Thickness gauge and its use and maintenance method

A technology for thickness gauges and signal detectors, applied in instruments, measuring devices, and using wave/particle radiation, etc., can solve the problems of insulation oil performance degradation, work performance and reliability degradation, oil temperature rise, etc., to achieve flexible Effects of exercise and radiation reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the embodiments and accompanying drawings. The embodiments are only used to explain the present invention and do not constitute a limitation of the protection scope of the present invention.

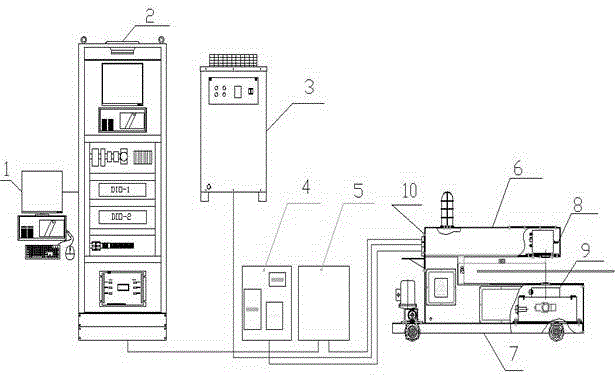

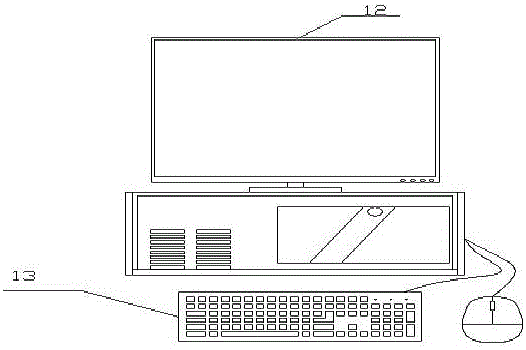

[0044] Attached below figure 1 Describe the preferred embodiment of the present invention in detail: the thickness gauge in the present invention consists of a C-shaped frame: a signal detector 8 comprising the upper cantilever 6, a ray source 9 of the lower cantilever 7, a junction box 5, an air control box, and an electrical room The main electrical cabinet 2 and the operation terminal 1 are composed.

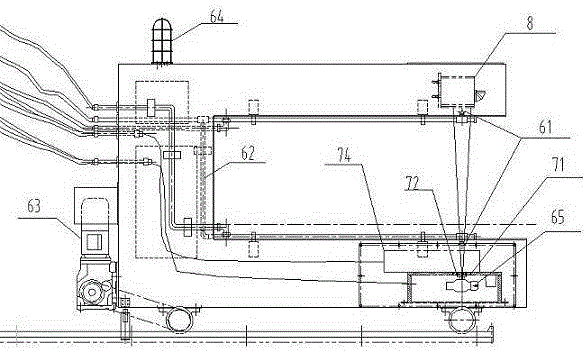

[0045] The ray source 9 (at the lower cantilever 7) and the detector (the signal detector 8 of the upper cantilever 6) of the thickness gauge are installed on the C-shaped frame. The traveling driving device 62 is housed on the C-shaped frame, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com