Integrated welding seam-free taper pipe

A technology without weld seam and taper, applied in the direction of pipes, rigid pipes, pipes/pipe joints/pipe fittings, etc., which can solve the problem of weld strength, fatigue strength decrease, oxygen lance strength and fatigue strength decrease, oxygen lance working environment, etc. problems, to achieve the effect of improving service life, avoiding adverse effects, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

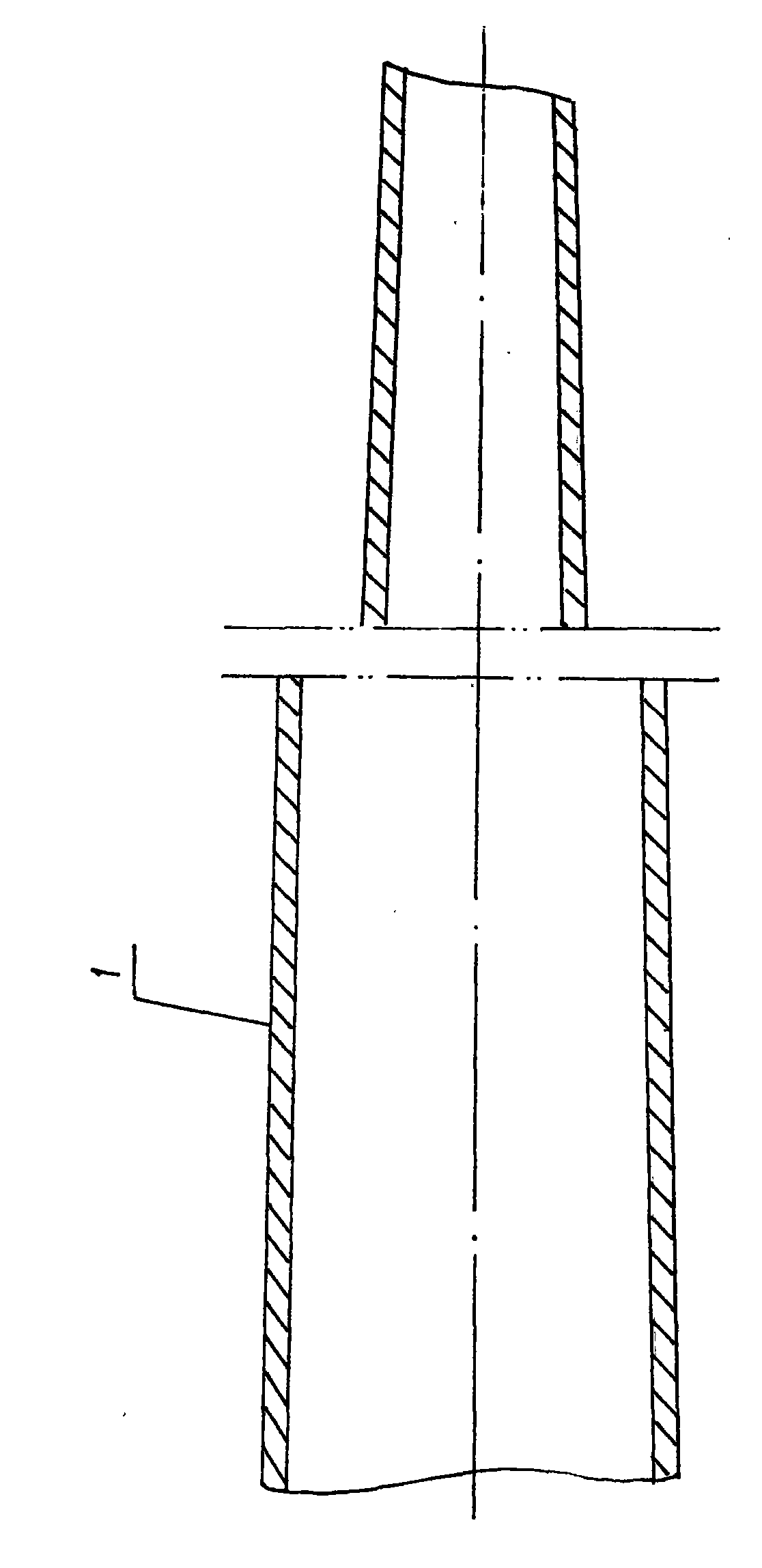

[0014] The integral weldless tapered pipe of the present invention is realized in this way, which will be described in detail below in conjunction with the accompanying drawings. See figure 1 , The whole tapered pipe without weld seam of the present invention, the tapered pipe without weld seam as a whole 1 is a tapered pipe with a taper of 0 to 30 degrees and a length of 1.5 to 20 meters; a diameter of φ89mm-φ2000mm and a wall thickness of 0.5 to 60mm.

[0015] The following steps are used to prepare the integral weldless tapered pipe:

[0016] (1) The steel pipe corresponding to the diameter of the overall non-welded tapered pipe is used as the raw material for thermal expansion. The steel pipe is made of seamless stainless steel pipe or seamless steel pipe or high-frequency welded pipe or spiral pipe or stainless steel pipe as raw material according to the design requirements;

[0017] (2) According to the specification and shape of the overall tapered tube, pre-design and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com