Patents

Literature

201 results about "Task network" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Task Network is a form to represent (visualize) dependency between actions to show how they are arranged into the correct/planned order. Example of a task network is a project activity diagram or WBS where particular tasks are linked up to each other to show their impact within project plan.

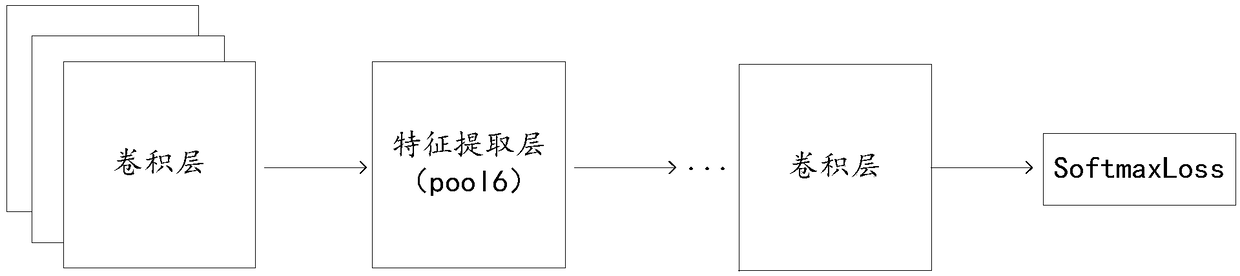

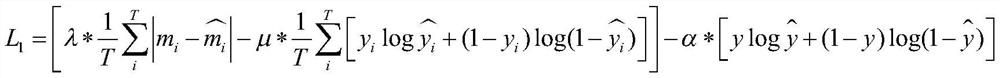

Multi-task learning convolutional neural network-based face attribute analysis method

ActiveCN106529402AImprove generalization abilityCalculation speedCharacter and pattern recognitionTask networkMulti attribute analysis

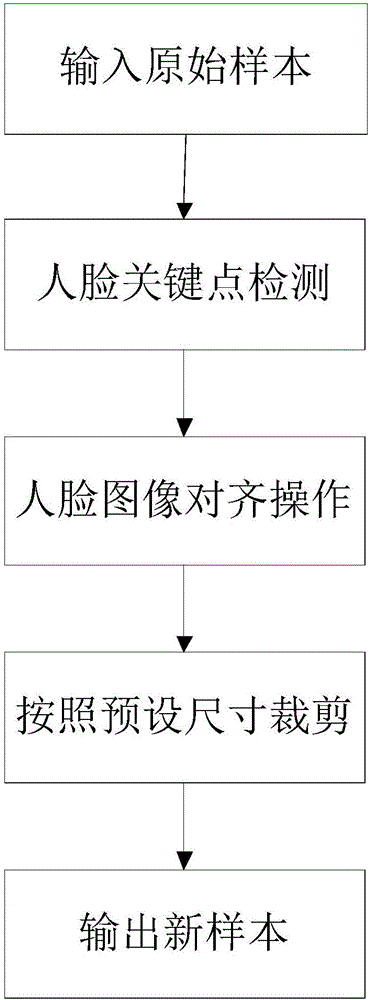

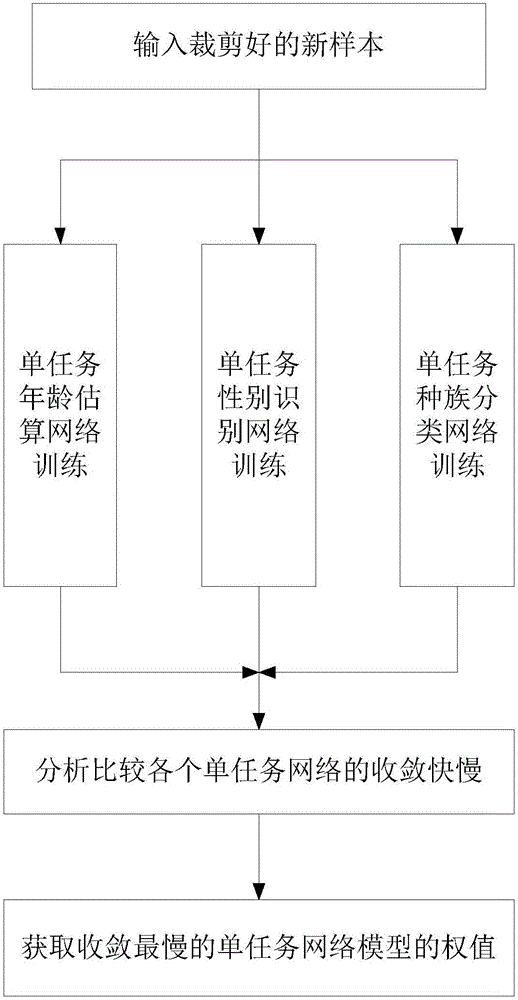

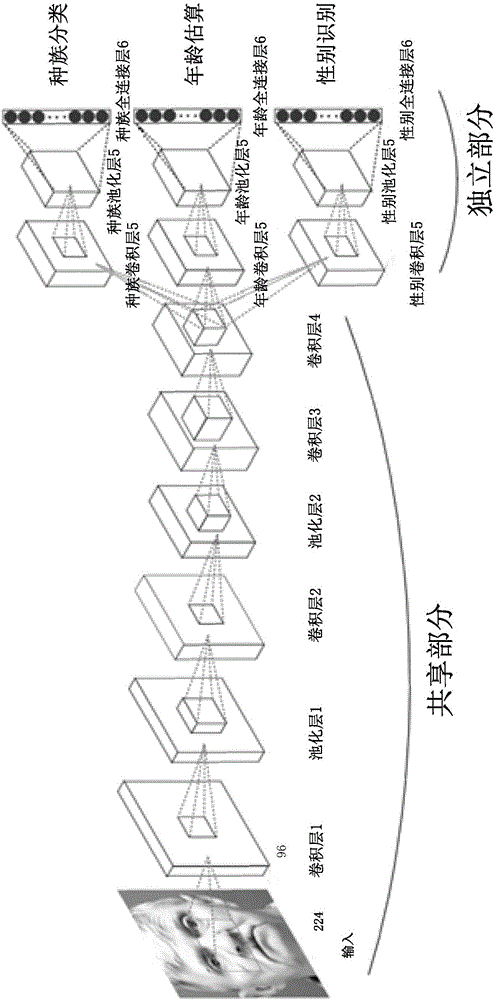

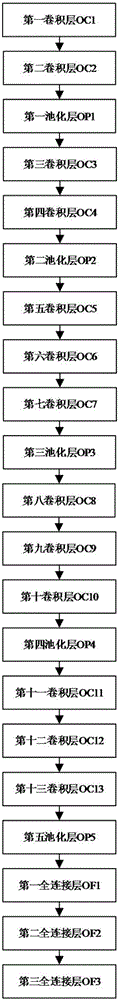

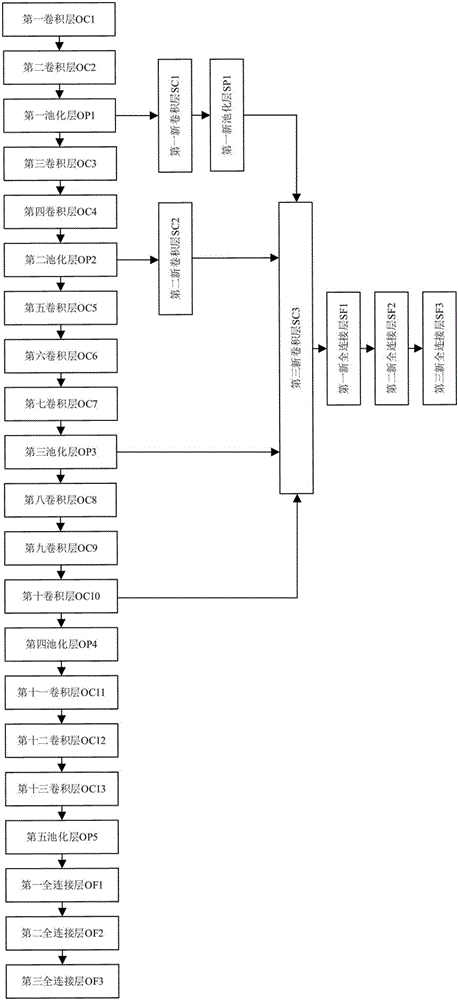

The present invention discloses a multi-task learning convolutional neural network (CNN)-based face attribute analysis method. According to the method, based on a convolutional neural network, a multi-task learning method is adopted to carry out age estimation, gender identification and race classification on a face image simultaneously. In a traditional processing method, when face multi-attribute analysis is carried out, a plurality of times of calculation are required, and as a result, time can be wasted, and the generalization ability of a model is decreased. According to the method of the invention, three single-task networks are trained separately; the weight of a network with the lowest convergence speed is adopted to initialize the shared part of a multi-task network, and the independent parts of the multi-task network are initialized randomly; and the multi-task network is trained, so that a multi-task convolutional neural network (CNN) model can be obtained; and the trained multi-task convolutional neural network (CNN) model is adopted to carry out age, gender and race analysis on an inputted face image simultaneously, and therefore, time can be saved, and accuracy is high.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI

Scene and target identification method and device based on multi-task learning

InactiveCN106845549ARealize integrated identificationImprove single-task recognition accuracyCharacter and pattern recognitionNeural architecturesTask networkGoal recognition

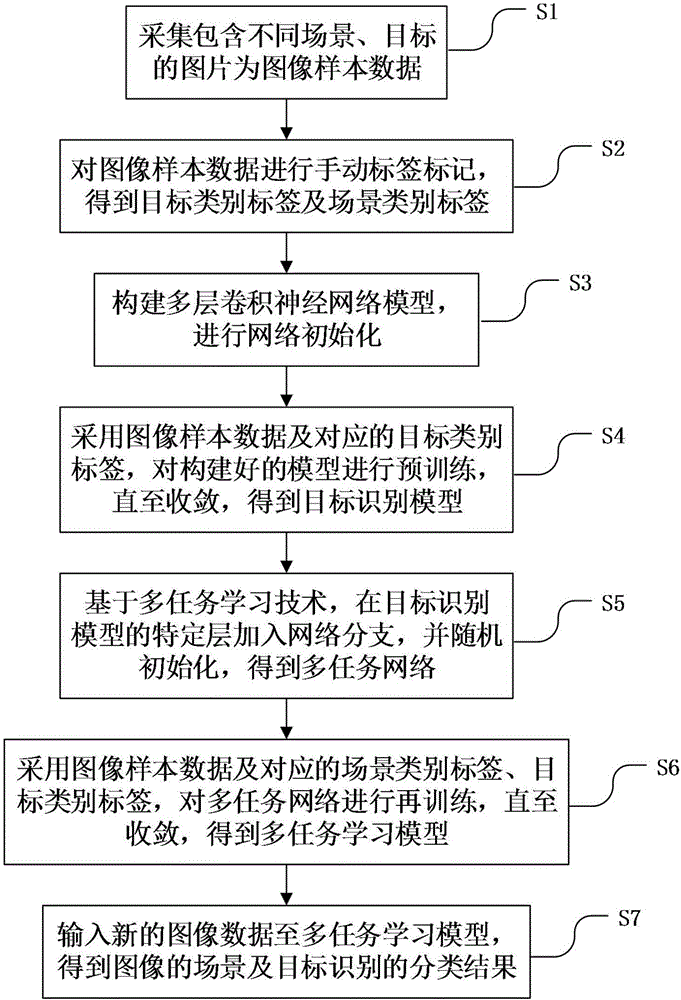

The invention relates to a scene and target identification method and device based on multi-task learning. The method comprises the steps that pictures containing different scenes and targets are collected as image sample data; the image sample data is subjected to manual label marking, and target class labels and scene class labels are obtained; a multi-layer convolutional neural network model is built, and network initialization is conducted; the image sample data and the corresponding target class labels are adopted for pre-training the built model till convergence, and a target identification model is obtained; based on a multi-task learning technology, network branches are added into a specific layer of the target identification model, random initialization is conducted, and a multi-task network is obtained; the image sample data and the corresponding scene class labels and target class labels are adopted for e-training the multi-task network till convergence, and a multi-task learning model is obtained; new image data is input to the multi-task learning model, and classification results of scene and target identification of images are obtained. Accordingly, the single task identification precision is improved.

Owner:珠海习悦信息技术有限公司

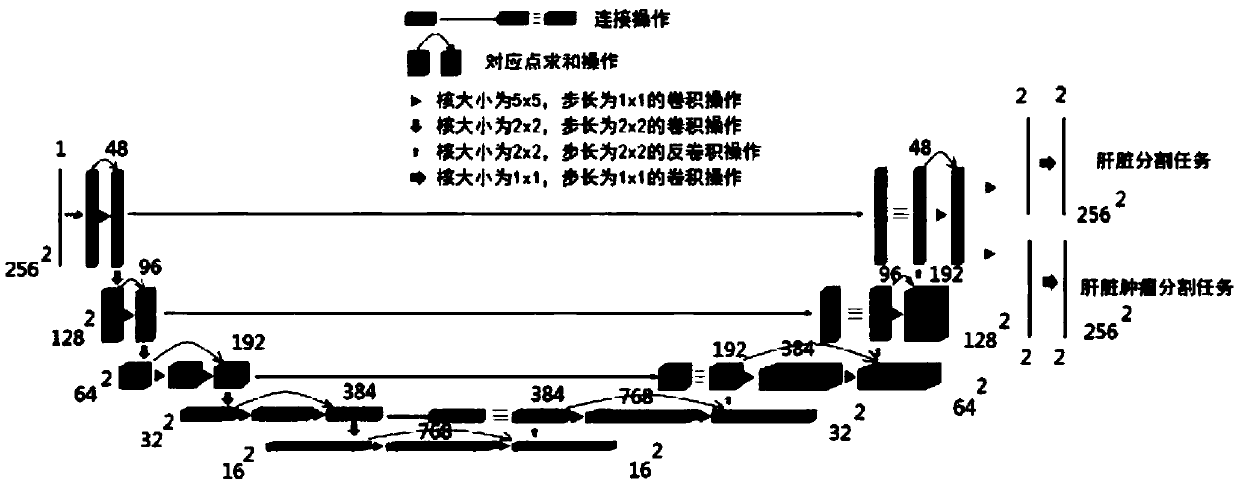

Liver and tumor segmentation method and system based on multitask deep convolution network

ActiveCN107784647AImprove Segmentation AccuracyFast learningImage enhancementImage analysisTask networkFeature extraction

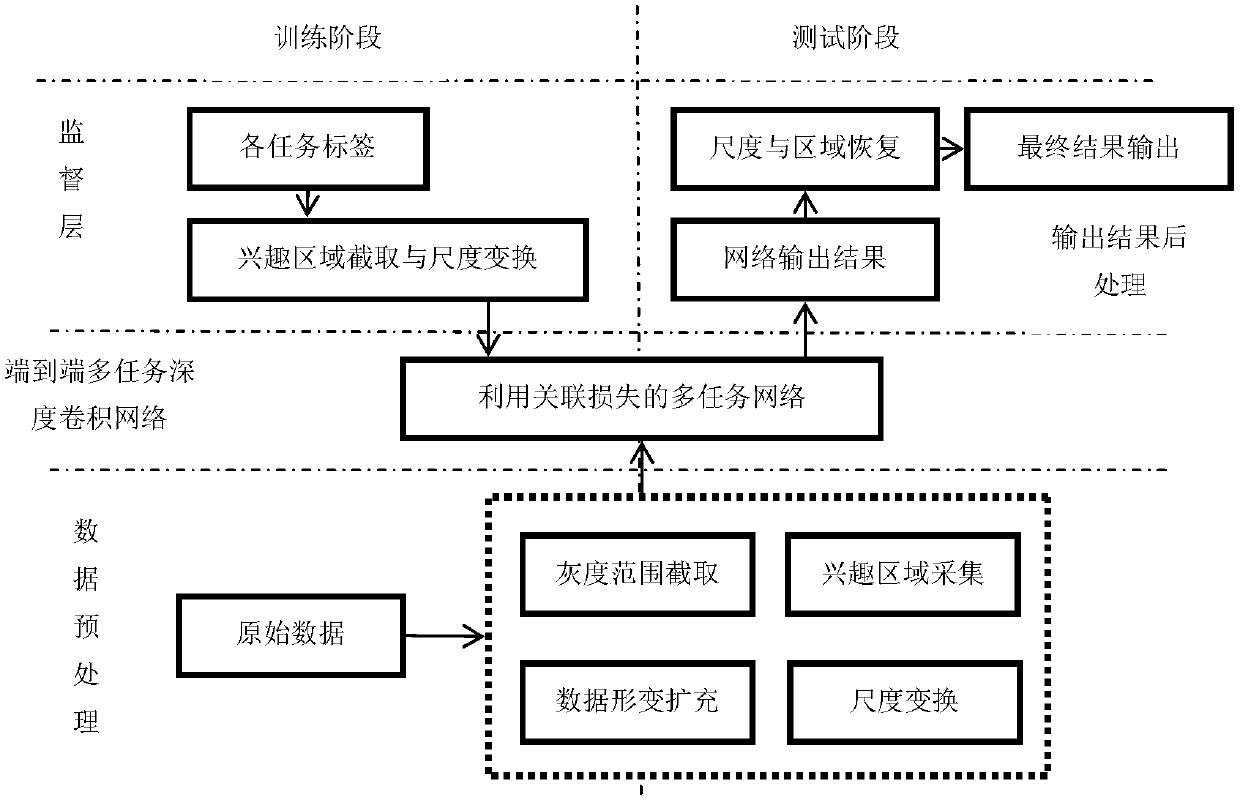

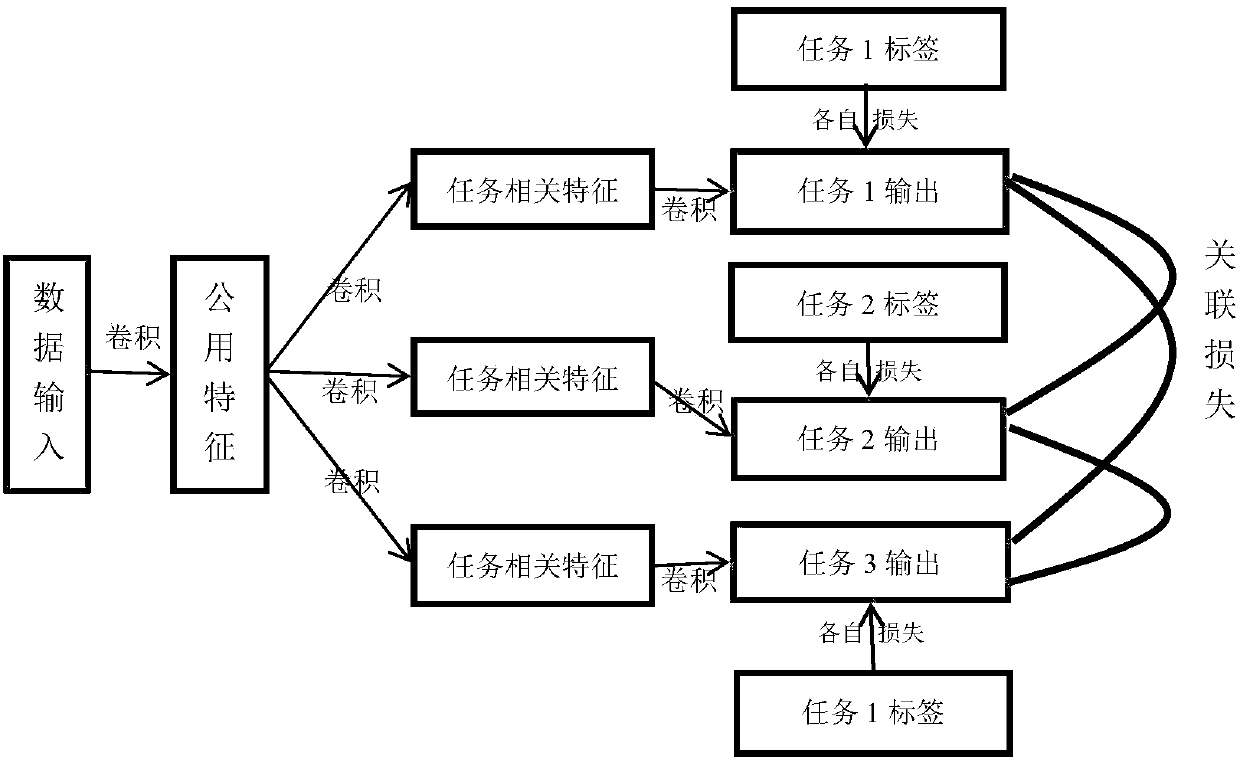

The invention provides a liver and tumor segmentation method and system based on multitask deep convolution network. The method comprises the steps of conducting data pre-processing and expanding; establishing the multitask deep convolution network; establishing a supervising layer having inter-task constraint; conducting network training; generating data test result. The invention is advantageousin that the multitask network includes two pathways, which are respectively used for realizing the identification and segmentation of liver and liver tumor; through sharing of the pathway part, the volume of the deep convolution network can be reduced, and the demand of model learning on the training data amount can be reduced; through connecting to a characteristic extracting module relevant torespective task and a corresponding output module after the sharing of the pathways, the multitask output can be realized; the aim of mutual constraint of the liver and liver tumor can be achieved bymeans of a supervising and learning module of multitask geometrical association information; liver and liver tumor can be accurately identified and segmented.

Owner:HUAQIAO UNIVERSITY

Network downloading method

InactiveCN101383751AEfficient use ofQuick downloadProgram initiation/switchingStore-and-forward switching systemsTask networkError processing

The invention relates to a task scheduling technology in a network downloading system. The technical problem that the invention aims to solve is to provide a network downloading method for a downloading system to automatically conduct downloading task scheduling. The network downloading method of the invention is added with technical measures of downloading task number limitation, downloading-speed detection, downloading task PRI, downloading mode mutex, error processing mechanism, and the like which ensure that the invention can more effectively use the network resource to more rapidly download content resource, and is applicable to various multi-mode multi-task network downloading systems.

Owner:SICHUAN CHANGHONG ELECTRIC CO LTD

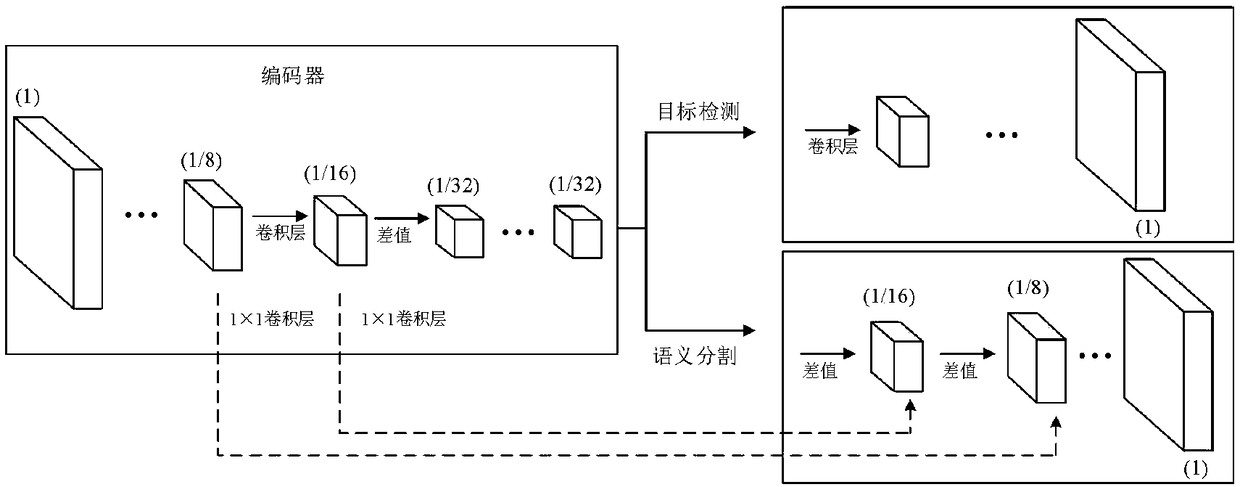

A traffic scene analysis method based on a multi-task network

InactiveCN108985250AMake up for the lossRich image featuresCharacter and pattern recognitionNeural architecturesTask networkTraffic scene analysis

The invention discloses a traffic scene analysis method based on a multi-task network, comprising the following steps: a multi-task network is divided into an encoder, a partition decoder and a detection decoder, wherein the encoder extracts the features of the image and extracts the multi-scale information from the feature map; the segmentation decoder enlarges the size of the feature map and fuses it with the feature map; the detection decoder processes the input characteristic map and outputs a corresponding target detection result; using a deep learning framework Tensorflow to configure, train and test the above multitasking network. The multi-task network of the invention can extract abundant image features, make up for the loss of image detail information caused by downsampling in the encoder, and help to improve the segmentation and detection effect. The invention designs a multi-task network structure, which can realize semantic segmentation and target detection of traffic scene images through one-time back propagation, and has better real-time performance and higher accuracy rate.

Owner:DALIAN UNIV OF TECH

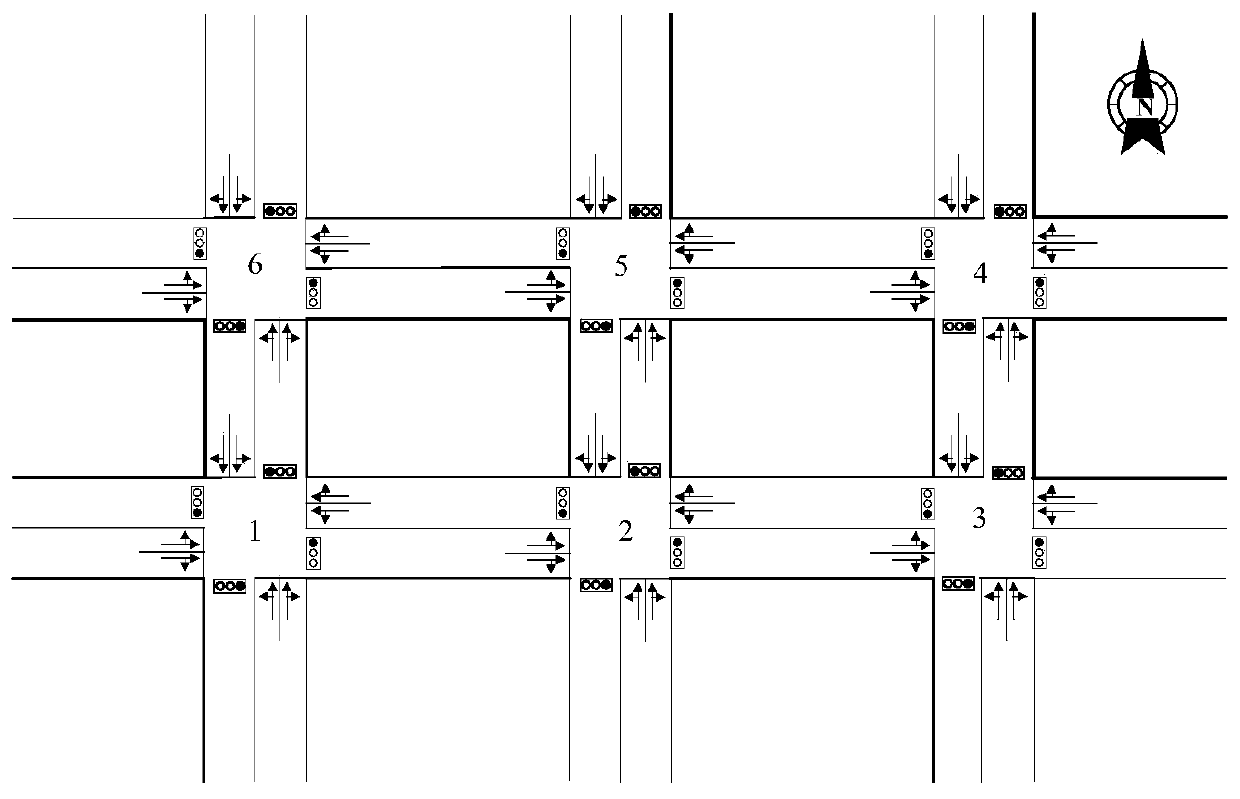

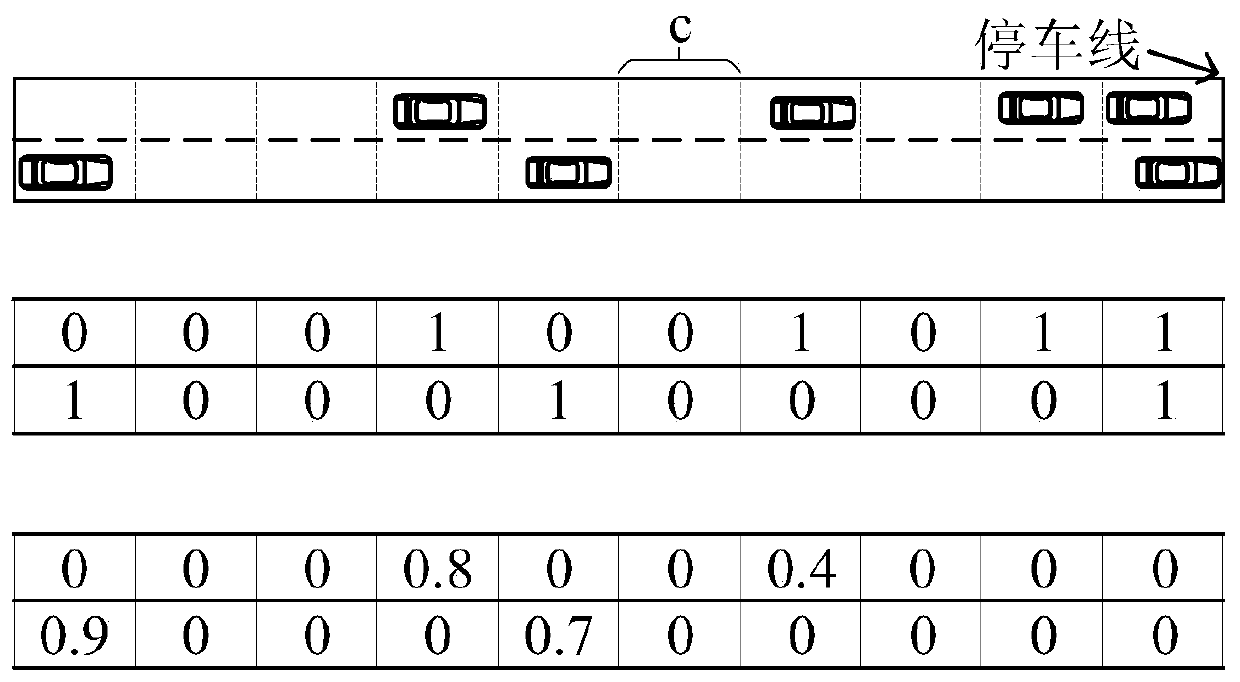

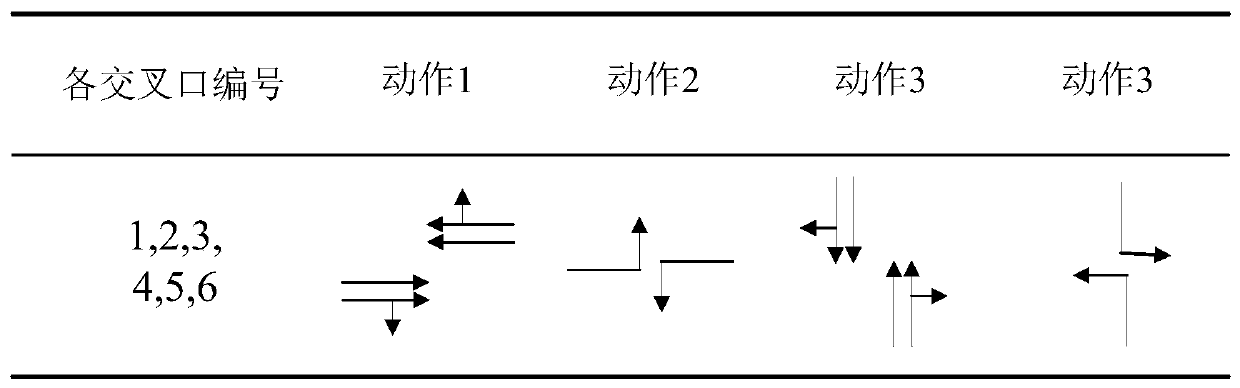

Multi-intersection cooperative traffic light control method based on Q-value migration of multi-task deep Q network

ActiveCN110264750AImprove traffic efficiencyReduce congestionData processing applicationsRoad vehicles traffic controlExtensibilityTraffic capacity

The invention, which belongs to the crossing field of artificial intelligence and intelligent transportation, provides a multi-intersection cooperative traffic light control method based on Q-value migration of a multi-task deep Q network. Multiple intersections are modeled into a multi-agent system; a multi-task network that is suitable for controlling of each intersection traffic light is trained at multiple intersections; knowledge learned at the multiple intersections is applied to a target problem, so that the multi-task network have much more knowledge than the single network and the single intersection feature extraction capacity is enhanced; and then on the basis of a cooperative algorithm, traffic lights of all intersections in a target area are controlled cooperatively. Therefore, the traffic flows of all intersections can be balanced to a certain degree; the road utilization rate in the regional traffic can be increased; the vehicle queuing length can be reduced; and the traffic congestion can be alleviated. The method has the high scalability to the traffic network.

