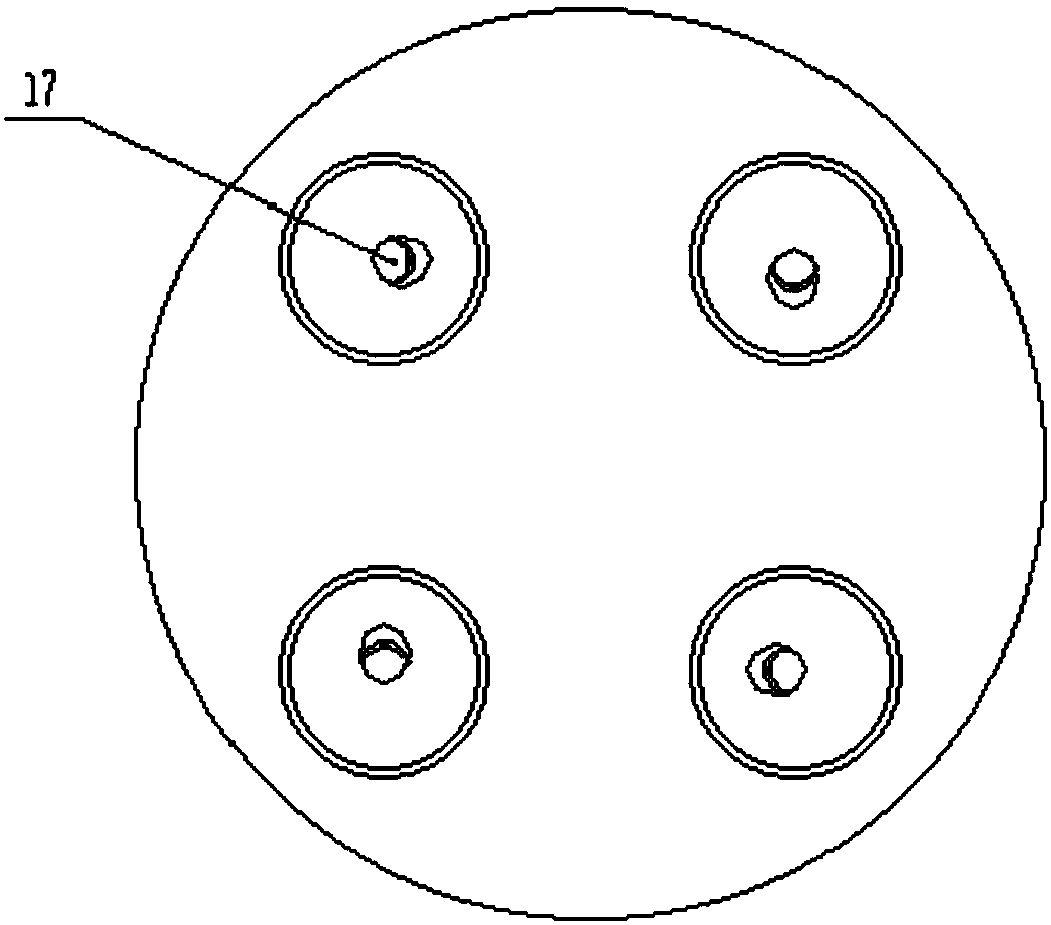

Rotary heating type curing furnace for composite propeller

ActiveCN108724557AQuality assuranceMeet temperature requirementsDomestic articlesRotational axisEngineering

The invention discloses a rotary heating type curing furnace for a composite propeller. A barrel-shaped curing chamber is formed in a furnace body. A plurality of rotating shafts are arranged in the curing chamber at interval along the axial direction of the furnace body, and the two ends of each rotating shaft are connected with the inner wall of the furnace body in a sliding mode. A center shaftis arranged at the center of the curing chamber along the axial direction of the furnace body, and the center shaft passes through the centers of the rotating shafts in order and is fixedly connectedwith the rotating shafts. A first support shaft and a second support shaft are positioned on the two sides of the center shaft and are connected with the rotating shafts, and a first mould rack and asecond mould rack are respectively hinged with the first support shaft and the second support shaft. According to the rotary heating type curing furnace, the rotating shafts are driven by the centershaft to rotate, and the first mould rack and the second mould rack are driven by the rotating shafts to move up and down, so that hot air in the curing chamber can be guided to flow, and the upper and lower temperatures of the curing chamber are uniform. Therefore, the difference of the upper and lower mould temperatures of a mould is within + / -1 or so, the temperature requirement of the composite propeller in the forming process can be met, and the quality of the propeller is ensured.

