Heating structure at bottom of bin of aluminium anode baking furnace

A technology for anode roasting furnace and bottom heating, which is applied to lighting and heating equipment, furnaces, muffle furnaces, etc. It can solve the problems of low temperature of anode roasting furnace material box, short replacement cycle of flue wall, large temperature difference between upper and lower material boxes, etc. Achieve environmental protection, reduce the roasting curve, reduce the effect of high temperature burning loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited by the embodiments.

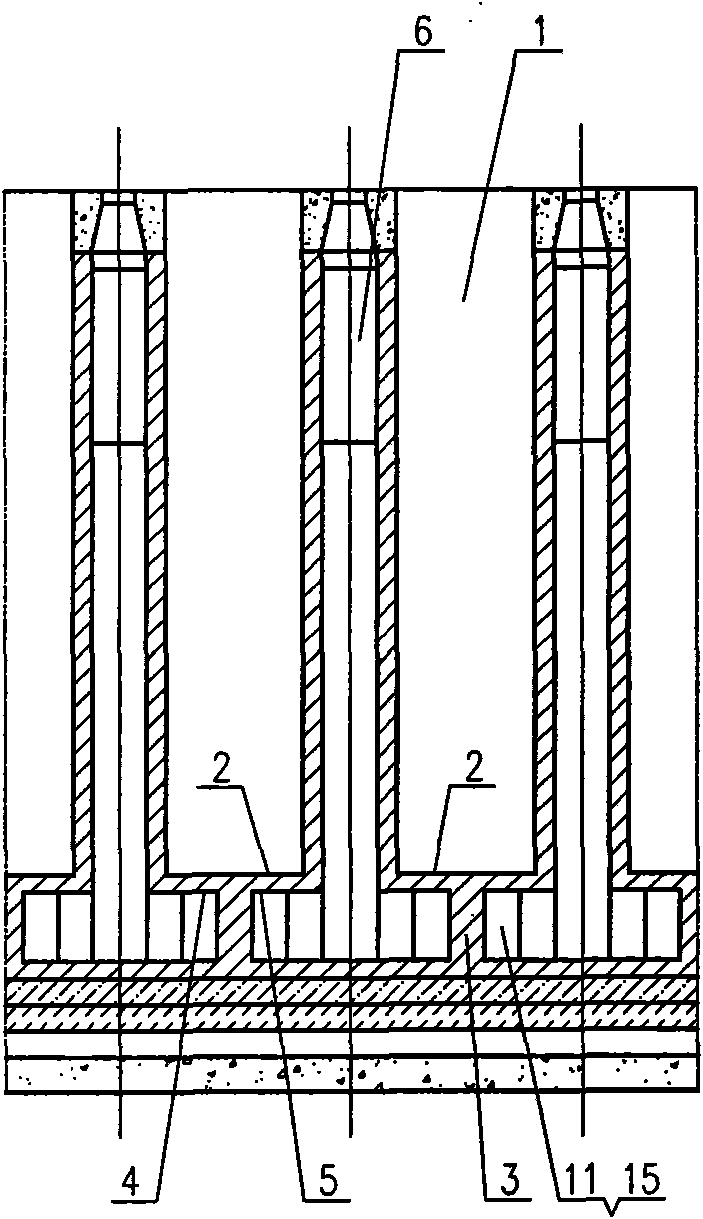

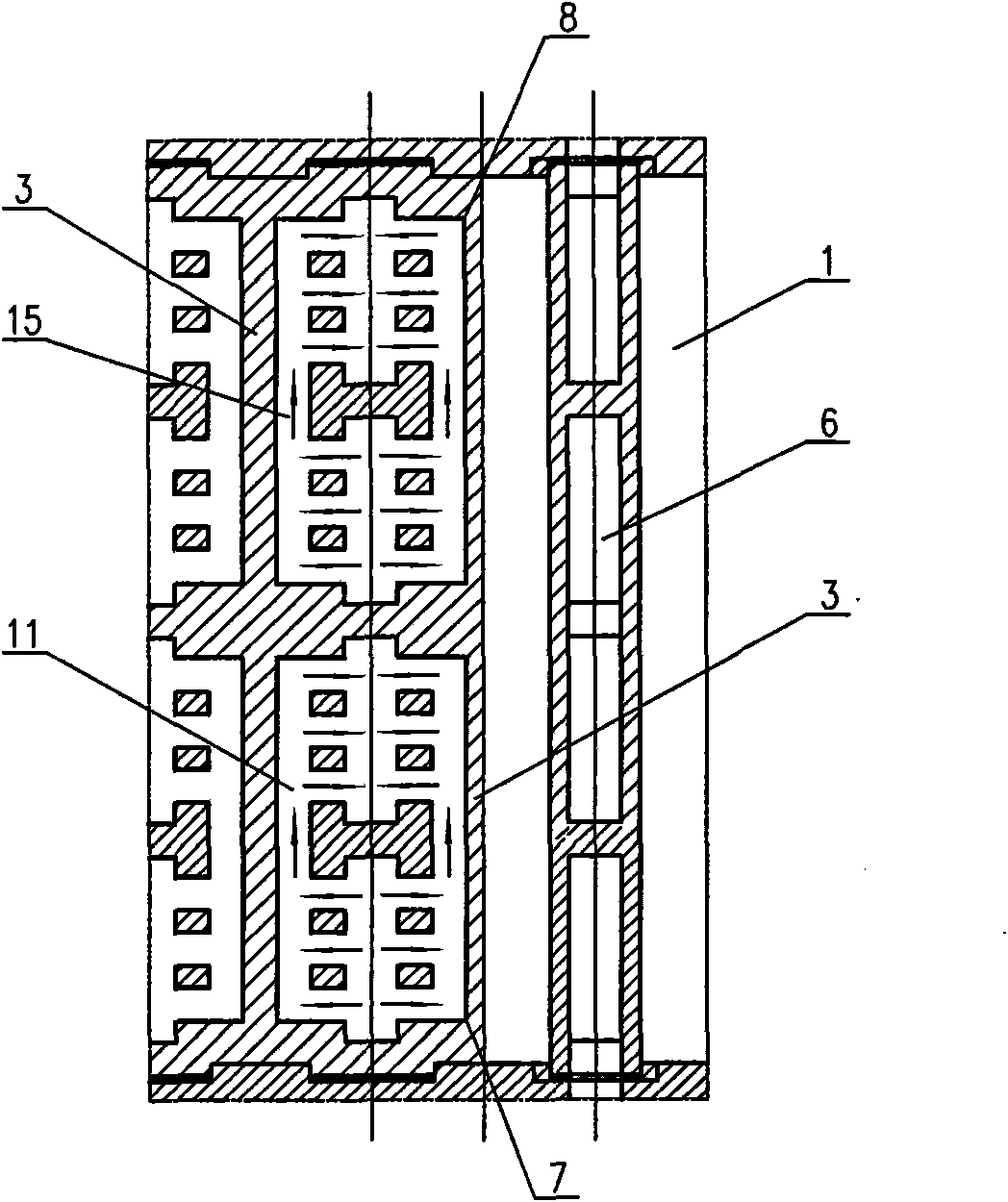

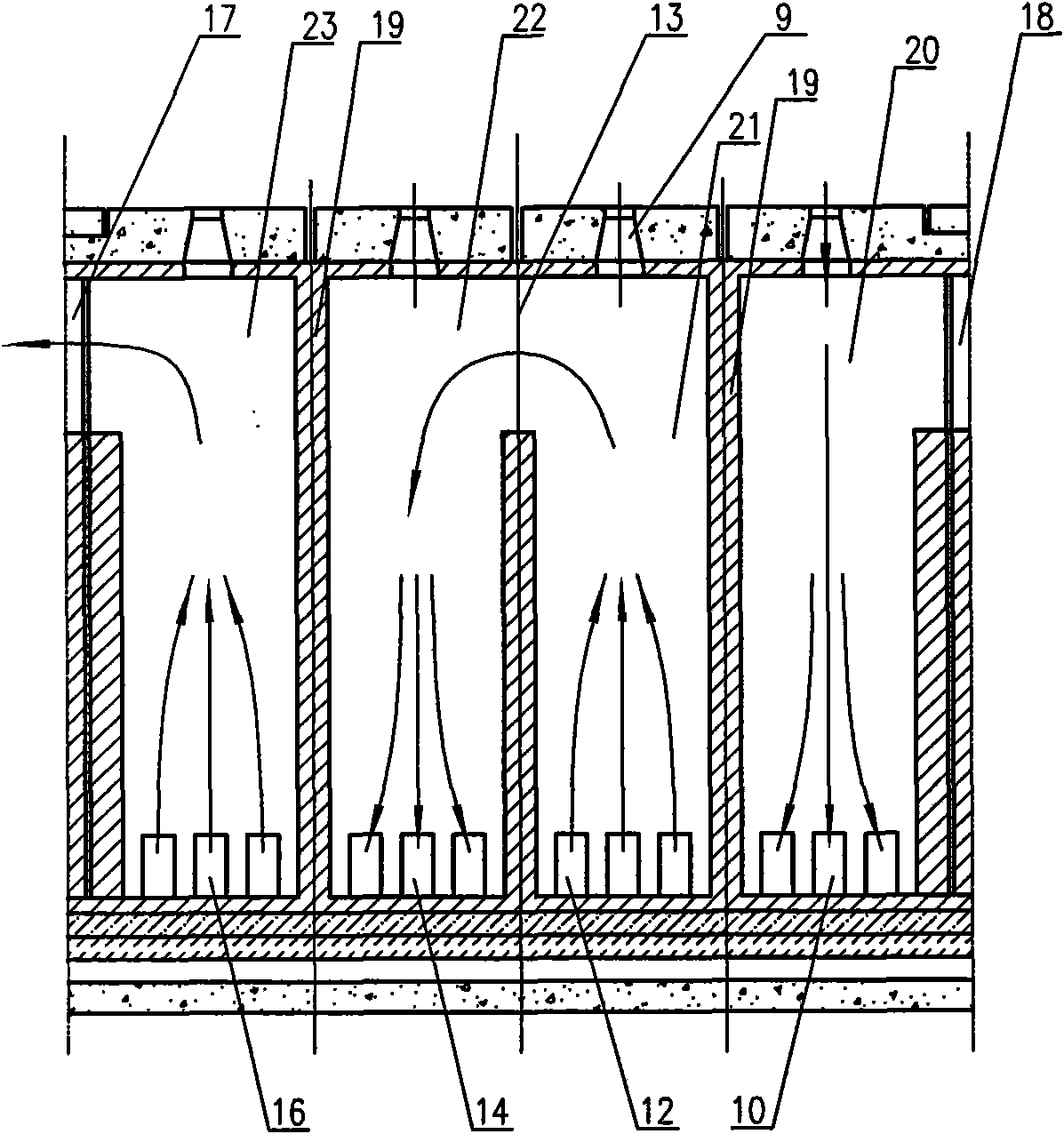

[0031] Such as Figure 1-3 As shown, the heating structure at the bottom of the material box of the anode roasting furnace for aluminum of the present invention includes a material box 1, a fire channel 6 arranged on both sides of the material box 1, a hot material box bottom 2 is provided at the bottom of the material box 1, and a hot material box bottom is provided at the bottom of the thermal material box. In the middle of the lower part of 2, there is an isolation pile 3. On both sides of the isolation pile 3, there are left and right heating zones 4, 5 communicating with the fire channels 6 on both sides of the material box 1. Each left and right heating zone 4, 5 is provided with a front heating section 7 And the rear heating section 8, each fire path 6 is di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com