Owner:DALIAN UNIV OF TECH

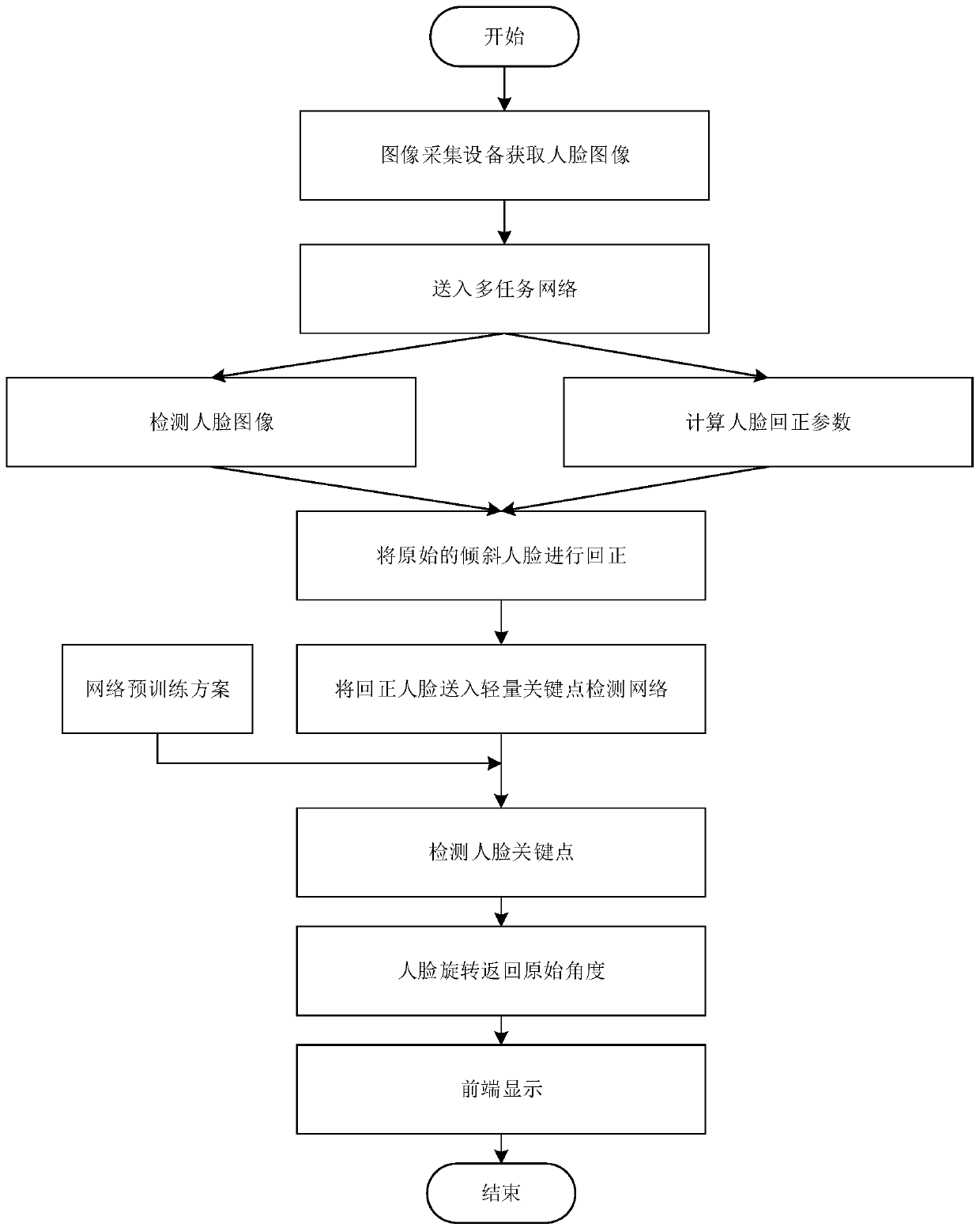

Lightweight human face key point detection method and system based on convolutional network and storage medium

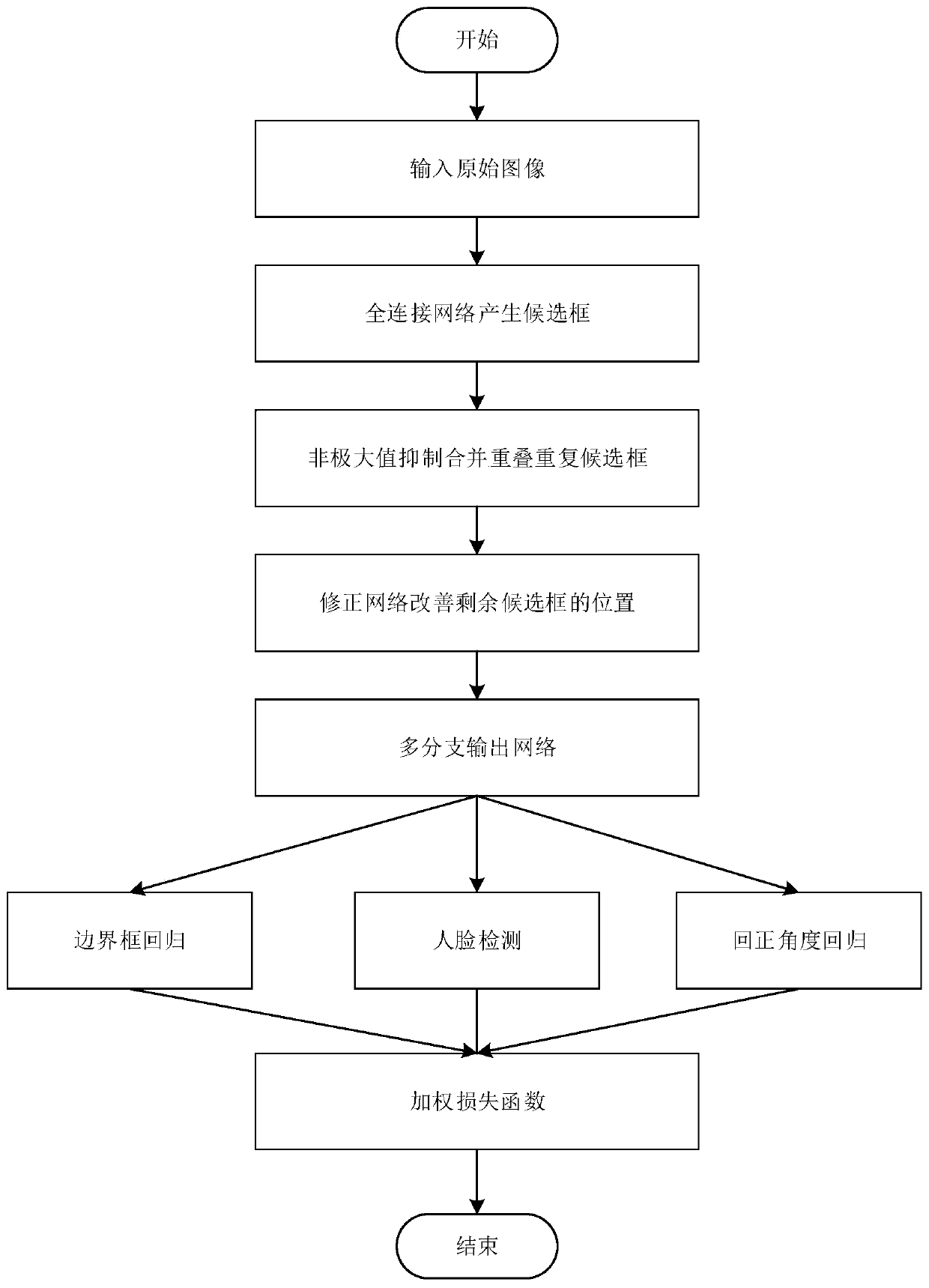

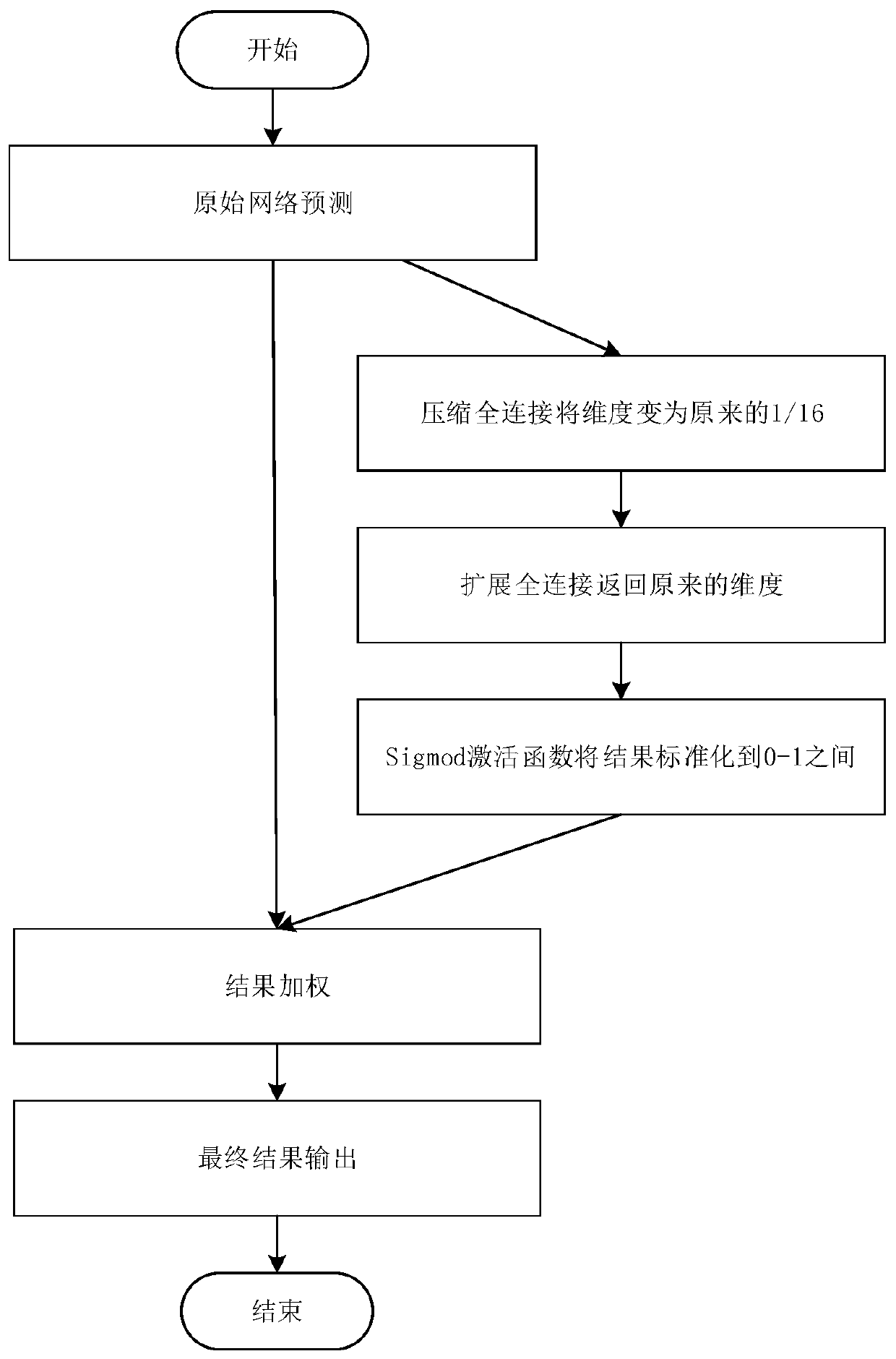

InactiveCN109711258AAlleviate loss function imbalance problemReduce complexityCharacter and pattern recognitionNeural architecturesFace detectionTask network

The invention provides a convolutional network-based lightweight face key point detection method and system, and a storage medium, and the method comprises the steps: employing a multi-task network tocomplete the face detection and face alignment parameter calculation in parallel, and carrying out the alignment of an original inclined face; sending the return face into a light weight key point detection network; detecting face key points, for a multi-face key point detection task,using a pre-training scheme of non-frozen transfer learning, training multiple face key points step by step, and using a parallel face aligning mechanism during training; face rotation return original angle. The method has the beneficial effects that the method is improved according to the characteristics of a face key point detection task, an attention mechanism is introduced to score and select the network output of the convolutional network, and the problem of loss function imbalance of face key point detection is relieved; and a face detection task and a face return parameter calculation task are synchronously trained, so that the efficiency of the overall architecture is improved, and the model complexity is reduced.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

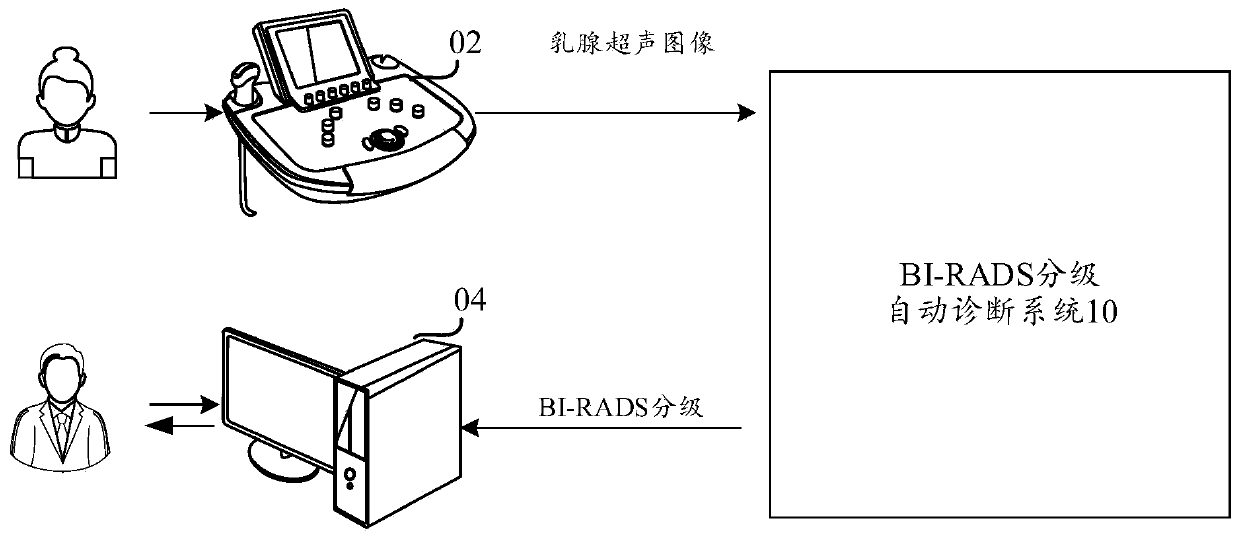

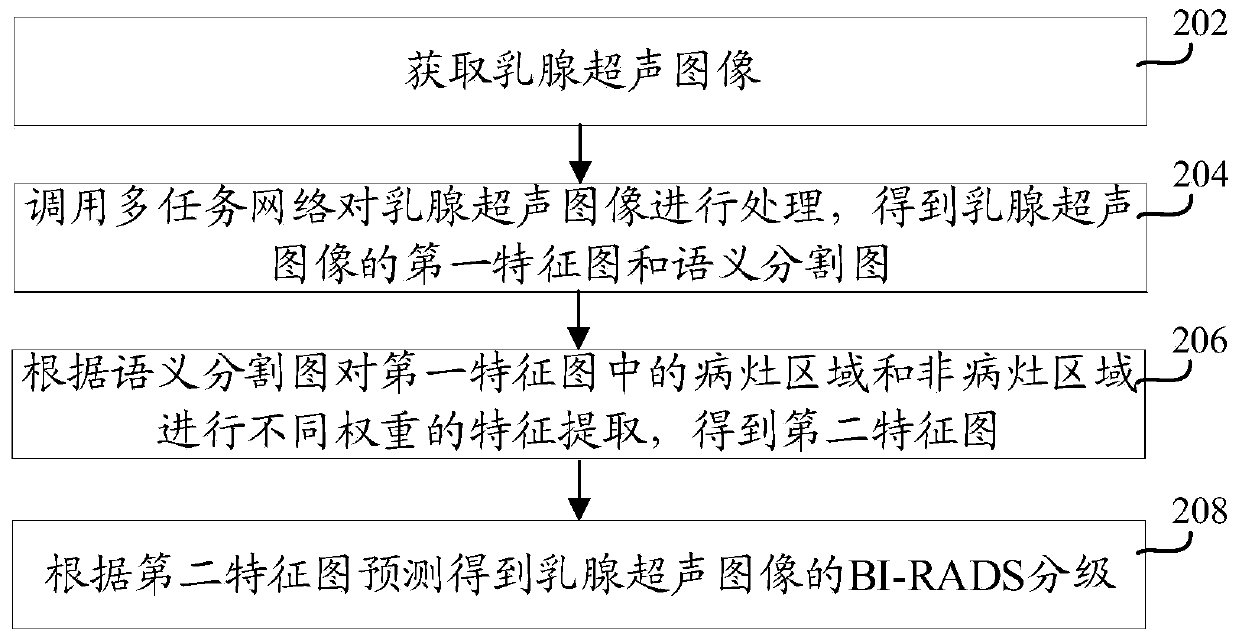

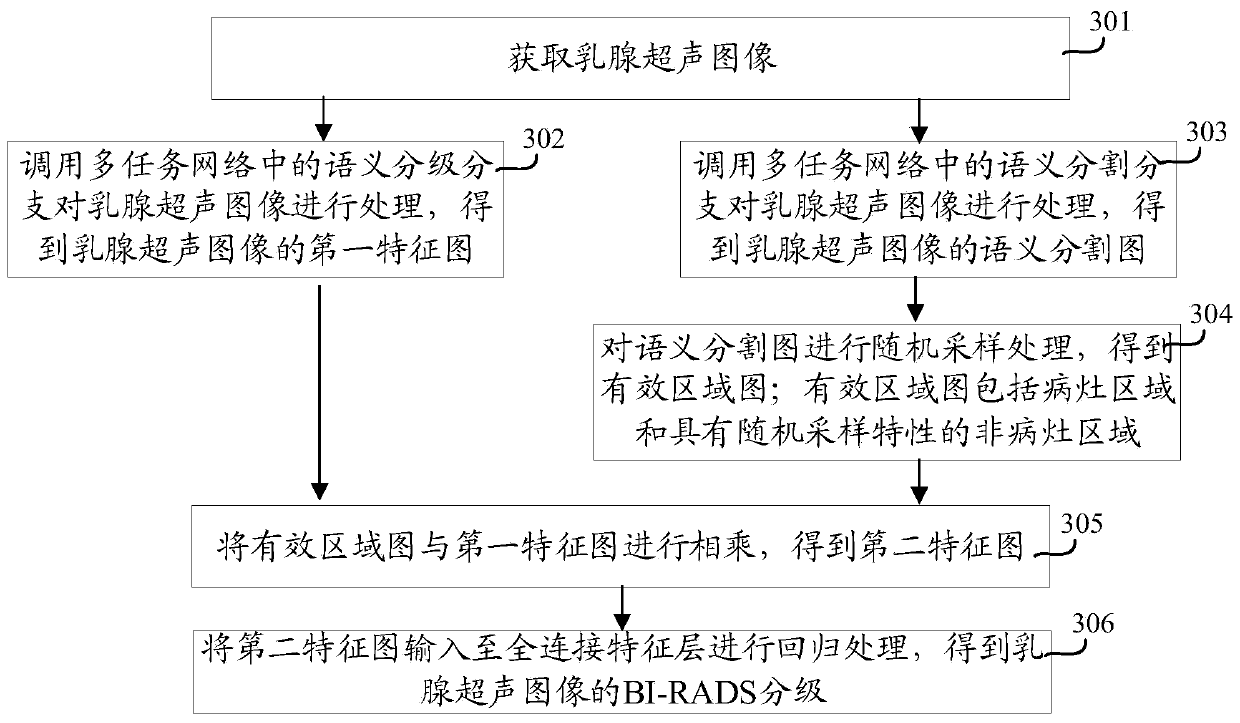

Disease grading method and device based on machine learning, equipment and medium

The invention discloses a disease grading method and device based on machine learning, equipment and a medium, the method belongs to the field of medical artificial intelligence, and the method comprises the following steps: acquiring a breast ultrasound image; calling a multi-task network to process the mammary gland ultrasonic image to obtain a first feature map and a semantic segmentation map of the mammary gland ultrasonic image, the first feature map comprising high-level semantic features of the mammary gland ultrasonic image, and the semantic segmentation map being a map for semantic segmentation of a focus area in the mammary gland ultrasonic image; performing feature extraction of different weights on the lesion area and the non-lesion area in the first feature map according to the semantic segmentation map to obtain a second feature map; and predicting according to the second feature map to obtain the BI-RADS grading of the breast ultrasound image. High-level semantic features with classification guidance are adopted as main grading features, different feature extraction is carried out on a lesion area and a non-lesion area by introducing a lesion contour, and an accurateBI-RADS grading result is obtained through regression.

Owner:TENCENT TECH (SHENZHEN) CO LTD

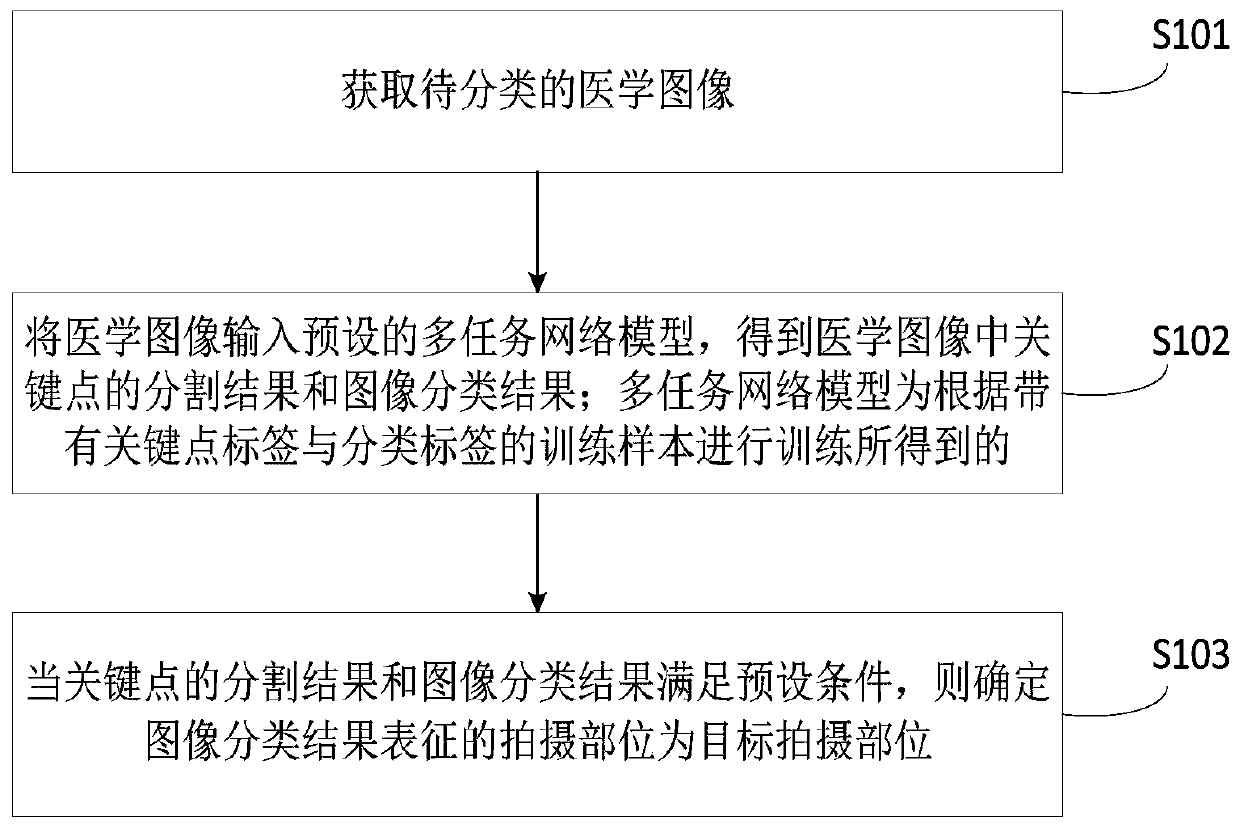

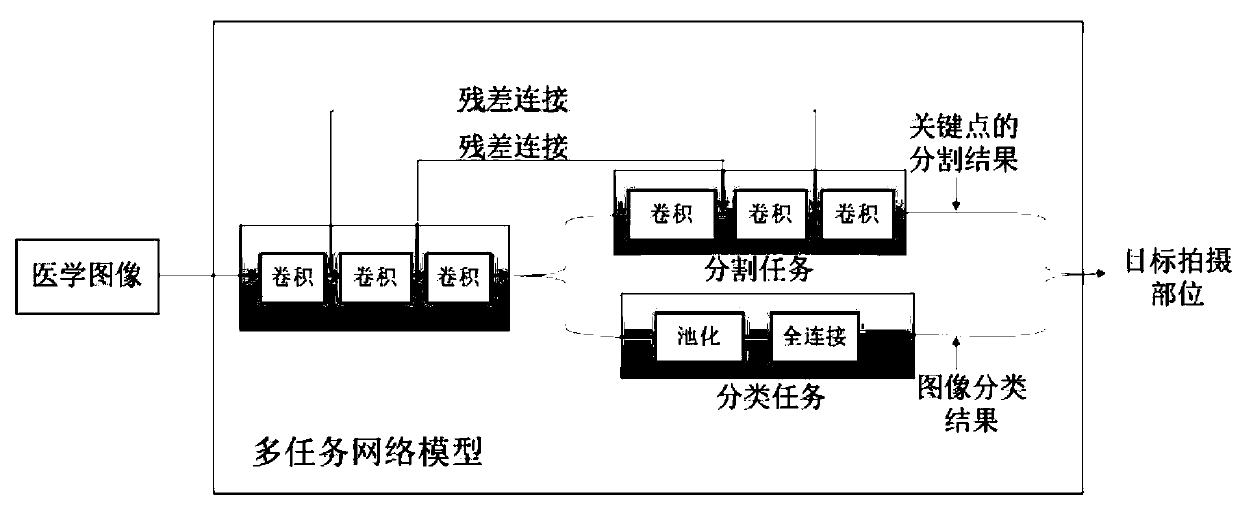

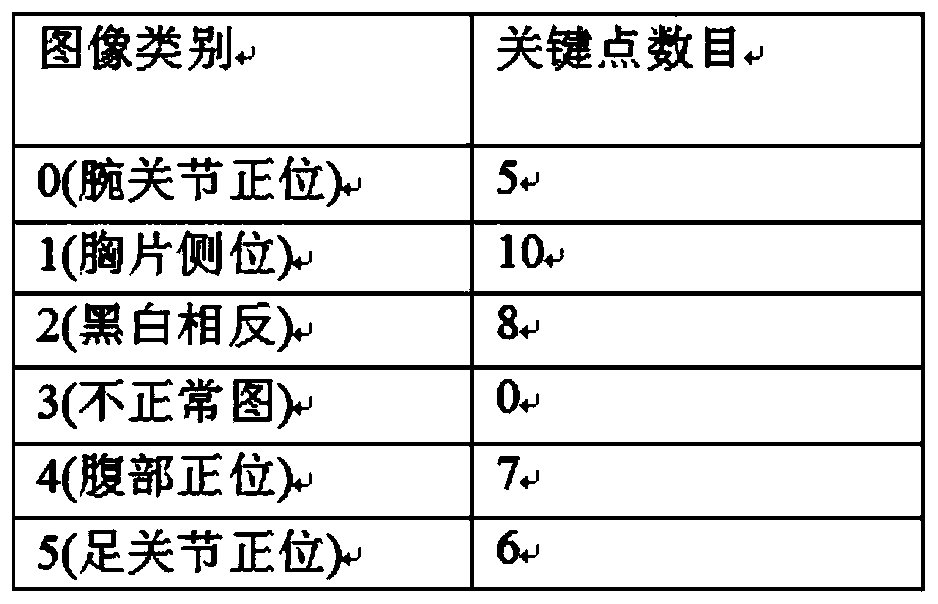

Image classification method and device, computer equipment and readable storage medium

PendingCN111160367AImprove accuracyImprove recognition efficiencyCharacter and pattern recognitionTask networkClassification methods

The invention relates to an image classification method and device, computer equipment and a readable storage medium. The method comprises the steps of obtaining a to-be-classified medical image; inputting the medical image into a preset multi-task network model to obtain a segmentation result and an image classification result of key points in the medical image; the multi-task network model beingobtained by training according to a training sample with a key point label and a classification label; and when the segmentation result of the key points and the image classification result meet a preset condition, determining the shooting part represented by the image classification result as a target shooting part. According to the method, the computer equipment determines the shooting part inthe medical image by adopting the multi-task network model, so that the accuracy of a target shooting part result can be improved, and the accuracy of a subsequent focus identification process is further improved; a radiologist does not need to make a confirmation process, and meanwhile, the efficiency of a focus recognition process is improved.

