Centrifugal air compressor system for large-scale air separation

An air compressor and air separation technology, applied in the field of air compressors, can solve the problems of practicality and long repair time, and achieve the effects of considerable benefits, reduced energy consumption, and considerable economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

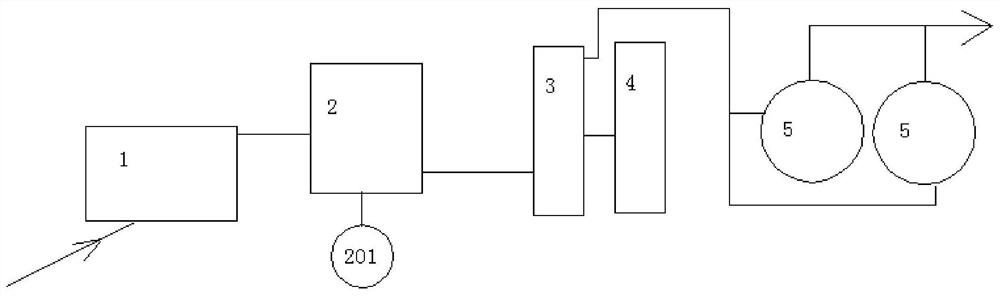

[0029] Please refer to figure 1 , the present embodiment provides a large centrifugal air compressor system for air separation, including:

[0030] Self-cleaning filter, the input end of the self-cleaning filter 1 is connected to the air inlet, the output end of the self-cleaning filter 1 is connected to the centrifugal air compressor 2 , and the centrifugal air compressor 2 is electrically connected to the motor 201 . The centrifugal air compressor 2 is connected to the air cooling tower 3; the air cooling tower 3 is respectively connected to the water cooling tower 4 and the molecular sieve 5; the molecular sieve 5 is connected to the air outlet.

[0031] The large-scale centrifugal air compressor system for air separation provided in this embodiment uses a large-scale centrifuge for air separation to transform the air supply, and its general air supply capacity is 2000-3000Nm3 / min, which is basically 10% of the air supply capacity of existing small air compressors. times, ...

Embodiment 2

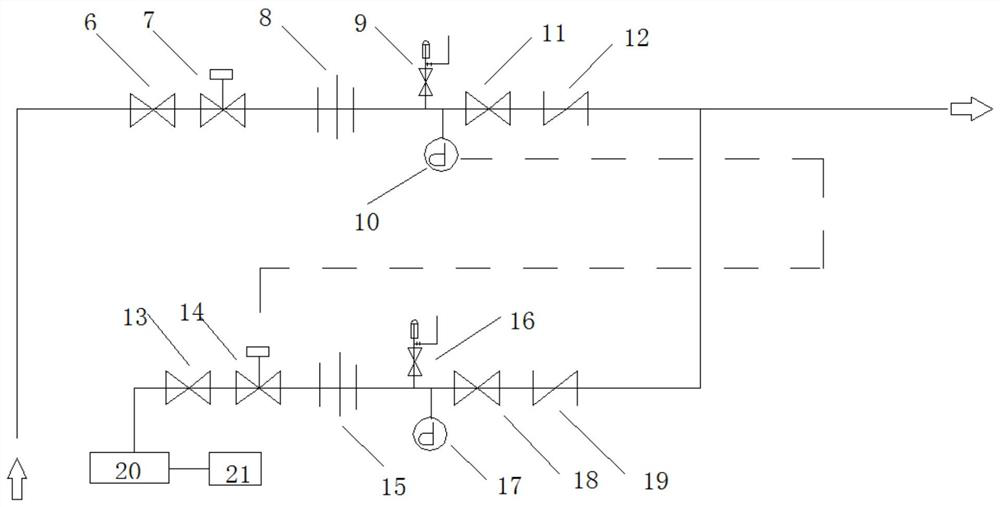

[0033] Please refer to figure 1 , figure 2 and image 3 , the present embodiment provides a large centrifugal air compressor system for air separation, including:

[0034] Self-cleaning filter, the input end of the self-cleaning filter 1 is connected to the air inlet, the output end of the self-cleaning filter 1 is connected to the centrifugal air compressor 2 , and the centrifugal air compressor 2 is electrically connected to the motor 201 . The centrifugal air compressor 2 is connected to the air cooling tower 3; the air cooling tower 3 is respectively connected to the water cooling tower 4 and the molecular sieve 5; the molecular sieve 5 is connected to the air outlet.

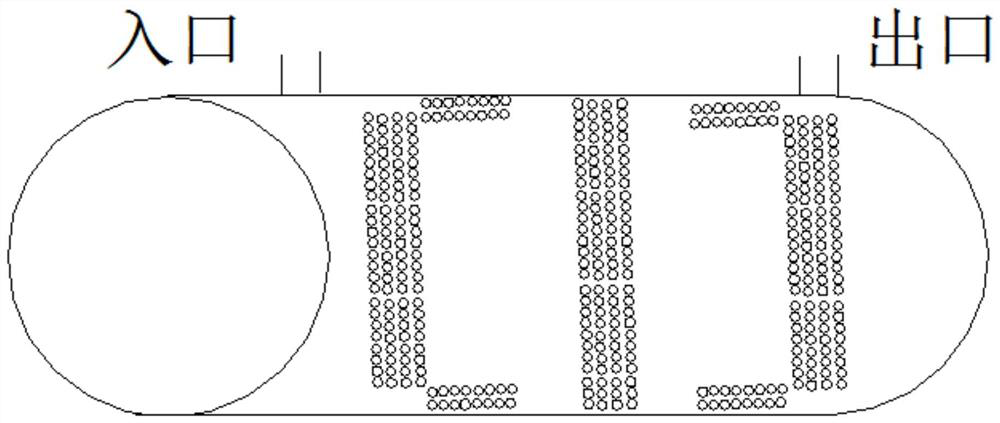

[0035] Among them, there are multiple molecular sieves 5, all of which are connected to the air cooling tower 3, and the desiccant in each molecular sieve 5 is filled with a grid interval structure. The small air compressor is equipped with a domestic inner-filled aluminum oxide dryer, with a flow capac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com