Microwave caulking maintenance vehicle for asphalt pavement repairing

A technology for asphalt pavement and maintenance vehicles, which is applied in road repair, roads, roads, etc. It can solve the problems of unreliable asphalt material at the bottom layer, troublesome construction process, and easy aging of asphalt, so as to achieve uniform temperature between the upper and lower layers of the material layer and improve work reliability. , the effect of reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

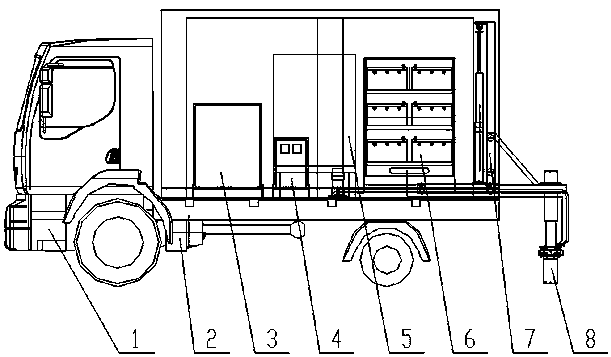

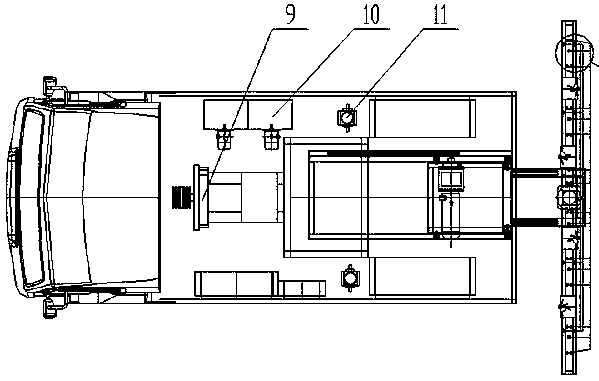

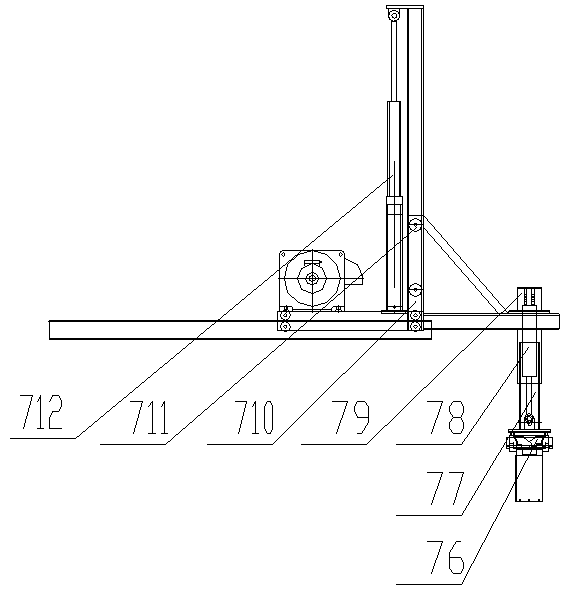

[0036] A microwave seam repairing maintenance vehicle for asphalt pavement maintenance, including a microwave seam repairing device and an adjustment mechanism 7 for adjusting the position of the microwave seam repairing device on the maintenance vehicle;

[0037] The microwave seam repairing device includes a microwave heater 8 and a power supply 9 for powering the microwave heater 8;

[0038] The adjustment mechanism 7 is used to adjust the position of the microwave heater 8 in the X, Y, Z three-axis directions.

[0039] The maintenance vehicle is also provided with a water tank 5 for cooling the microwave heater 8 and providing a cooling medium, and a water pump 11 for delivering the cooling medium to the microwave heater 8 for cooling it,

[0040] A radiator 10 is also provided, and the radiator 10 is used for dissipating heat from the cooling medium that has undergone heat exchange in the water tank 5 .

[0041] The electric energy of the power supply 9: one is obtained ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com