Owner:SHANGHAI UNITED IMAGING INTELLIGENT MEDICAL TECH CO LTD

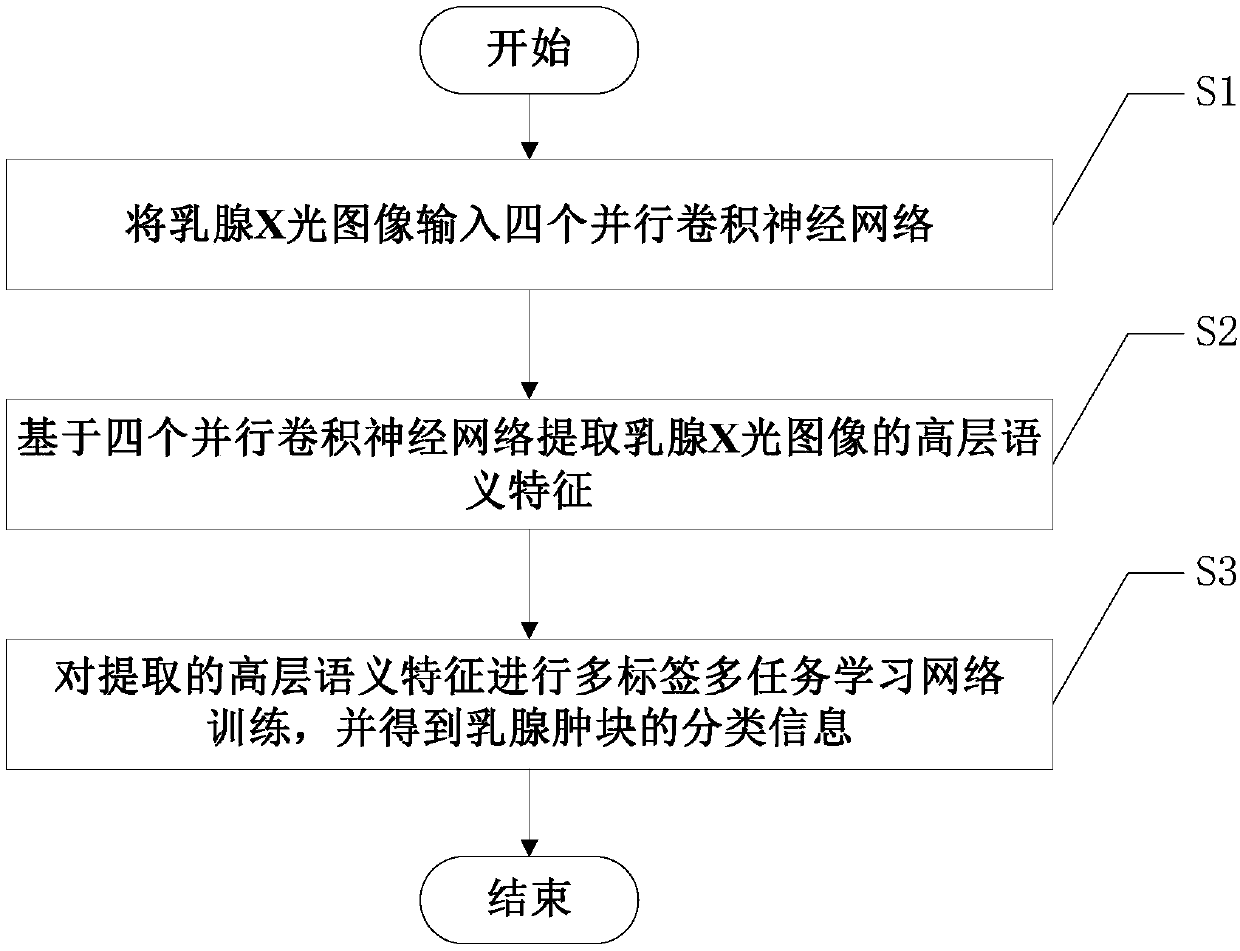

Breast lump information extraction and classification method for breast X-ray image

InactiveCN108830282ARemove redundant featuresMedical automated diagnosisCharacter and pattern recognitionDiseaseTask network

The invention discloses a breast lump information extraction and classification method for a breast X-ray image. The method comprises the following steps of S1, inputting the breast X-ray image into four parallel convolutional neural networks; S2, extracting high-level semantic features of the breast X-ray image on the basis of the four parallel convolutional neural networks; and S3, performing multi-label multi-task learning network training on the extracted high-level semantic features, and obtaining classification information of breast lumps. According to the breast lump information extraction and classification method for the breast X-ray image, redundant features extracted by the convolutional neural networks can be effectively removed; four classification tasks can be mutually entangled and constrained and mutually promoted through a multi-label multi-task network; clear breast lump classification information is provided for doctors; and auxiliary diagnosis of breast lump relateddiseases is provided.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

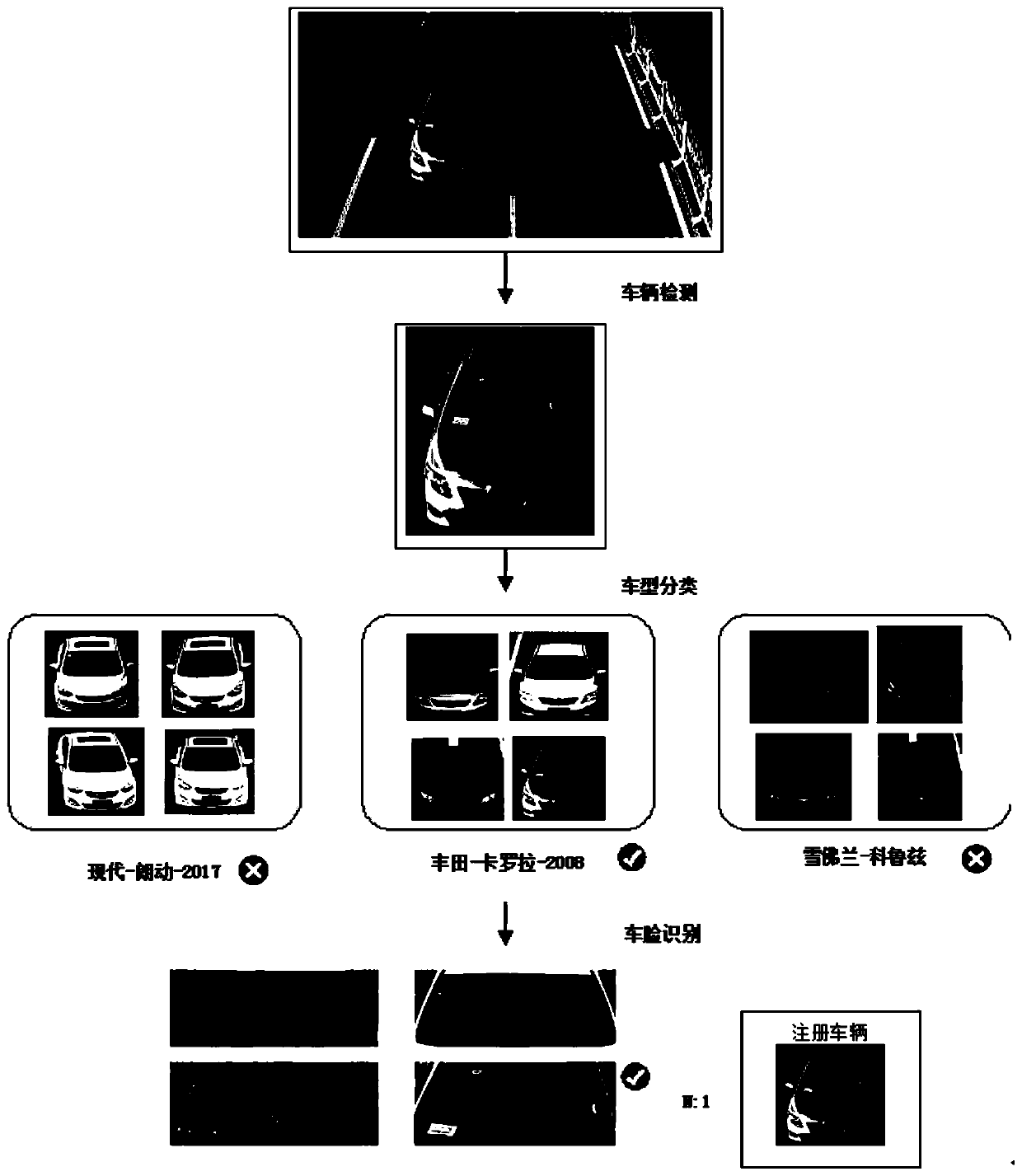

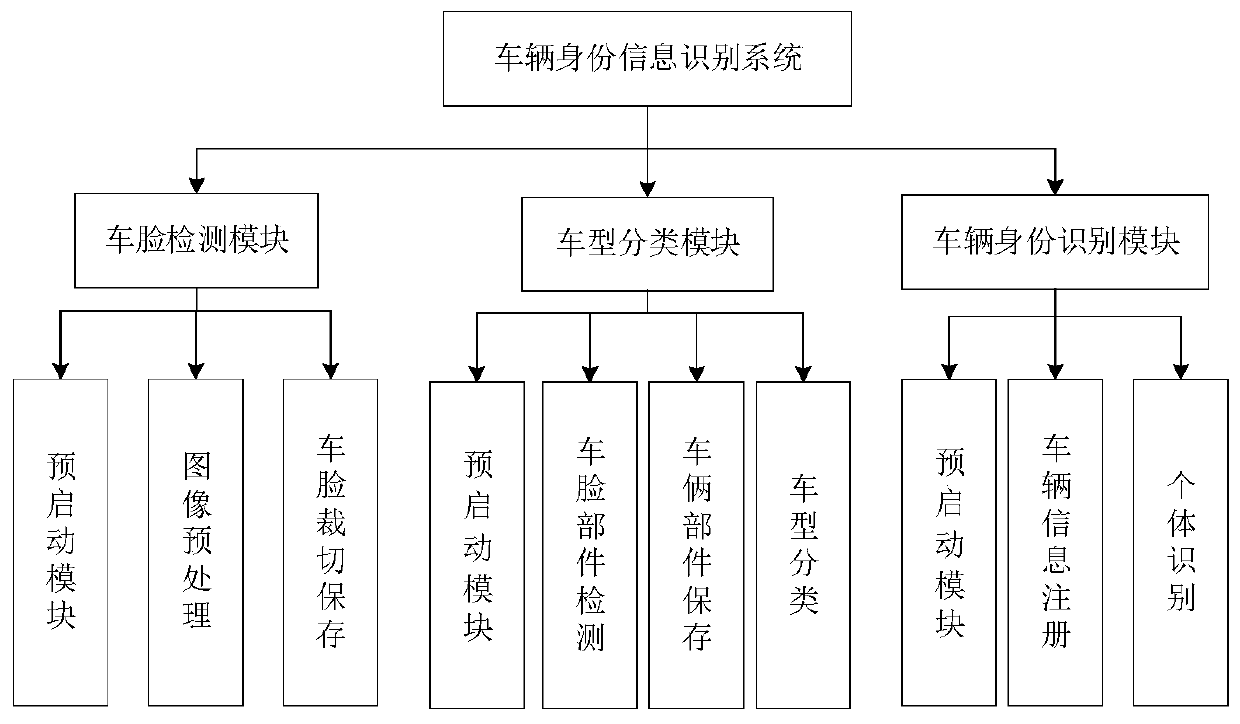

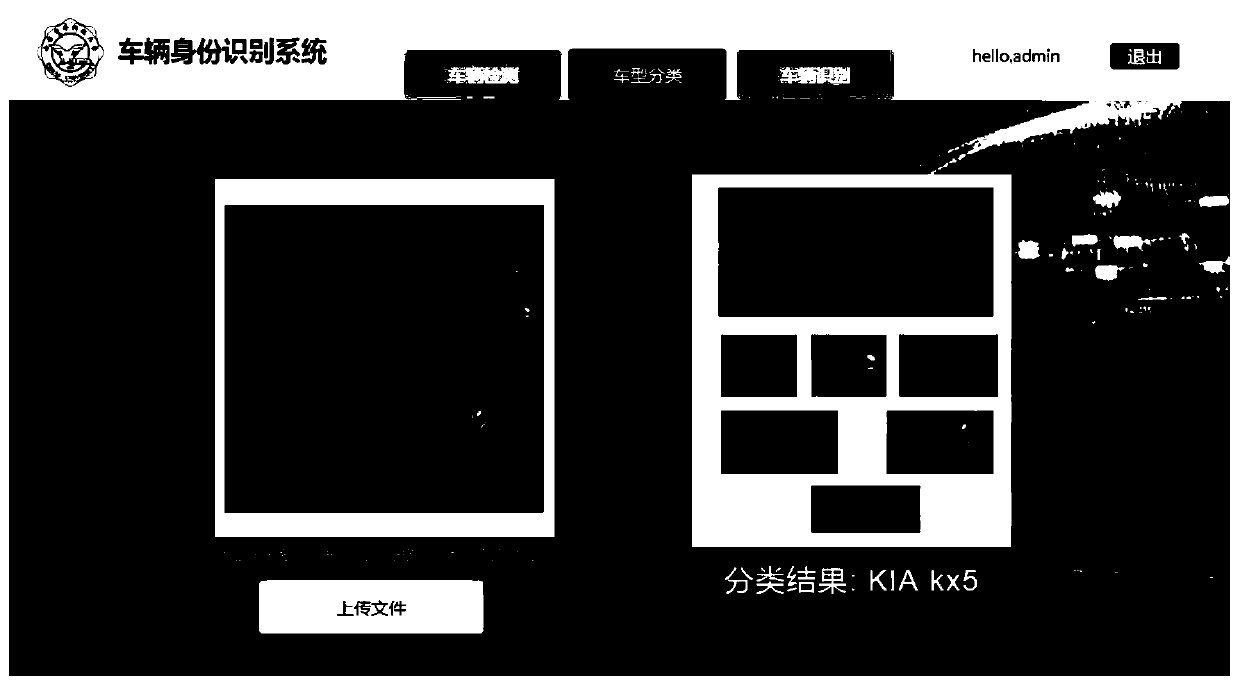

Vehicle identity recognition model construction method and system based on deep learning and vehicle identity recognition method and system based on deep learning

ActiveCN110378236AComplete Extraction ProcessComplete identification methodInternal combustion piston enginesCharacter and pattern recognitionInformation repositoryTask network

The invention belongs to the technical field of computer vision, and relates to a vehicle identity recognition model construction and recognition method and a system based on deep learning. Firstly, large-scale road monitoring pictures are used for carrying out model training of vehicle detection, and a multi-loss function staged joint training strategy is adopted for training; then, part extraction is carried out on the detected vehicle face image, and classification is carried out through a feature extraction and fusion network or a common classification network according to the vehicle facepart extraction situation; and finally, the identity feature vector of the vehicle face is extracted and filtered by using a multi-task network, and similarity measurement is performed on the featureof the image to be analyzed and the feature vector of the image in the vehicle information base to obtain a vehicle identity recognition result. According to the deep learning network framework provided by the invention, the feature extraction capability of the network model in different aspects can be improved according to requirements, so that the optimal model expression capability is realized, and the identification feature vector with significant discrimination is convenient to extract.

Owner:XIDIAN UNIV

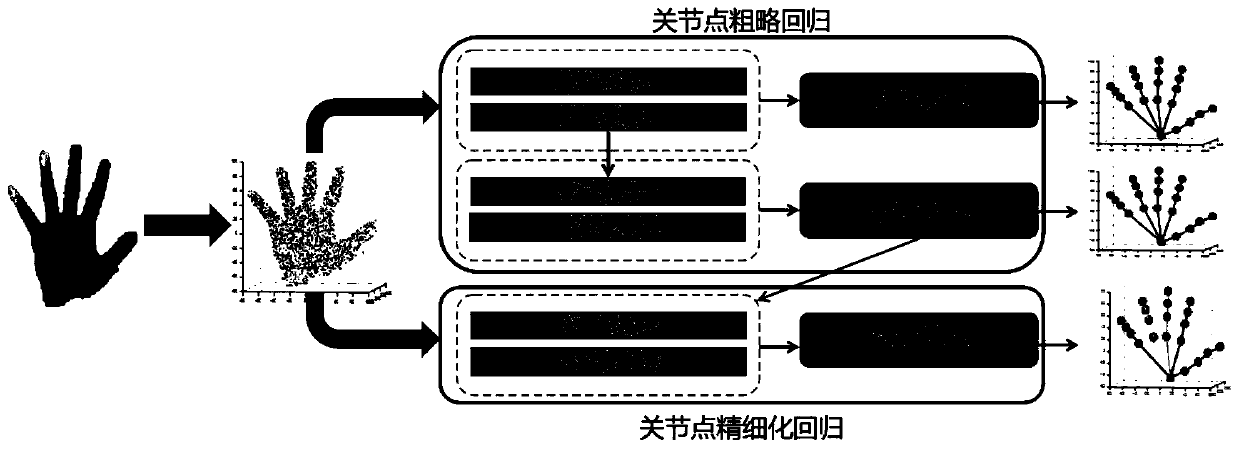

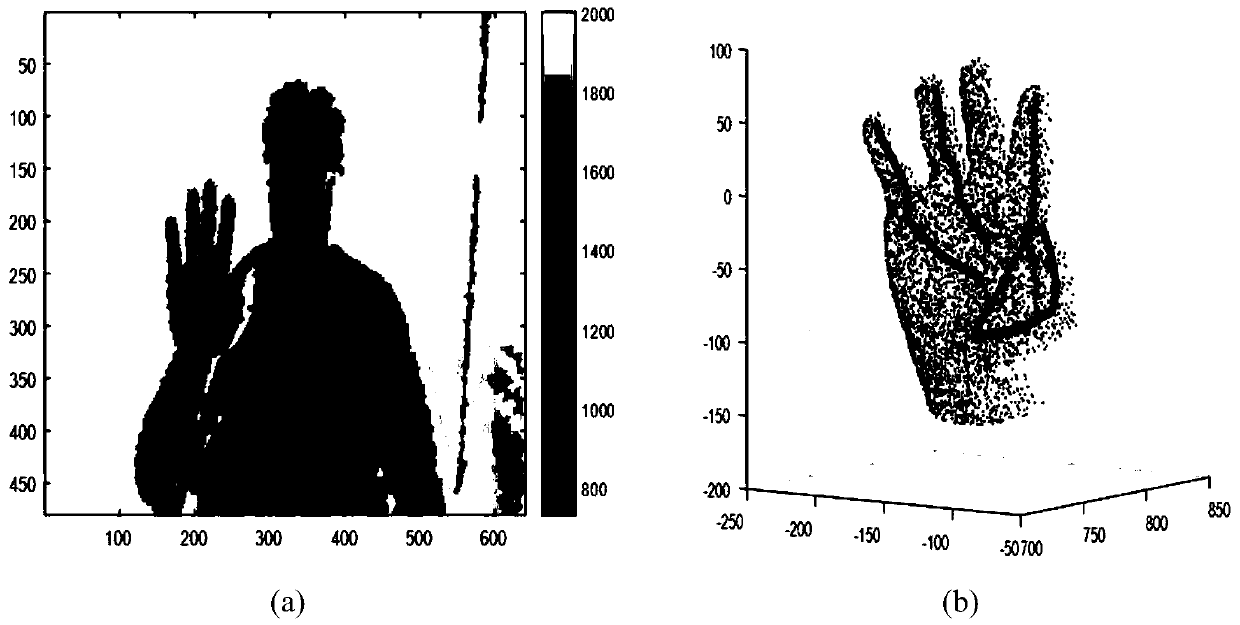

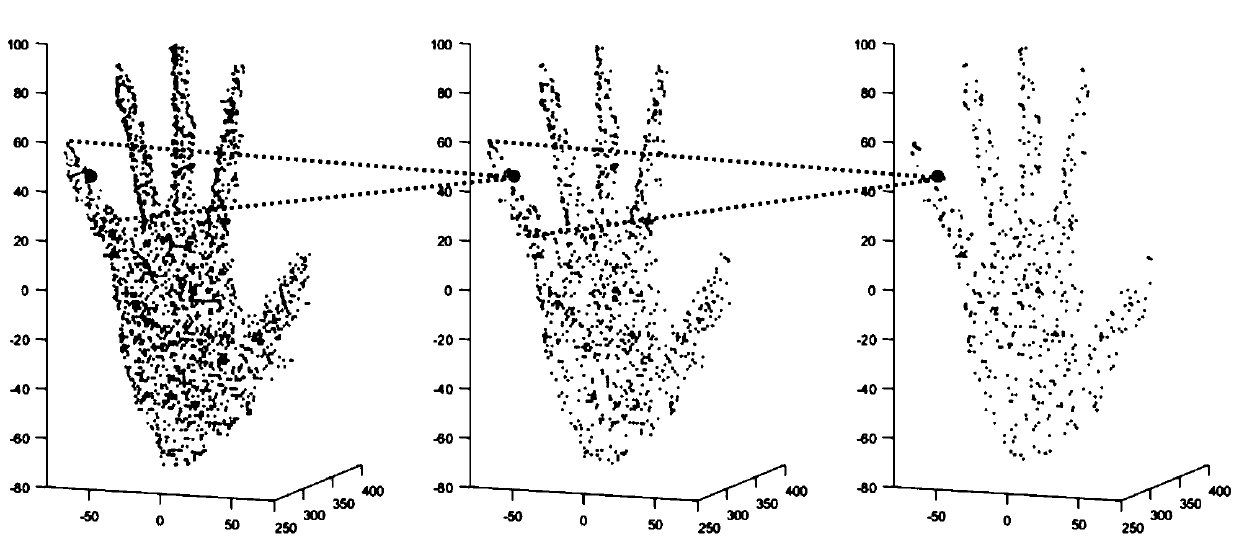

Human hand three-dimensional posture estimation method and device based on three-dimensional point cloud

ActiveCN110222580AImprove generalization abilityAlleviate the problem of poor feature generalization abilityImage enhancementImage analysisTask networkPoint cloud

The invention relates to a human hand three-dimensional posture estimation method and device based on three-dimensional point cloud which mainly solves the problem of how to recover the three-dimensional posture of a human hand from the human hand point cloud obtained by a single depth map, and has the main technical difficulties of disordered point cloud arrangement, higher noise, rich gesture changes of the human hand, self-shielding of the human hand caused by a shooting angle and the like. The invention provides a human hand posture estimation algorithm based on a deep neural network by which the features can be adaptively extracted from the rich training data. Meanwhile, the local and global features of the point cloud can be predicted while the three-dimensional positions of the joint points of the human hand are regression in real time, the generalization ability of the network is improved through the internal connection of joint labeling, and the problem that the generalizationability of the features extracted by a single-task network is poor, is solved. The actual use verifies that the method and the device have the advantages of high automation degree, high precision andreal-time performance, and can meet the professional or popular application requirements.

