Control method of food processing machine

A technology of food processing machine and control method, applied in liquid level control, non-electric variable control, control/regulation system, etc., can solve abnormal equipment failures, affect the accuracy, reliability, response speed of detection, and cannot realize continuous detection Water level and other issues to achieve the effect of reducing water inflow errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

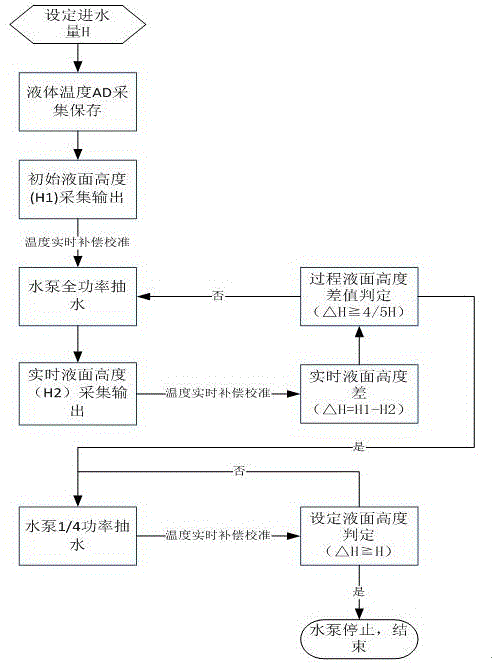

[0022] The present invention relates to a control method of a food processing machine. The food processing machine includes a water tank and a processing cavity for food processing, wherein the food processing machine is provided with an ultrasonic sensor for detecting the water level in the water tank. The food processing is also provided with a temperature detection device for detecting the water temperature in the water tank, and the food processing machine adjusts the water level value detected by the ultrasonic sensor according to the water temperature.

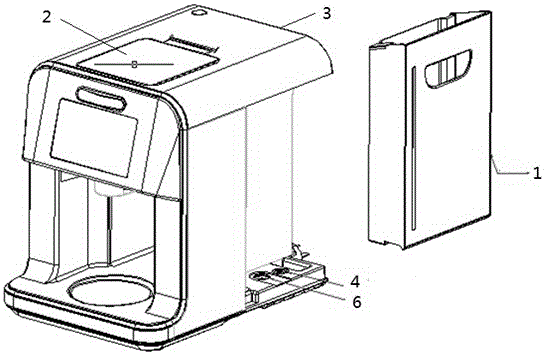

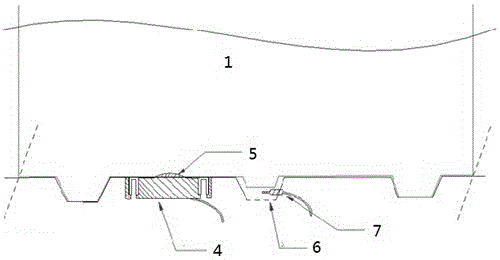

[0023] like figure 1 , 2, the water tank 1 and the processing chamber 2 are set on the base 3 of the food processor, and the ultrasonic sensor 4 is set on the base 3 . The water tank 1 is detachably installed on the machine base 3 , and a silica gel 5 is provided in front of the ultrasonic sensor 4 and the water tank 1 , and the upper surface of the silica gel 5 is higher than the surface of the machine base 3 . A water...

Embodiment 2

[0034] The difference between this embodiment and Embodiment 1 is that: the water level detected by the ultrasonic sensor in the water tank is h, the temperature detected by the temperature sensor is T, and the food processing machine is provided with fixed temperature compensation coefficients A and B and 0°C The following corresponds to system C, H=(A*T*T+B*T+C)*h. In this implementation, A=-0.0000257, B=0.0031, and C=0.93. Among them, A*T*T+B*T+C is the temperature correction coefficient of the distance value read by the ultrasonic sensor at the measurement temperature T. This value is based on the coefficient corresponding to 0°C and passed the one-to-two value under the corresponding coefficient of the actual temperature detection point. The value of ABC is a fixed coefficient value specific to the ultrasonic sensor, and the function of temperature correction is realized through the algorithm equation fitting calculation.

[0035] By using the ultrasonic sensor to detect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com