Emergency tool for facilitating dismounting roller ring on line

A technology for dismantling roll rings and tools, which is applied in manufacturing tools, metal processing equipment, metal rolling, etc., can solve problems such as the limit of pressure for pulling out roll rings, difficult use of disassembly tools, and failure to pull out roll rings, etc., to improve production Efficiency, on-site use and easy replacement, and the effect of avoiding production delays

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

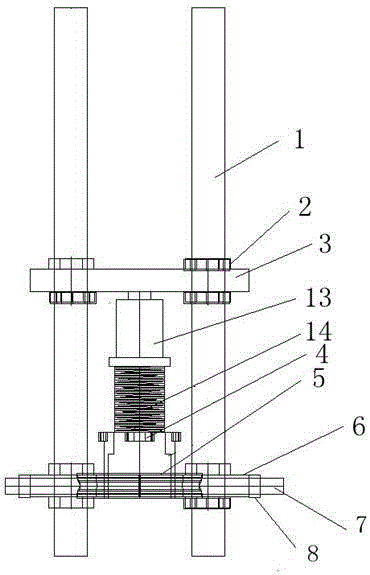

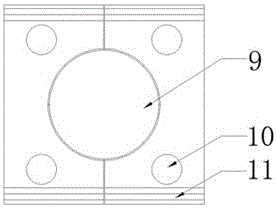

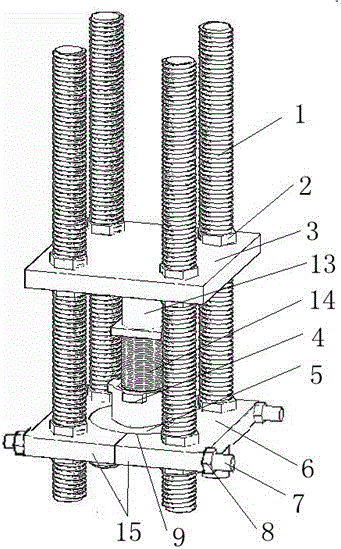

[0019] Embodiment 1: as figure 1 , 2 A kind of emergency tool that facilitates online dismantling of the roll collar shown in and 3, the emergency tool is fixedly installed on the end of the roller shaft 14, and the emergency tool includes a working plate 6, a support plate 3, a traction screw 1, and adjusting Screw rod 7 and jack 13, described working board and 6 supporting boards 3 are all provided with four positioning through holes 10 and 12, working board 6 and supporting board 3 are connected into a whole by four traction screw rods 1, working board 6 It is arranged below the support plate 3, the center of the working plate 6 is provided with a roller ring fixing hole 9, the working plate 6 is composed of two positioning plates 15 of the same size, and the bottom of the supporting plate is provided with Jack 13, said jack 13 is installed directly above the roller ring fixing hole 9.

Embodiment 2

[0020] Embodiment 2: as figure 1 , 2 As shown in and 3, the positioning plate 15 is provided with a transverse through hole 11, and the adjusting screw 7 is movably installed in the transverse through hole 11, and the two positioning plates 15 are connected into one by the adjusting screw 7 in the transverse through hole 11. Overall; the working plate 6 is divided into two parts from the middle, which is convenient for installation on roller rings of different sizes. The main function of the adjustment screw 7 is to facilitate the opening of the fixing hole 9 of the roller ring, which facilitates the fixing and positioning of the roller ring 5. The connection is tight and convenient. Disassembly work of roller ring 5.

Embodiment 3

[0021] Embodiment 3: as figure 1 , 2 As shown in and 3, the upper and lower sides of the working plate 6 are provided with lock nuts 2 connected to the draw screw 1, and the upper and lower sides of the support plate 3 are provided with lock nuts 2 connected to the draw screw 1; The left and right ends of the support plate 3 described in the invention are provided with locking nuts 8 connected to the adjusting screw 7; Nut 2, the connection between the screw rod and the two plates is stable, which improves the stability of the disassembly work.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com