Owner:INST OF SOFTWARE - CHINESE ACAD OF SCI

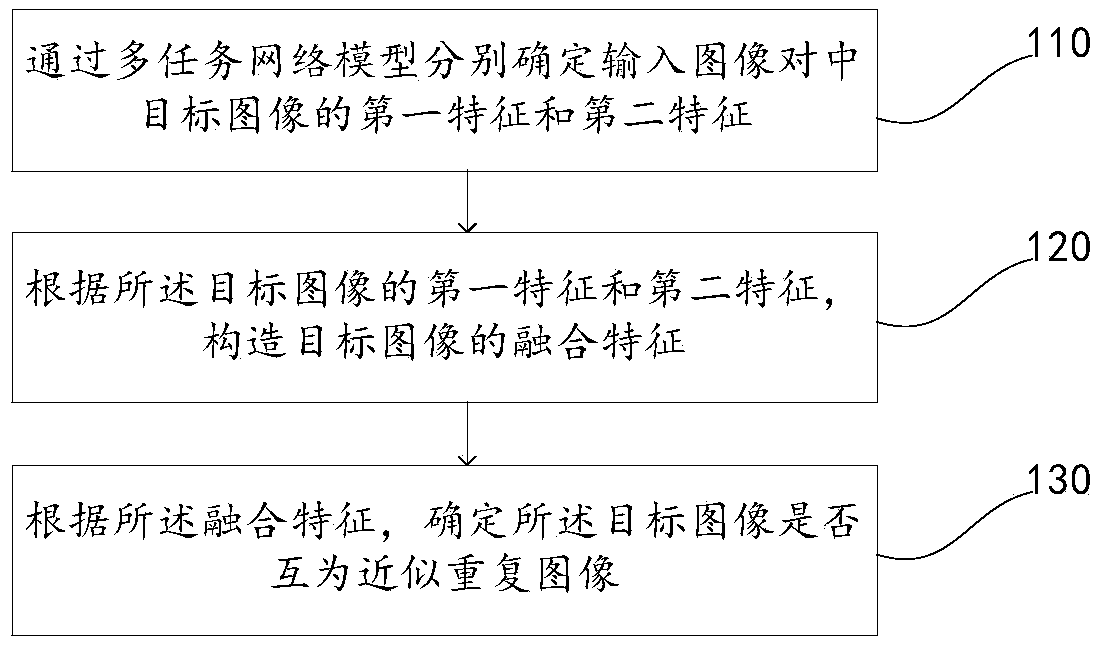

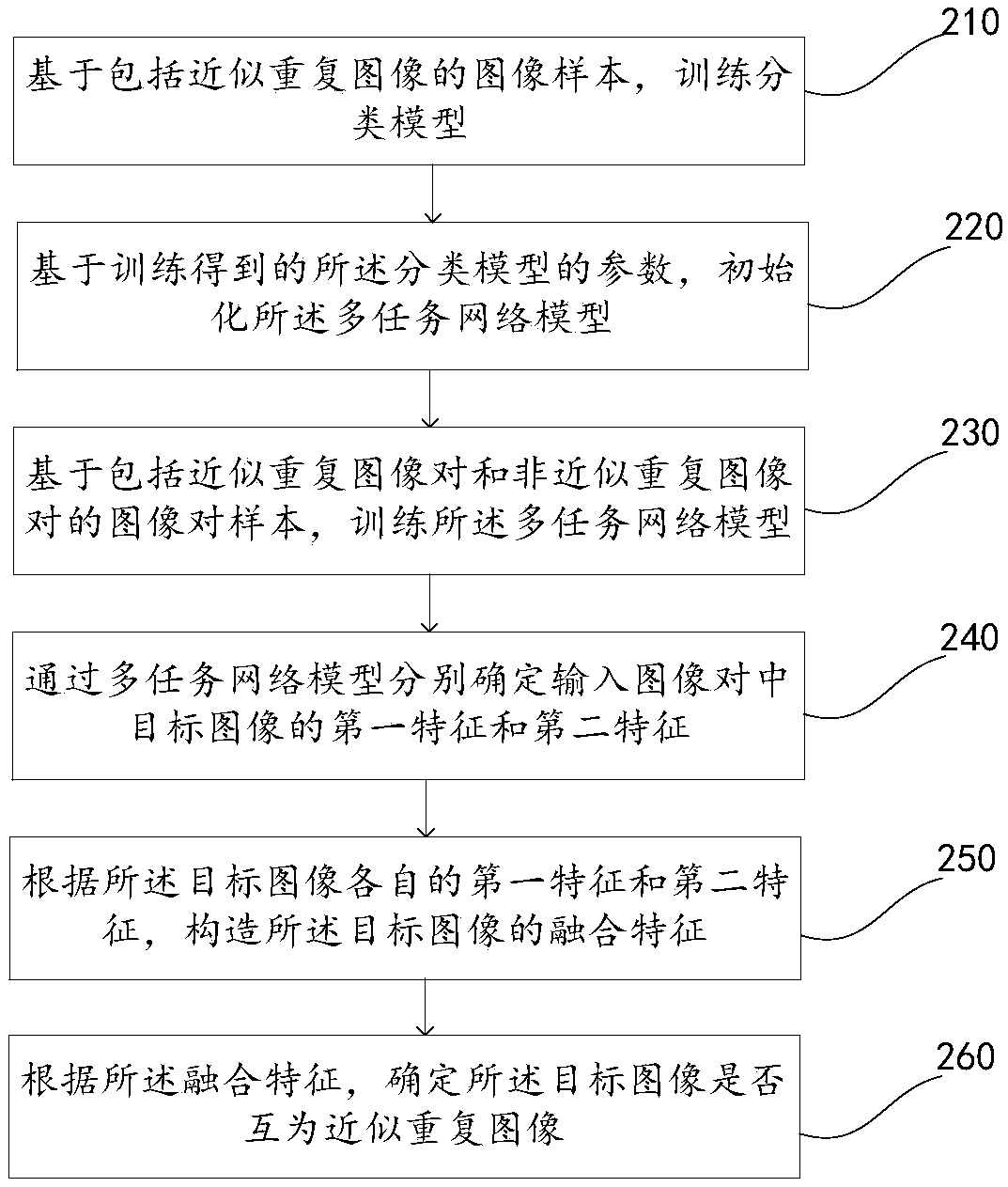

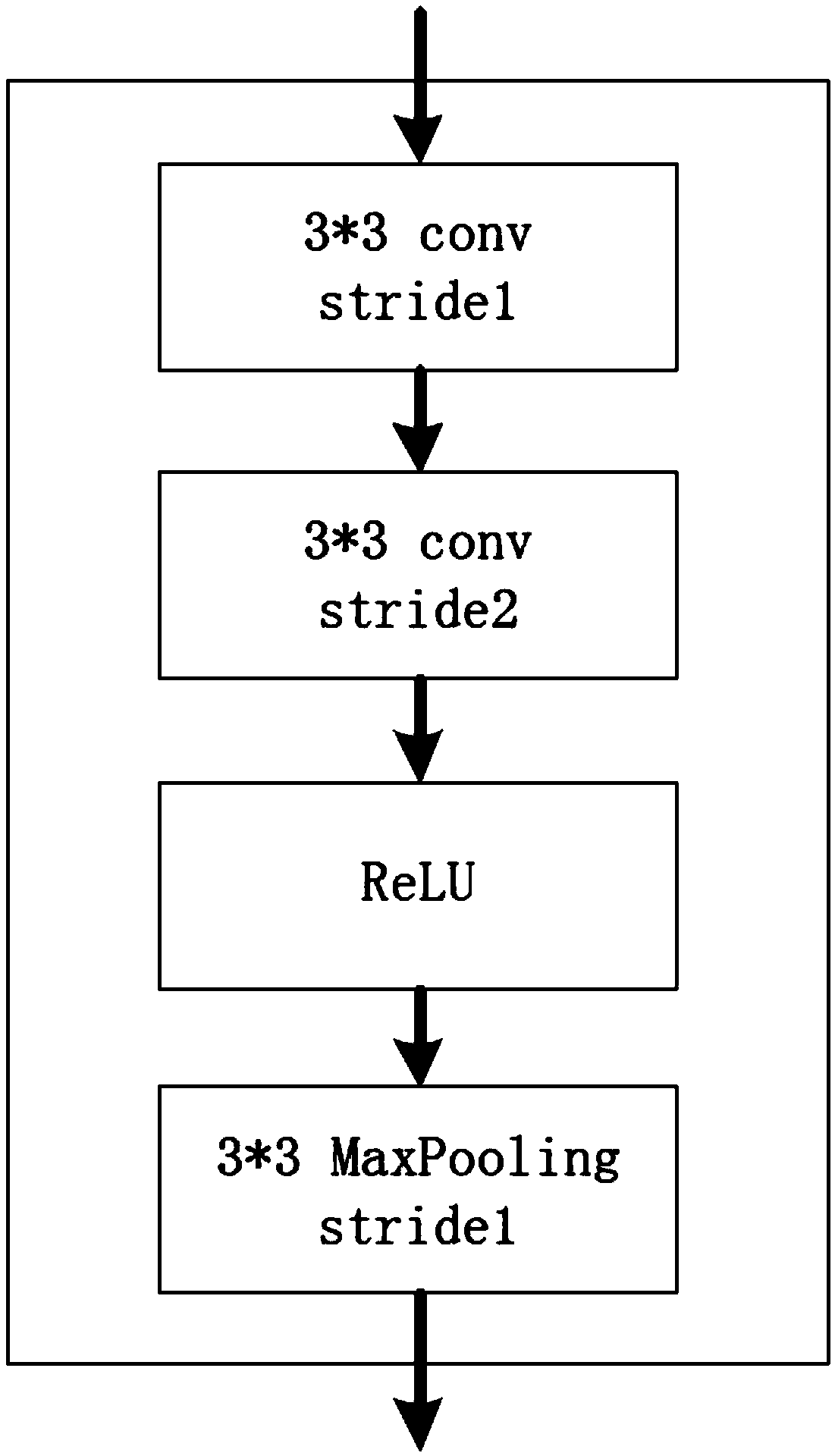

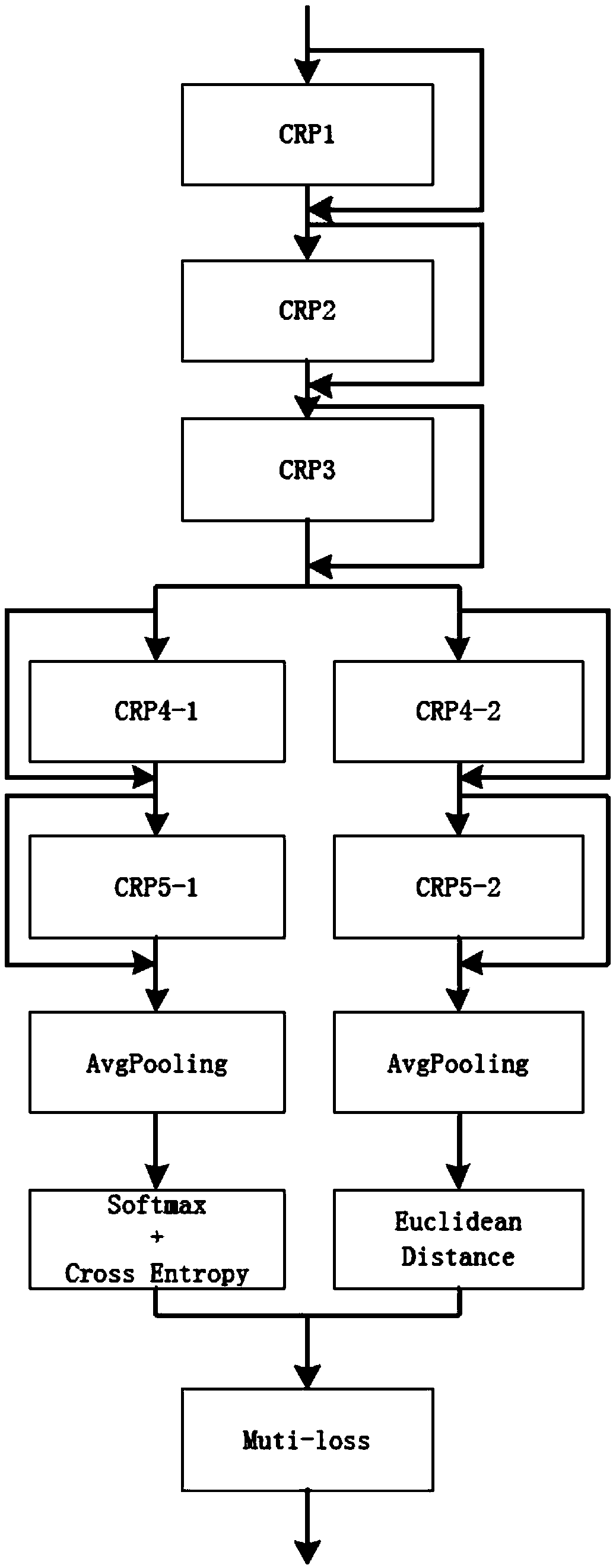

Near-duplicate image detection method and device and electronic equipment

ActiveCN108665441AImprove accuracySolve the low detection accuracyImage enhancementImage analysisImaging FeatureTask network

An embodiment of the invention discloses a near-duplicate image detection method and belongs to the computer technical field and solves the problem of low accuracy of near-duplicate image detection inthe prior art. The method comprises the steps of: determining a first feature and a second feature of a target image in an input image pair by a multi-task network model respectively, wherein the first feature comprises image features reflecting inter-class differences and intra-class differences, and the second feature comprises image features reflecting the intra-class differences; constructinga fusion feature of the target image according to the first feature and the second feature of the target image; and according to the fusion feature, determining whether the target image is a near-duplicate image. The near-duplicate image detection method disclosed in the present application further improves the comprehensiveness and accuracy of the image fusion feature by combining the intra-class information and inter-class information of the image to construct the fusion feature of the image, thereby improving the accuracy of the near-duplicate image detection.

Owner:BEIJING SANKUAI ONLINE TECH CO LTD

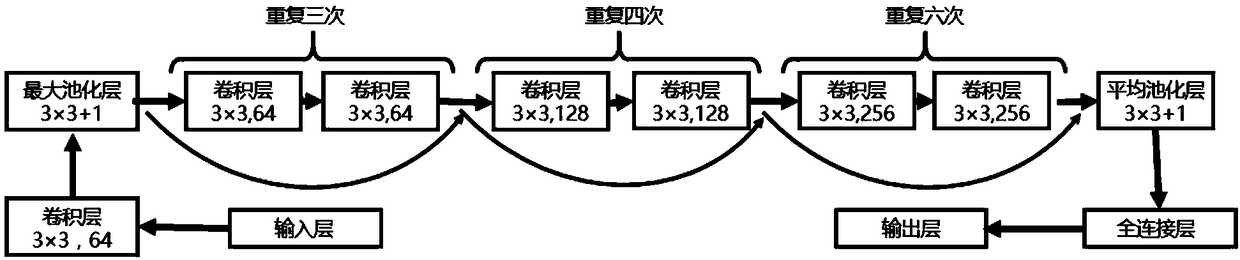

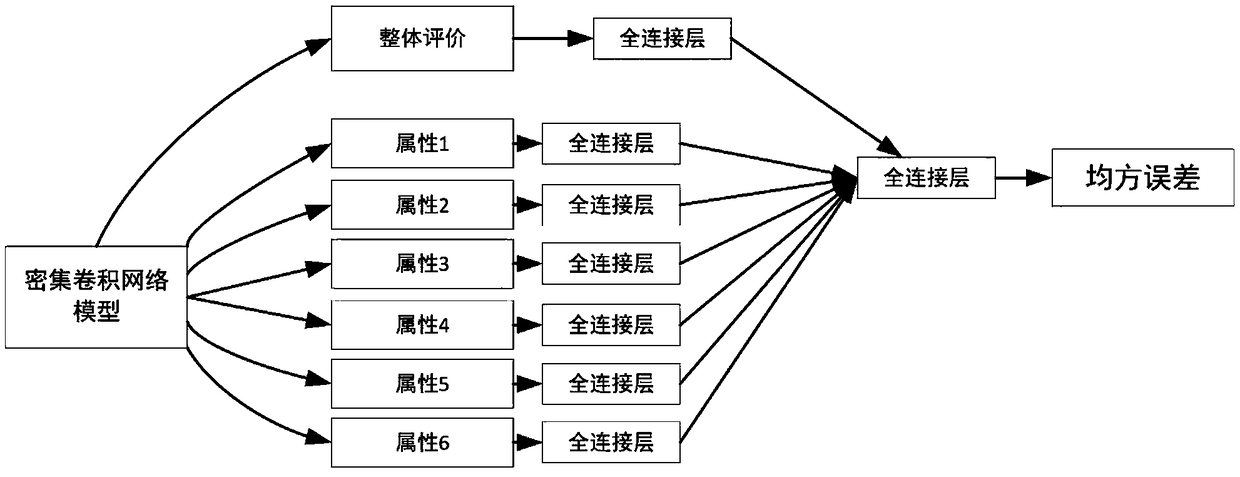

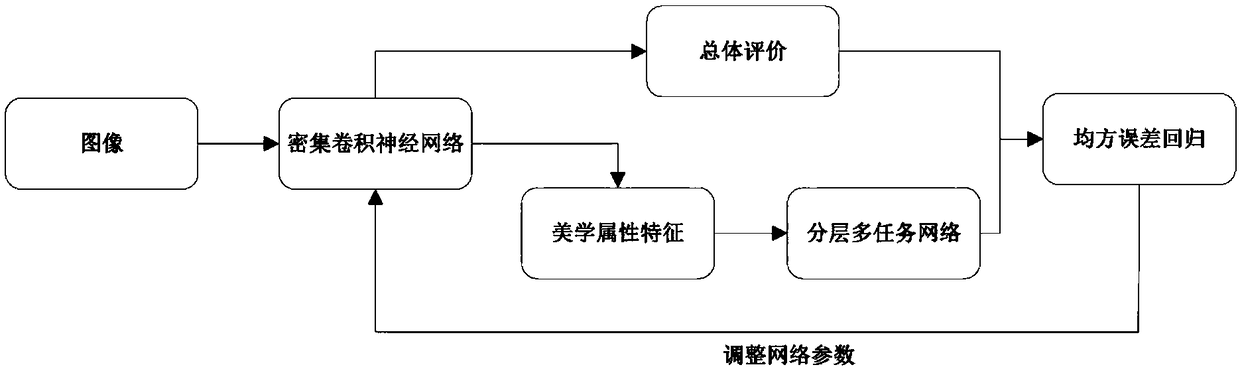

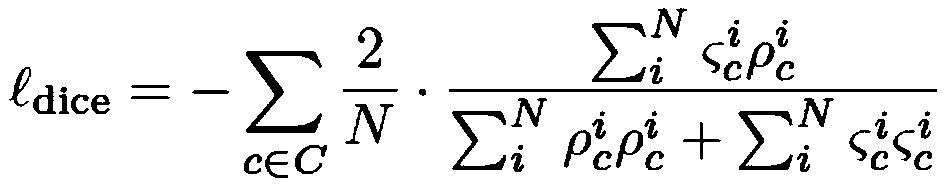

An aesthetic attribute evaluation method based on dense convolution network and multi-task network

InactiveCN109255374AEasy to passImprove computing efficiencyCharacter and pattern recognitionNeural architecturesData setPrediction algorithms

The invention provides an aesthetic attribute evaluation method based on a dense convolution network and a multi-task network. Aesthetic features of images are extracted from dense convolution neuralnetwork model, and a part of image features are preserved in multi-dimensional matrix. The hierarchical multi-task network is used for regression analysis of known image attributes. After many times of training analysis, the prediction results and the data in the training data set reach a high degree of fitting, the final training model is saved, and the model is tested on the test data set to getthe regression results of the method. Because the data set used does not have a certain tendency, the aesthetic attribute prediction algorithm model has a certain universality. The method is implemented using Google's Tensorflow framework, and can be widely used in computer vision, image analysis and processing, digital photography and digital entertainment and other fields.

Owner:中共中央办公厅电子科技学院

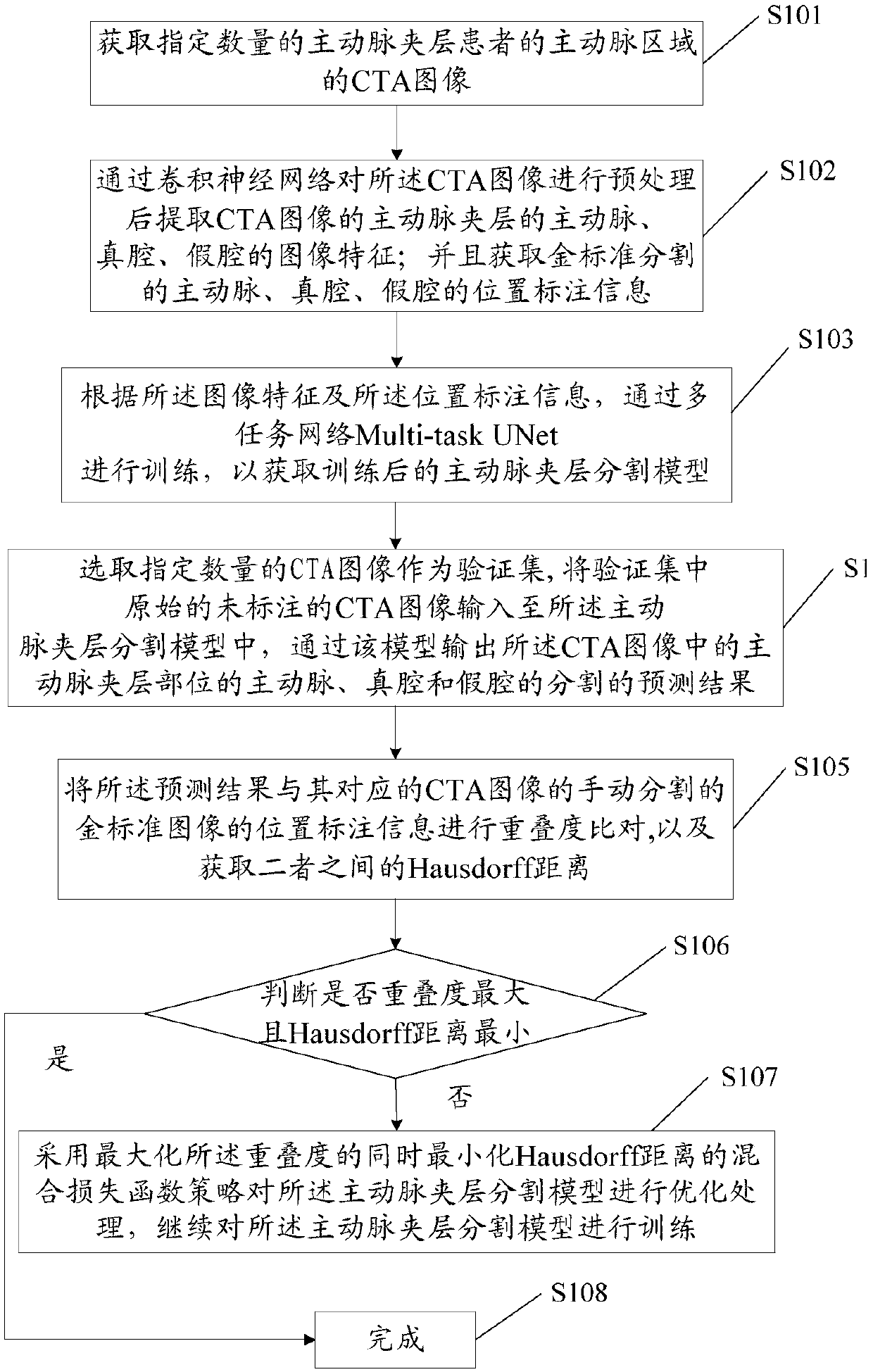

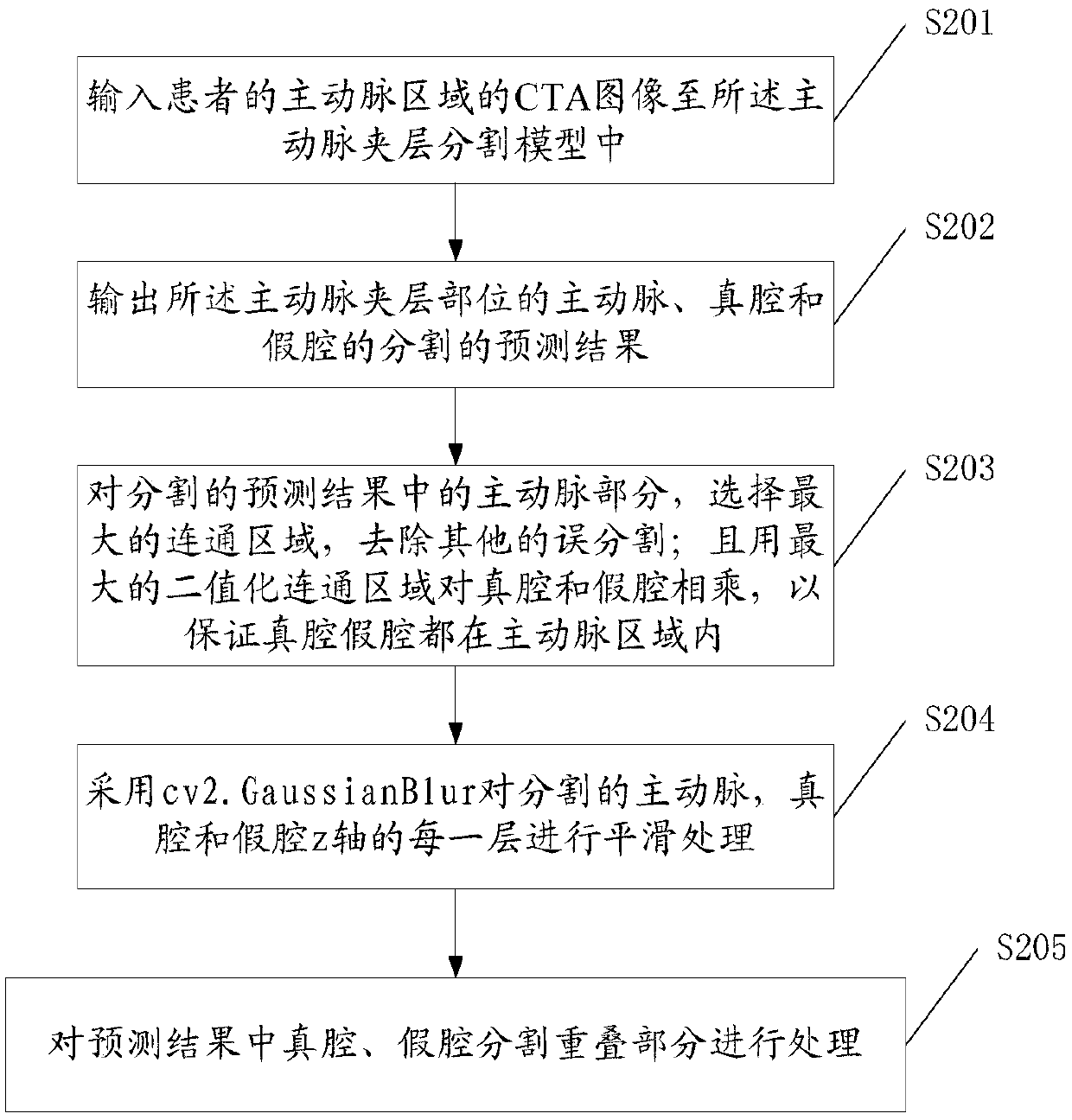

Construction method and application of aortic dissection segmentation model

ActiveCN108805134AShorten diagnostic timeEfficient acquisitionRecognition of medical/anatomical patternsAortic dissectionTask network

The invention provides a construction method and application of an aortic dissection segmentation model. The method comprises the following steps: A. acquiring a specified number of CTA images of aortic regions of aortic dissection patients; B, preprocessing the CTA images through a convolutional neural network, and extracting image features of the aorta, a true cavity and a pseudo-cavity of the aortic dissection of the preprocessed CTA images, and acquiring location annotation information of the aorta, the true cavity and the pseudo-cavity divided by the golden standard; and C, performing training according to the image features and the location annotation information through a multi-task network Multi-task UNet to obtain a trained aortic dissection segmentation model. Therefore, a segmentation prediction result of the aortic dissection can be obtained quickly and effectively via the above model, the diagnosis time of a doctor is greatly shortened, and an effective support is providedfor the surgical plan formulation.

Owner:HUIYING MEDICAL TECH (BEIJING) CO LTD

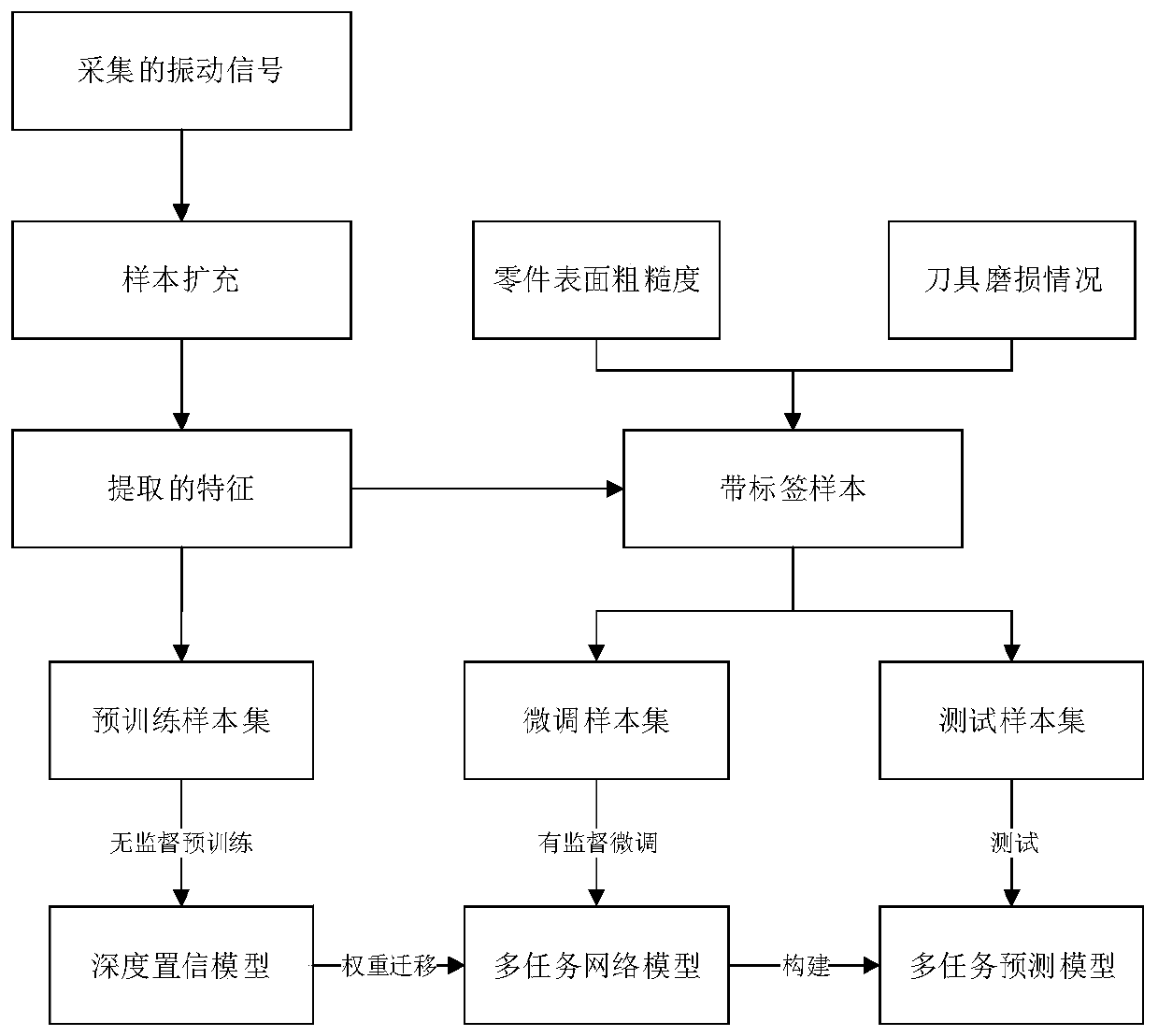

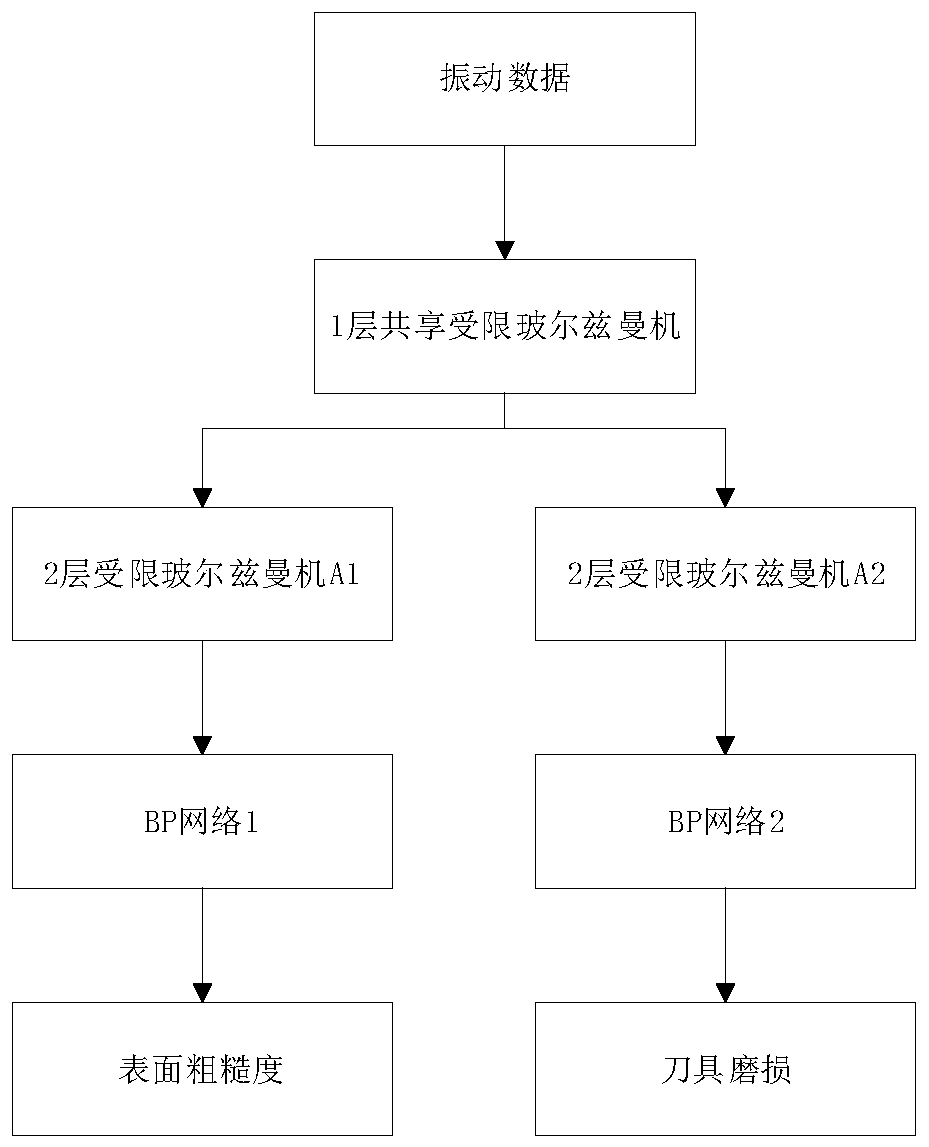

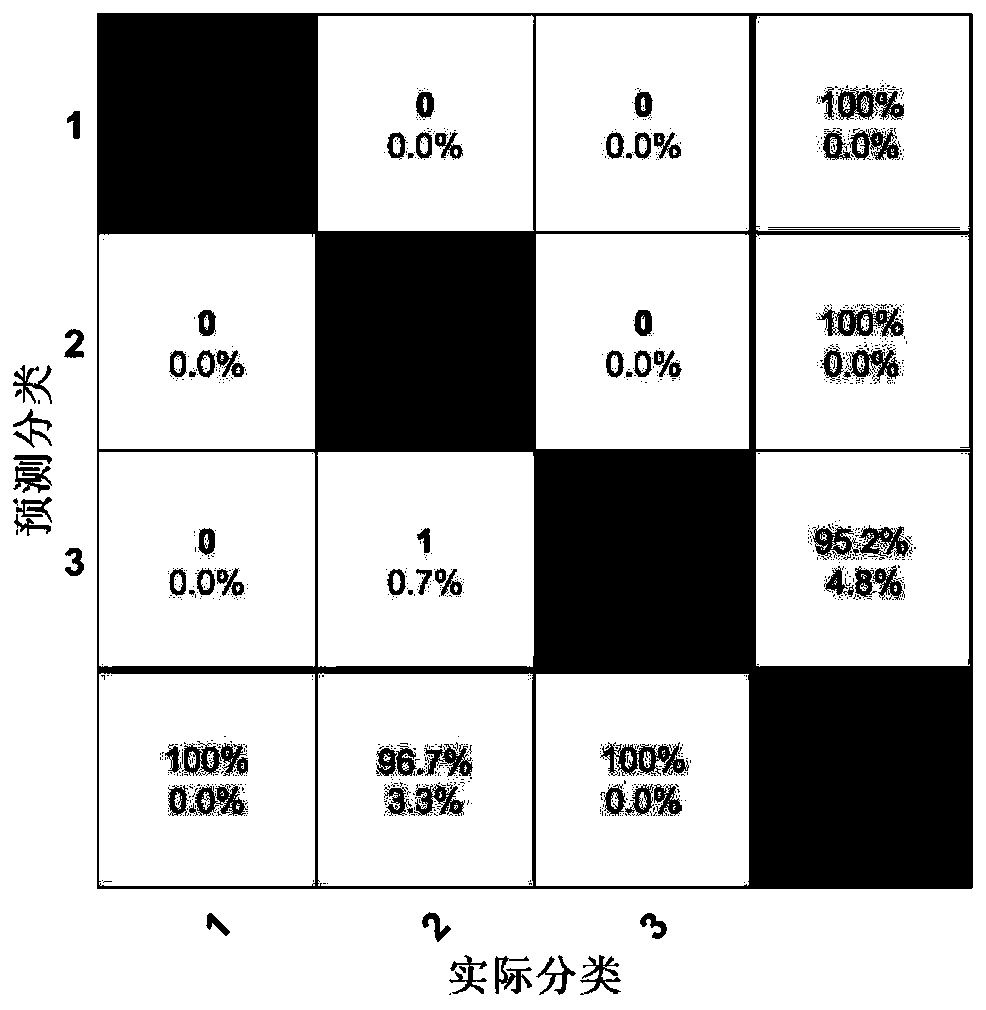

Part surface roughness and tool wear prediction method based on multi-task learning

ActiveCN111366123AIncrease productivityImprove product qualityMeasurement devicesNeural architecturesDeep belief networkTask network

The invention belongs to the technical field of machining and provides a part surface roughness and tool wear prediction method based on multi-task learning. The method is characterized in that firstly, vibration signals in the machining process are collected, next, the surface roughness of a part and the abrasion condition of a cutter are measured, and the measured results are made to correspondto vibration signals respectively; secondly, sample expansion is carried out, and features are extracted and normalized; then, a multi-task prediction model based on a deep belief network is constructed, the surface roughness of the part and the cutter abrasion condition serve as model output, features are extracted as input, and a multi-task DBN network prediction model is established; and finally, test verification is performed, a vibration signal is inputted into the multi-task prediction model, and the surface roughness and the cutter wear condition are predicted. The method is mainly advantaged in that online prediction of the part surface roughness and the tool wear condition is achieved through one-time modeling, the hidden information contained in monitoring data is fully utilized,and the workload and model building cost are reduced.

