Spiral inner wall crucible furnace

A crucible furnace and spiral technology, which is applied in the field of spiral inner wall crucible furnaces, can solve the problems of increased use cost, influence on the service life of the crucible, damage to the crucible furnace, etc. The effect of improving the efficiency of the energy cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is described in detail below in conjunction with accompanying drawing and specific embodiment:

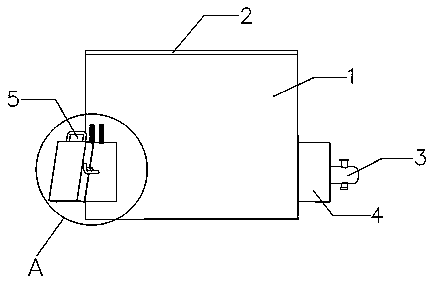

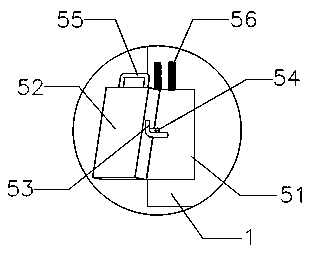

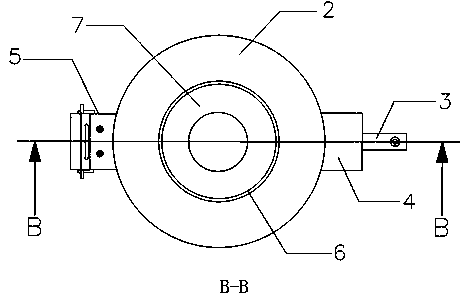

[0022] figure 1 with image 3 A spiral inner wall crucible furnace is shown, comprising a furnace body 1, the furnace body 1 is made of a refractory material into a column, and its exterior is wrapped by an iron sheet; A crucible 6 is placed, the bottom of the crucible 6 is supported by a crucible seat 11 arranged at the center of the bottom of the furnace 9, and the top of the crucible 6 is pressed and fixed by a gland 2 arranged on the top of the furnace body 1. The hearth 9 is sealed, the center of the gland 2 is provided with a soup intake 7 communicating with the inside of the crucible 6, the outer side of the furnace body 1 near the bottom is provided with a flame port 4, and the end surface of the flame port 4 is provided with A connecting hole 10 communicating with the furnace 9, a burner 3 is installed in the connecting hole 10, and the burne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com