Owner:安徽劲旋风航空科技有限公司

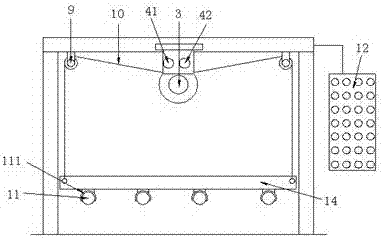

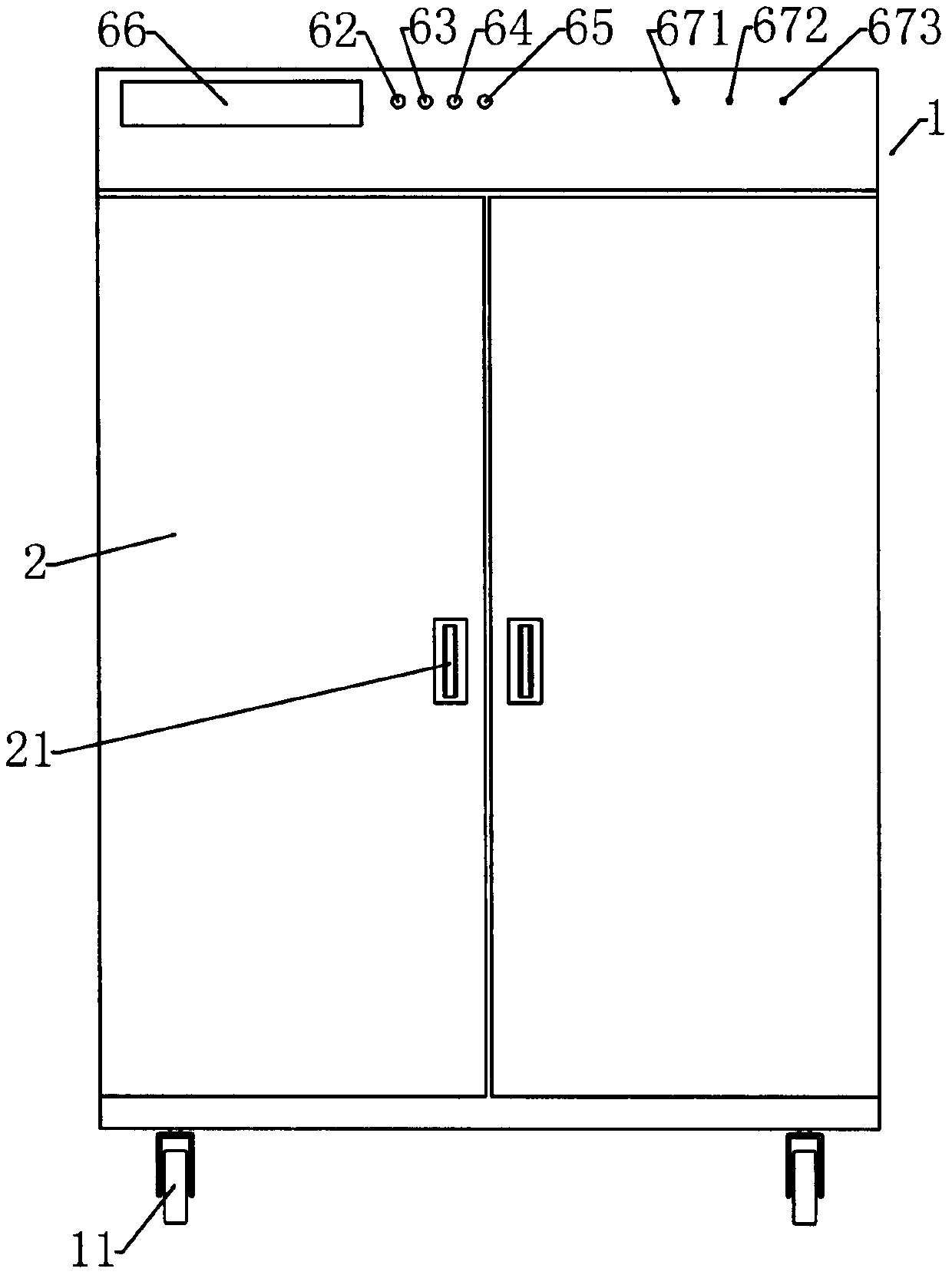

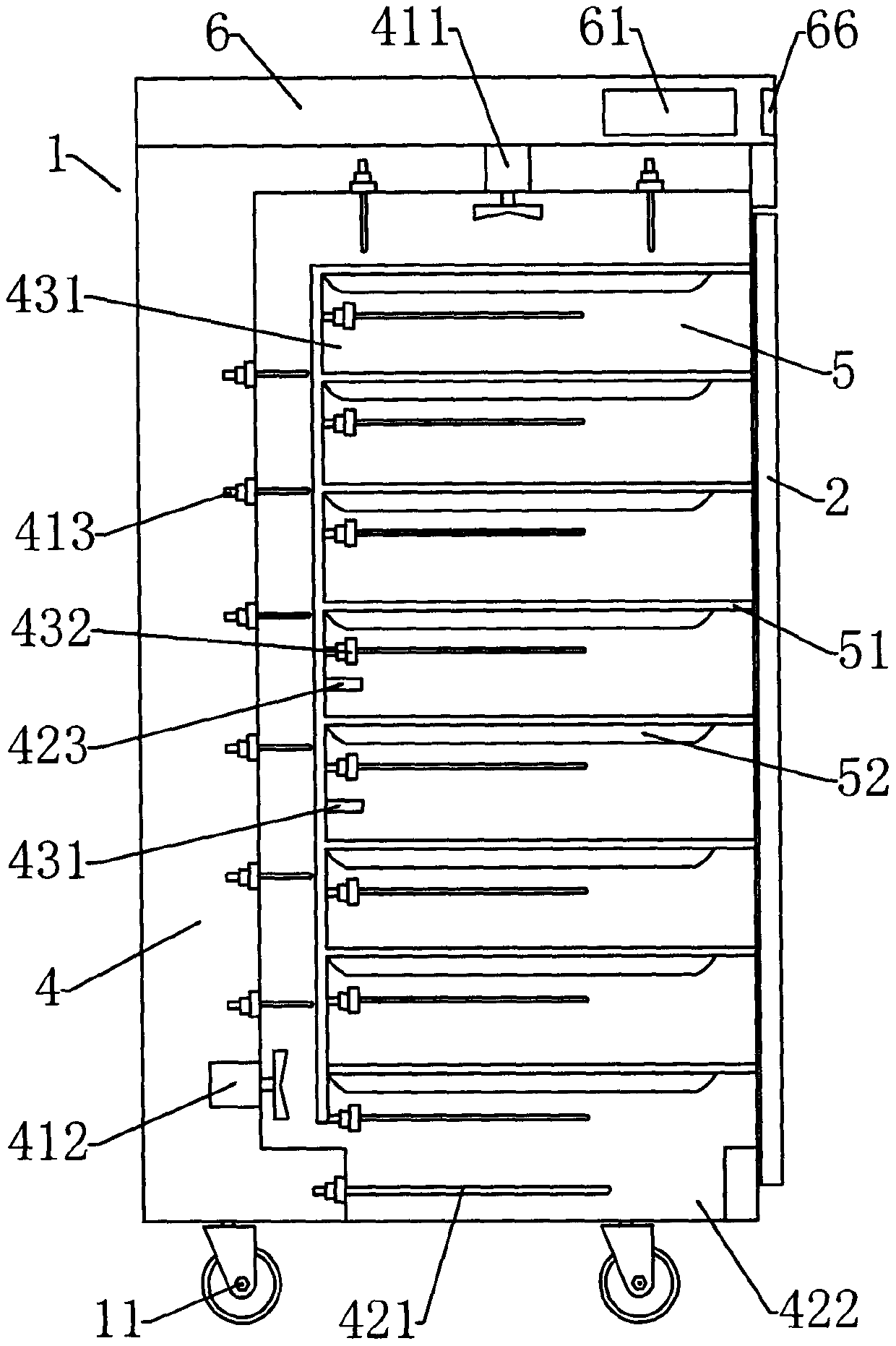

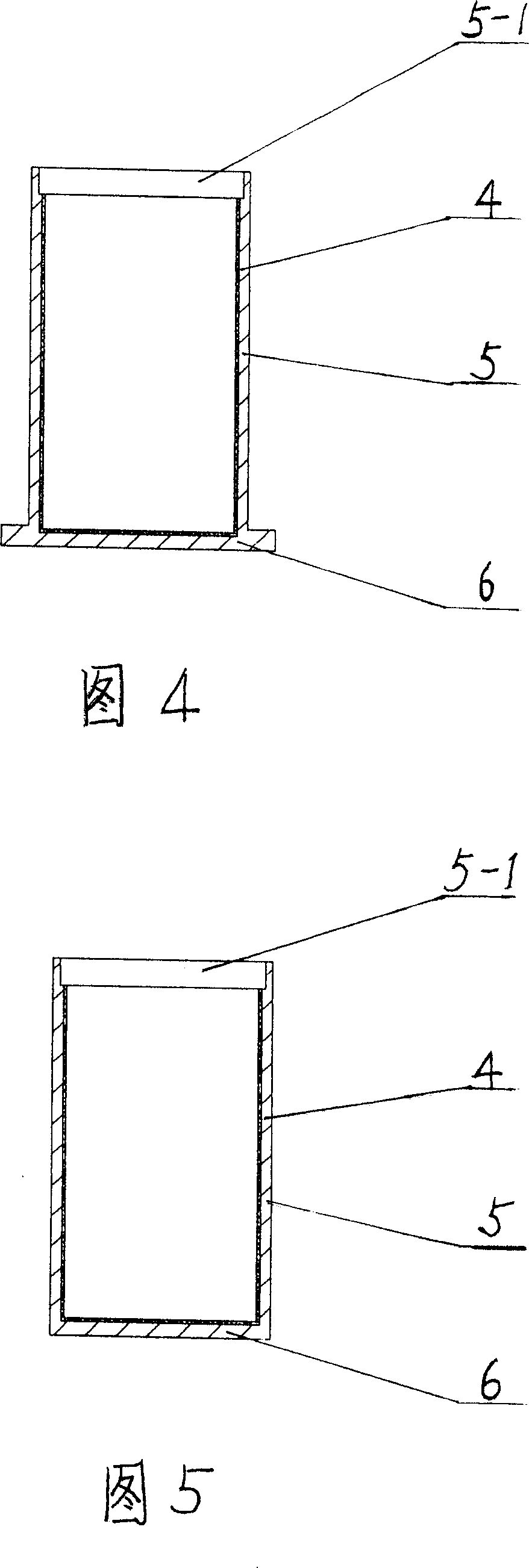

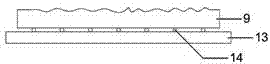

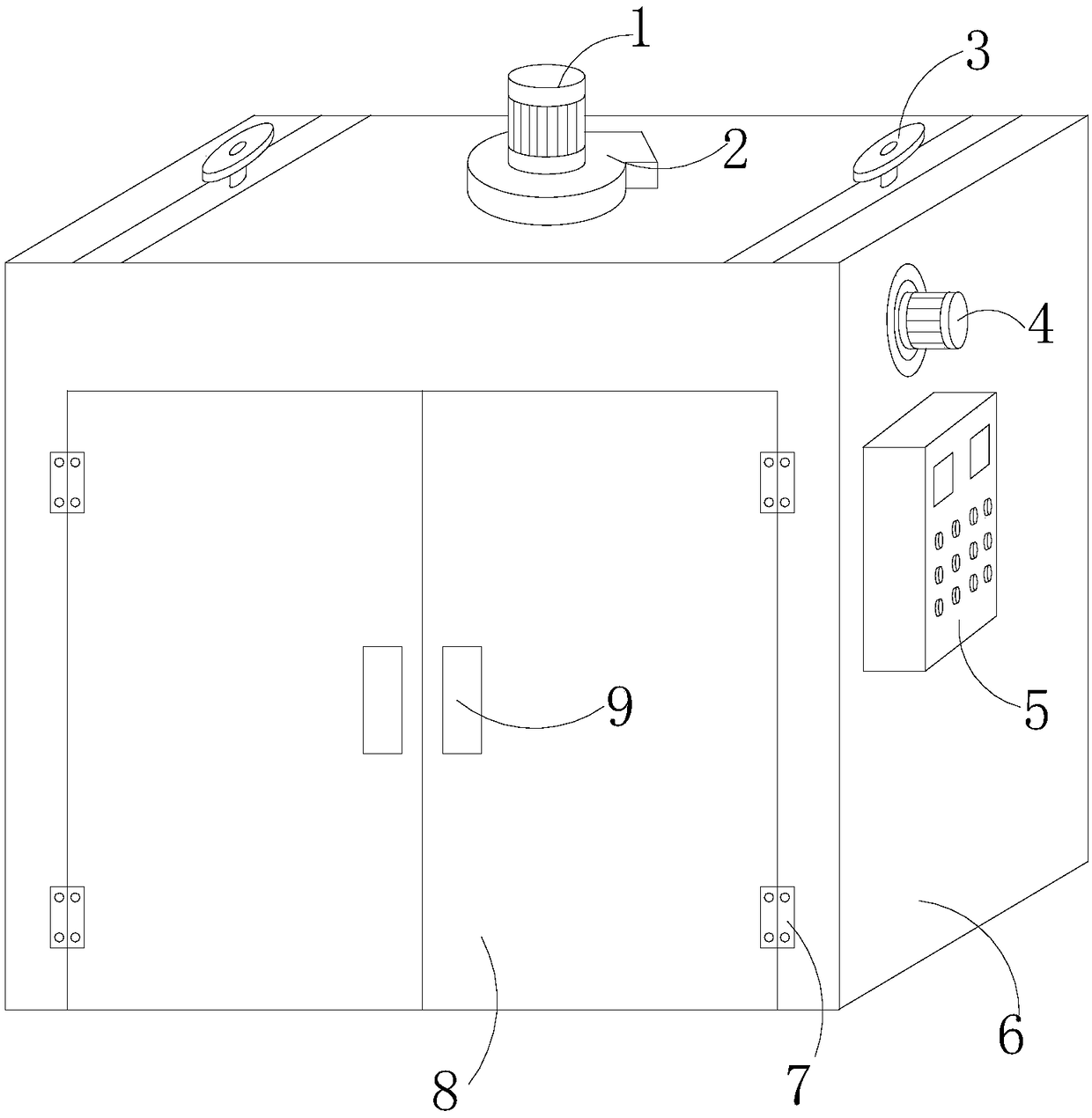

Meal heat insulation box

PendingCN107826494AUniform temperature up and downIntelligent up and down temperatureContainers for heating foodLinings/internal coatingsMicrocomputerThermodynamics