Owner:DALIAN UNIV OF TECH

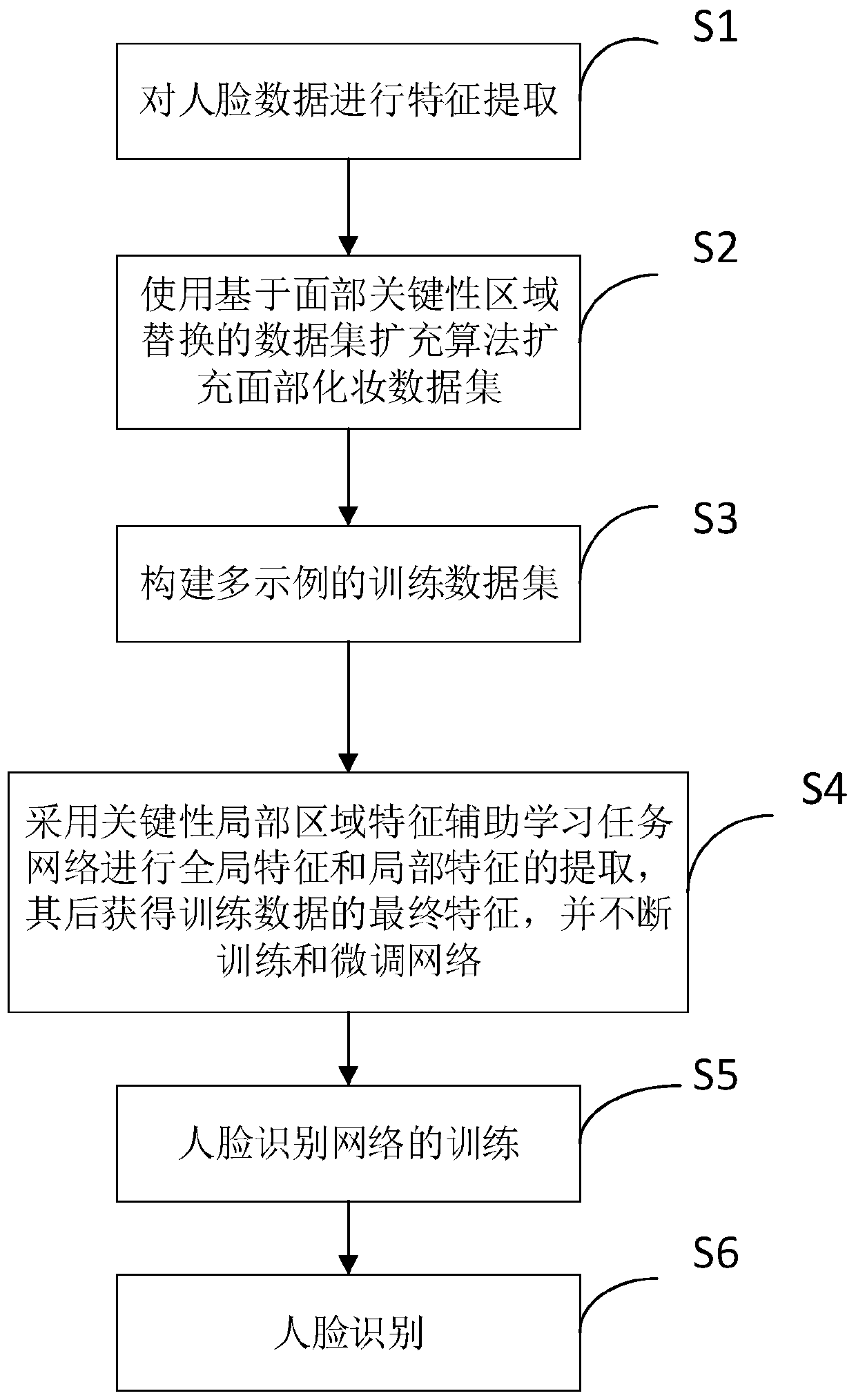

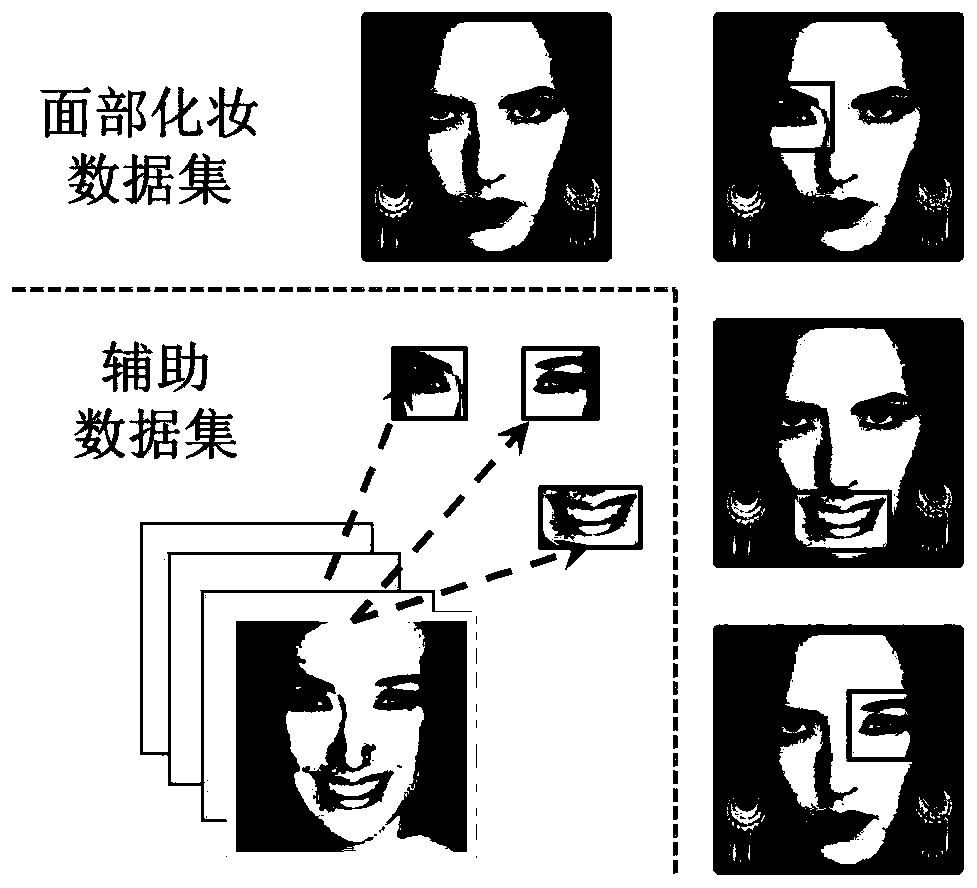

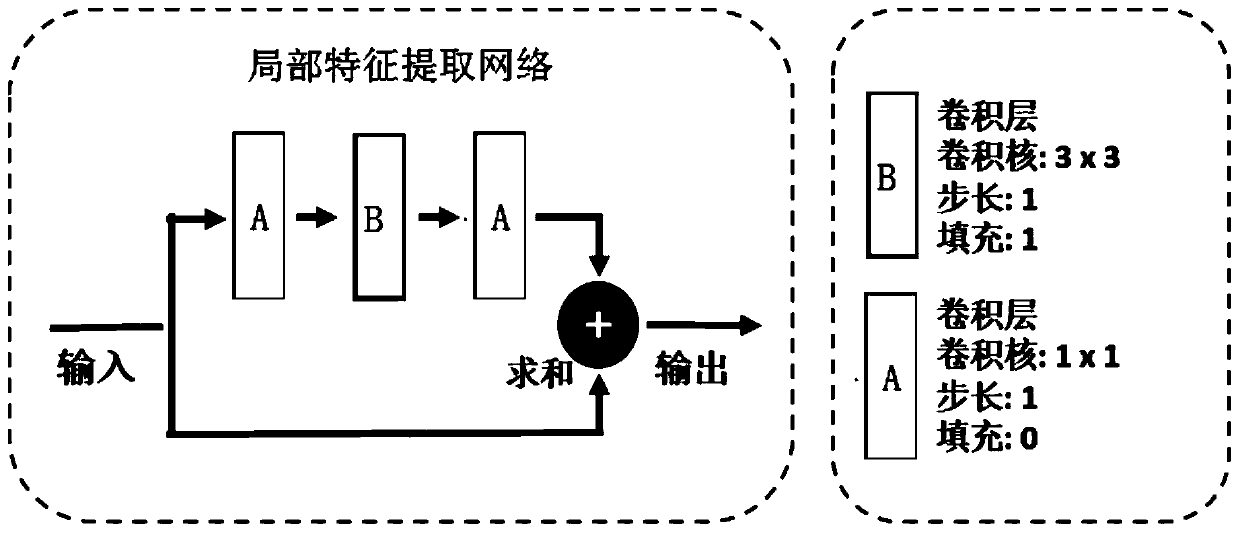

Method for automatically identifying face images before and after makeup

ActiveCN109858392AHigh precisionBig amount of dataCharacter and pattern recognitionFeature extractionData set

The invention discloses a method for automatically identifying face images before and after make-up. The method comprises the following steps: S1, carrying out feature extraction on face data; S2, expanding the facial makeup data set by using a data set expansion algorithm based on facial key region replacement; S3, constructing a multi-example training data set; S4, extracting global features andlocal features by adopting a critical local area feature assisted learning task network, then obtaining final features of the training data by adopting a feature information fusion method of an attention mechanism, and continuously training and finely adjusting the network; S5, continuously iterating and repeating the step S2 and the step S3 until the network converges to realize the training ofthe face recognition network; and S6, on the test data set, giving to-be-identified face data before and after makeup, and performing feature extraction and similarity calculation through a face identification network obtained through training, thereby realizing face identification.

Owner:FUDAN UNIV

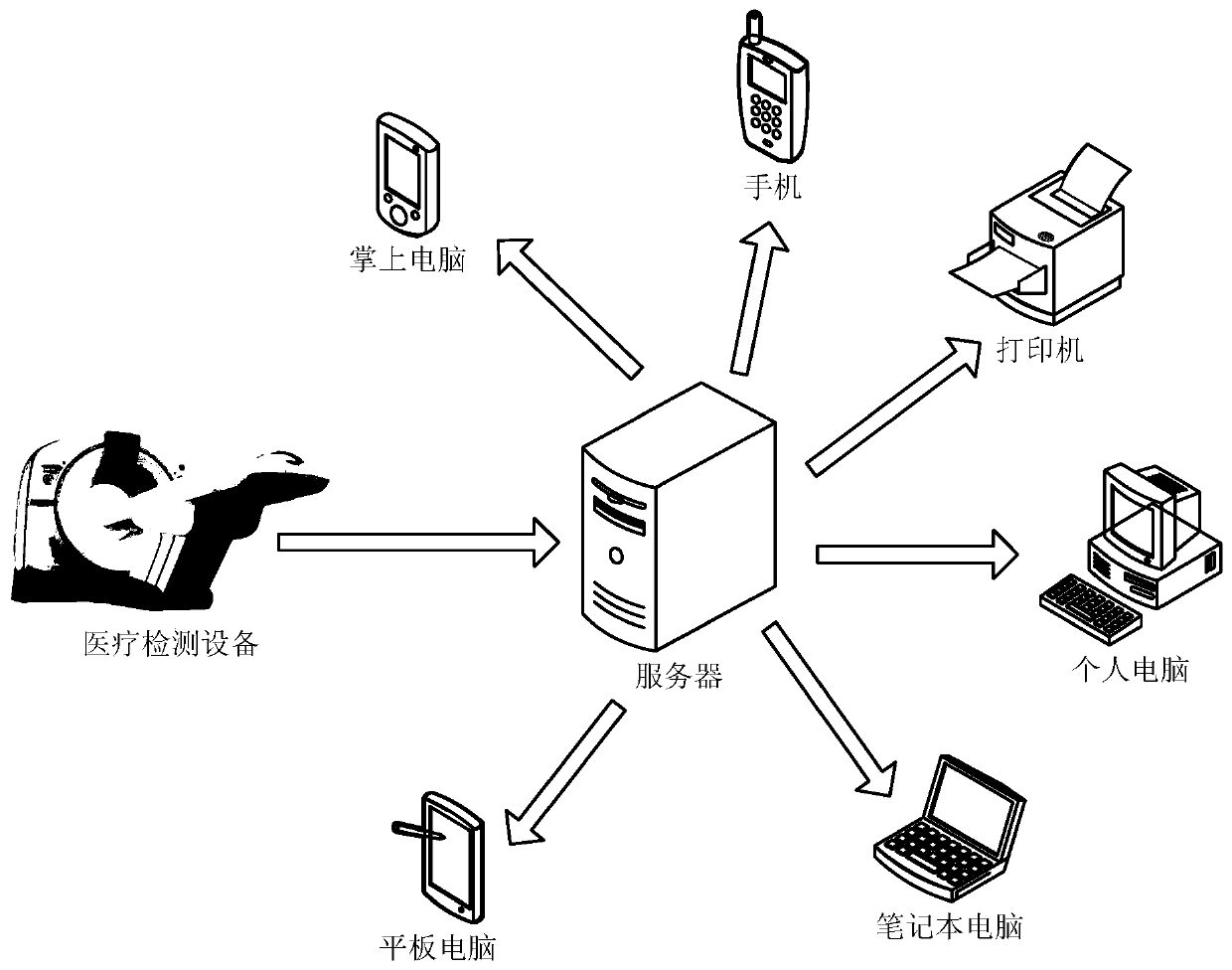

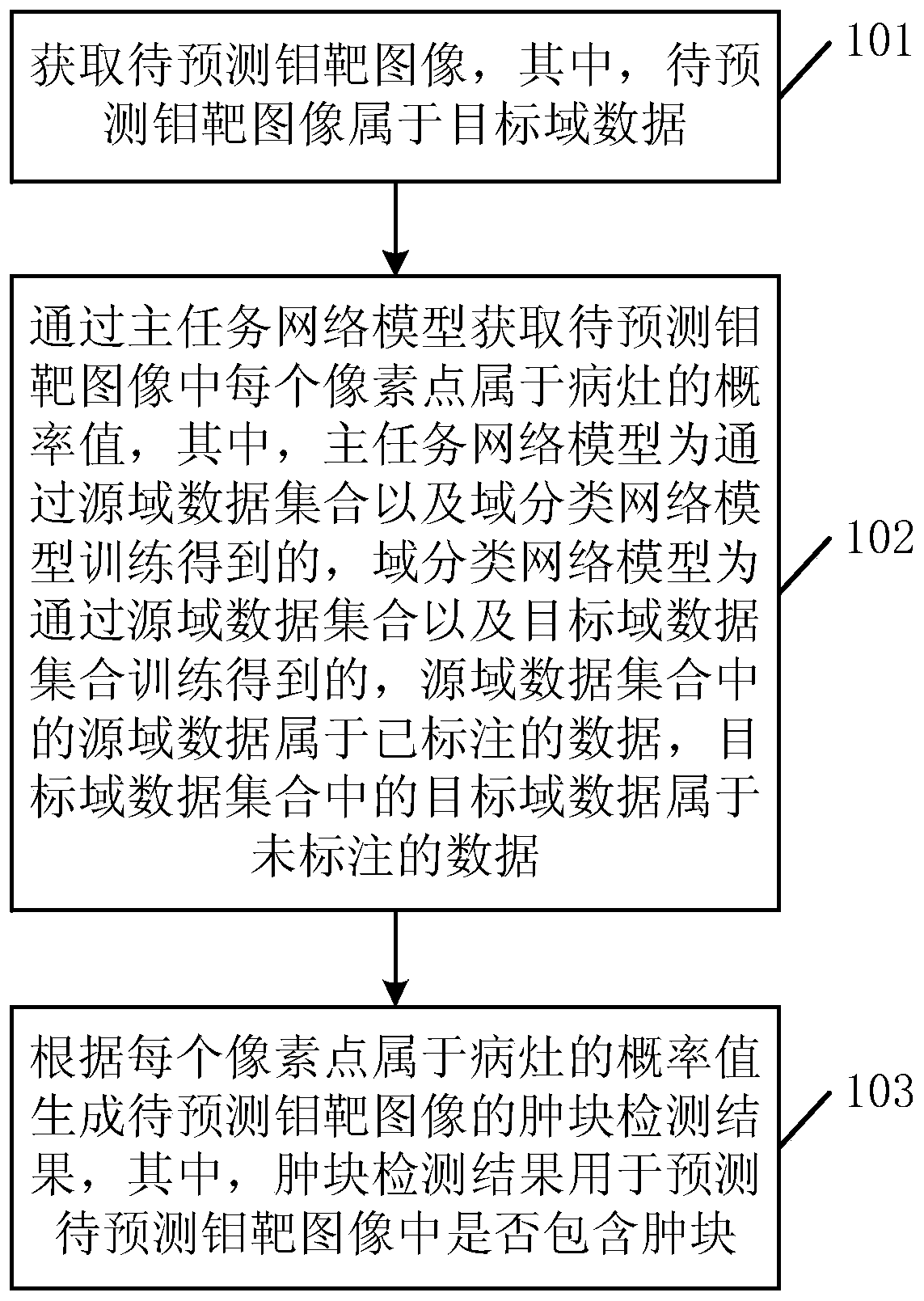

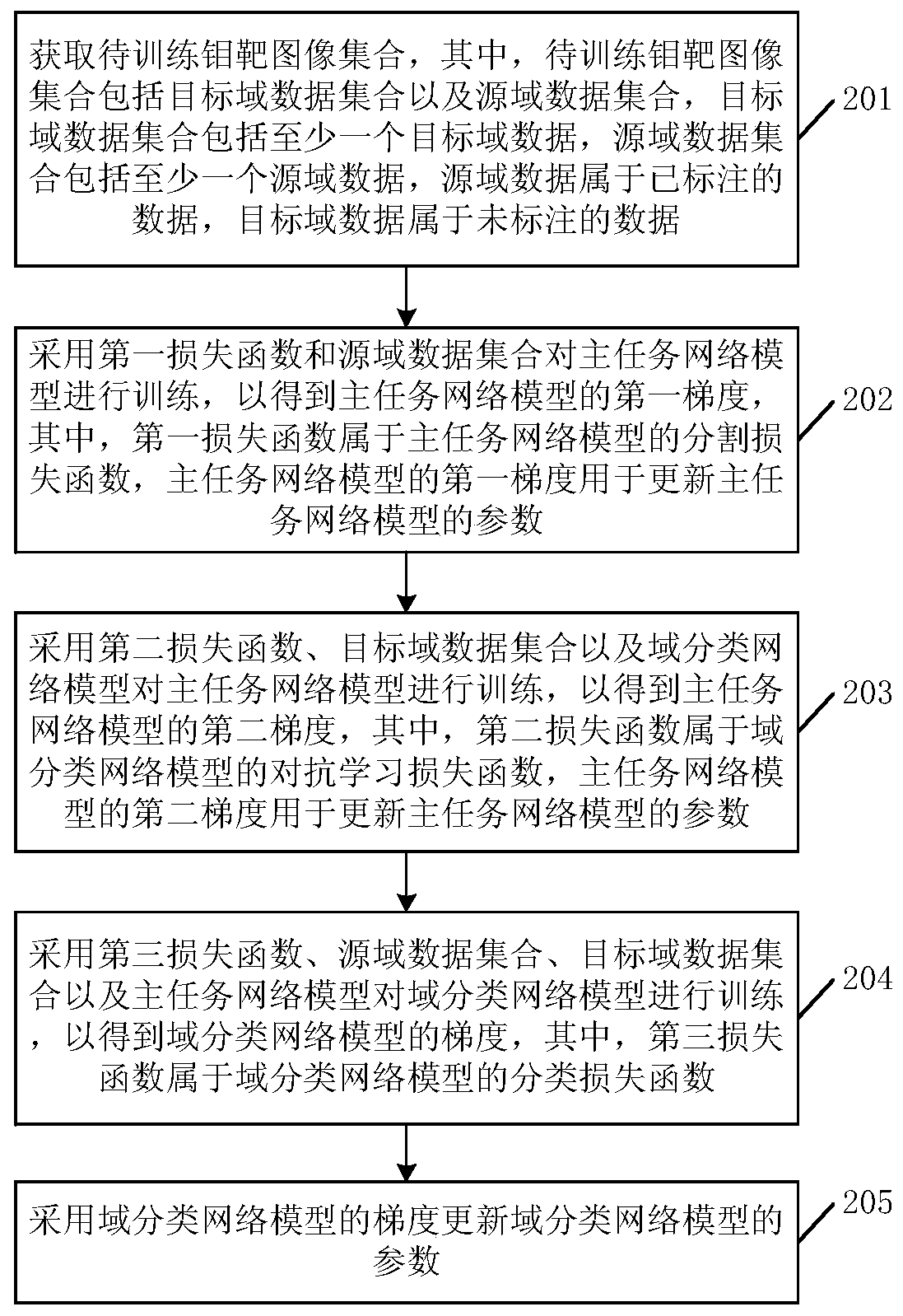

Medical image-based focus detection method, model training method and model training device

ActiveCN110414631AEasy to detectDomain difference suppressionRecognition of medical/anatomical patternsTask networkData set

The invention discloses a medical image-based focus detection method. The method is applied to the field of artificial intelligence. The method can be specifically applied to the field of intelligentmedical treatment. The method comprises the steps: obtaining a to-be-predicted molybdenum target image; obtaining a probability value of each pixel point belonging to a focus in the to-be-predicted molybdenum target image through a main task network model, the main task network model being obtained through training of a source domain data set and a domain classification network model, and the domain classification network model being obtained through training of the source domain data set and a target domain data set; and generating a lump detection result of the to-be-predicted molybdenum target image according to the probability value of each pixel point belonging to the focus. The invention further provides a model training method and device. According to the method, the problem of domain difference between the source domain data set and the target domain data set is solved by utilizing the relationship between the main task network model and the domain classification network model.Therefore, the main task network model obtains excellent detection performance on the target data set.

