A ladle baking device with adjustable burner

A technology of baking device and adjusting device, which is applied to metal processing equipment, manufacturing tools, casting melt containers, etc., can solve the problems of large temperature difference, poor baking quality, uneven temperature distribution of ladle, etc., and achieve uniform combustion and uniform temperature. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

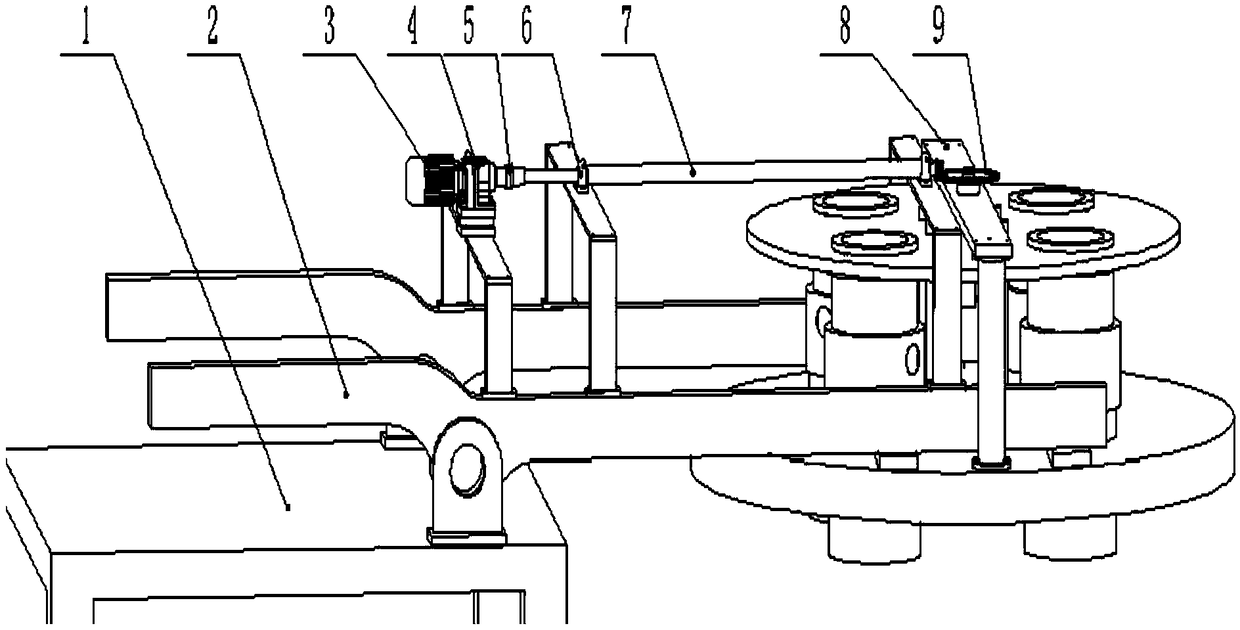

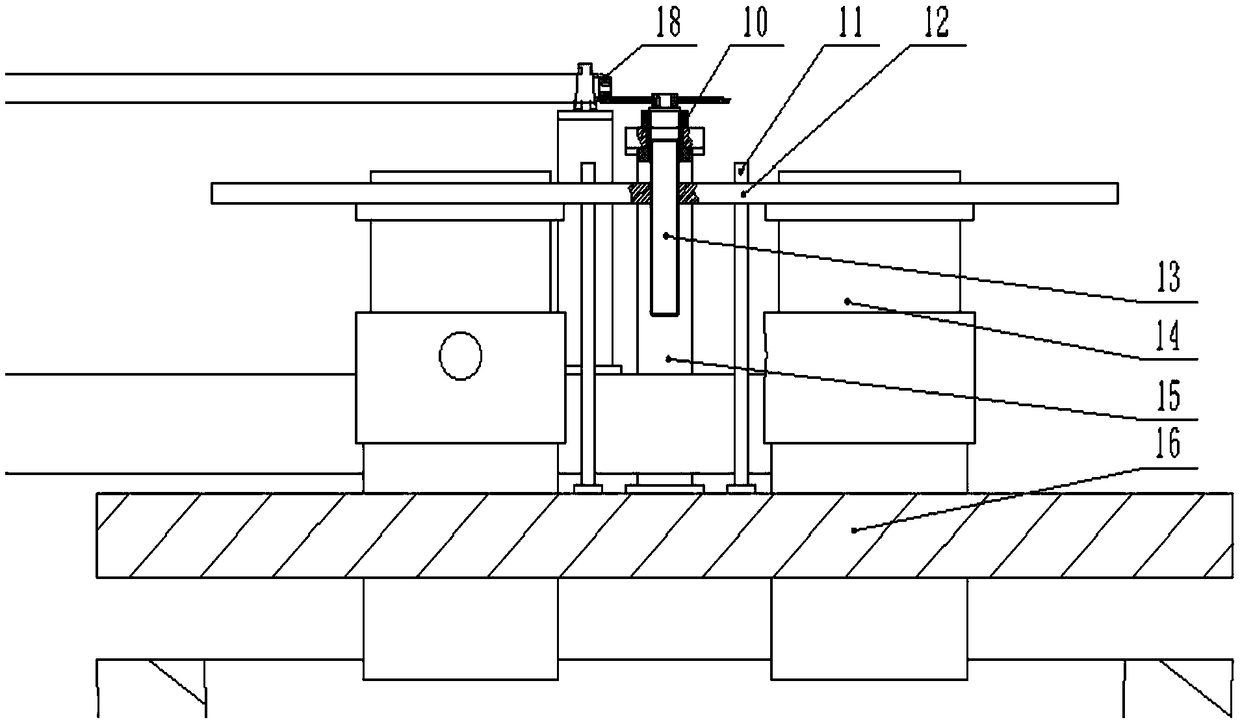

[0023] For further understanding of the present invention, now further explanation in conjunction with accompanying drawing:

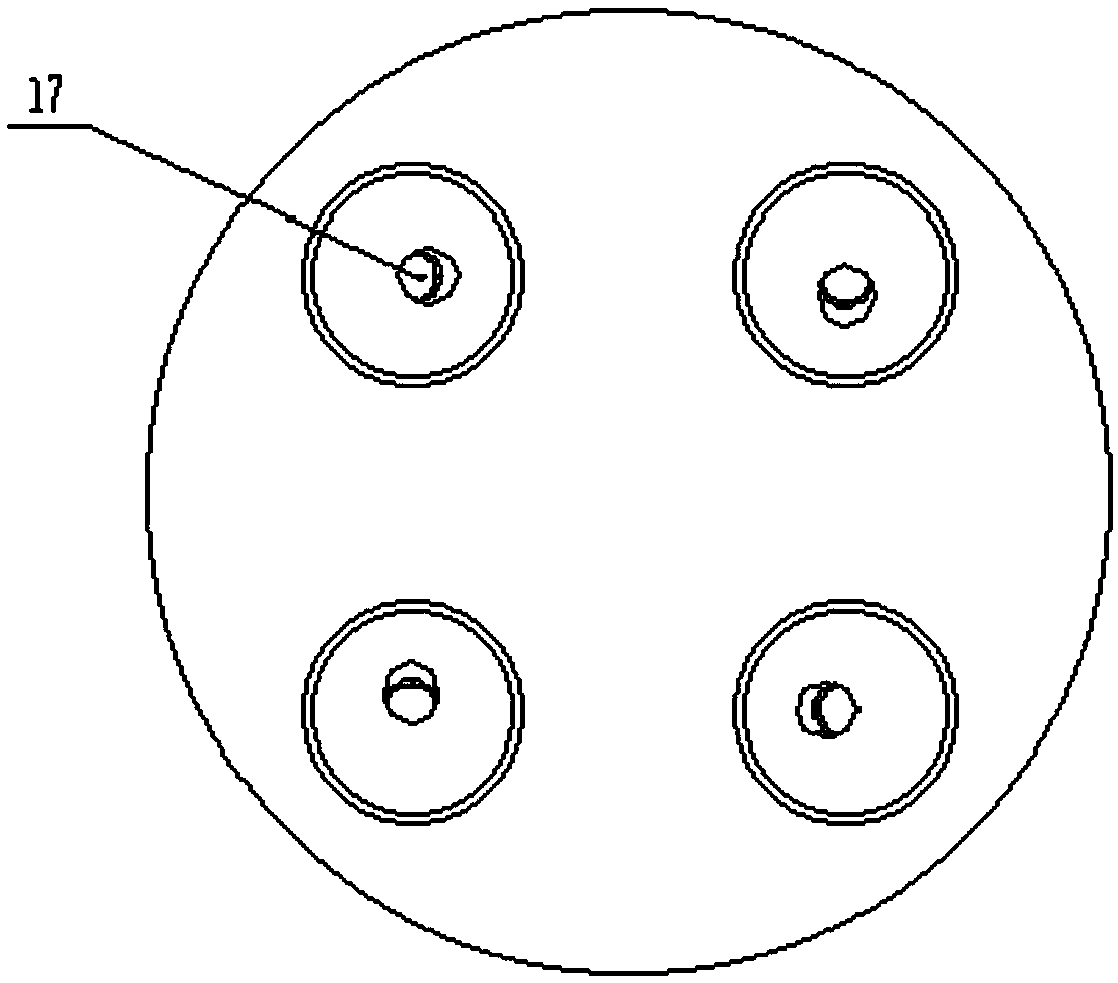

[0024] Such as figure 1 As shown, the burner adjustable lifting ladle baking device of the present invention includes a frame 1, a rotating arm 2, a bag cover 16 and a burner adjusting device; one end of the rotating arm 2 is connected to the frame 1 by a pin. The other end is fixedly arranged on the upper surface of the cover 16; the burner adjustment device includes an adjustment and power device and a regenerative burner 14; the adjustment and power device includes a screw 13, a disc 12, a cover 16 and Motor 3; the screw rod 13 is arranged on the support plate 8, the two ends of the support plate 8 are fixedly supported by the pillar 15, the pillar 15 is arranged on the cover 16, and the screw rod 13 at the upper surface position of the support plate 8 passes through the key Cooperate with the large bevel gear 9, the large bevel gear 9 meshes with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com