The invention relates to the field of food heating and provides a meal heat insulation box. The insulation can comprises a box body and a box door, wherein the box body is internally provided with a heating cavity, a storage cavity and a control cavity; the heating cavity surrounds and is communicated with the storage cavity; the control cavity is located on the top of the box body; a hot air circulation device, a steam humidification device and a temperature compensation device are arranged in the heating cavity; the hot air circulation device comprises blast fans and a first electric heatingtube; the first blast fan supplies air horizontally; the second blast fan supplies the air vertically; the steam humidification device comprises a second electric heating tube, a water tank and a humidity sensor; the humidity sensor is arranged in the storage cavity; the temperature compensation device comprises a temperature sensor and a third electric heating tube that are arranged in the storage cavity; a shelf and dinner plates are arranged in the storage cavity; and a microcomputer controller, a first blast fan switch, a second blast fan switch, a first electric heating tube switch, a second electric heating tube switch, a touch display screen and an indication lamp are arranged in the control cavity.

Owner:NINGBO HENGLONG KITCHEN EQUIP

Electronic-grade ultra-high-purity aluminum crystallization device

ActiveCN112708778AHigh purityAchieve purificationProcess efficiency improvementMaterials scienceAluminium

The invention discloses an electronic-grade ultra-high-purity aluminum crystallization device. The electronic-grade ultra-high-purity aluminum crystallization device comprises a rotating body and a driving device; the rotating body is installed above a crucible; the lower end of the rotating body extends into the position below the liquid level of molten aluminum in the crucible; the driving device is connected with the rotating body and is used for driving the rotating body to rotate; a cooling gas circuit is arranged in the rotating body and is filled with cooling gas to cool the rotating body, and then high-purity aluminum crystals are formed at the lower end of the rotating body through solidification and accumulation. The electronic-grade ultra-high-purity aluminum crystallization device solves the problems of high purification cost and poor purification effect in the prior art.

Owner:宁波锦越新材料有限公司

Spiral inner wall crucible furnace

The invention discloses a spiral inner wall crucible furnace. The spiral inner wall crucible furnace comprises a furnace body, a hearth is arranged in the furnace body, a crucible is placed in the hearth, the top of the crucible is compressed and fixed through a gland, a flame opening is formed in the position, close to the bottom, of the outer side of the furnace body, a burner is mounted on theflame opening, a spiral guide groove from bottom to top is formed in the hearth along the wall surface of the hearth, a vertical exhaust channel is formed in the position, above the spiral guide groove, of the wall surface of the hearth, the top end of the exhaust channel communicates with the hearth, and the tail end of the exhaust channel communicates with a connecting hole; and a leakage detection alarming opening communicating with the hearth is formed in the outer side of the furnace body. According to the spiral inner wall crucible furnace, the crucible heating efficiency is improved, the dissolving speed is increased, the service life of a crucible is longer, the up-down temperature in the crucible is uniform, the defective rate of a product is increased, waste heat can be recycledfor exhausting, the energy circulating efficiency is improved, the energy-saving effect is achieved, meanwhile, through design of the leakage detection alarming opening, the safety coefficient of thecrucible furnace is increased, and the service life of the crucible furnace is prolonged.

Owner:昆山北陆技研工业设备有限公司

Column-type heat tube and its manufacturing method

InactiveCN100535574CSmall fluctuationUniform temperature up and downIndirect heat exchangersWorking fluidHeat conducting

Owner:嘉善华昇电子热传科技有限公司

Aluminizing furnace

InactiveCN101463459AUniform temperature up and downStrong self-controlSolid state diffusion coatingAutomatic controlElectric arc furnace

The invention relates to an electric furnace, in particular to an alumetized furnace which is specially used for iron pan alumetized compound bottom. In order to solve the technical problems, the invention adopts the technical proposal that the alumetized furnace is specially used for iron pan alumetized compound bottom, and is characterized by comprising an external body, an electric furnace flue arranged inside the external body, an electric furnace wire groove positioned on the outer wall of the electric furnace flue, electric furnace wires wound inside the electric furnace wire groove, a plurality of heat transferring holes which are evenly distributed in the electric furnace wire groove, and a temperature controller connected with connectors of the electric furnace wires by electric wires. The alumetized furnace has the advantages of high temperature resistance, uniform temperature between the top and bottom of the flue, strong automatic control and humanized operation.

Owner:王新田

Energy Saving and Emission Reduction Method for Carbon Anode Roasting Furnace

ActiveCN103868349BReduce energy consumptionImprove sealingMuffle furnacesRetort furnacesCold airThermocouple

The invention provides an energy saving and emission reduction method of a carbon anode baking furnace, and relates to the field of metallurgical industry carbon techniques. A special furnace face sealing furnace cover is specially configured for the baking furnace, and the process of the baking furnace is optimized, namely the flame jetting length is 0.35 time of the flame path depth, the difference between temperature of products in a preheating furnace chamber and flame path smoke temperature is more than 280 DEG C, and a thermocouple is inserted into a second feed box of the preheating furnace chamber. According to the method, the sealing effect of the baking furnace is greatly improved, and cold air is effectively prevented from entering the baking furnace; meanwhile according to the practical experience of temperature distribution in the furnace chamber, the operation technique of the baking furnace is optimized, it is guaranteed that volatile matter fully burns and temperature on the upper portion of a flame path and temperature on the lower portion of the flame path are uniform, and energy consumption of the carbon anode baking furnace is greatly reduced.