Owner:TENCENT TECH (SHENZHEN) CO LTD +1

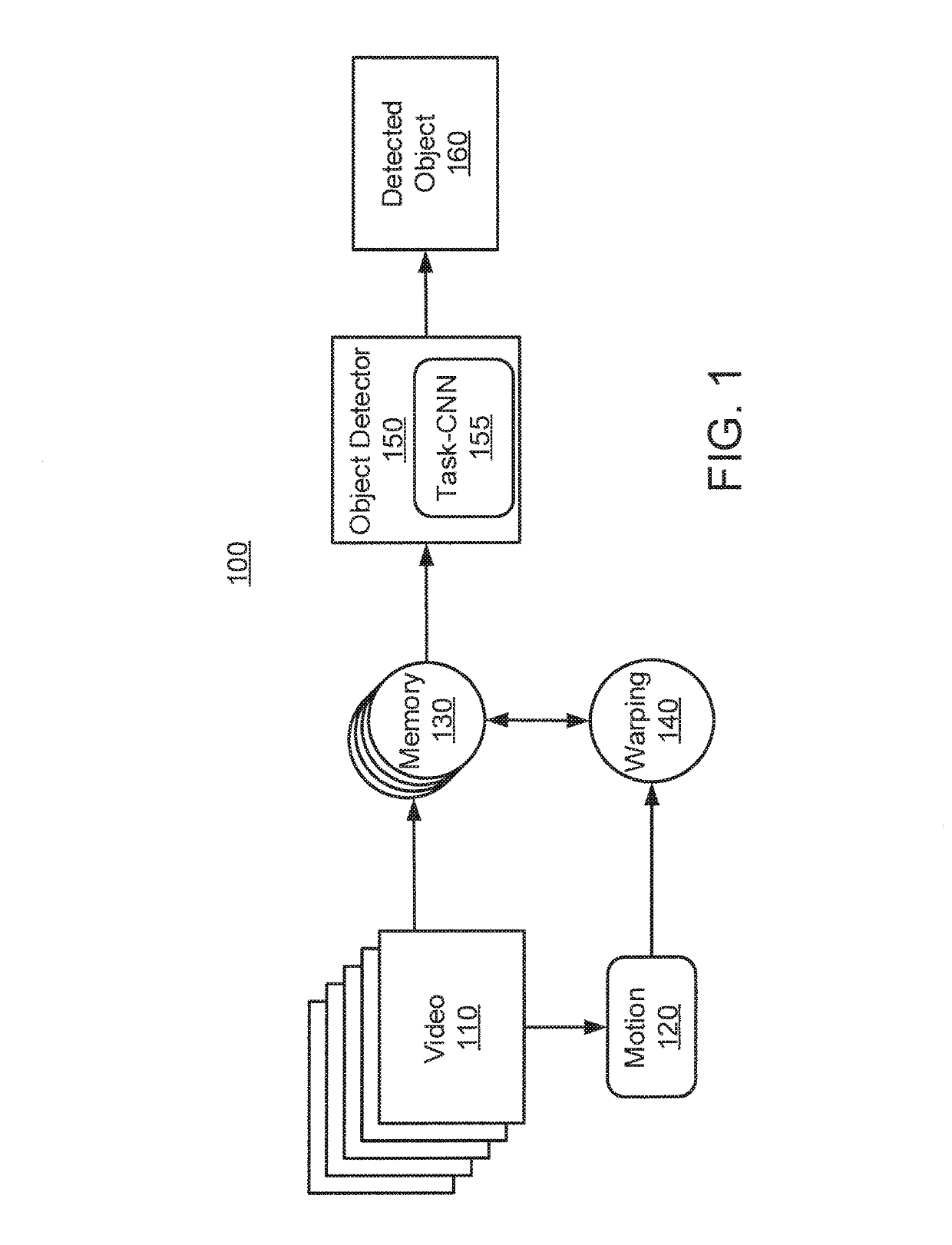

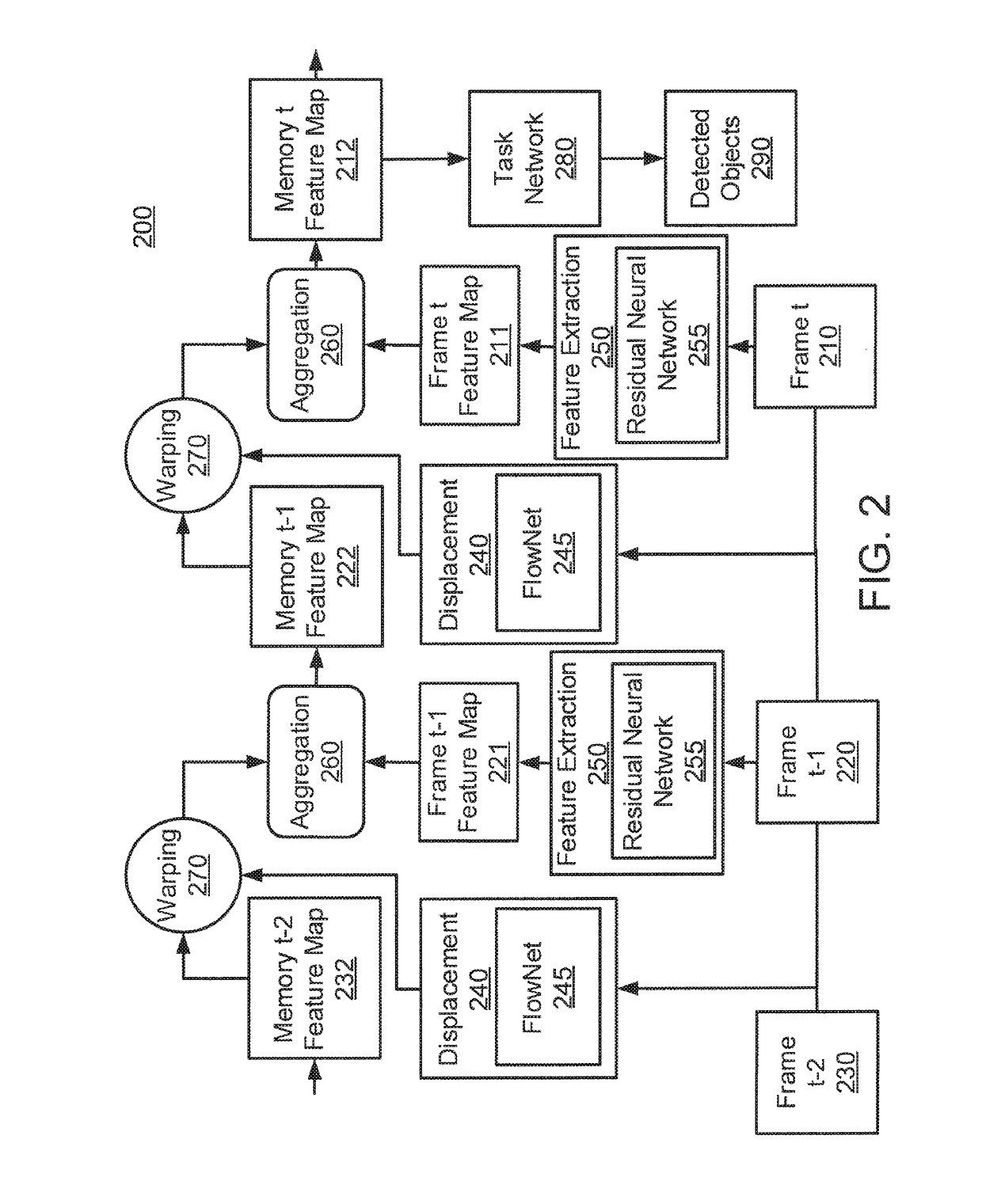

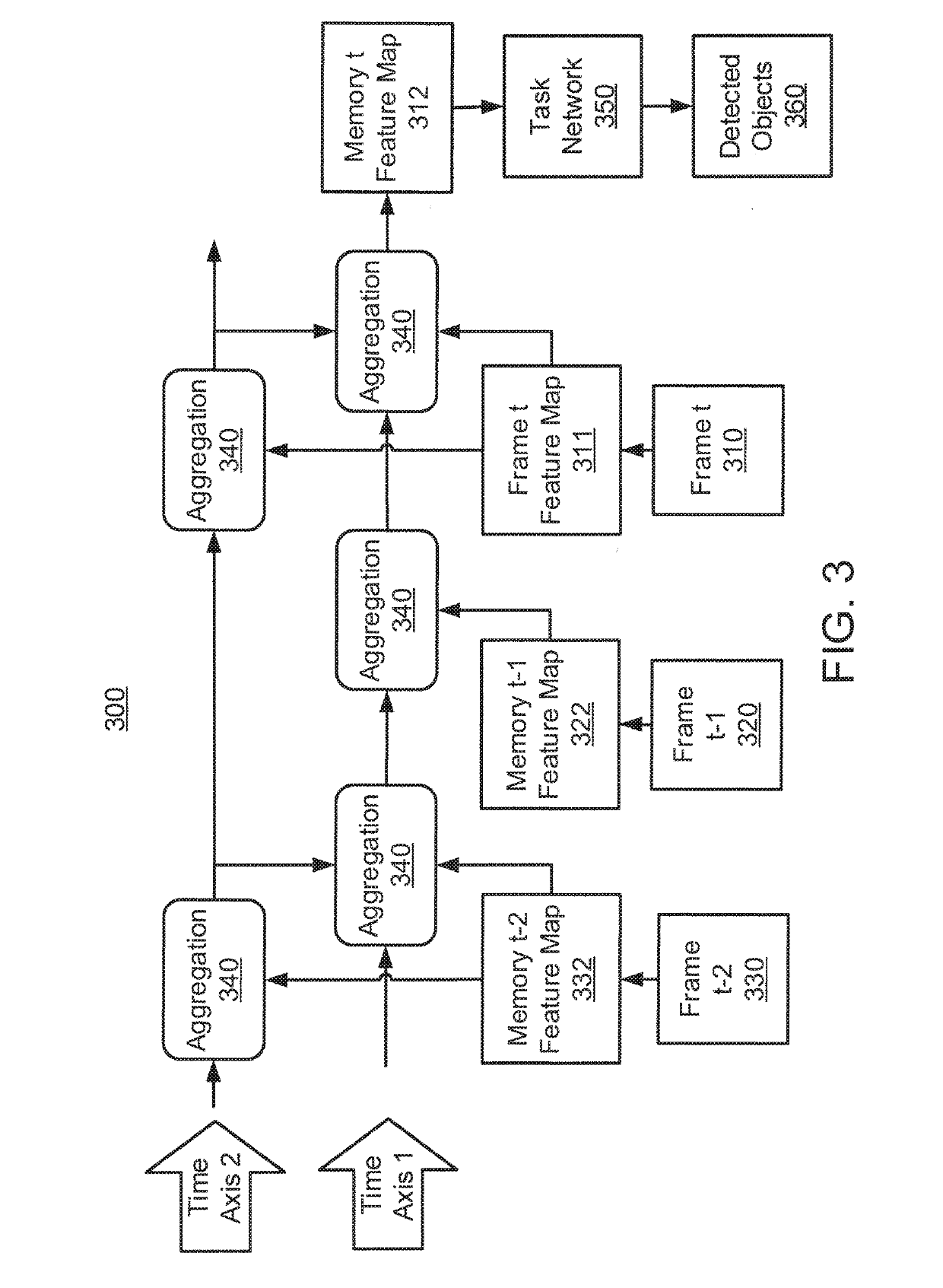

Online flow guided memory networks for object detection in video

A computer-implemented method, system, and computer program product are provided for object detection utilizing an online flow guided memory network. The method includes receiving, by a processor, a plurality of videos, each of the plurality of videos including a plurality of frames. The method also includes generating, by the processor with a feature extraction network, a frame feature map for a current frame of the plurality of frames. The method additionally includes determining, by the processor, a memory feature map from the frame feature map and a previous memory feature map from a previous frame by warping the previous memory feature map. The method further includes predicting, by the processor with a task network, an object from the memory feature map. The method also includes controlling an operation of a processor-based machine to react in accordance with the object.

Owner:NEC CORP

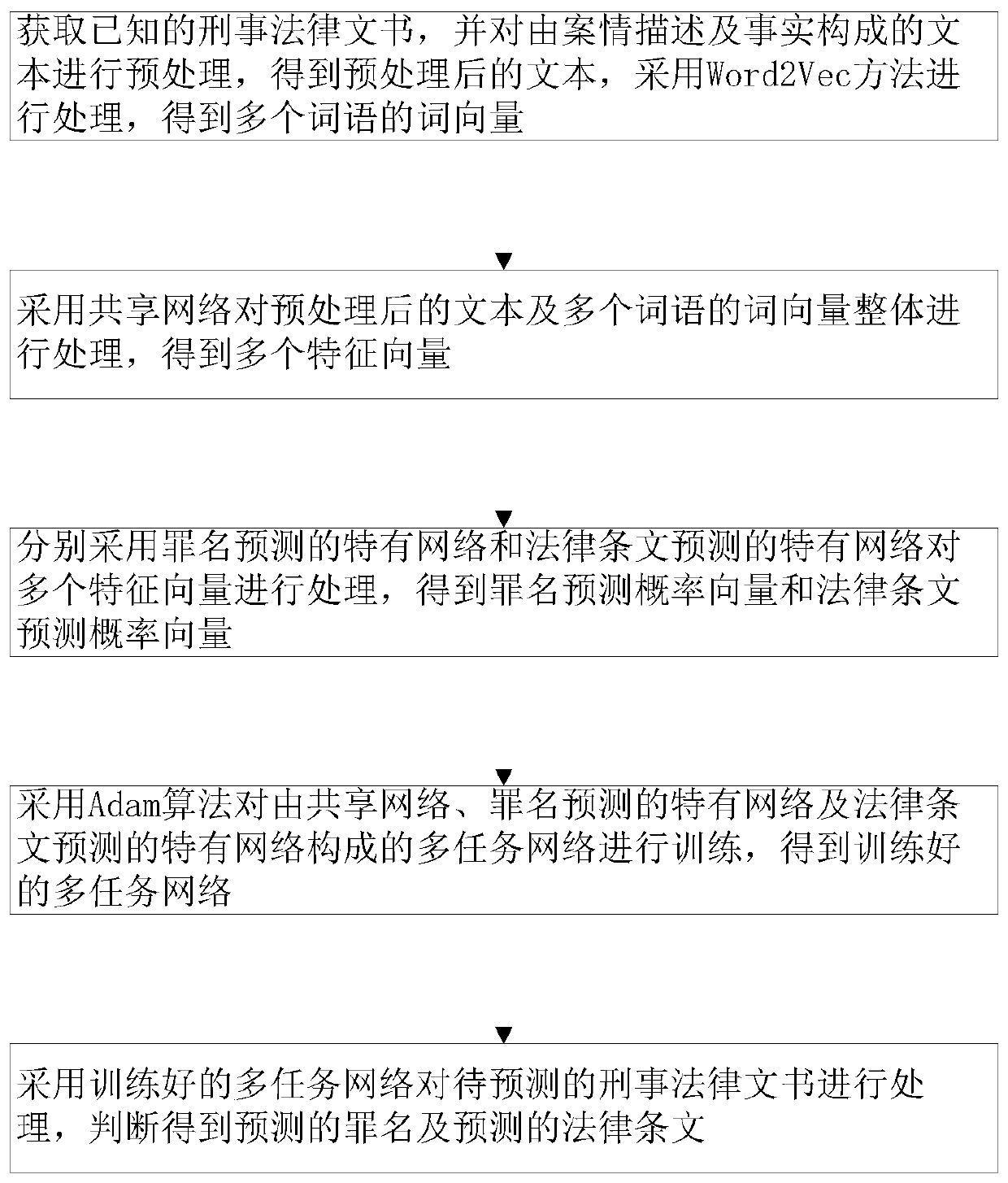

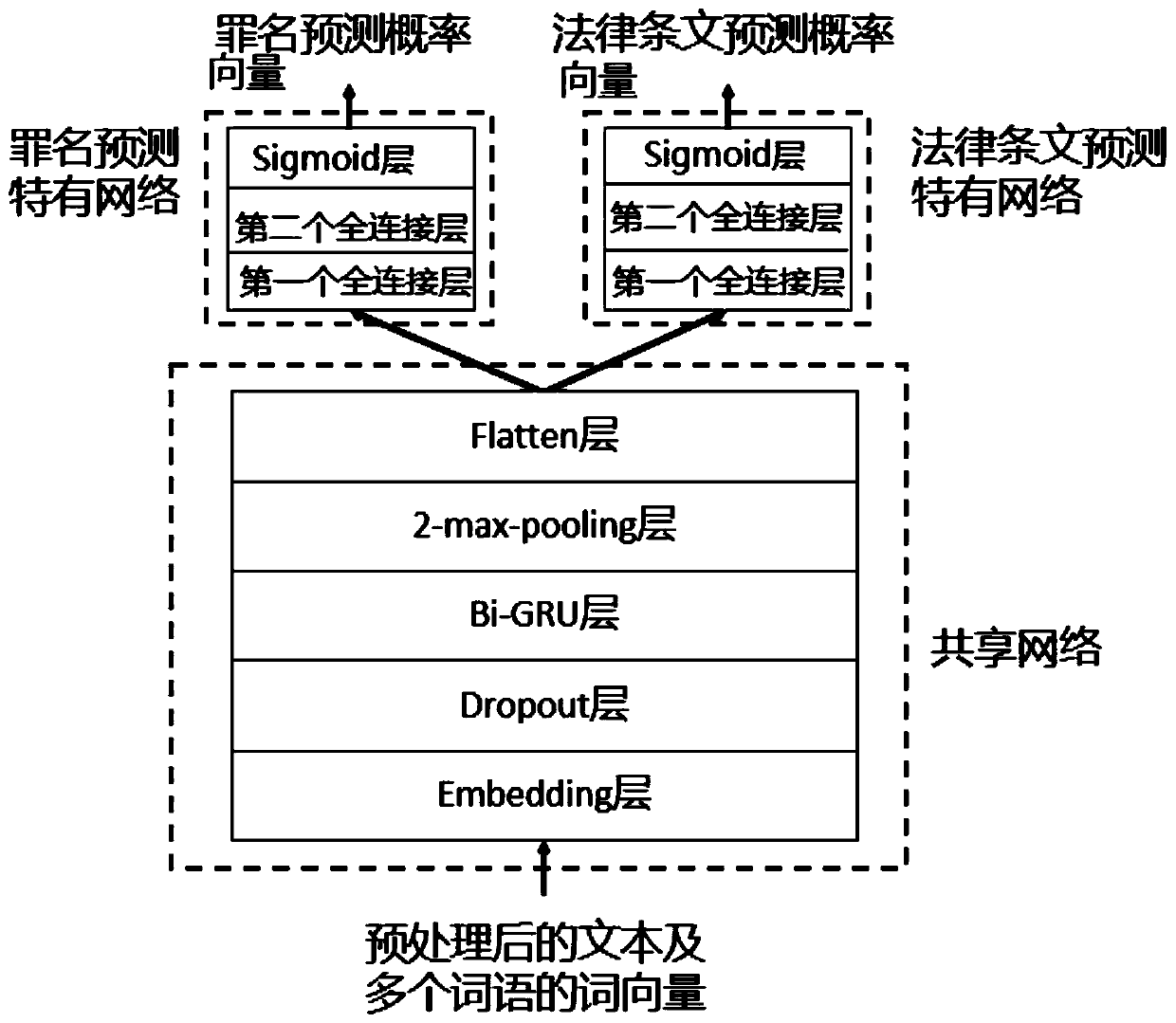

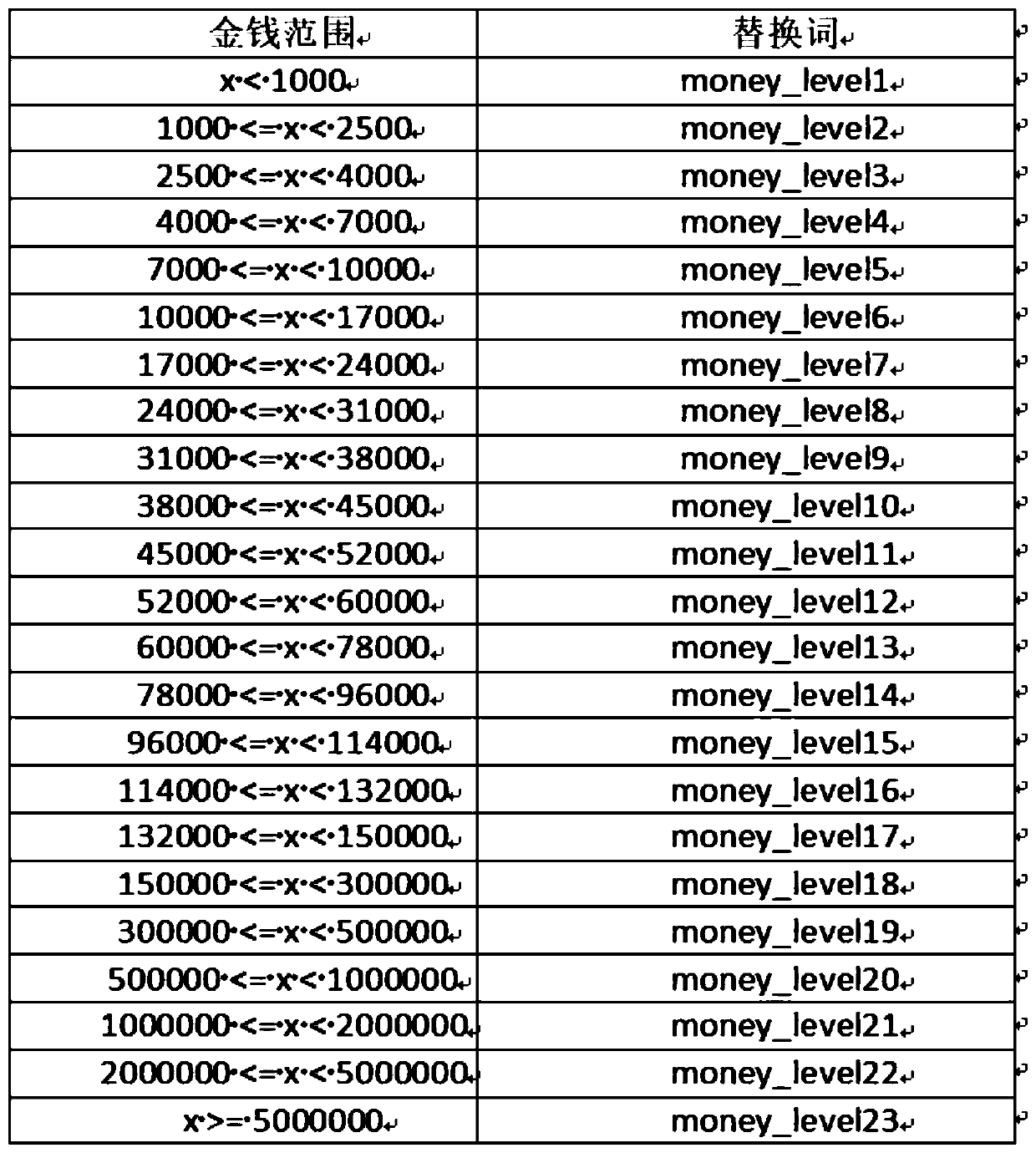

Multi-task network construction and multi-scale charge legal provision joint prediction method

ActiveCN110188192AQuick updateImprove accuracySemantic analysisForecastingTask networkCoverage ratio

The invention provides a multi-task network construction method, which comprises the following steps: processing a text consisting of case description and facts in a known criminal legal document to obtain a preprocessed text and word vectors of a plurality of words; processing and training the preprocessed text and word vectors of a plurality of words by adopting a multi-task network formed by aspecial network of a shared network, charge prediction and legal provision prediction, and finally obtaining a trained multi-task network. The invention also provides a multi-scale charge legal provision joint prediction method, which comprises the following steps: processing a text consisting of case description and facts in the charge legal document to be predicted to obtain a preprocessed textand word vectors of a plurality of words, processing by adopting the trained multi-task network, and judging to obtain a predicted charge and a predicted legal provision. According to the method, thetwo tasks are combined to extract the features together, the prediction accuracy can be effectively improved, and meanwhile, the coverage rate and diversity of prediction on categories are improved.

Owner:XIDIAN UNIV

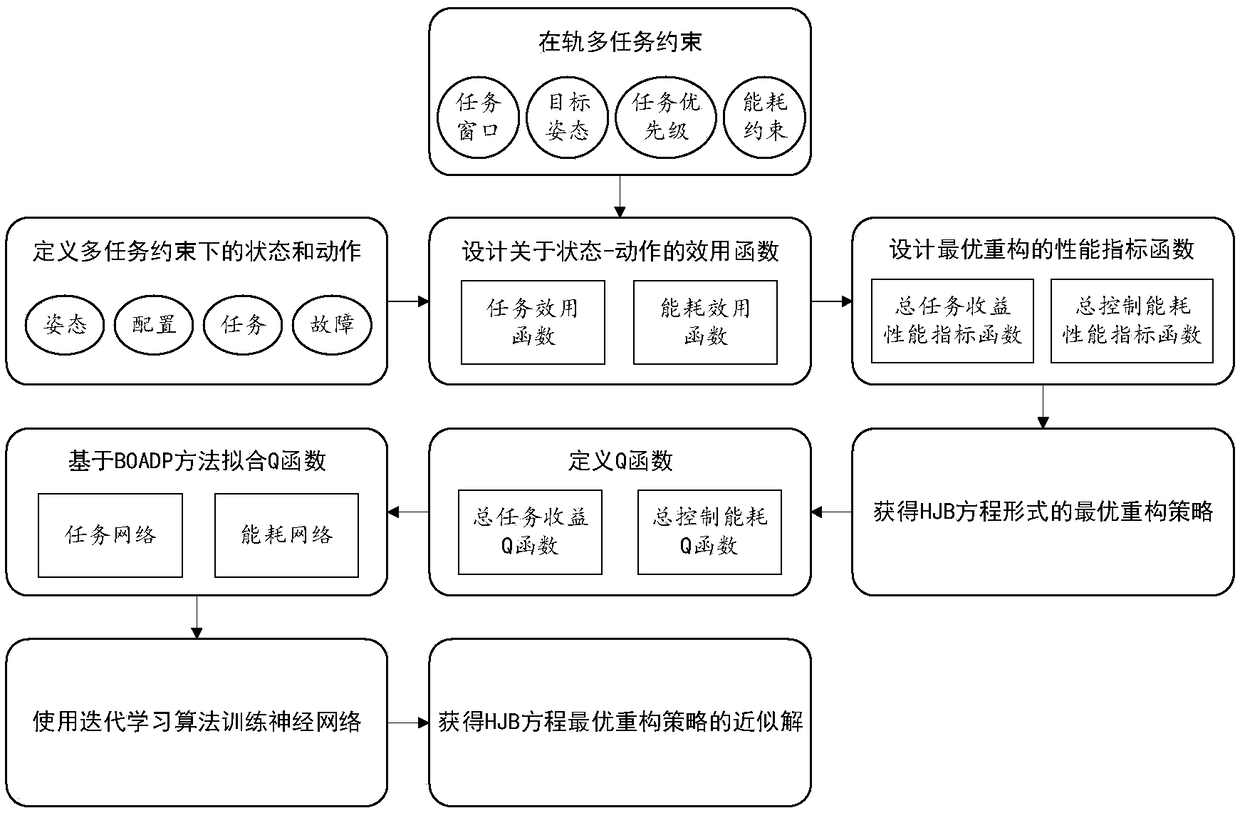

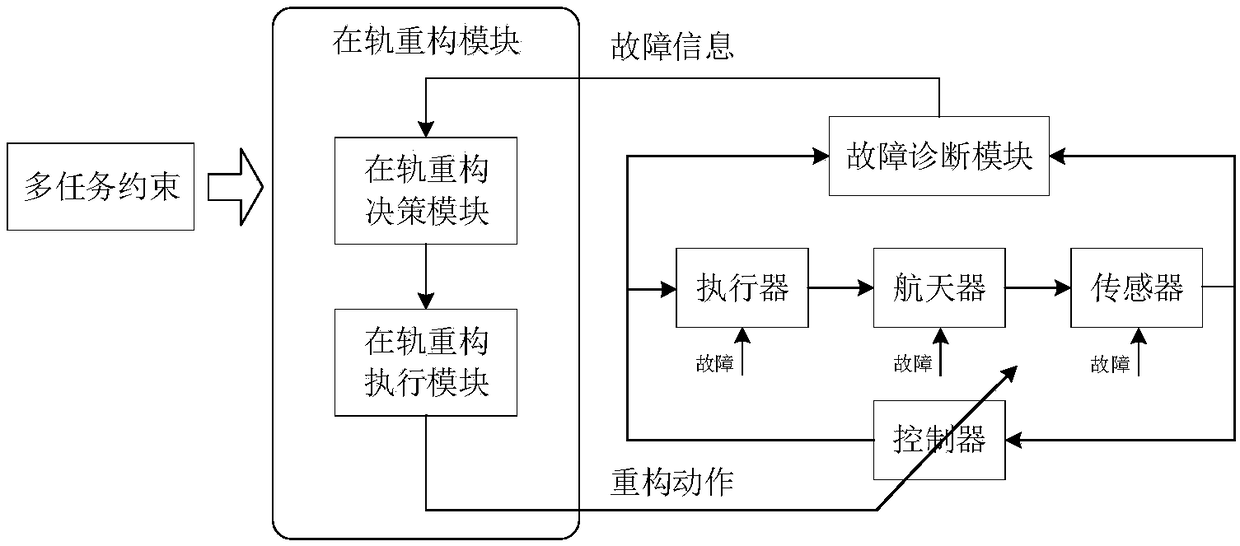

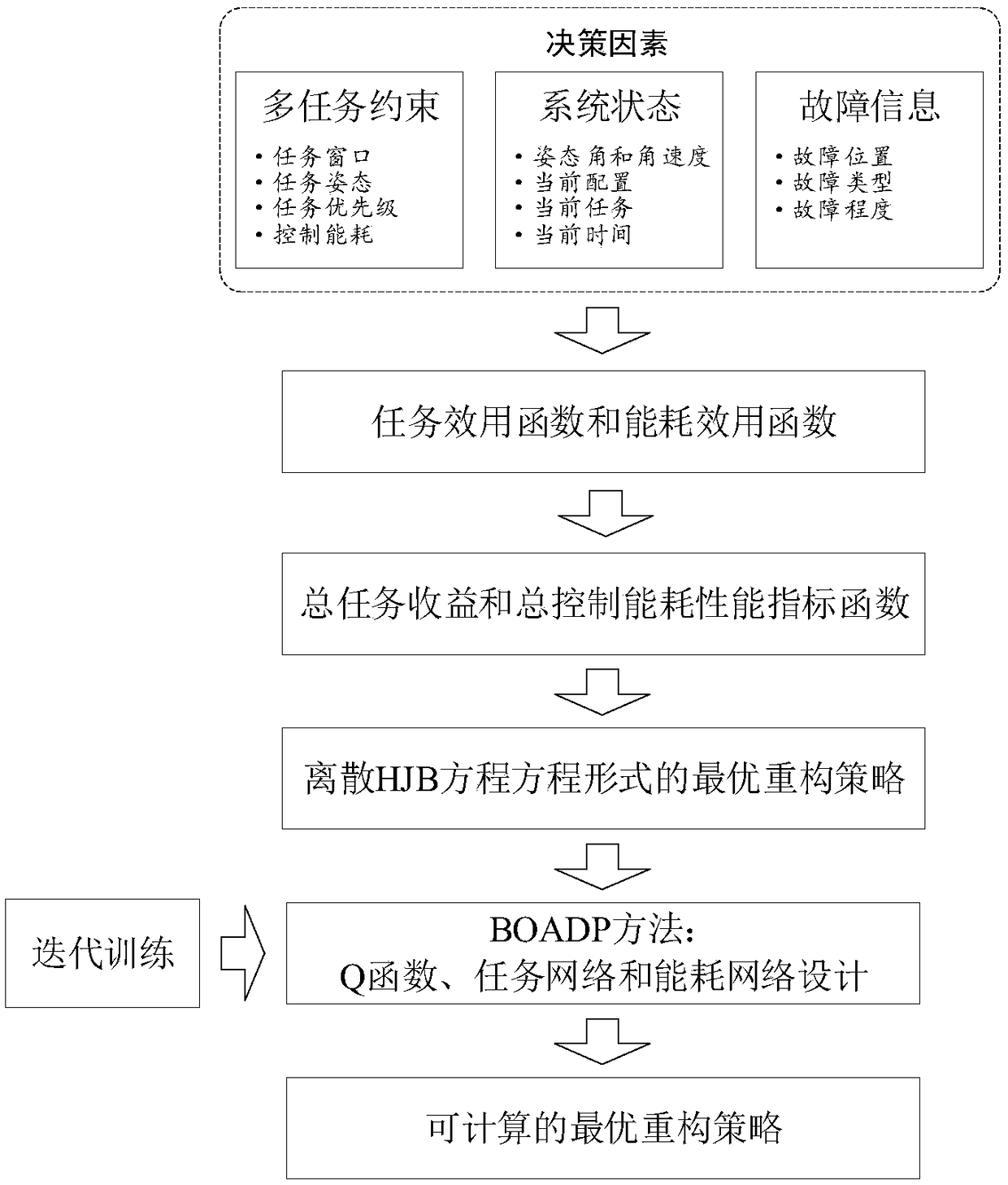

Spacecraft ACS on-orbit reconstruction method oriented to multi-task multi-index optimization constraints

ActiveCN108594638AImprove task performanceImprove failure response capabilitiesAdaptive controlIterative learning algorithmTask completion

The invention discloses a spacecraft ACS on-orbit reconstruction method oriented to multi-task multi-index optimization constraints, and belongs to the technical field of spacecraft attitude control.According to the method, for a spacecraft with on-orbit time relevant multi-task constraint, the state and the motion under the multi-task constraint are defined, a utility function about the state-motion is designed and a performance index function is determined, and then an optimal reconstruction strategy in the form of the HJB equation is obtained. Aiming at the problem that the HJB equation isdifficult to solve accurately, an approximate solution method based on the BOADP is provided, the task network and the energy consumption network are designed for estimating two performance index functions, and the convergence of neural network estimation errors is achieved through an iterative learning algorithm, so that an approximate solution of the HJB equation is achieved, and then an optimal reconstruction strategy is obtained, and the maximization of the task earnings is achieved by controlling the energy consumption as few as possible. According to the invention, the multi-task completion capability and the fault response capability of the spacecraft are improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

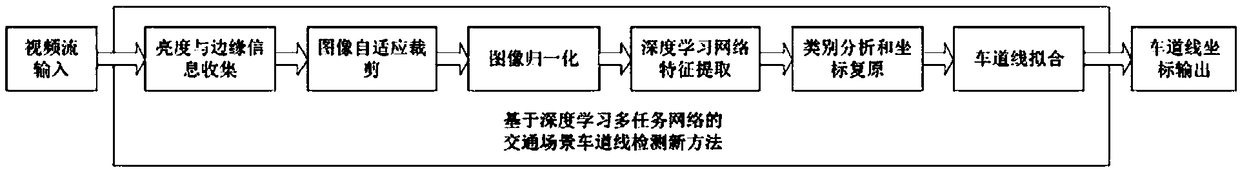

Traffic lane detection method and device based on depth learning multitask network

ActiveCN109345547AMeet real-time requirementsImprove adaptabilityImage enhancementImage analysisTask networkImage type

The invention discloses a traffic scene lane line detection method and device based on depth learning multi-task network, Compared with the traditional lane detection algorithm based on straight linedetection, A deep learning multitask convolution neural network (CNN) is introduced, extracting lane characteristic information, As that detail information of each layer of the image is fully utilize,At first, that brightness and the edge information of the image are collect and evaluated, According to the evaluation results, the image is divided into several image blocks, then the image is normalized and sent to the depth learning network to output the lane image types and coordinates, and then the lane fitting is carried out by using the spatial image correlation, so as to realize the function of identifying the lane information accurately and quickly in different scenes and brightness. The invention is suitable for the application of bayonet camera and electronic police in the field ofintelligent transportation. On the premise of ensuring the real-time image analysis, the invention fully utilizes the depth learning network, and effectively improves the adaptability and accuracy ofthe lane line detection function.

