Siphon type dewatering wiper for hot plate blank

A siphon type, wiper technology, applied in lighting and heating equipment, drying solid materials without heating, workpiece surface treatment equipment, etc. To achieve the effect of good promotion and use value, reduce the temperature difference between upper and lower, and easy to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

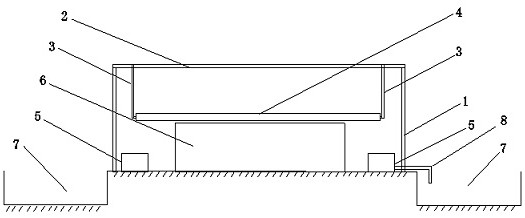

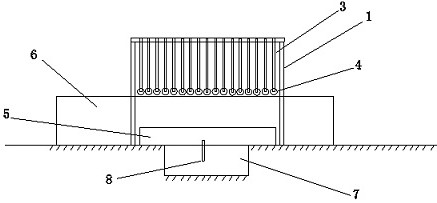

[0020] Below in conjunction with accompanying drawing, the present invention will be further described by examples.

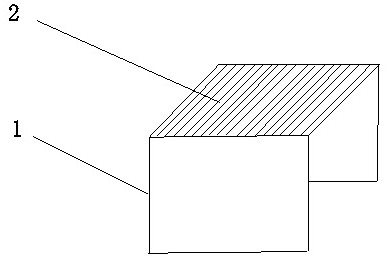

[0021] Refer to attached Figure 1-6 , a hot slab siphon dewatering wiper, comprising a fixed bracket 1, a hoisting connecting rod 3, a siphon dewatering roller 4, a water collection tank 5 and a hot rolling conveying roller table 6, above the hot rolling conveying roller table 6 Along the running direction of the hot slab, there are a plurality of siphon dewatering rollers 4 arranged side by side. The bottom is respectively provided with water collecting tank 5; the roll body of described siphon dewatering roll 4 is the concave roll with thin center and two thick ends, engraved with multiple identical grooves 9 along the axial direction on the surface of the roll body, the grooves 9 is a structure narrow in the middle and wide at both ends.

[0022] In this example, figure 2 It shows that the siphon dewatering rollers 4 are installed in a row along the mov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com