Fully enclosed telescopic safety protection device of transloading machine

A safety protection device and fully enclosed technology, which is applied in transportation and packaging, earthwork drilling, underground transportation, etc., can solve the problems of operating equipment not fully enclosed protection, personal accidents, unsafety, etc., and reduce secondary coal dust , Safe and easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

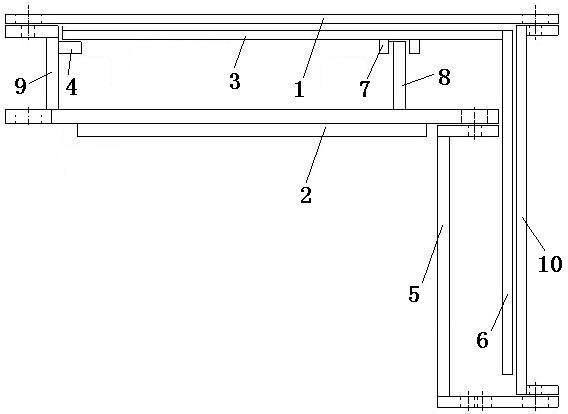

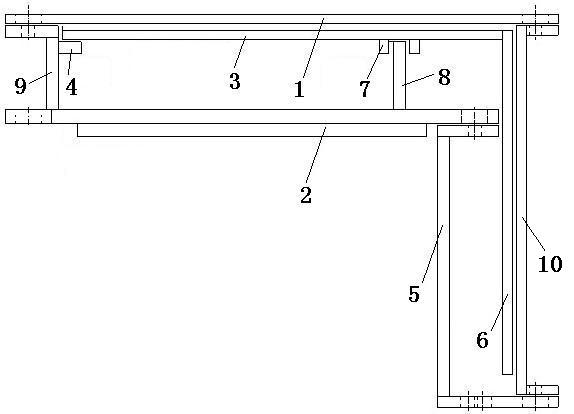

[0016] Accompanying drawing is a kind of specific embodiment of the present invention.

[0017] The fully-enclosed telescopic safety protection device for the reloading machine of the present invention includes a fully-enclosed slide plate 3 capable of sliding forward and backward, its cross-section is L-shaped with a rotation of 180°, and its horizontal part is slidably installed on the upper seal cover 1 and the lower seal cover 2, its vertical part 6 is located outside the coal retaining plate 5 of the loader, and its driving device is installed on the lower closed cover plate. The driving device is a hydraulic jack, which is installed on the lower closing cover and is located between the upper closing cover and the lower closing cover. The upper closed cover plate 1 and the lower closed cover plate 2 are fixed as a whole at the left end by a connecting piece 9, the right side of the connecting piece has a slideway 4 for sliding the left end of the horizontal part of the fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com