Owner:TIANJIN TIANDY DIGITAL TECH

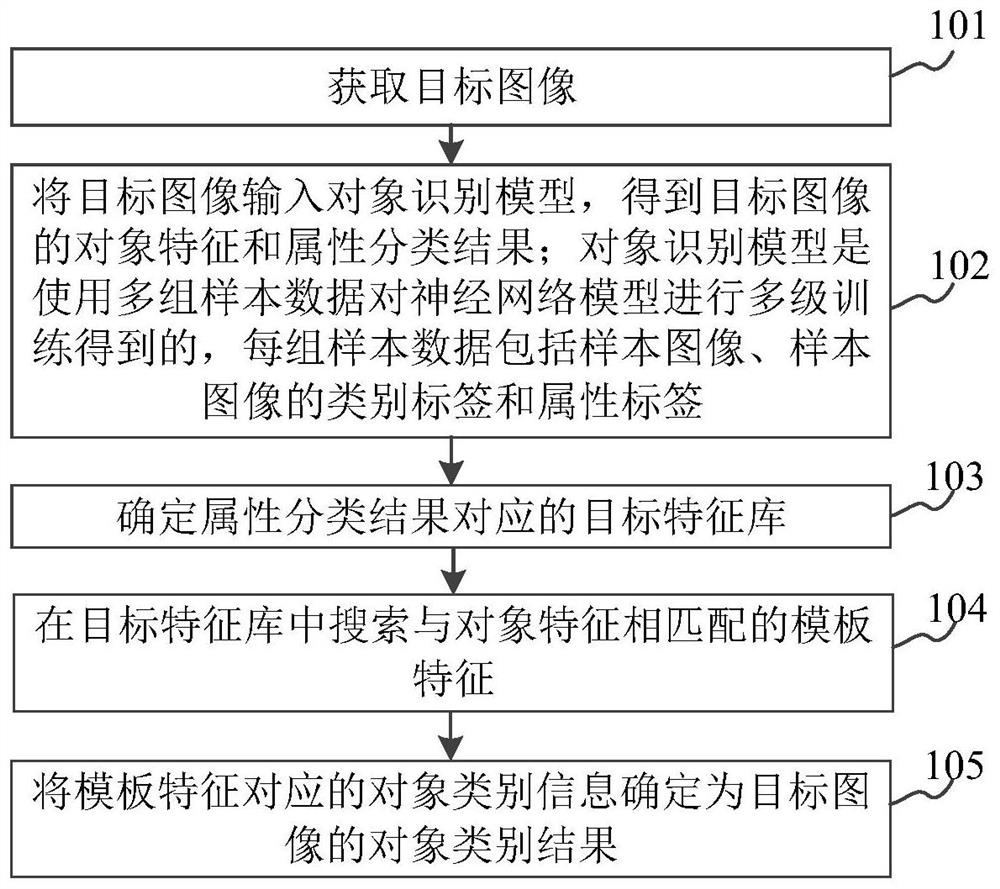

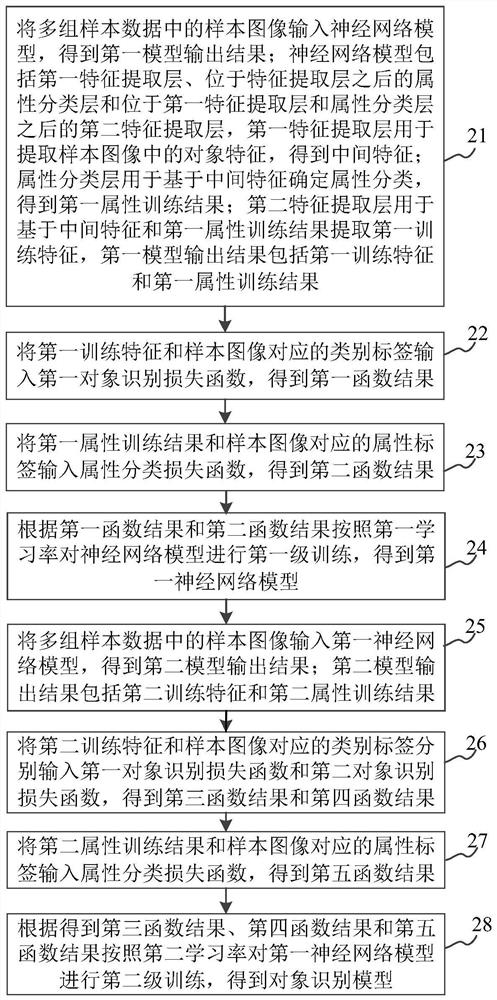

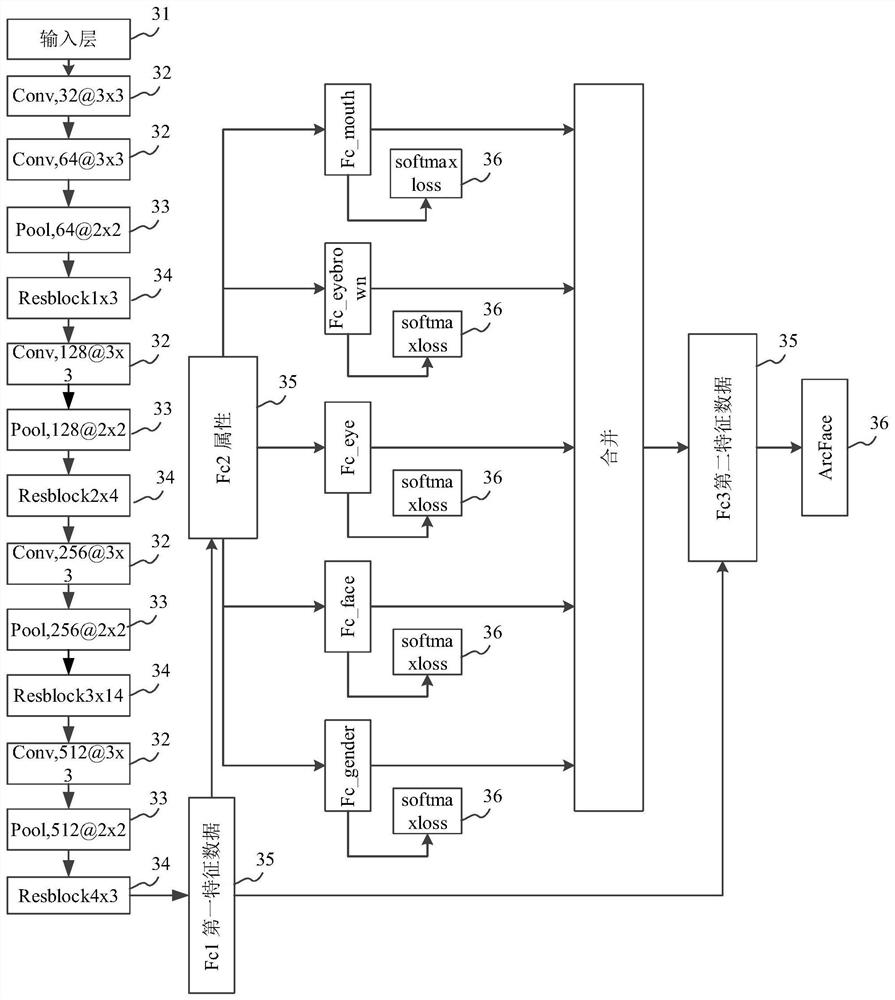

Object recognition method and device and storage medium

ActiveCN111931592AResolve identifiabilitySolve efficiency problemsCharacter and pattern recognitionNeural architecturesData packSample graph

The invention relates to an object recognition method and device and a storage medium, and belongs to the technical field of computers. The method comprises the steps: inputting a target image into anobject recognition model, and obtaining the object features and attribute classification results of the target image; wherein the object recognition model is obtained by using multiple groups of sample data to perform multi-stage training on a neural network model, and each group of sample data comprises a sample image, and a category label and an attribute label of the sample image; searching template features matched with the object features in a target feature library corresponding to the attribute classification result to obtain object category information corresponding to the template features; as the object recognition model learns two tasks of object features and object attributes together, the object features and the object attributes can assist each other to improve the model performance during training; sharing of two task network parameters can reduce the number of models and improve the feature extraction speed; and the template features are searched from the target feature library, so that the comparison frequency can be reduced, and the matching efficiency is improved.

Owner:SUZHOU KEDA TECH

Dynamic combination method for geographic model network services

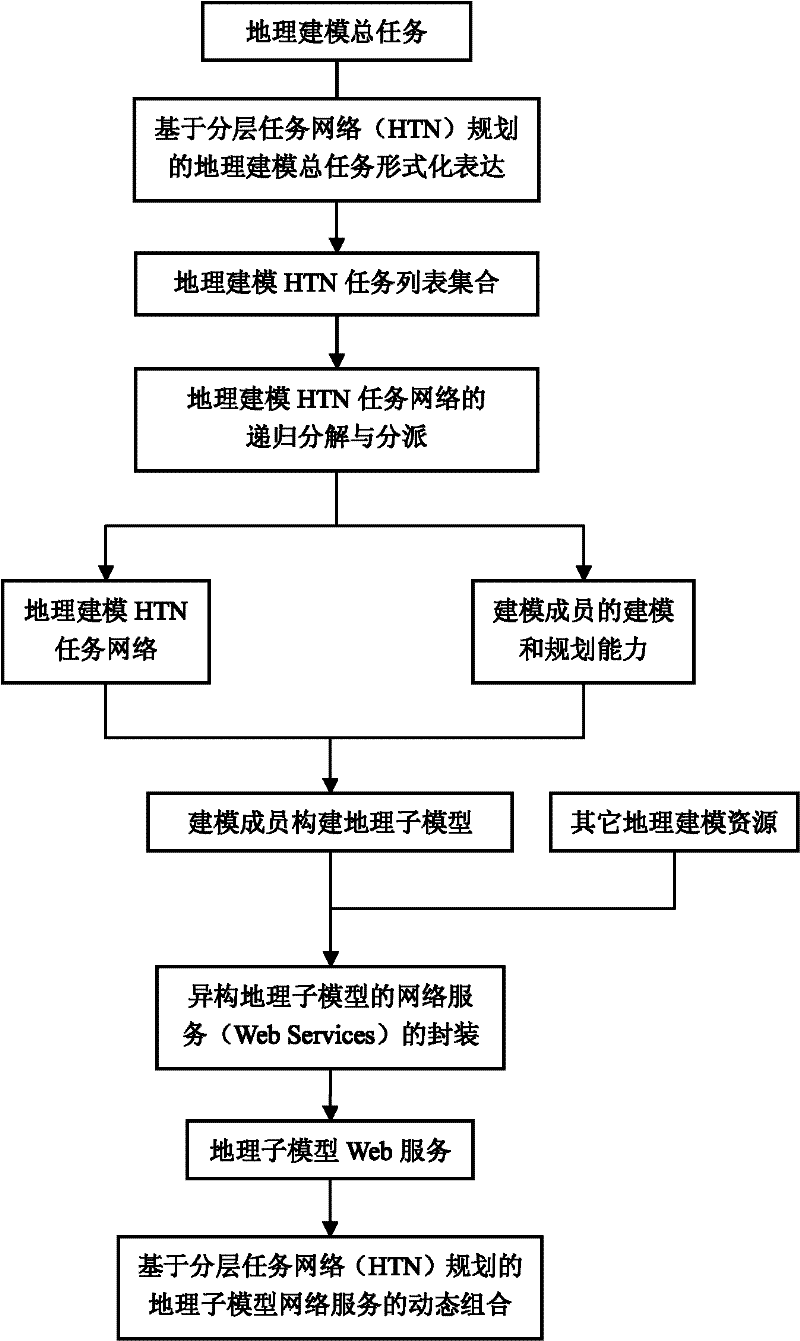

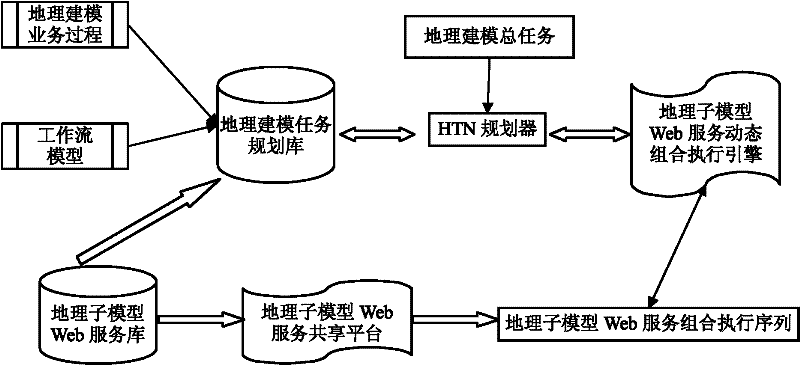

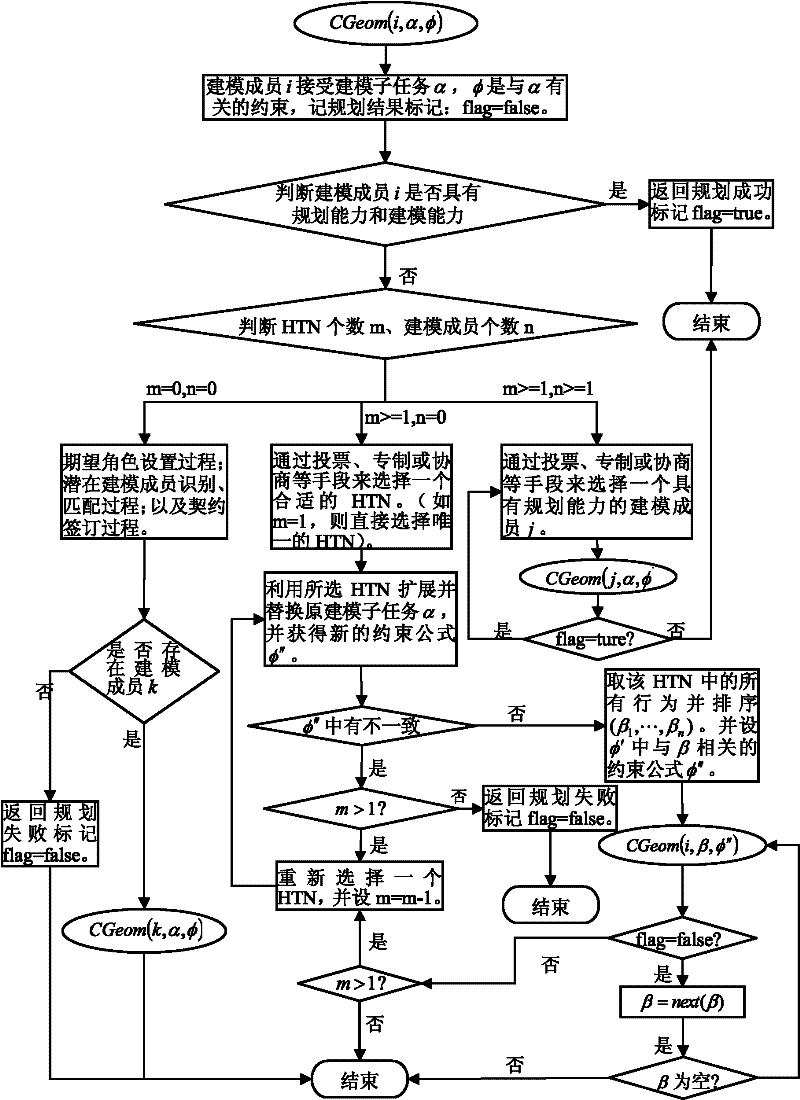

InactiveCN102253974ARealize collaborative combination execution communicationEfficient packagingTransmissionSpecial data processing applicationsTask networkDecomposition

The invention relates to a dynamic combination method for geographic model network services. The method comprises the following steps: carrying out formalization expression on a general task of complicated geographic modeling based on HTN (Hierarchical Task Network) planning and generating a geographic modeling HTN task network set; implementing the recursion decomposition and assignment of a geographic modeling HTN task network, obtaining the geographic modeling HTN task network and assigning to corresponding modeling members; encapsulating isomerous geographic sub-models established by eachmember into the corresponding network services by adopting a web service technique and deploying each geographic sub-model network service on a sharing platform to be shared and reused; and realizingthe dynamic combination of the geographic sub-model network services by utilizing an HTN planning method and executing an engine to realize cooperative execution and computation through the dynamic combination of the geographic sub-model network services. Under the condition that the program and operation mode of each geographic sub-model are not changed, the dynamic combination method provided by the invention can realize the dynamic combination of distributed cooperative geographic model network services and has the advantages of good autonomy, encapsulation, dynamism and flexibility.

Owner:CHINA UNIV OF MINING & TECH

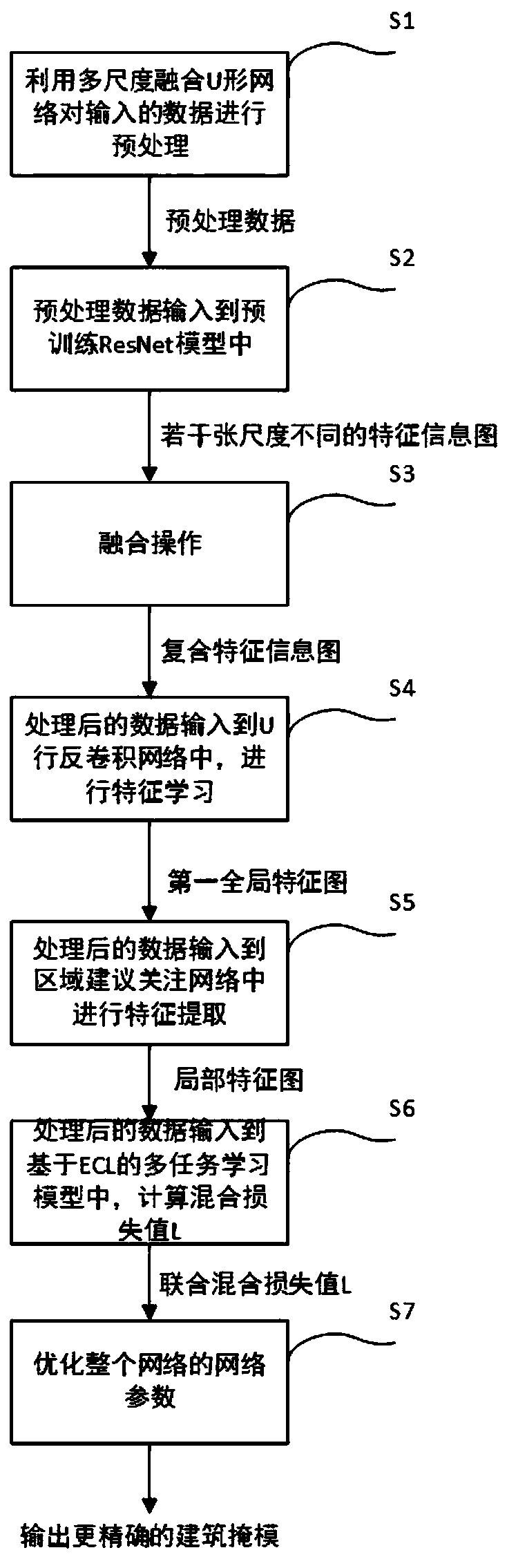

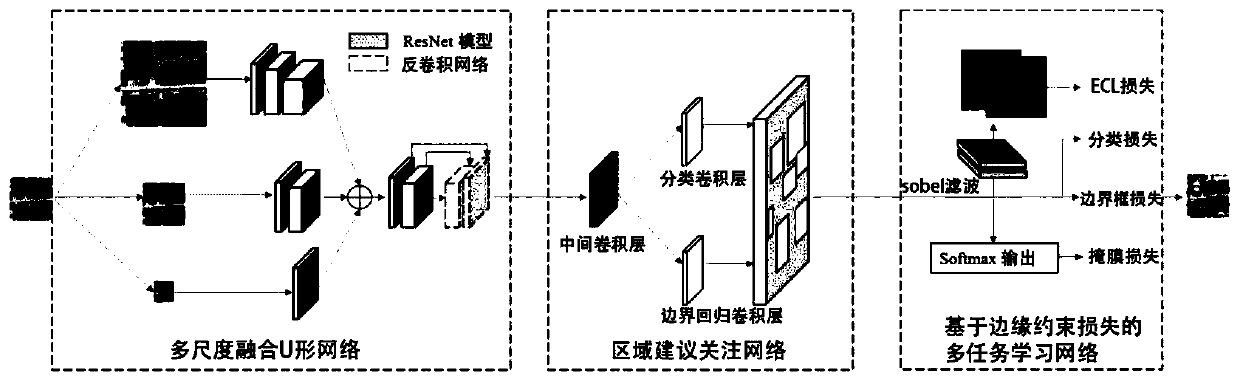

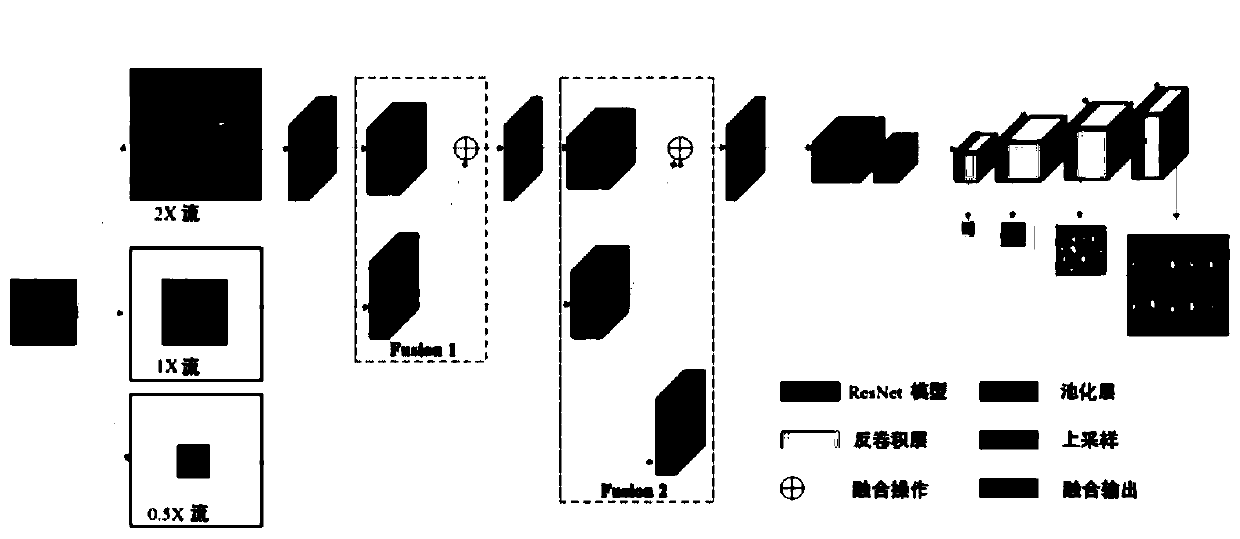

And realizing building instance mask extraction method of remote sensing image based on U-shaped CNN model

ActiveCN110110729ASuppress overcompensationImprove performanceCharacter and pattern recognitionNeural architecturesTask networkData set

The invention provides a building mask extraction method for realizing a remote sensing image based on a multi-scale and multi-task U-shaped CNN network model. Accurate building mask extraction of a high-resolution remote sensing image under different scales is realized in an instance segmentation mode. According to the building mask extraction method provided by the invention, a multi-scale multi-task network integrating a U-shaped network, a region suggestion attention network and edge constraint loss is applied, and the whole network is quickly converged by optimizing multi-task mixed lossof a joint ECL and the like, so that excessive compensation in limited available training data is inhibited. According to the method, excellent performance and high robustness are achieved on different scales, and the precision of various data sets is remarkably improved.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

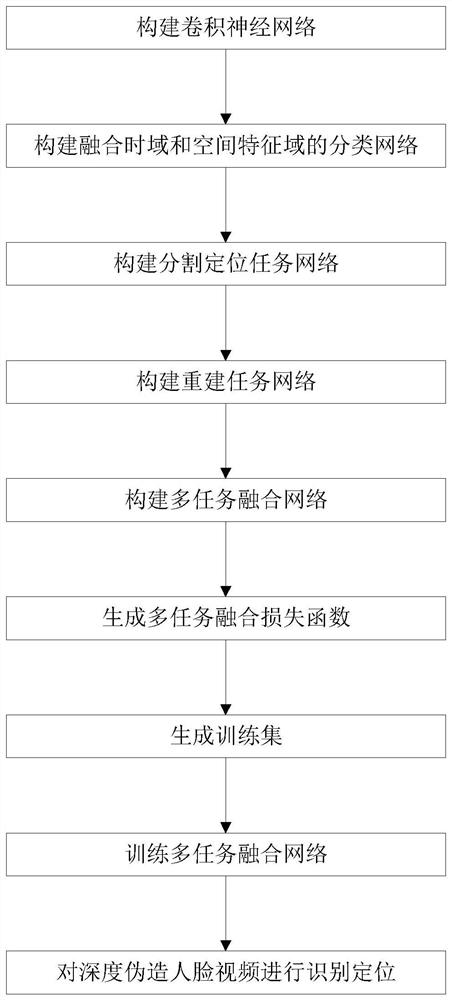

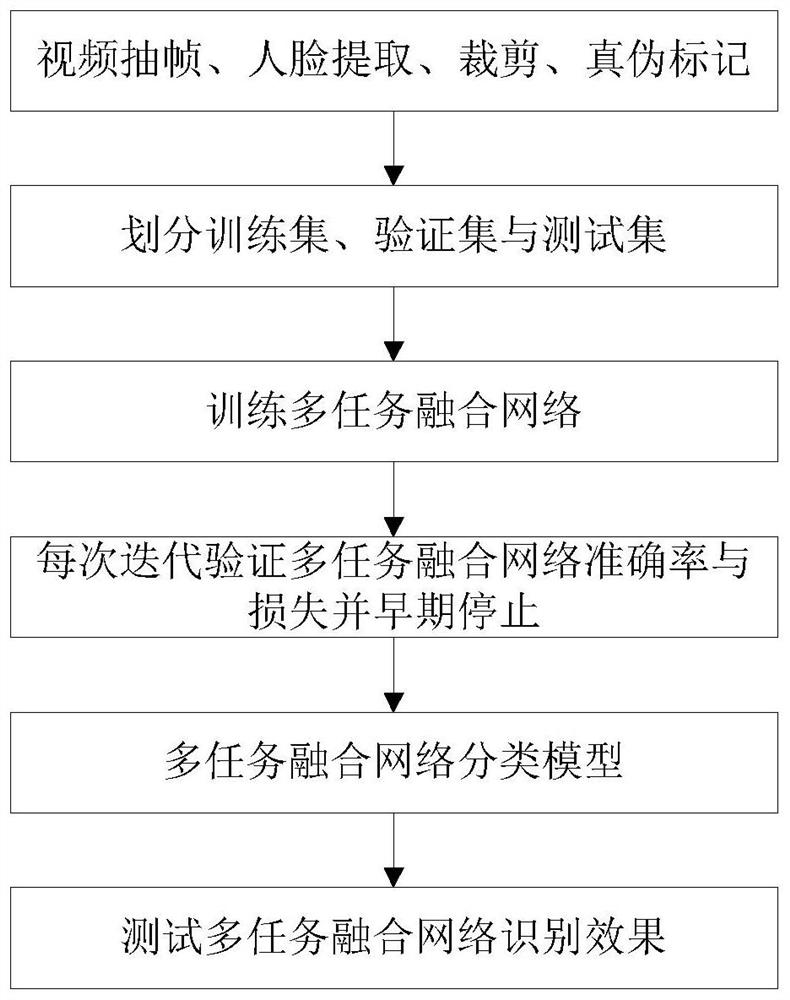

Deep fake face video positioning method based on space-time fusion

ActiveCN113011357AOvercoming the problem of reduction in recognition accuracyImprove the accuracy of false identification classificationCharacter and pattern recognitionNeural architecturesTime domainTask network

The invention discloses a deep fake face video positioning method based on space-time fusion. The method comprises the following steps: (1) constructing a convolutional neural network; (2) constructing a classification network fusing time domain and space domain features; (3) constructing a segmentation positioning task network; (4) constructing a reconstruction task network; (5) constructing a multi-task fusion network; (6) generating a multi-task fusion loss function; (7) generating a training set; (8) training the multi-task fusion network; (9) identifying and positioning the deeply-forged face video. According to the method, the classification network fusing the time domain and space domain features is constructed to extract the features, more complete intra-frame and inter-frame features can be extracted, and higher accuracy is obtained; meanwhile, the multi-task fusion loss function used for training the multi-task fusion network is constructed, and the accuracy of the multi-task fusion network is improved. The problem that generalization ability and function completeness are affected due to the fact that no attack category exists and tasks are simplified is solved.