Owner:SUNSTONE DEV

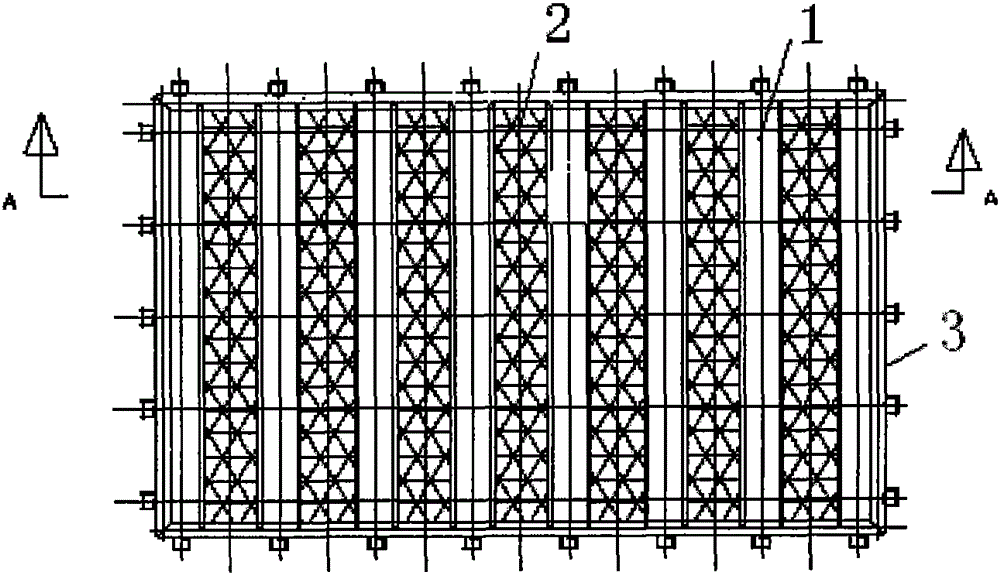

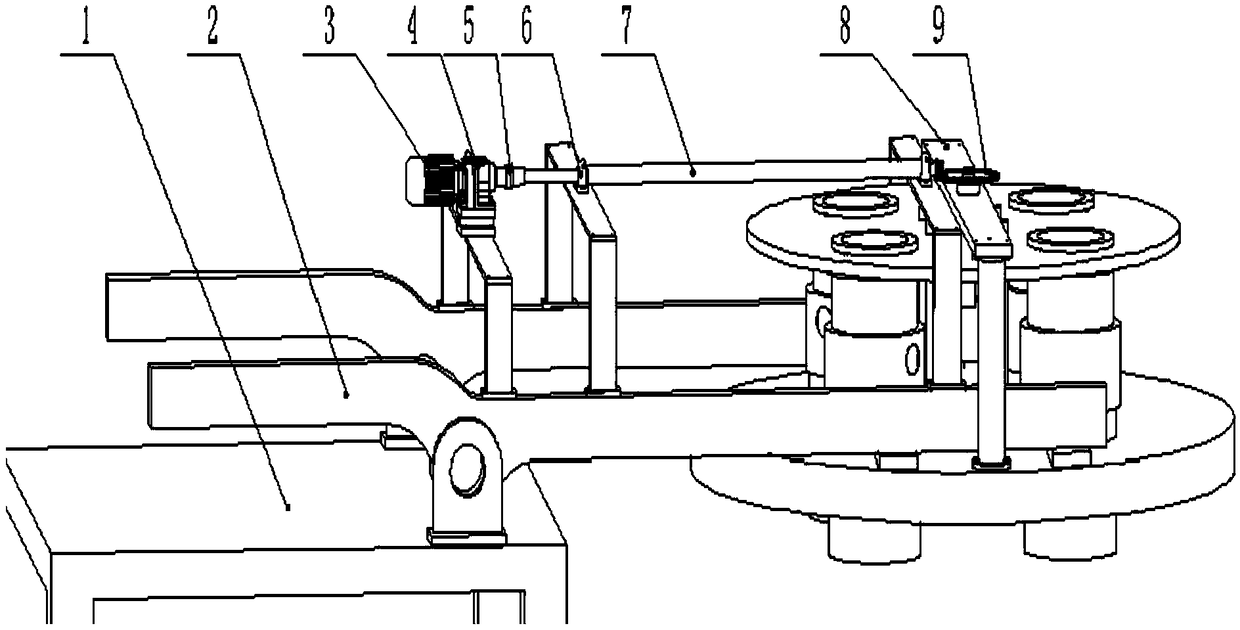

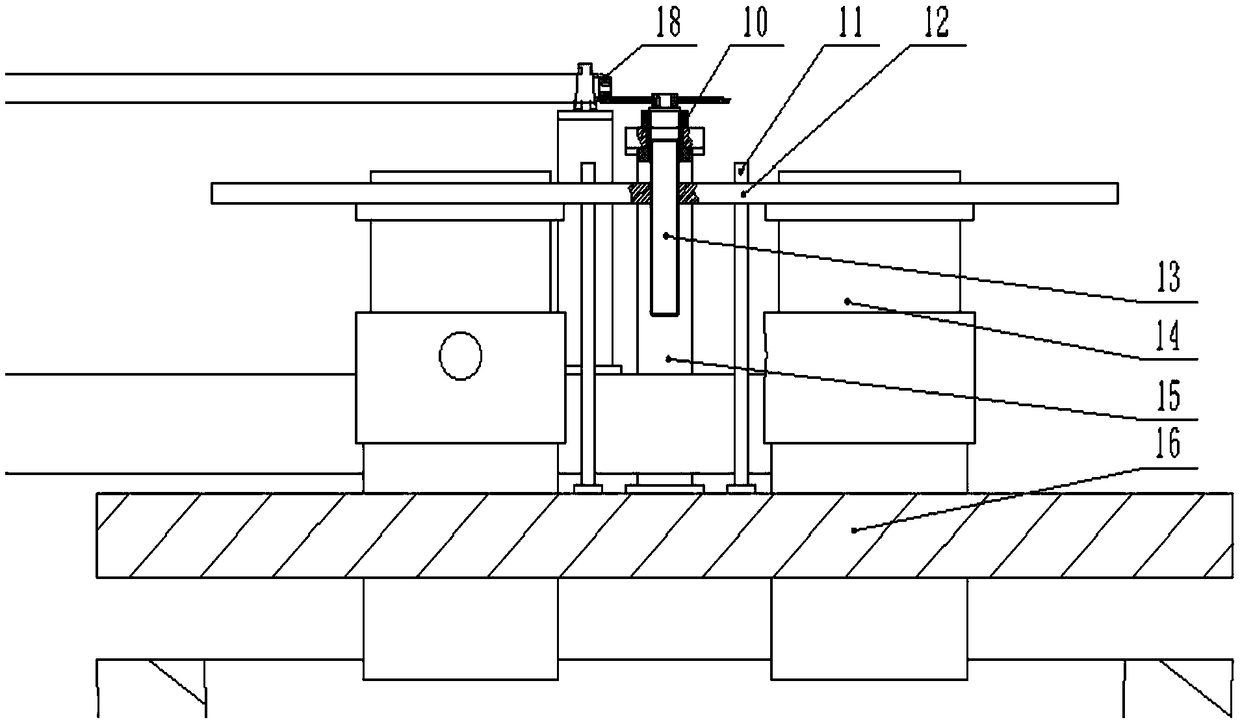

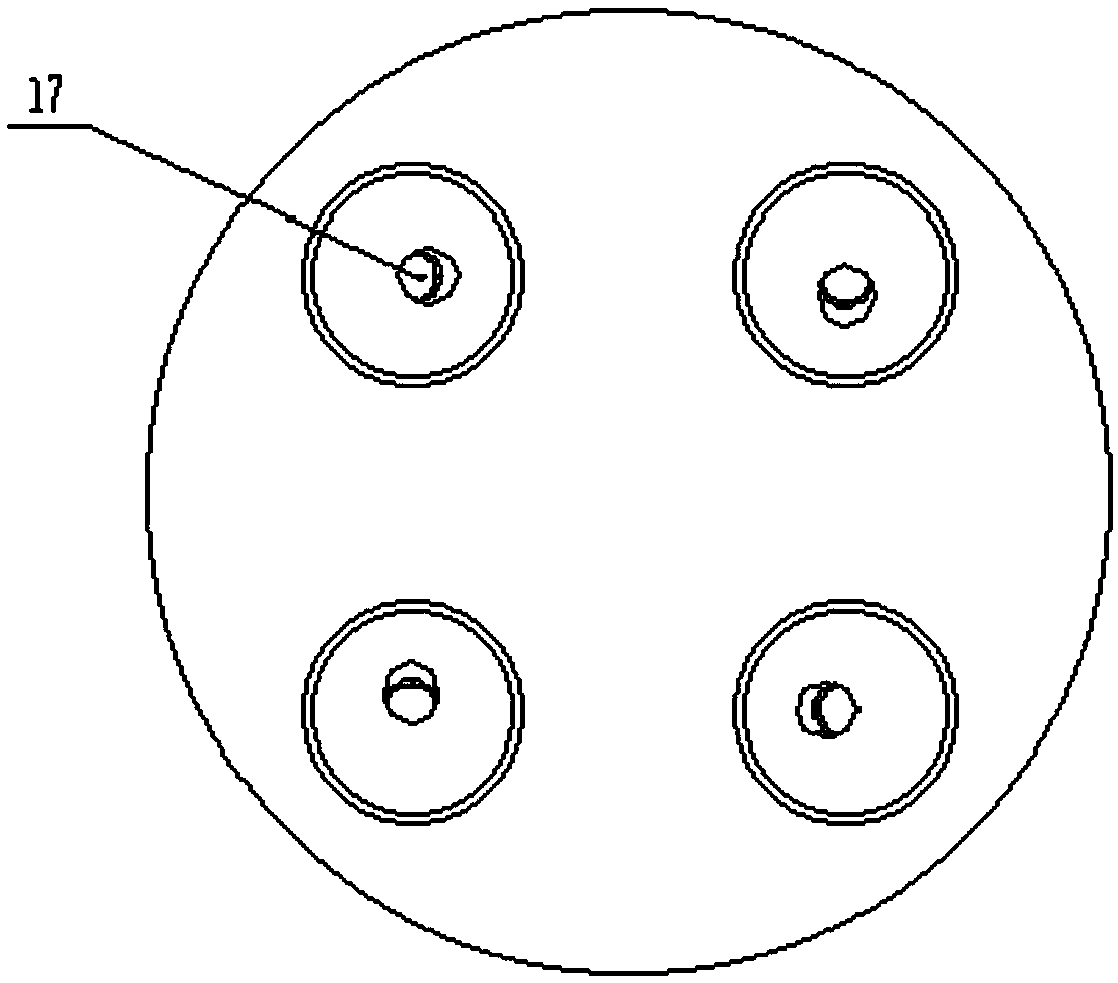

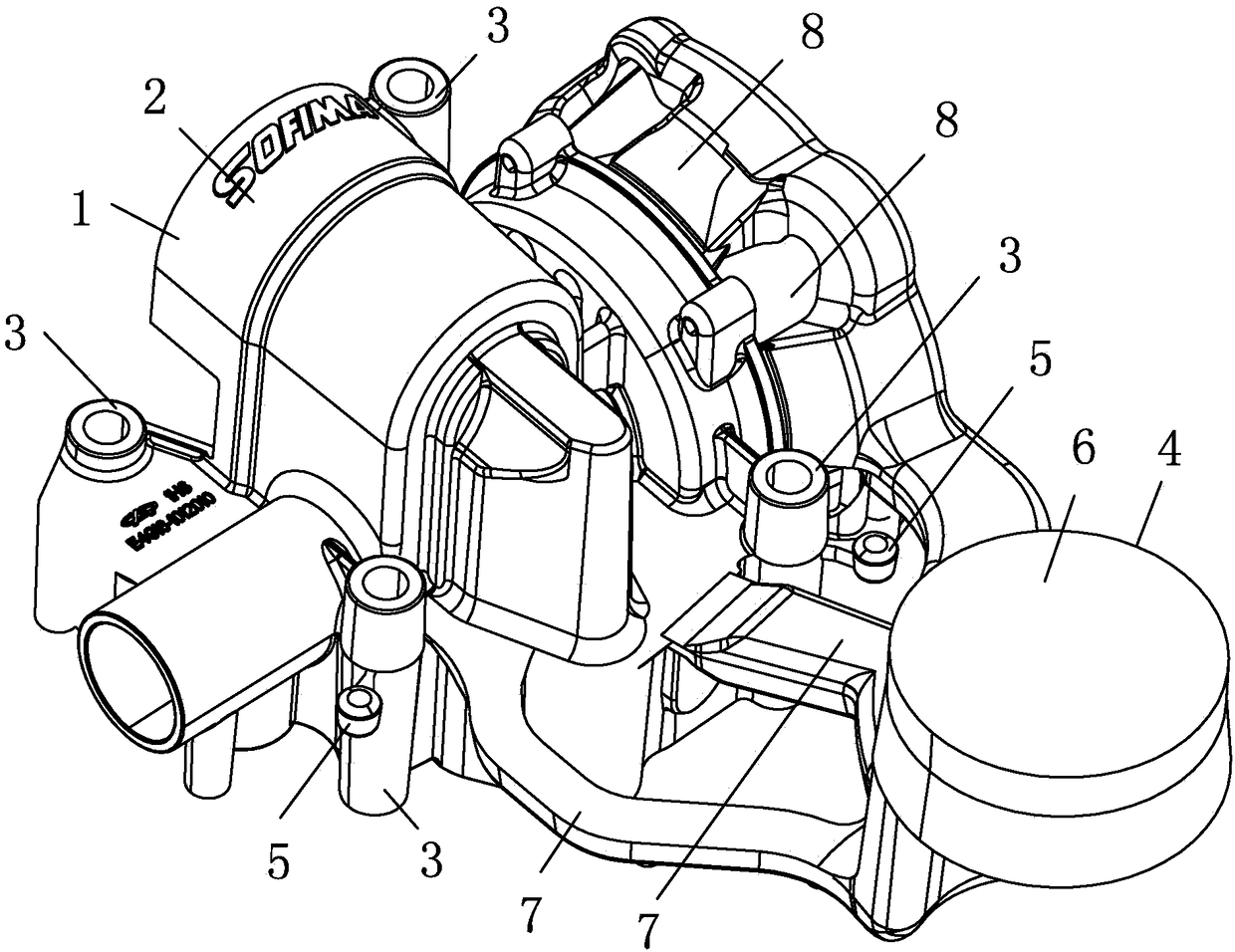

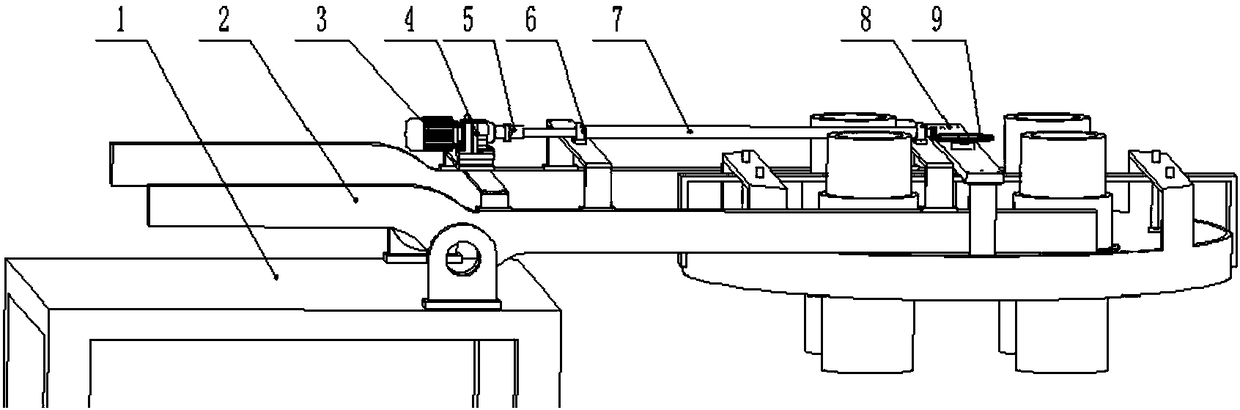

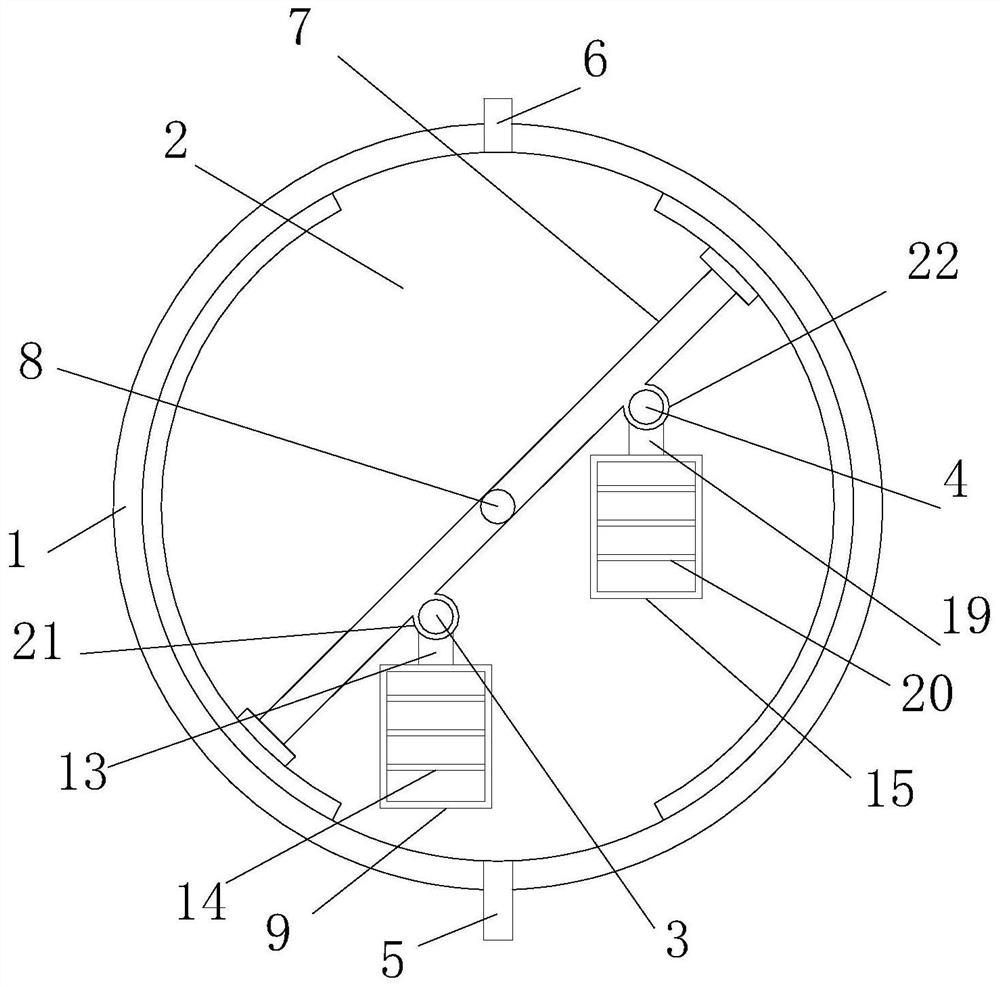

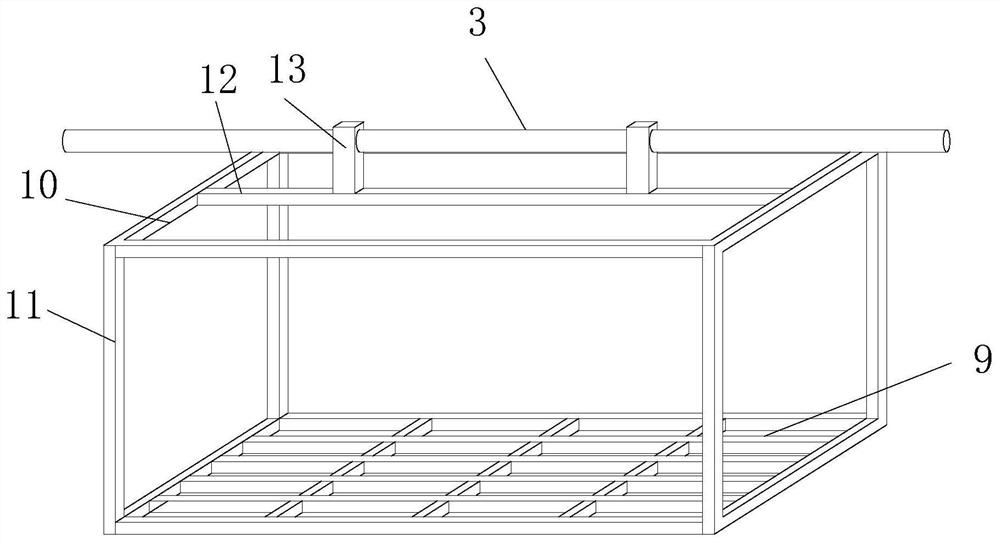

A ladle baking device with adjustable burner

ActiveCN107214328BUniform temperature up and downRealize moving up and downMelt-holding vesselsFlue gasEngineering

The invention relates to a burner ascending and descending adjustable steel ladle baking device. The burner ascending and descending adjustable steel ladle baking device comprises a rack, two rotary arms, a ladle cover and a burner adjusting device. One end of each rotary arm is connected to the rack. The other end of each rotary arm is fixedly arranged on the upper surface of the ladle cover. The burner adjusting device is fixed to the rotary arms and the ladle cover. The burner adjusting device comprises an adjustment and power unit and four regenerative burners. The four regenerative burners are symmetrically fixed to a disk and can move up and down along with the disk. Nozzles of the regenerative burners are inclined at a certain angle, so that burning flames are sprayed into a steel ladle at a certain angle. The flames flow and rotate around the surface of the steel ladle to form a plurality of vortexes when impacting onto the inner wall of the steel ladle, and flowing of hot flue gas is accelerated. According to the burner ascending and descending adjustable steel ladle baking device, the burners can be adjusted to ascend and descend so as to make the temperature in the steel ladle rise to some extent, and the temperature of an inner lining at different heights is more uniform. The working efficiency is improved. The quality of flames and the baking quality are obviously improved.

