Group control method for deviation rectification of conveyor belt and detection and correction system thereof

A conveyor belt and group control technology, which is applied in the direction of conveyor control devices, conveyors, conveyor objects, etc., can solve problems such as the inability to provide long-distance conveyor belt deviation and return to the center, and the inability to achieve deviation correction effects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] In order to elaborate the technical content, achieved purpose and effect of the present invention, the following will be described in detail in conjunction with the accompanying drawings.

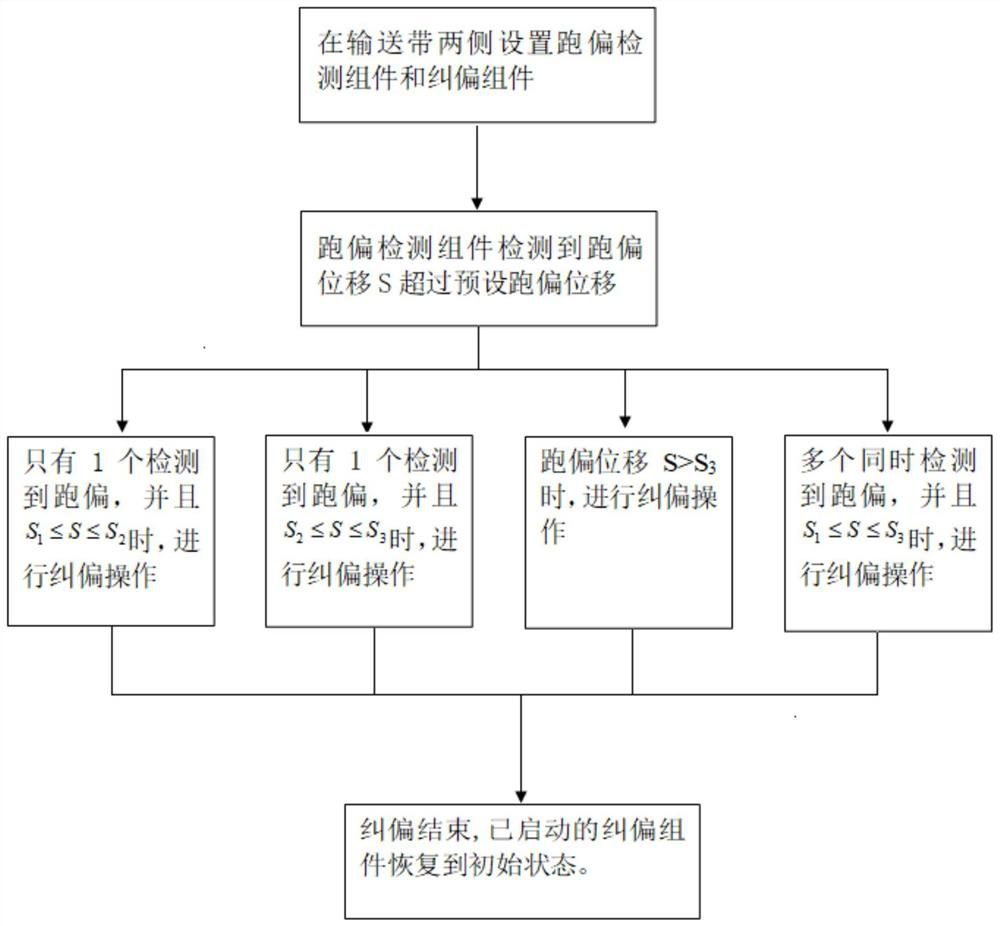

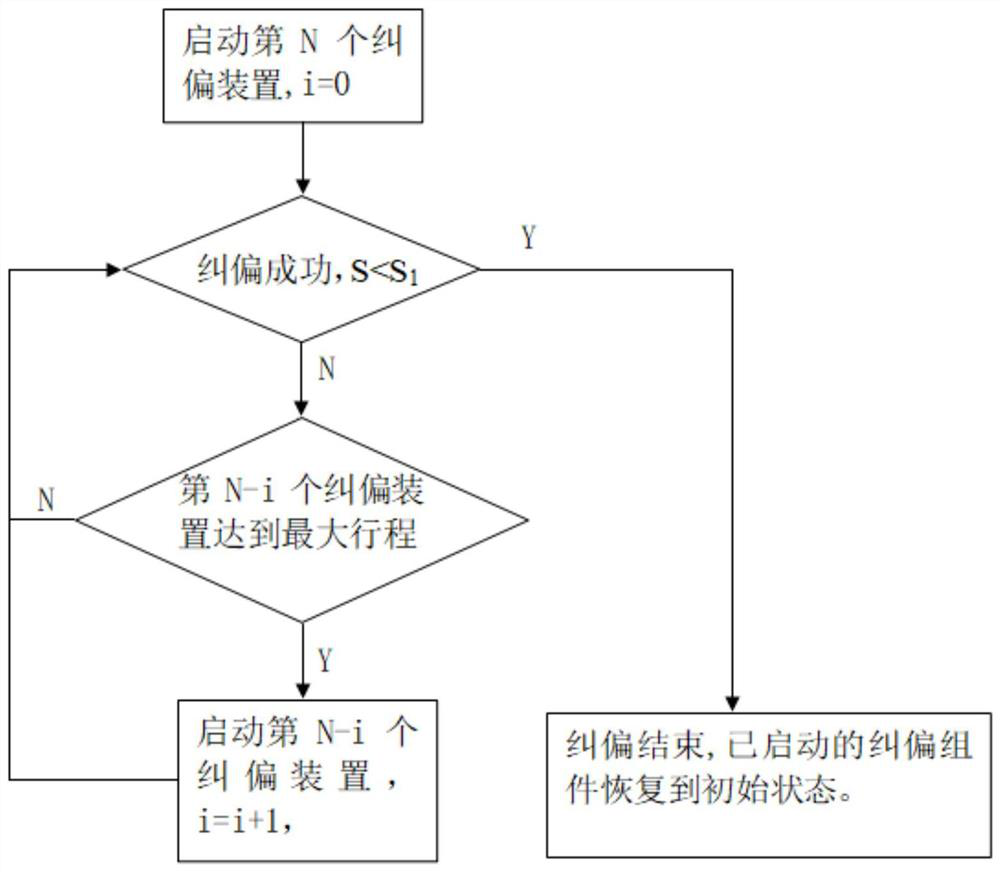

