Heat-conductive and energy-saving refractory brick used for fire path wall in carbon roasting furnace and preparation method thereof

A refractory brick and roasting technology, which is applied in the field of heat-conducting and energy-saving refractory bricks for the flue wall of carbon roasting furnaces and its preparation, can solve the problems of low softening temperature under load, low thermal shock stability, and low high-temperature flexural strength, and achieve High softening temperature under load, high thermal shock stability, high temperature flexural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

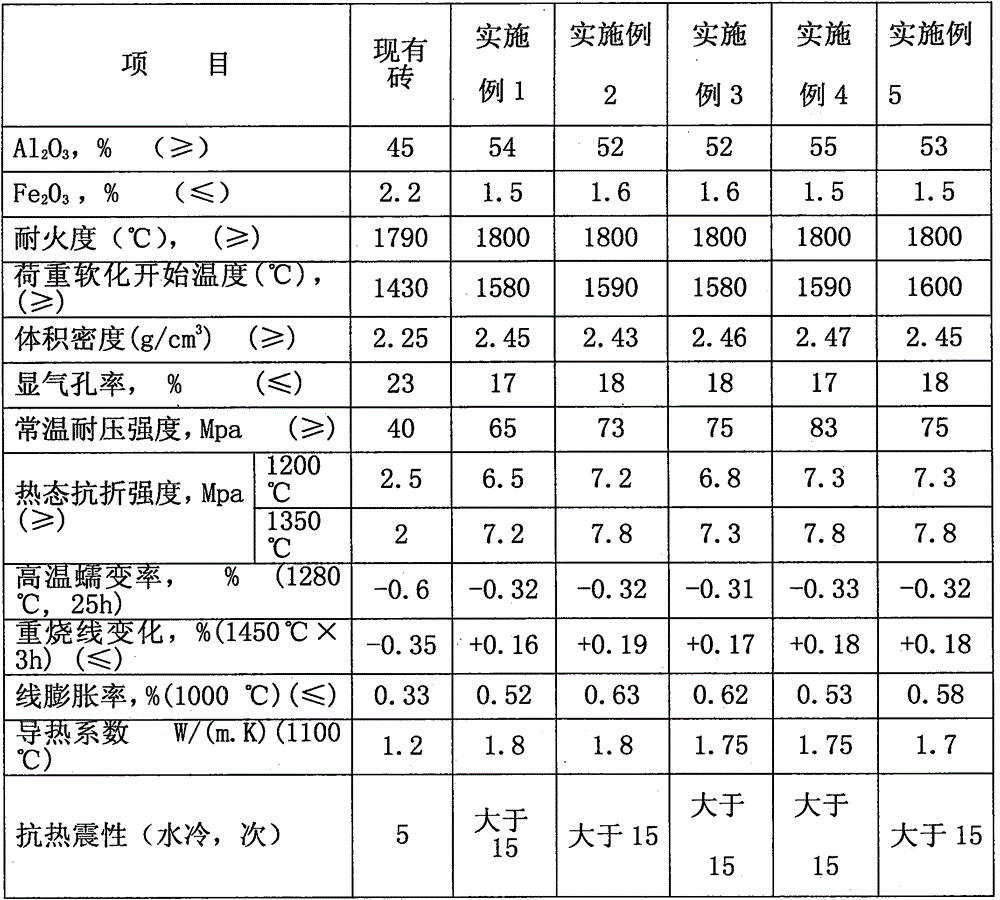

Examples

Embodiment 1

[0040] S1, crushing mullite, andalusite, silicon carbide, tertiary bauxite, and high alumina corundum respectively;

[0041] A1. Crushing the mullite to screen out granular materials with a particle size of 0.1 to 3 mm;

[0042] A2, crushing the three-grade high-alumina bauxite, and screening out the granular material with a particle size of 0.1-5 mm;

[0043] A3, crush the high alumina corundum and andalusite, and screen out the granular material with a particle size of 0.1-1mm;

[0044] S2. Select 16 parts by mass of super-grade high-alumina bauxite, 8 parts by mass of silicon carbide, 10 parts by mass of brown corundum, 5 parts by mass of alumina, 5 parts by mass of high-quality bonded clay, 1 mass part Parts of metal silicon are mixed, co-milled in a ball mill, and processed into a mixed fine powder with a particle size of less than 0.088mm;

[0045]S3, choose the mullite particle of 15 parts by mass, the andalusite particle of 10 parts by mass, the silicon carbide parti...

Embodiment 2

[0050] S1, crushing mullite, andalusite, silicon carbide, tertiary bauxite, and high alumina corundum respectively;

[0051] A1. Crushing the mullite to screen out granular materials with a particle size of 0.1 to 3 mm;

[0052] A2, crushing the three-grade high-alumina bauxite, and screening out the granular material with a particle size of 0.1-5 mm;

[0053] A3, crush high alumina corundum, silicon carbide, andalusite, and screen out the granular material with a particle size of 0.1-1mm;

[0054] S2. Select 20 parts by mass of super-grade high-alumina bauxite, 5 parts by mass of silicon carbide, 5 parts by mass of andalusite, 3 parts by mass of alumina, 10.5 parts by mass of high-quality bonded clay, and 1.5 parts by mass of Parts of metal silicon are mixed, co-milled in a ball mill, and processed into a mixed fine powder with a particle size of less than 0.088mm;

[0055] S3, select the mullite particle of 10 parts by mass, the andalusite particle of 8 parts by mass, the ...

Embodiment 3

[0060] S1, crushing mullite, andalusite, silicon carbide, tertiary bauxite, and high alumina corundum respectively;

[0061] A1. Crushing the mullite to screen out granular materials with a particle size of 0.1 to 3 mm;

[0062] A2, crushing the three-grade high-alumina bauxite, and screening out the granular material with a particle size of 0.1-5 mm;

[0063] A3, crush high alumina corundum, silicon carbide, andalusite, and screen out the granular material with a particle size of 0.1-1mm;

[0064] S2. Select 13 parts by mass of super-grade high-alumina bauxite, 8 parts by mass of silicon carbide, 5 parts by mass of brown corundum, 8 parts by mass of andalusite, 10 parts by mass of high-quality bonded clay, 1 mass part Parts of metal silicon are mixed, co-milled in a ball mill, and processed into a mixed fine powder with a particle size of less than 0.088mm;

[0065] S3, select the mullite particle of 10 parts by mass, the andalusite particle of 5 parts by mass, the silicon ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com