Electrolytic production device for rare earth alloy

A technology for production equipment and rare earth alloys, applied in the direction of electrolysis process, electrolysis components, electrodes, etc., can solve the problems of waste, high energy consumption of electrolysis reaction, increase of production cost, etc., and achieve reduction of abnormal production loss, uniform upper and lower temperatures, Effect of Reducing Reactive Current Consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

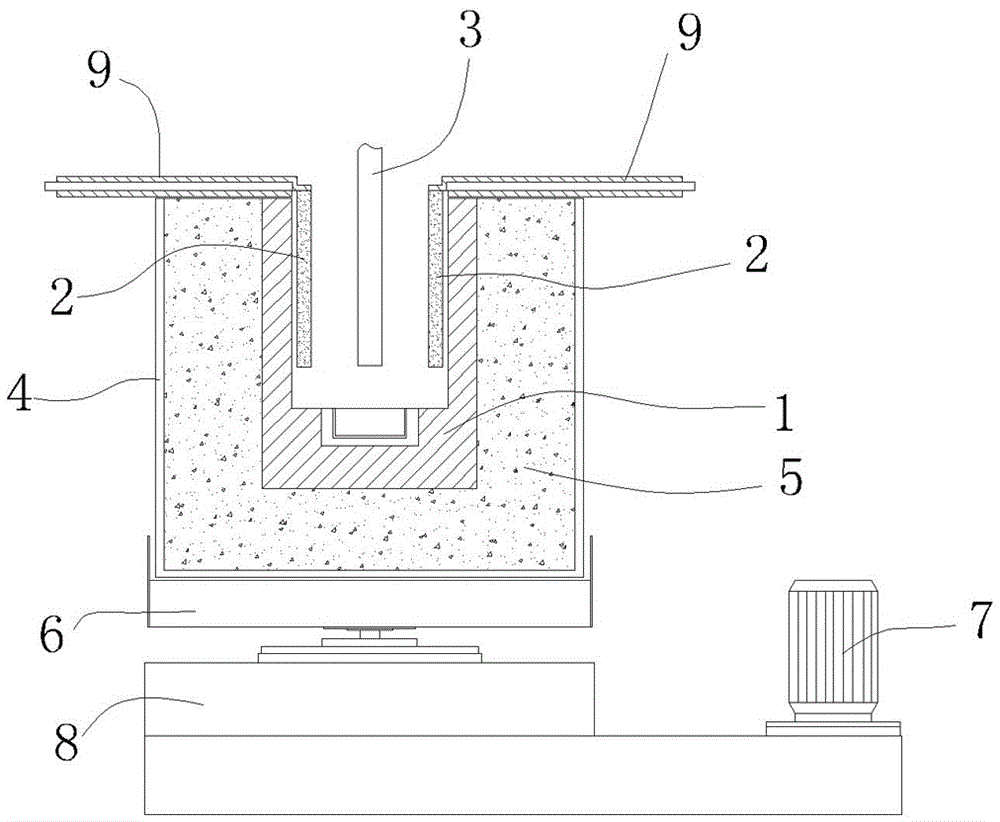

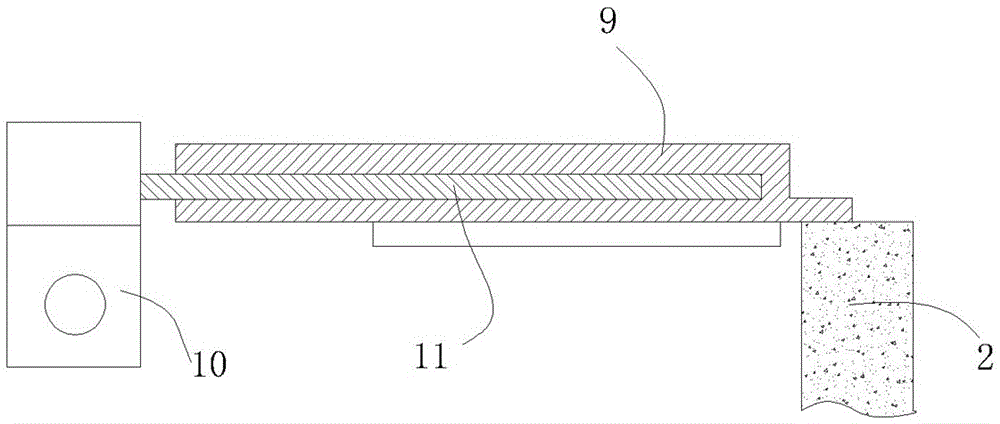

[0015] refer to figure 1 , figure 2 , a rare earth alloy electrolytic production equipment, comprising a graphite electrolytic cell 1, a graphite anode 2 extending into the graphite electrolytic cell 1, and a cathode 3 extending into the graphite electrolytic cell 1.

[0016] It also includes a sheath 4, and a thermal insulation layer 5 is provided between the sheath 4 and the graphite electrolytic cell 1.

[0017] It also includes a rotary drive mechanism, which is in transmission connection with the graphite electrolytic cell 1 so that the rotary drive mechanism can drive the graphite electrolytic cell 1 to rotate.

[0018] In this embodiment, the graphite electrolytic cell 1 is placed in a base 6 , and the rotation driving mechanism is connected with the base 6 . The rotary drive mechanism includes a rotary drive motor 7 and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com