Owner:XIDIAN UNIV

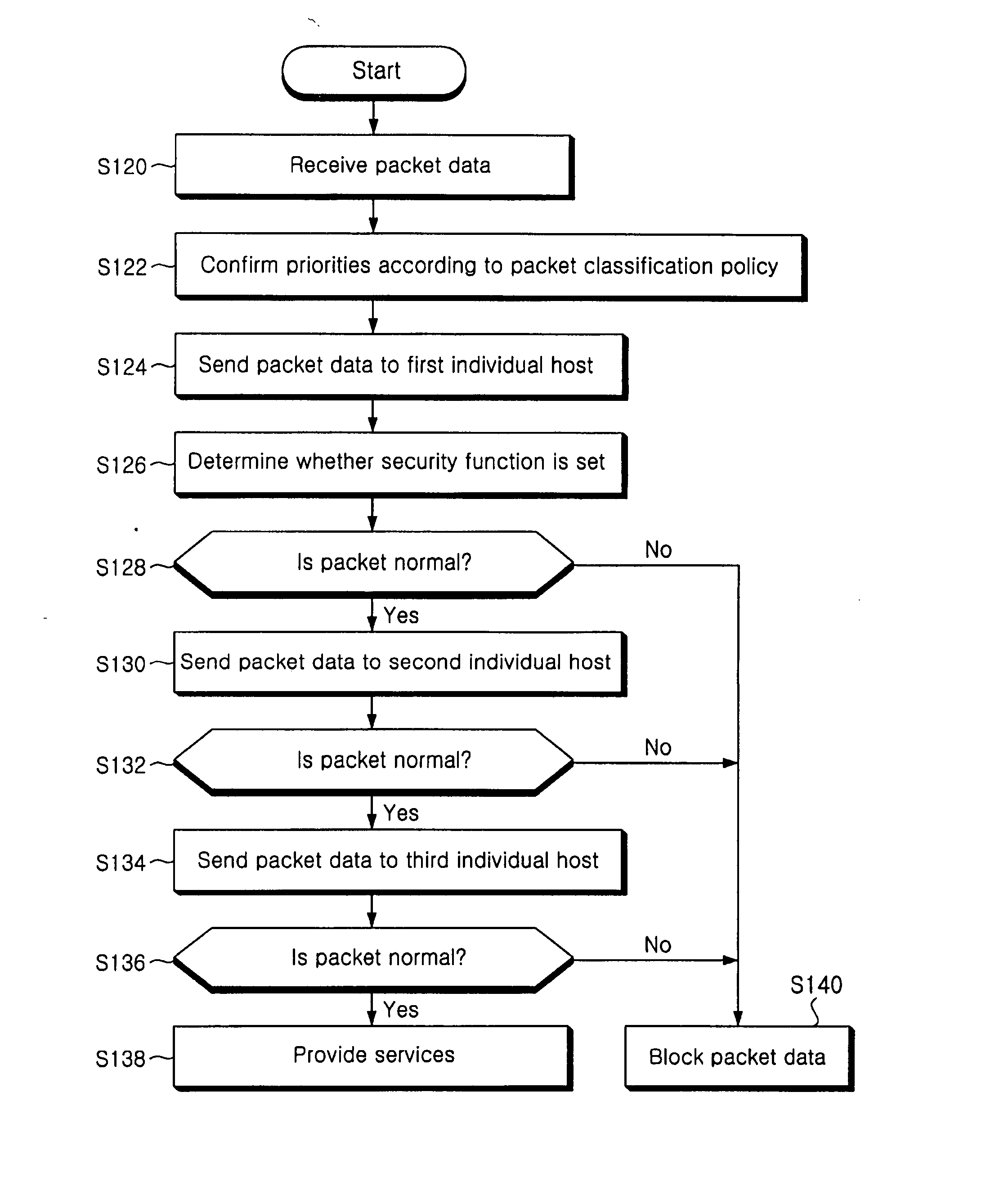

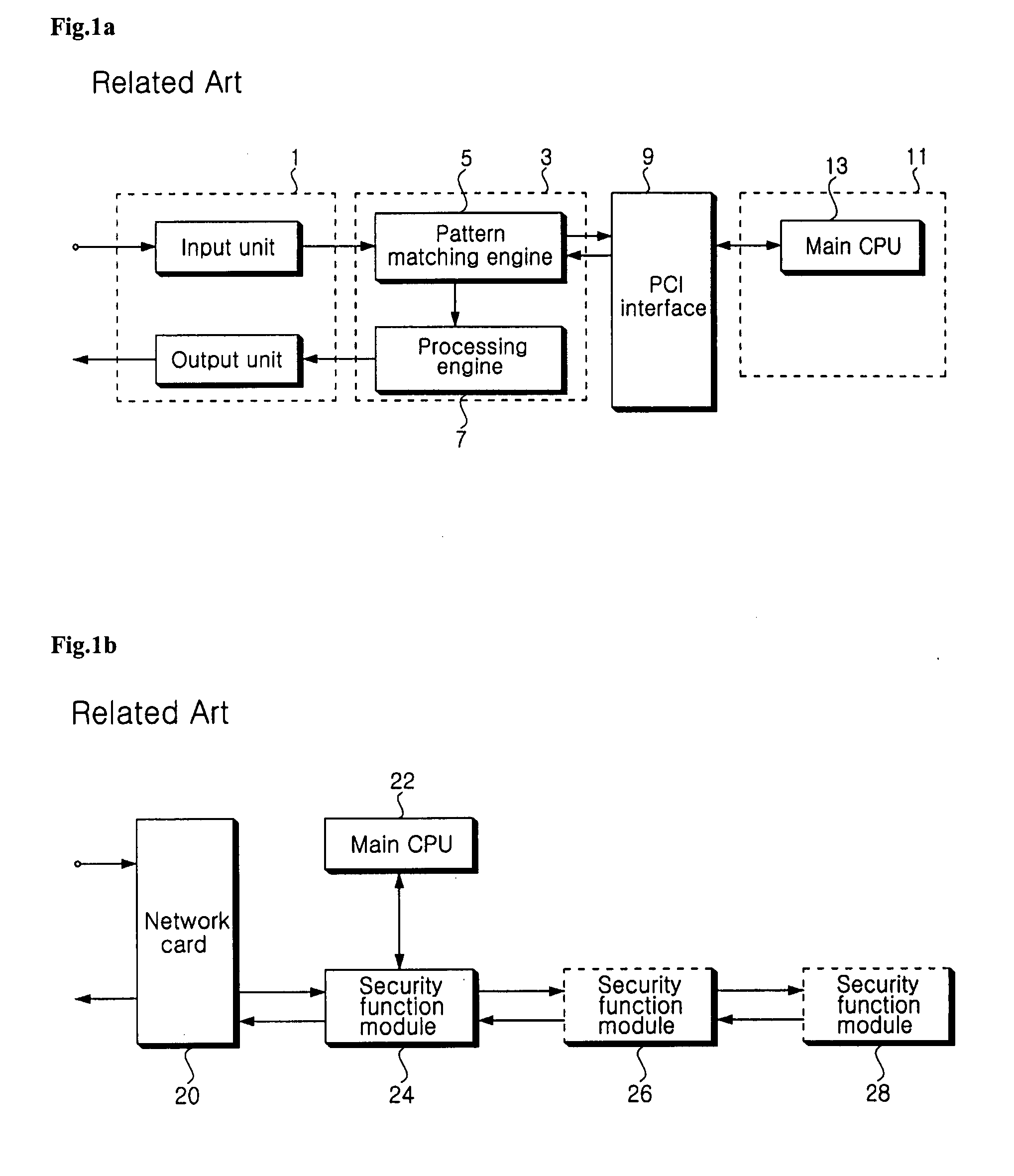

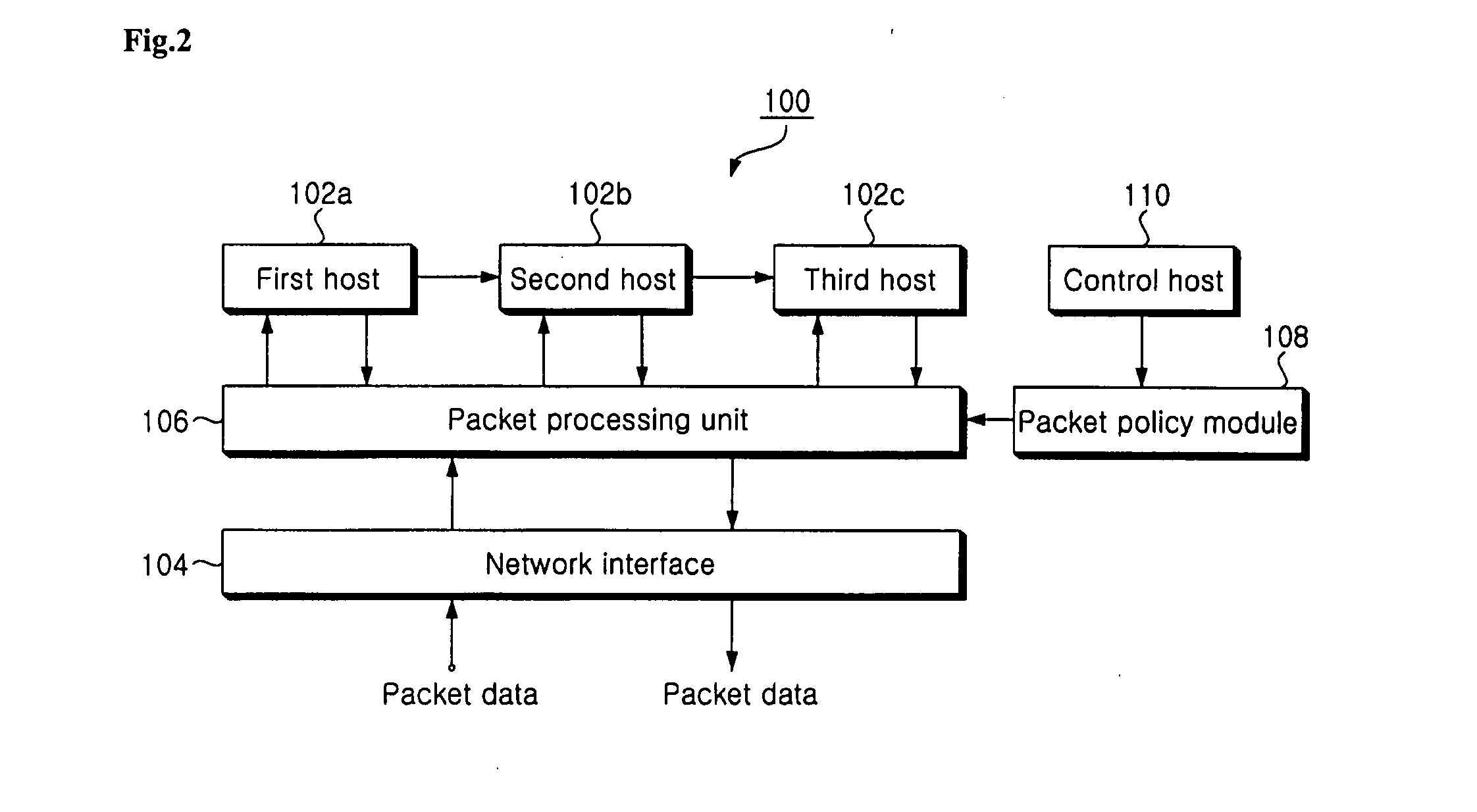

Network security device and method for processing packet data using the same

InactiveUS20070289014A1Increase packet processing rateImprove processing speedMemory loss protectionData taking preventionData packTask network

The present invention relates to a multiple host-based network security device and a method for processing packet data using the network security device. The multiple host-based network security device of the present invention comprises at least two individual hosts in a single host system. Each of the individual hosts comprises individual resources such as a central processing unit (CPU) and a memory, and performs a different task in a single host system. The network security device comprises a packet policy module for providing a packet classification policy such that packet data are sent properly to the individual hosts, and a packet processing unit for sending the packet data to a relevant individual host according to the packet classification policy and providing services or blocking the packet data in accordance with packet checking results performed in the individual hosts. Thus, the data processing performance can be improved and the packet data can be stably checked.

Owner:LG CNS

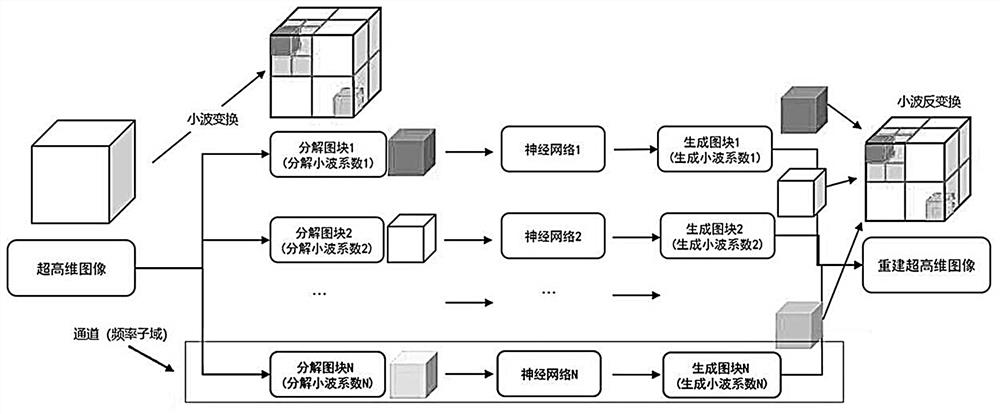

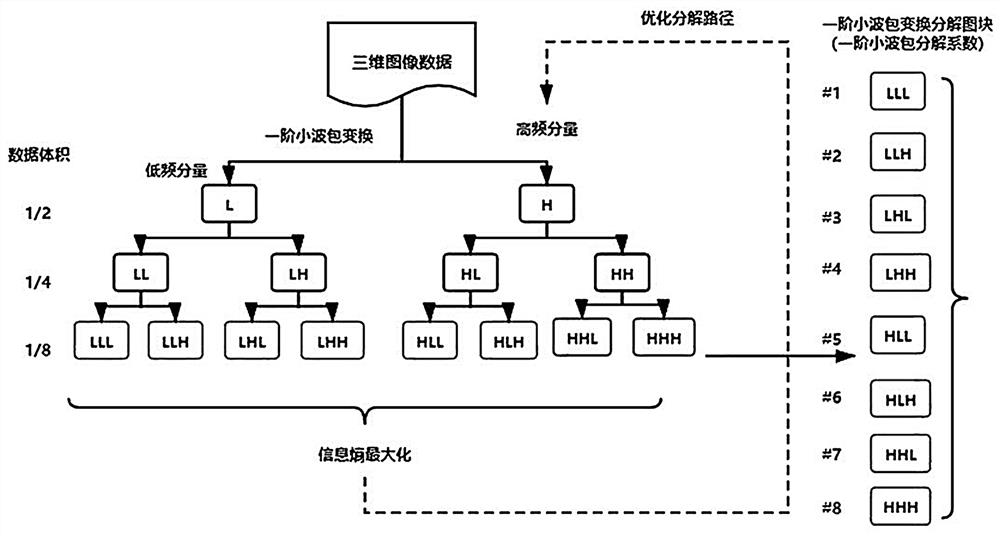

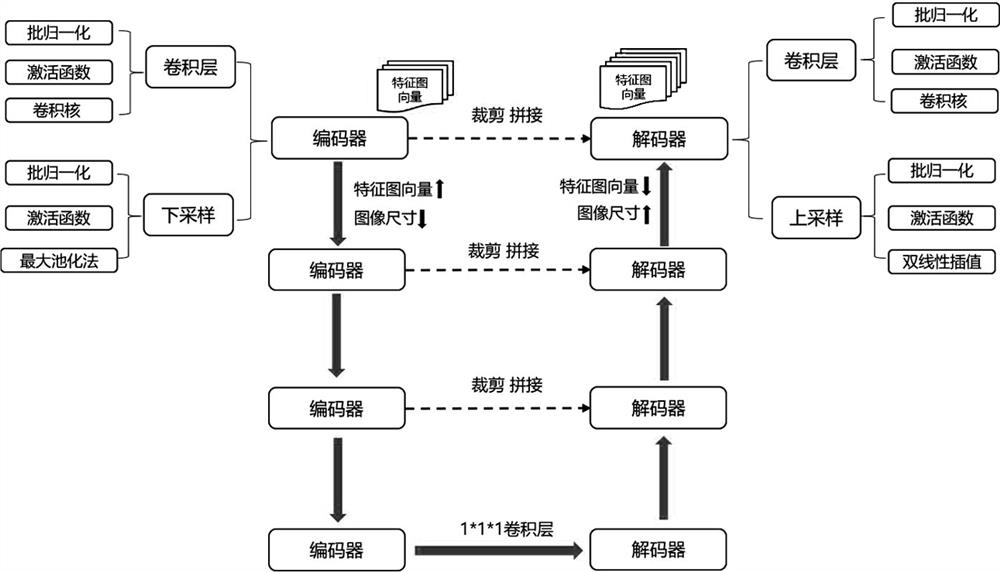

Ultrahigh-dimensional data reconstruction deep learning method based on wavelet analysis

ActiveCN113256536ASpeed up the training processImage enhancementImage analysisTask networkNetwork output

The invention discloses an ultrahigh-dimensional data reconstruction deep learning method based on wavelet analysis, and the method comprises the steps: expanding high-dimensional data to different frequency domain channels through high-dimensional and high-order discrete wavelet packet transformation, and achieving the reconstruction task of the high-dimensional data in combination with a plurality of parallel neural networks; according to the method, data preprocessing is firstly carried out, then wavelet packet coefficients of different frequency band sub-domains are obtained through wavelet packet transformation, an independent network is set up and trained for the wavelet packet coefficients, and the output of the network is subjected to wavelet packet inverse transformation to reconstruct an original image. According to the method, the property that each frequency domain is independent after the high-dimensional data is subjected to wavelet transformation is utilized, and the GPU memory is utilized in parallel, so that the training process of the neural network is accelerated, and a deep learning artificial task which is originally limited by hardware computing resources becomes possible. The method is also popularized to segmentation and generation tasks. For a segmentation task, a U-net network output result is subjected to deconvolution up-sampling to obtain an original image resolution segmentation label. For a generation task, the neural network of each channel is changed into a GAN.

Owner:ZHEJIANG LAB

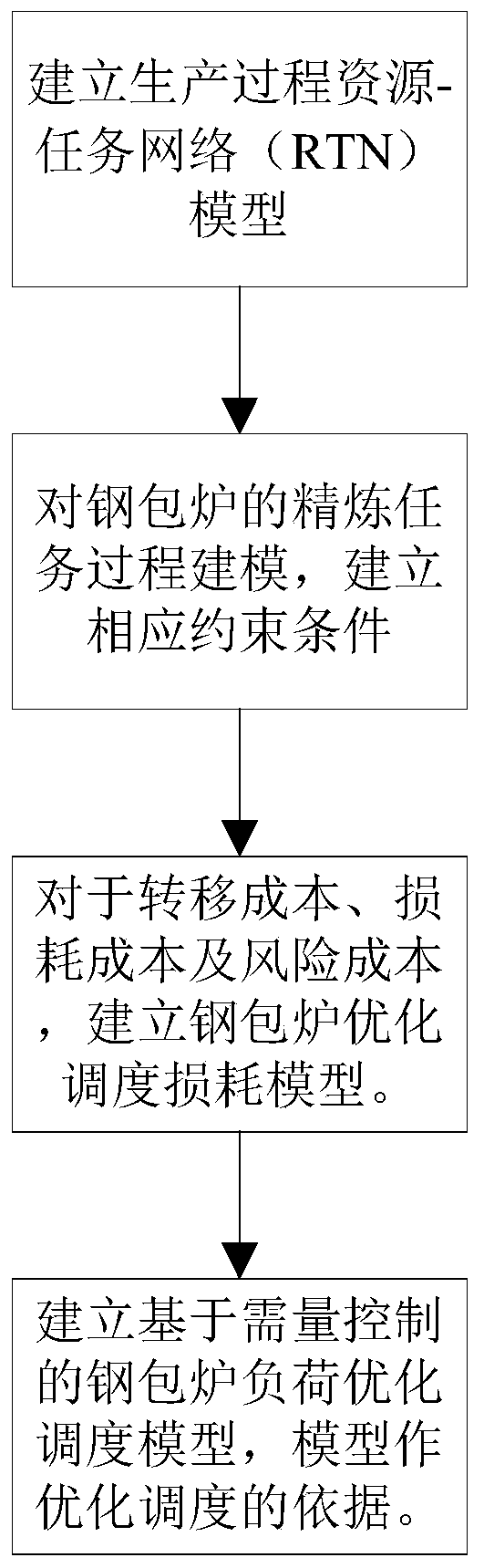

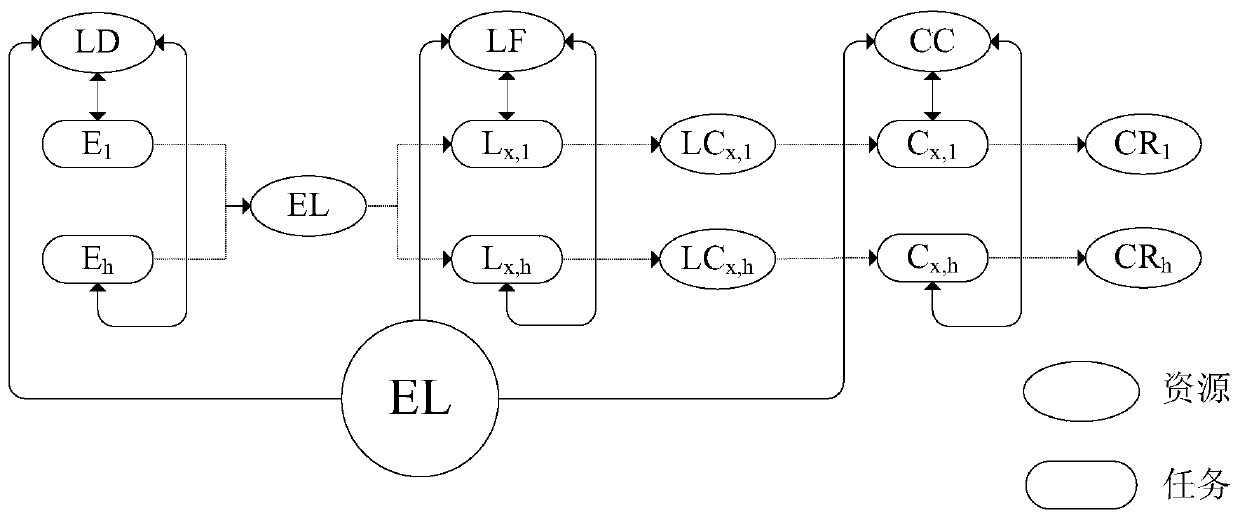

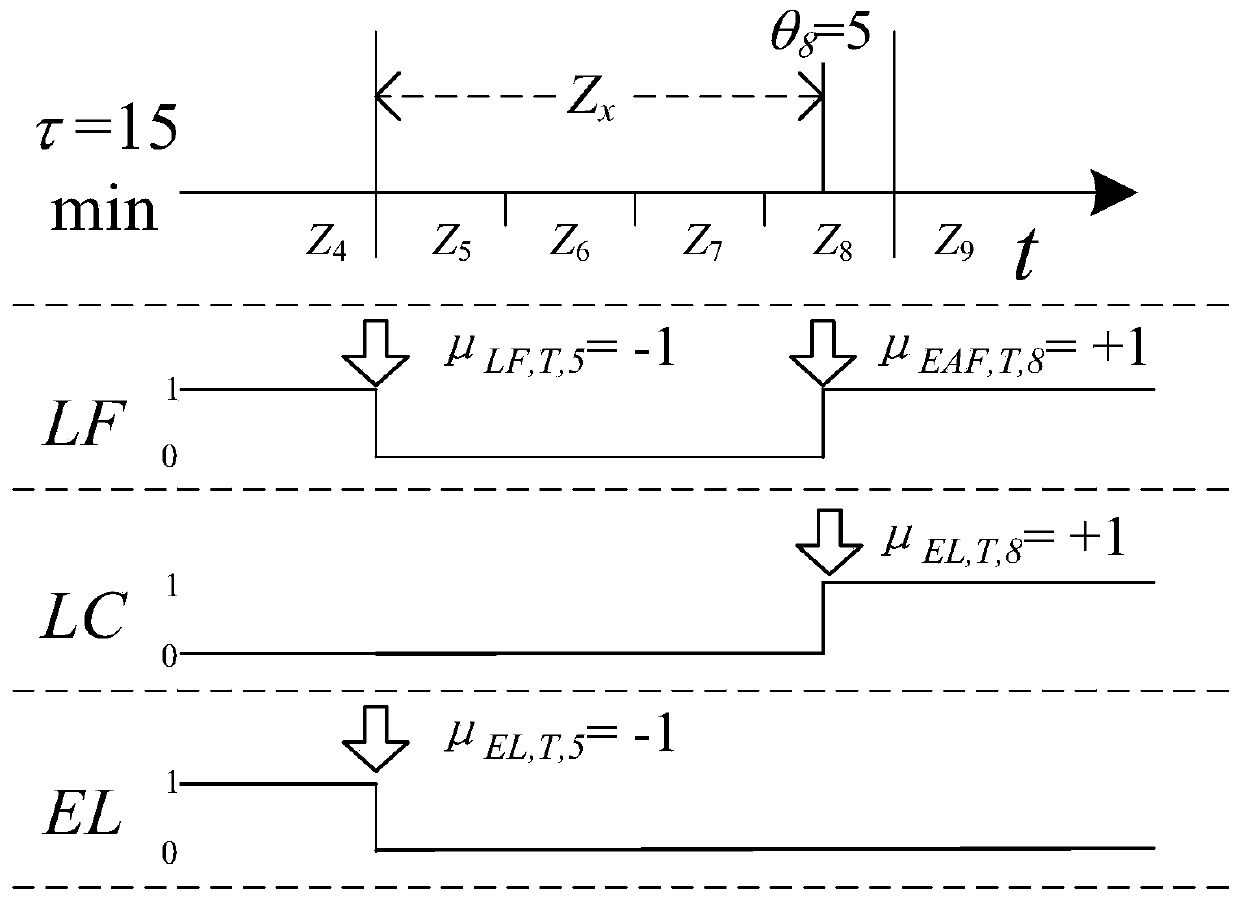

Ladle furnace optimal scheduling method based on demand control

The invention discloses a ladle furnace load optimal scheduling model based on demand control. The ladle furnace load optimal scheduling model comprises the steps: 1, establishing a production process resource-task network (RTN) model according to the technological process of the steel industry, establishing task nodes and resource nodes, setting Boolean variables for the resource nodes except electric power to represent resource states, and setting a Boolean variable for the running state of the task node to represent as well; 2, modeling a refining task process of the ladle furnace, and establishing corresponding constraint conditions for various power receiving control methods such as translation, interruption and reduction; 3, for transfer cost, loss cost and risk cost possibly caused by a power receiving control means, establishing a ladle furnace optimal scheduling loss model by considering the cost; and 4, aiming at an objective function under a real-time maximum demand charging background, establishing a steel ladle furnace load optimization scheduling model based on demand control. Compared with a traditional optimization scheduling method based on time-of-use electricity price rearrangement of all-day task time periods, the ladle furnace load optimal scheduling model based on demand control has the advantages of reducing the peak demand under the condition of not influencing the tasks of other time periods of the whole day, greatly reducing the production power consumption cost, and for a power grid, reducing the pressure of steel industry users on the reserve capacity of power grid transformation facilities, and reducing the power grid construction cost.

Owner:XIANGTAN UNIV

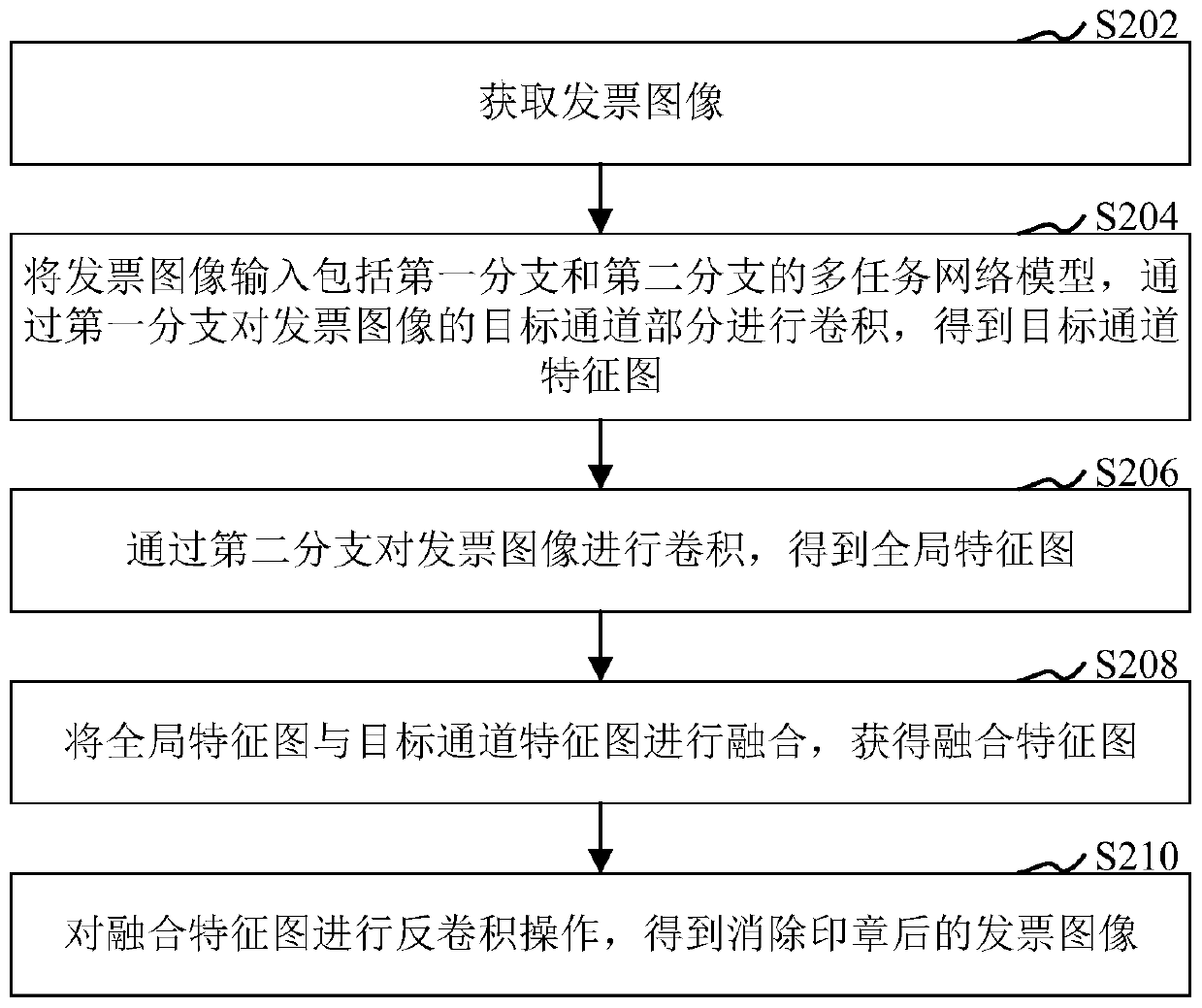

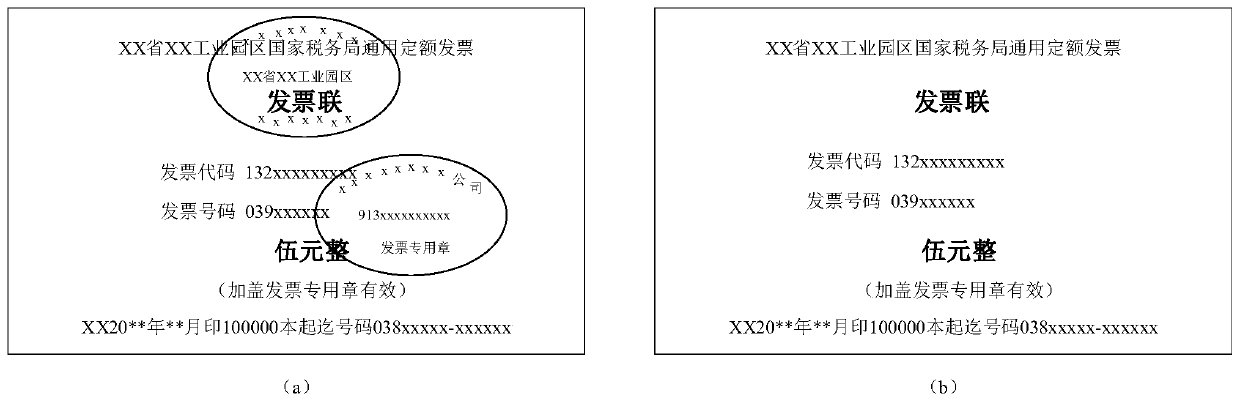

Method and device for eliminating invoice seal, storage medium and computer equipment

ActiveCN110517186AAvoid missingImprove recognition accuracyImage enhancementImage analysisTask networkComputer graphics (images)

The invention relates to a method and device for eliminating an invoice seal, a storage medium and computer equipment. The method comprises the steps: acquiring an invoice image; inputting the invoiceimage into a multi-task network model comprising a first branch and a second branch, and performing convolution on a target channel part of the invoice image through the first branch to obtain a target channel feature map; carrying out convolution on the invoice image through the second branch to obtain a global feature map; fusing the global feature map and the target channel feature map to obtain a fused feature map; and performing deconvolution operation on the fusion feature map to obtain an invoice image after the seal is eliminated. According to the scheme provided by the invention, thesituation that the text covered by the seal is also eliminated in the seal eliminating process can be avoided, so that the situation that the text information in the invoice is missing is avoided, and the recognition accuracy of the text information in the invoice is improved.

Owner:KINGDEE SOFTWARE(CHINA) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com