Process for producing fine porcelain relief plate painting with high light transmittance

A technology with high light transmittance and production process, applied in the field of ceramics, it can solve the problem that the embossed pattern is difficult to achieve fineness, and achieve the effect of unique beauty and artistic sense, preventing deformation, and avoiding cracking and deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

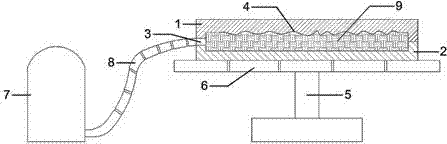

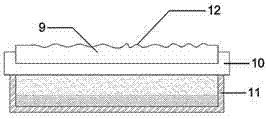

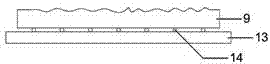

[0038] Example: such as Figure 1~3 As shown, the manufacturing process of the high-transmittance ceramic fine relief panel painting of the present invention is characterized in that it includes the following production steps:

[0039] (1) Preparation of finished mud

[0040] (1) Take the kaolin and beat it mechanically for 22 hours, then pass the mud through a 300-mesh sieve for use;

[0041] (2) Rinse the ashes for later use;

[0042] (3) According to the weight percentage of 62% of bone ashes, 20% of kaolin, 10% of feldspar, and 8% of quartz, mix feldspar and quartz with the spare ashes and kaolin after the above treatment;

[0043] (4) Put the above-mentioned mixed materials into a ball mill, add 15% water according to the weight ratio of the mixed materials, and perform ball milling for 27 hours, then pass through a 320-mesh sieve, and then undergo iron removal treatment and mud squeezing to make finished mud;

[0044] (5) The finished mud is reserved after 15 days of conventional ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com