Motor comprehensive protector tester

A comprehensive protector and tester technology, applied in the direction of instruments, measuring electricity, measuring devices, etc., can solve the problems of bumpy long-distance transportation, inability to detect the protector, and the protector cannot be used normally, and achieve the effect of improving the efficiency of fault detection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

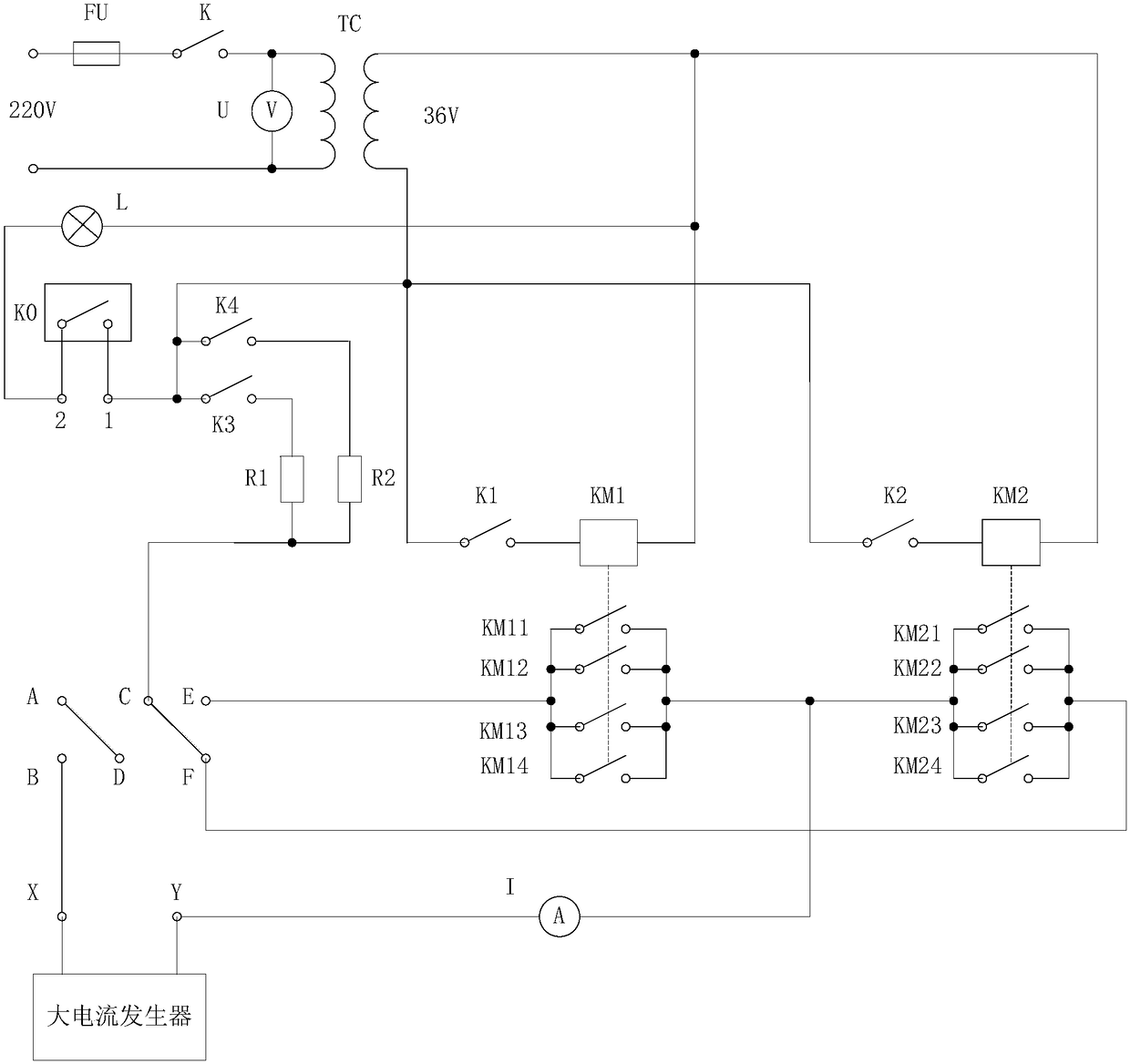

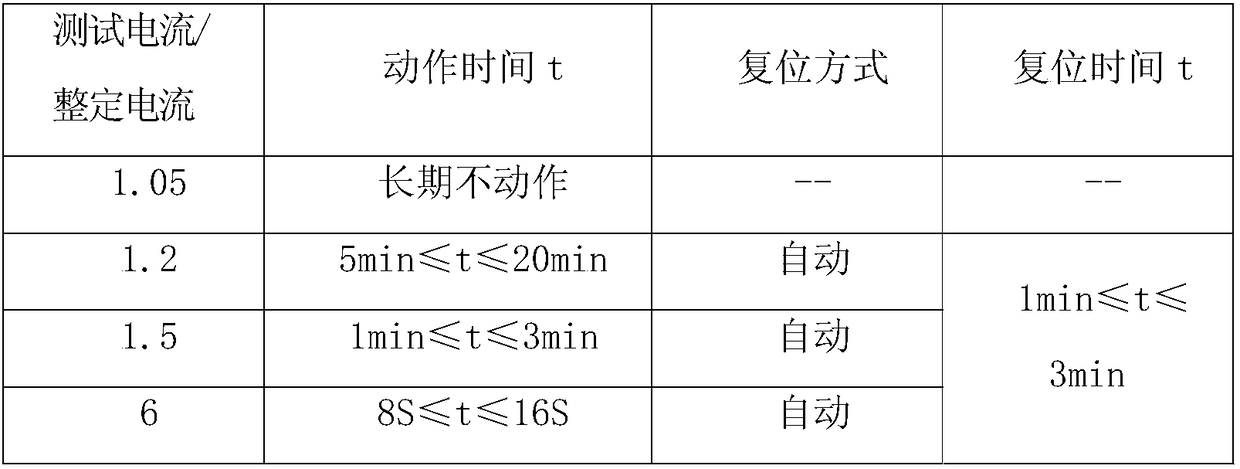

[0019] The motor comprehensive protector tester according to the embodiment of the present invention includes a large current generator, a transformer TC, an ammeter I, an overload test switch K1, an overload test contactor coil KM1, a plurality of parallel main contacts of the overload test contactor, and a phase loss test. Switch K2, phase loss test contactor coil KM2, main contacts of multiple parallel phase loss test contactors, leakage test resistance 1 R1, leakage test resistance 2 R2, leakage test switch 1 K3, leakage test switch 2 K4, indicator light L, contact one 1, contact two 2, A stud A, B stud B, C stud C, D stud D, E stud E and F stud F, the schematic diagram of the circuit structure is shown in figure 1 , Among them, the primary side of the transformer TC is used to connect with the AC voltage source, and one end of the secondary side is respectively connected to one end of the leakage test switch 1 K3, one end of the leakage test switch 2 K4, one end of the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com