Owner:YANGZHOU HONGCHENG METALLURGICAL EQUIP

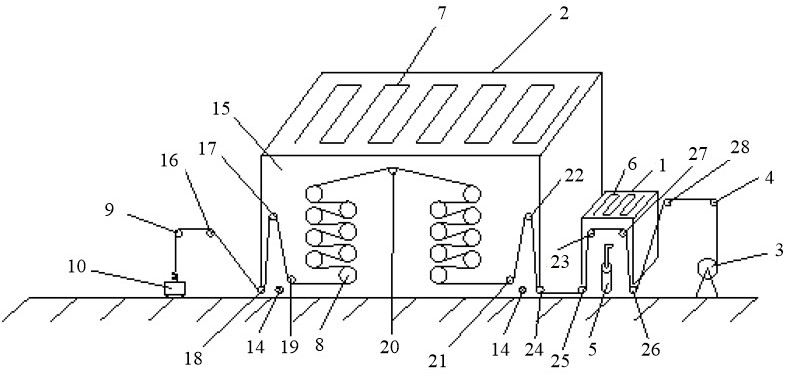

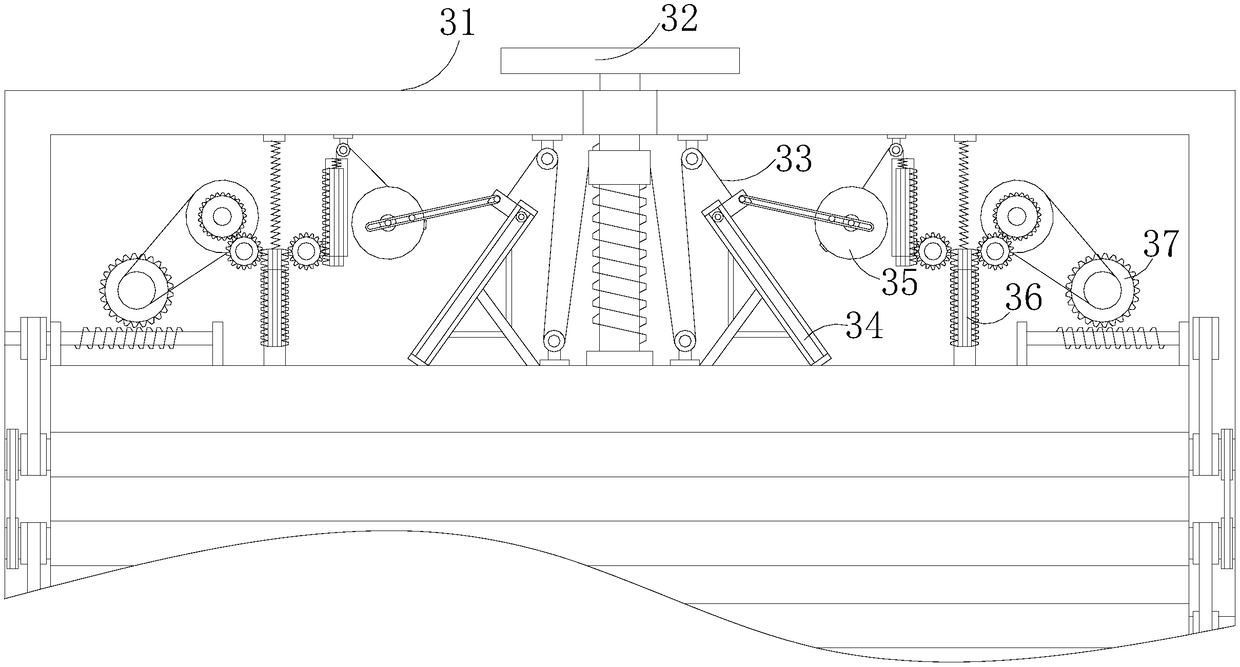

A high-efficiency propeller curing furnace

ActiveCN108705711BUniform temperature up and downReduce the temperatureDomestic articlesElastic componentPropeller

