Ladle furnace optimal scheduling method based on demand control

A scheduling method and technology for ladle furnaces, applied in manufacturing computing systems, instruments, data processing applications, etc., can solve problems such as huge changes in electricity cost structure, failures, and large demand peaks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

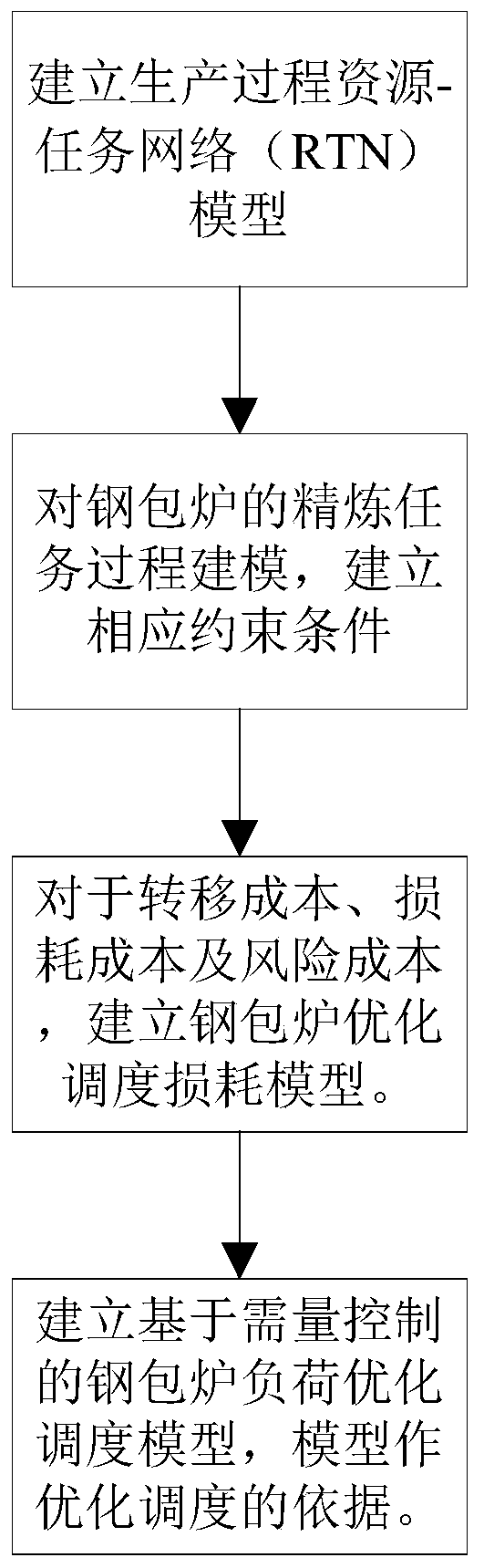

[0081] Such as figure 1 As shown, the present invention proposes a method for optimal scheduling of ladle furnace load based on demand control, and the specific steps are as follows:

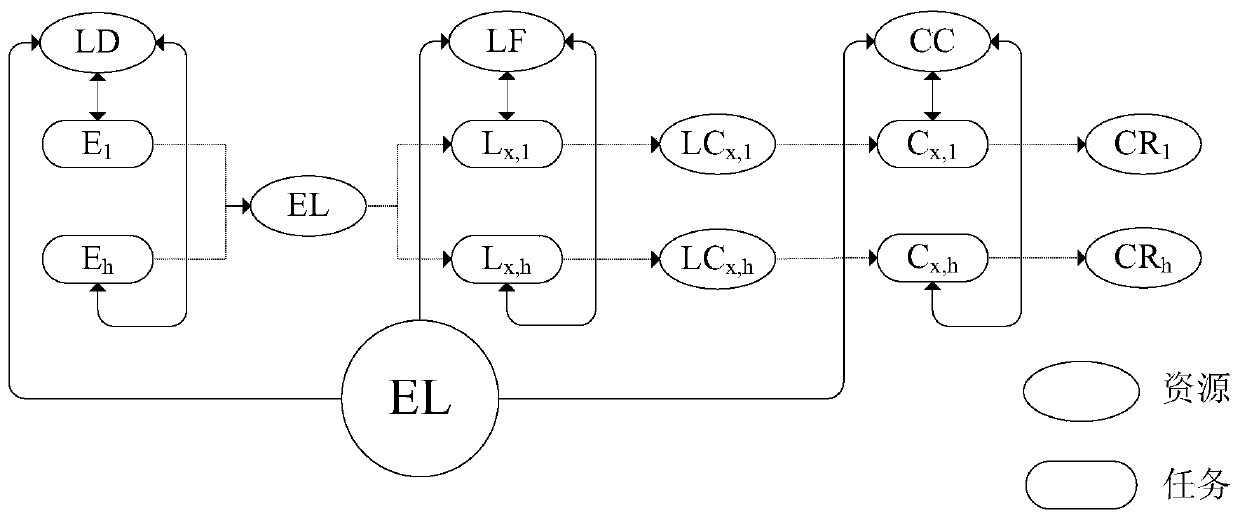

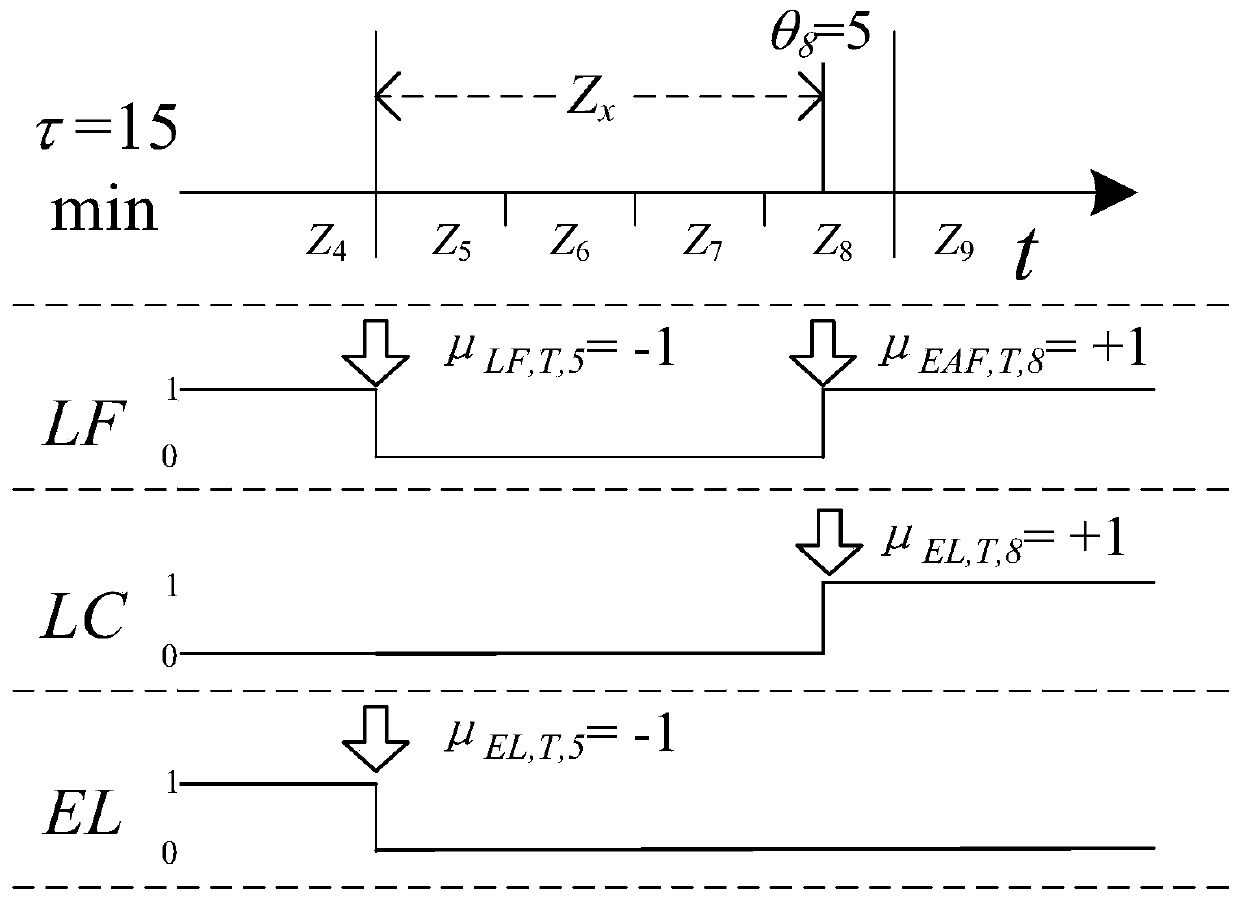

[0082] Step 1, the present invention has set up a resource-task network (RTN) model based on the discrete time system for the main part of the continuous casting process, such as figure 2 shown. The discrete time system of this model has four different time variables: a day is divided into a time period of fixed duration τ, Z represents the time period; t is a certain moment; period δ is not equal to the duration of the fixed period Z; Time θ is related to the start time of each period.

[0083] The resource-task network (RTN) model contains two types of nodes: resource node R and task node T

[0084] Resource nodes represent all resources related to the process flow. The resources in the model include: equipment resources (LD, LF and CC); intermediate products (EL, LC) and board (CR), and p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com