A self-organized machine interconnection method

A self-organizing and machine-based technology, applied in transmission systems, electrical components, etc., can solve problems such as inconvenience in industrial production, lack of consideration, and high communication pressure in communication centers, and achieve the effects of strong communication capabilities, flexible and open networks, and easy management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

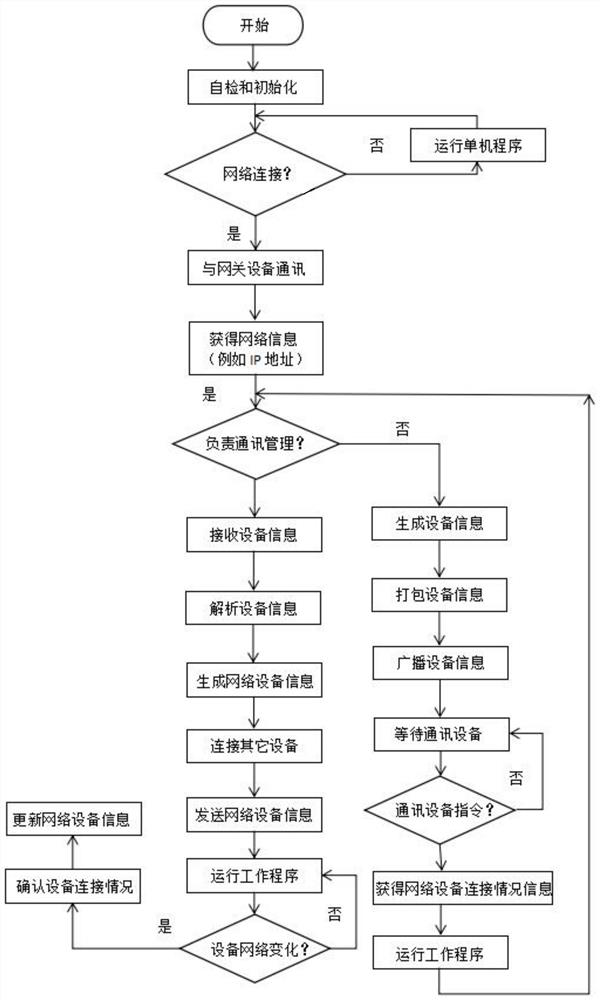

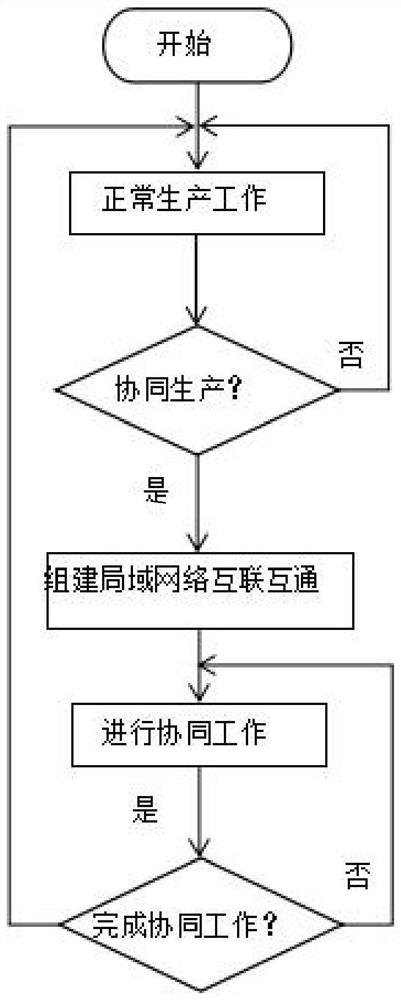

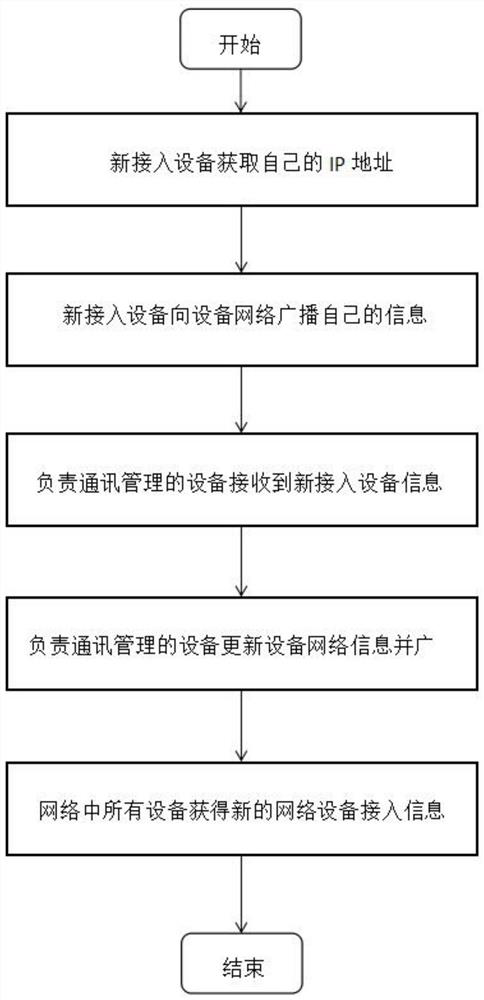

[0038] In order to express the embodiments, significance and advantages of the present invention more clearly, the present invention will be described in more detail below in conjunction with the accompanying drawings.

[0039] Such as figure 2 It is a schematic diagram of a network system of a machine equipment self-organizing network component of the present invention. In the industrial site 200, the self-organizing network 210 is formed between the devices, and the devices in the self-organizing network 210 can be monitored on the monitoring device 220 of the industrial site 200, the parameters of the devices can be changed, and the cloud 230 can also communicate with the client 240 , the user terminal 240 monitors the devices in the ad hoc network 210 and changes the parameters of the devices. Devices a1 to a5 in the ad hoc network, that is, 211 to 215, pass as image 3 The communication interface of the loom connected to the network is connected with the router 216, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com