Owner:安徽劲旋风航空科技有限公司

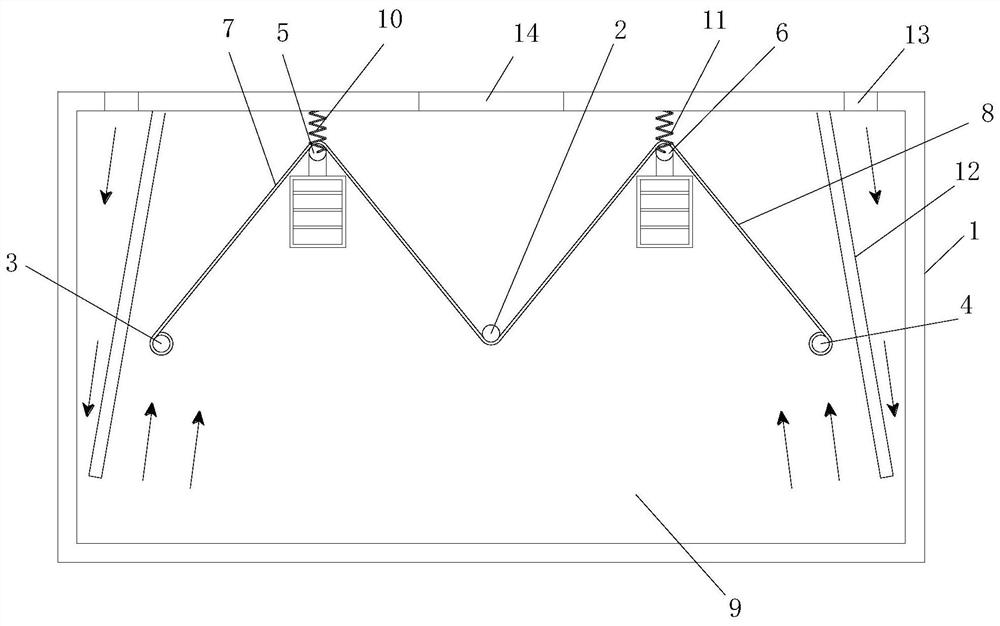

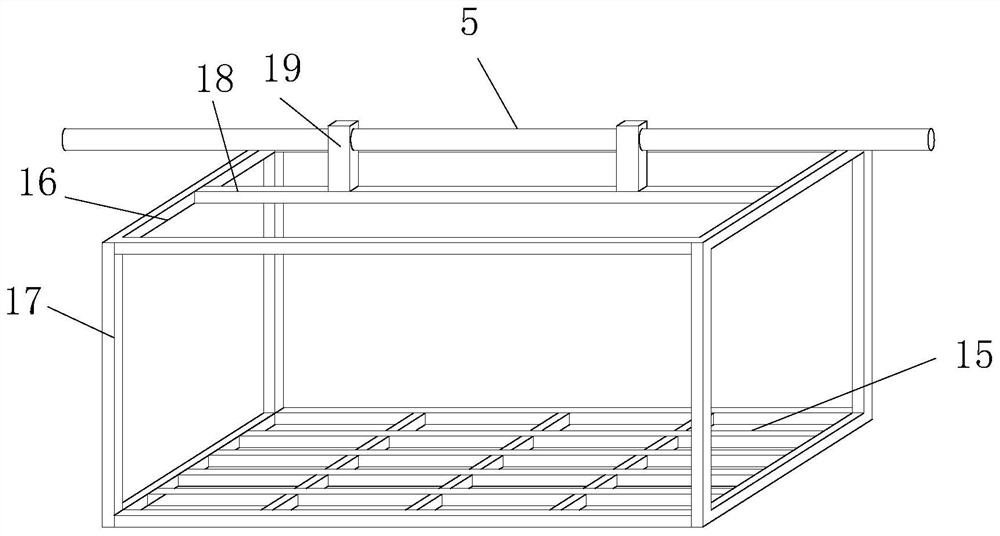

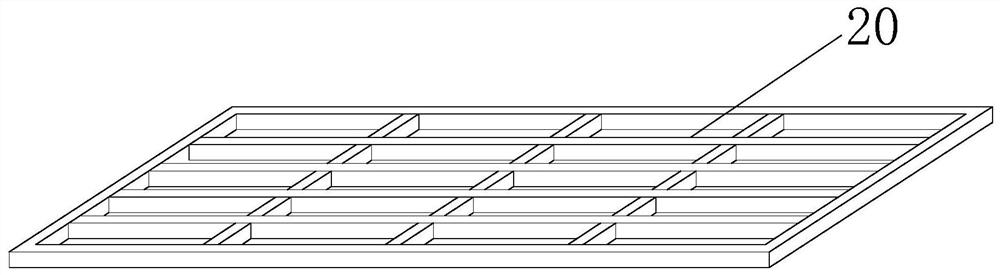

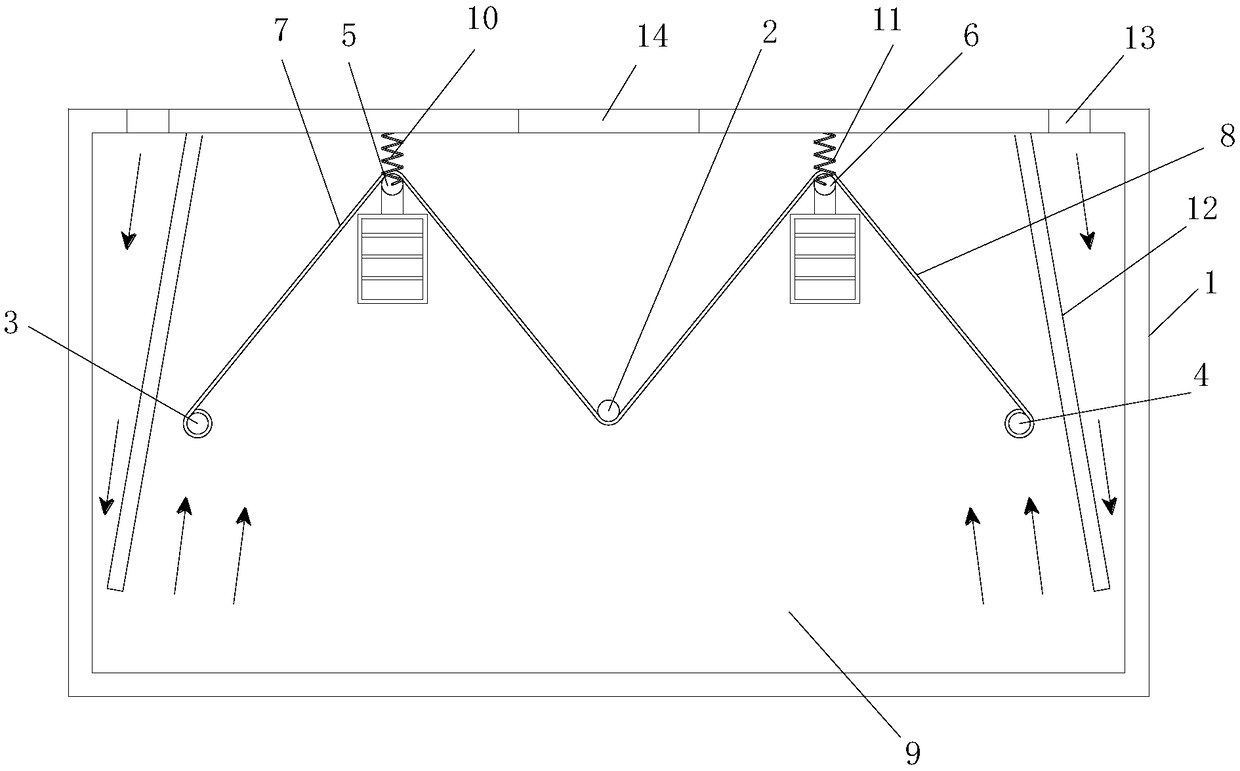

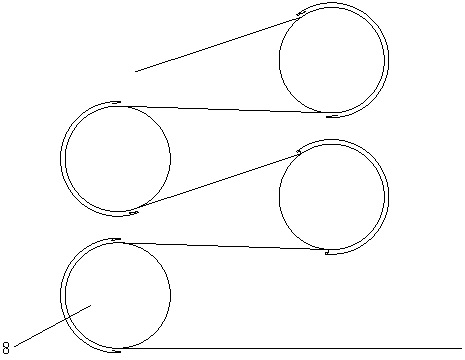

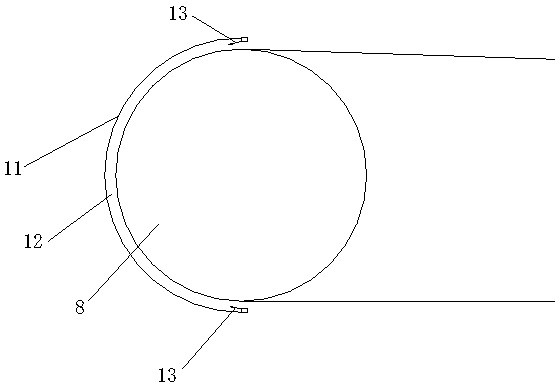

High-efficient propeller curing furnace

ActiveCN108705711AUniform temperature up and downReduce the temperatureDomestic articlesElastic componentPropeller

The invention discloses a high-efficient propeller curing furnace. The high-efficient propeller curing furnace comprises a furnace body, a fixing shaft, a first material roller, a second material roller, a first supporting shaft, a second supporting shaft, a first supporting belt, a second supporting belt, multiple first mould racks and multiple second mould racks; the first material roller rotates anti-clockwise to reel the first supporting belt; the second material roller rotate clockwise to reel the second supporting belt; the first and second supporting belt separately drive the first supporting shaft and the second supporting shaft to move downwards; the first and second supporting shafts separately drive the multiple first mould racks and the multiple second mould racks to move downwards; the first material roller rotates clockwise to unreel the first supporting belt; the second material roller rotates anti-clockwise to unreel the second supporting belt; the first and second supporting shafts separately move upwards under the effect of a first elastic component and a second elastic component; the upper and lower mould temperature difference of the mould is small; and requirement to the temperature in a moulding process of a composite-material propeller is met.

Owner:安徽劲旋风航空科技有限公司

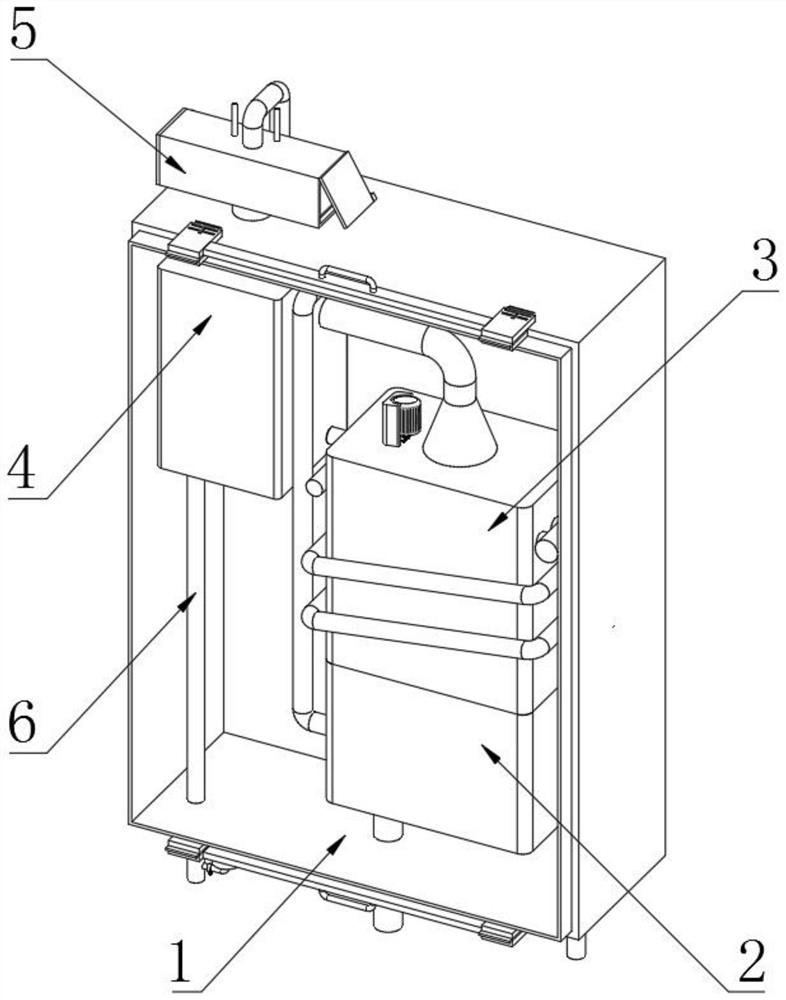

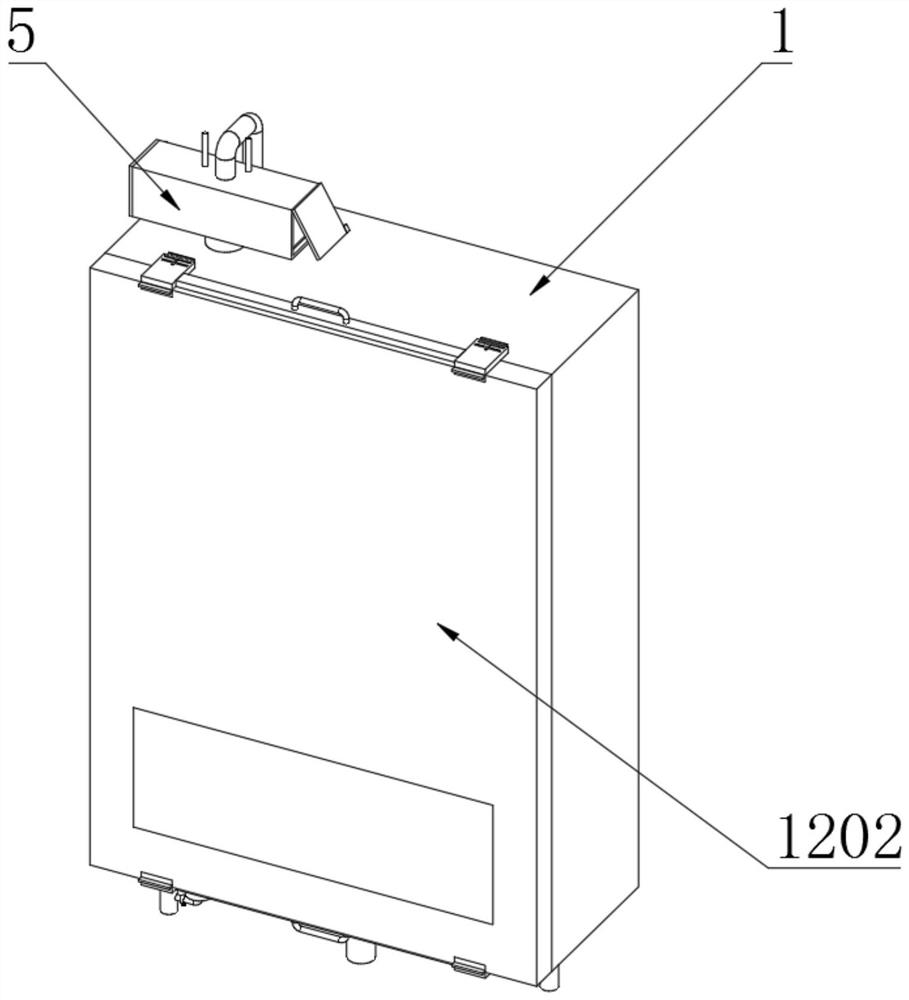

A household high-efficiency water heater

ActiveCN112344548BScientific and reasonable structureEasy to useWater heatersThermodynamicsEngineering