[0053] Group control methods for conveyor belt deflection correction, such as figure 2 As shown, the specific implementation steps are as follows:

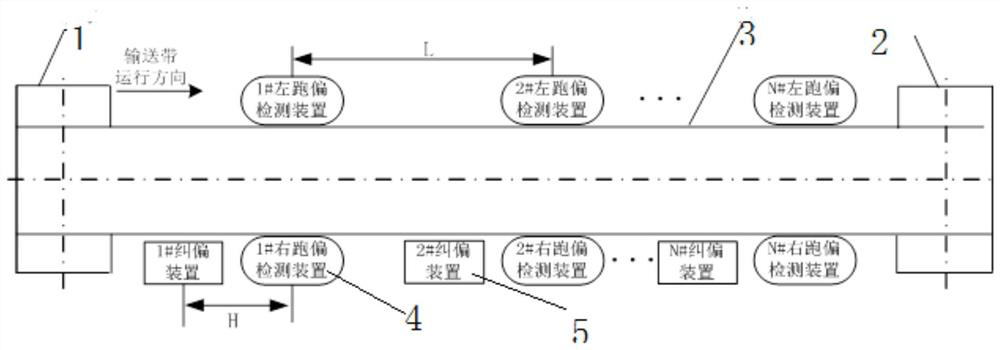

[0054] S1, according to the length of the conveyor belt 3, such as figure 1 As shown, multiple sets of deviation detection components 4 are arranged on both sides of the conveyor belt 3, and at a distance H upstream of the deviation detection component 4, a corresponding deviation correction component 5 is set, and the conveyor belt 3 is sequentially moved from upstream to downstream. The deviation detection components 4 are numbered from 1 to Z, and each deviation correction component 5 has the same number as the corresponding deviation detection component 4 .

[0055] S2. The deviation detection component 4 detects the deviation dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com