The invention discloses a household type high-efficiency water heater, which includes a shell, one end of the water inlet pipe is evenly installed inside the copper water tank, and a heating water pipe is evenly installed. The bottom end is connected with a surrounding water pipe, and the surrounding water pipe surrounds the outside of the copper water tank. The outside of the heating water pipe is fixedly sleeved with a driving leaf. Both ends of the copper water tank are welded with U-shaped wind deflectors near the bottom of the driving leaf. An arc-shaped air deflector is installed between two U-shaped air deflectors. Compared with the prior art, the invention has the beneficial effect of ensuring that the temperature of the top and bottom ends of the heating water pipe is consistent during the heating process, reducing the cost of water heating. Time, improve the efficiency of water heating, and absorb the emitted heat, reduce heat consumption, and reduce the energy consumption rate during heating, and reduce the cost of using water heaters.

Owner:山东飞天新能源有限公司

Die-casting method of automobile engine cylinder cover

The invention relates to the casting field and provides a die-casting method for an automobile engine cylinder cover. According to the die-casting method for the automobile engine cylinder cover, the automobile engine cylinder cover is provided with an upper convex cover and four side pipes. A die-casting mould of the automobile engine cylinder cover is provided with a casting system, slag collecting bags and a mold cavity provided with four side pipe cavities and an upper convex cover cavity. The die-casting method comprises the following steps that firstly, the die-casting mould with the mold cavity being evenly sprayed with mould release agents is fixed on a die-casting machine and preheated to the set temperature; secondly, smelted alloy liquid is quantificationally input into a charging chamber of the die-casting machine; and thirdly, a pressure head of the die-casting machine presses the alloy liquid into the mold cavity in an injecting mode for forming through the casting system, and the forming process comprises the initial low-speed press-injecting stage and the high-speed press-injecting stage. According to the die-casting method for the automobile engine cylinder cover, the casting defects of air holes and included slag are not produced in the automobile engine cylinder cover.

Owner:宁波环亚机械制造有限公司

Cylindrical heat pipe

InactiveCN100360888CSmall fluctuationUniform temperature up and downIndirect heat exchangersWorking fluidEvaporation

The columnar heat pipe has sealed vacuum cavity comprising gas exhaust pipe, top cover, tube and bottom board; and has bottom board below the tube, step in the upper end of the tube, capillary cover mounted in the step, top cover on the capillary cover, sealed gas exhaust pipe on the top cover, sintered porous capillary layer in the inner wall of the tube and the inner surface of the bottom board to form work liquid circulating passage together with the capillary cover and work liquid adsorbed to the sintered layer and the capillary cover. The present invention has the beneficial effects caused by the phase change heat transfer of the evaporation and condesation of work fluid inside the columnar heat pipe, including fast heat transfer rate, great heat transfer capacity, homogeneous temperature, high stability, etc.

Owner:嘉善华昇电子热传科技有限公司

A high-efficiency drum steamer

ActiveCN113580759BGuaranteed temperature environmentImprove printing qualitySimultaneous control of multiple variablesPrinting press partsThermodynamicsReal-time data

The invention relates to a high-efficiency drum steamer, which includes: a main steamer, in which a dryer assembly is arranged, a heating device is arranged inside each dryer, and a temperature setting is set on the inner wall of the main steamer. Sensors and humidity sensors are used to detect the real-time temperature and real-time humidity in the main steamer; the control unit is connected with the temperature sensor, humidity sensor and heating device, the first valve and the second valve respectively, and the control unit receives The real-time data of the temperature sensor and the humidity sensor adjust the power of the heating device according to the real-time temperature of the temperature sensor, and at the same time adjust the working time and opening and closing degree of the first valve or the second valve according to the real-time humidity of the humidity sensor. By ensuring the temperature environment and humidity environment of the fabric to be fixed, establish a suitable temperature environment, humidity environment and air pressure environment to establish the printing and dyeing conditions of the fabric to be fixed to meet production requirements.

Owner:江苏京可为纺织科技有限公司

Baking furnace wall

The invention provides a baking furnace wall comprising a wall body and flame channels, wherein two flame channels inside the wall body are arranged, and the two flame channels are intersected at the middle part of the wall body. The baking furnace wall has the beneficial effects that the temperatures at the upper and lower parts of the furnace body are even; carbon evenly combusts and is evenly heated, and the baking furnace wall is light in wall body weight, not easy to deform, and long in service life.

Owner:天津至勤科技发展有限公司

Process for producing fine porcelain relief plate painting with high light transmittance

ActiveCN103011797BInconsistent thicknessThe degree of light transmission is differentAdobeMetallurgy

The invention discloses a process for producing a fine porcelain relief plate painting with high light transmittance. The process comprises the producing steps as follows: step one, preparation of finished clay material; step two, preparation of an adobe base plate; step three, fine carving of decorative patterns and drawings on the adobe base plate; and step four, sintering of the adobe base plate. The process has the advantages as follows: the light transmittance is higher than 50%; the decorative patterns have three-dimensional sense; the adobe base plate is formed smoothly, so that defects such as cracking deformation, air bubbles and the like are avoided; smooth and effective fine carving is guaranteed; the sintering effect is improved, and the qualified ratio of the product is increased; and the plate painting has unique aesthetic sense and artistic sense.

Owner:CHAOZHOU LIANYUAN CERAMICS MFG

Energy-saving type craft house and home processing drying device

InactiveCN108709370AQuality improvementUniform temperature up and downDrying gas arrangementsDrying solid materialsElectric machineReducer

The invention discloses an energy-saving type craft house and home processing drying device. The energy-saving type craft house and home processing drying device structurally comprises a motor, a speed reducer, uniform air guiding devices, a draught fan, a controller, a machine body, symmetric hinges, drying chamber door panels and door handles. The speed reducer is arranged at the center positionof the top face of the machine body. The upper portion of the speed reducer is connected with the motor perpendicular to the speed reducer. The uniform air guiding devices are arranged on the left side and the right side of the motor, and the two uniform air guiding devices are symmetrically arranged in parallel and connected with the machine body. According to the energy-saving type craft houseand home processing drying device, the drying device is provided with the adjustable uniform air guiding devices, the uniform air guiding function is achieved, meanwhile, the aperture of air homogenizing plates can be adjusted up and down, accordingly, the air guiding direction can be adjusted, the up-down temperature in the machine body is more uniform, and the temperature difference is small; and the drying time is shortened while the house and home quality is improved, the drying efficiency is high, and electric energy is saved.

Owner:江炎秋

A ladle baking device with adjustable lifting of the outer ring of the cover

ActiveCN107008887BUniform temperature up and downAir intake constantMelt-holding vesselsCombustionFlue gas

Owner:YANGZHOU HONGCHENG METALLURGICAL EQUIP

A rotary heating type curing furnace for composite material propeller

ActiveCN108724557BQuality assuranceMeet temperature requirementsDomestic articlesRotational axisComposite propeller

The invention discloses a rotary heating type curing furnace for a composite propeller. A barrel-shaped curing chamber is formed in a furnace body. A plurality of rotating shafts are arranged in the curing chamber at interval along the axial direction of the furnace body, and the two ends of each rotating shaft are connected with the inner wall of the furnace body in a sliding mode. A center shaftis arranged at the center of the curing chamber along the axial direction of the furnace body, and the center shaft passes through the centers of the rotating shafts in order and is fixedly connectedwith the rotating shafts. A first support shaft and a second support shaft are positioned on the two sides of the center shaft and are connected with the rotating shafts, and a first mould rack and asecond mould rack are respectively hinged with the first support shaft and the second support shaft. According to the rotary heating type curing furnace, the rotating shafts are driven by the centershaft to rotate, and the first mould rack and the second mould rack are driven by the rotating shafts to move up and down, so that hot air in the curing chamber can be guided to flow, and the upper and lower temperatures of the curing chamber are uniform. Therefore, the difference of the upper and lower mould temperatures of a mould is within + / -1 or so, the temperature requirement of the composite propeller in the forming process can be met, and the quality of the propeller is ensured.

Owner:安徽劲旋风航空科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com