Waterproof construction method for building outer wall

A technology for building exterior walls and construction methods, which is applied in the direction of buildings, building components, and building structures. It can solve problems such as uneven paving, bulges, and unsatisfactory laying effects of waterproof membranes, so as to improve the laying speed and laying effect. , Guarantee the tightness of fit and eliminate the effect of low work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035]The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be embodied in various ways of claims defined and covered.

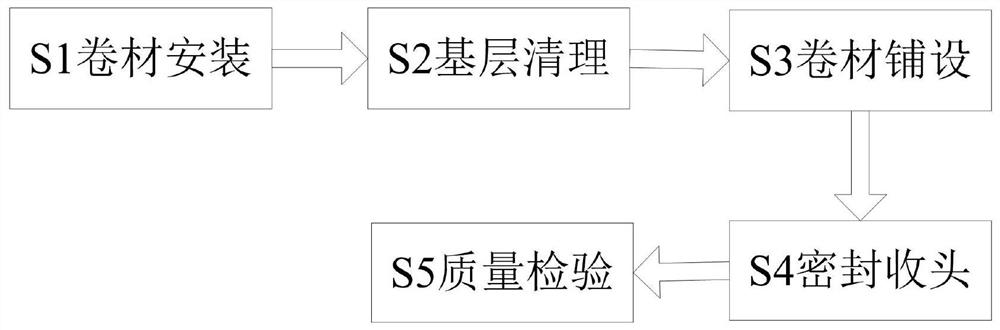

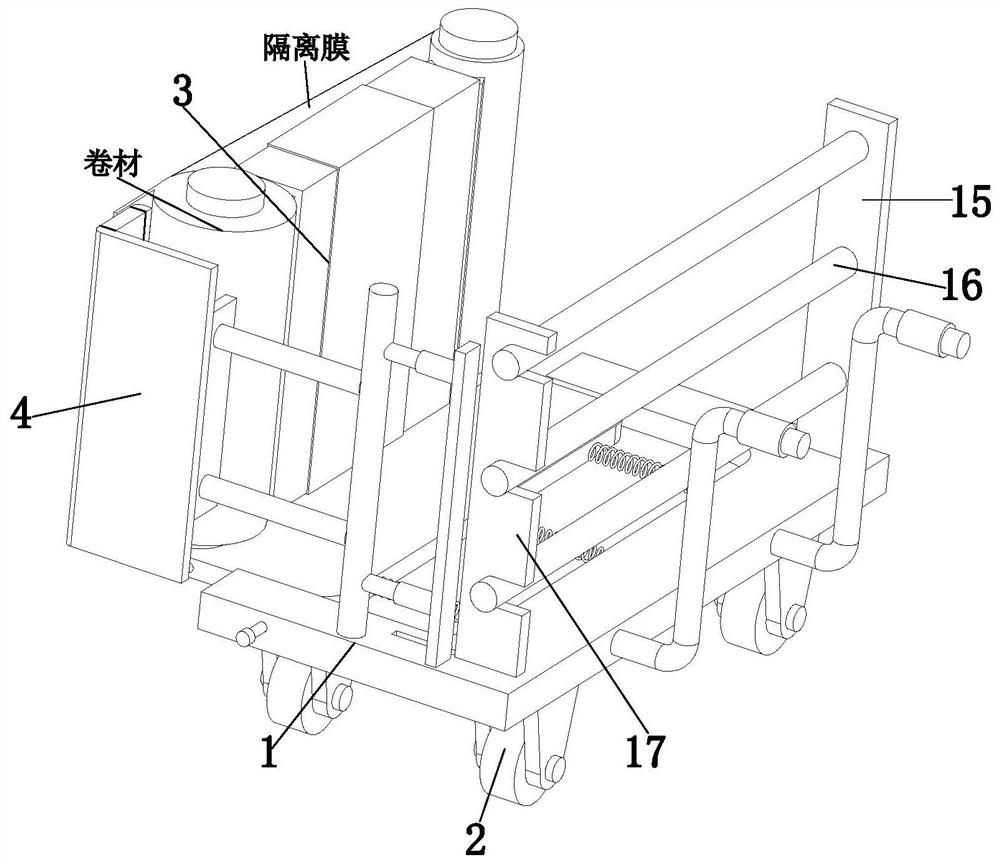

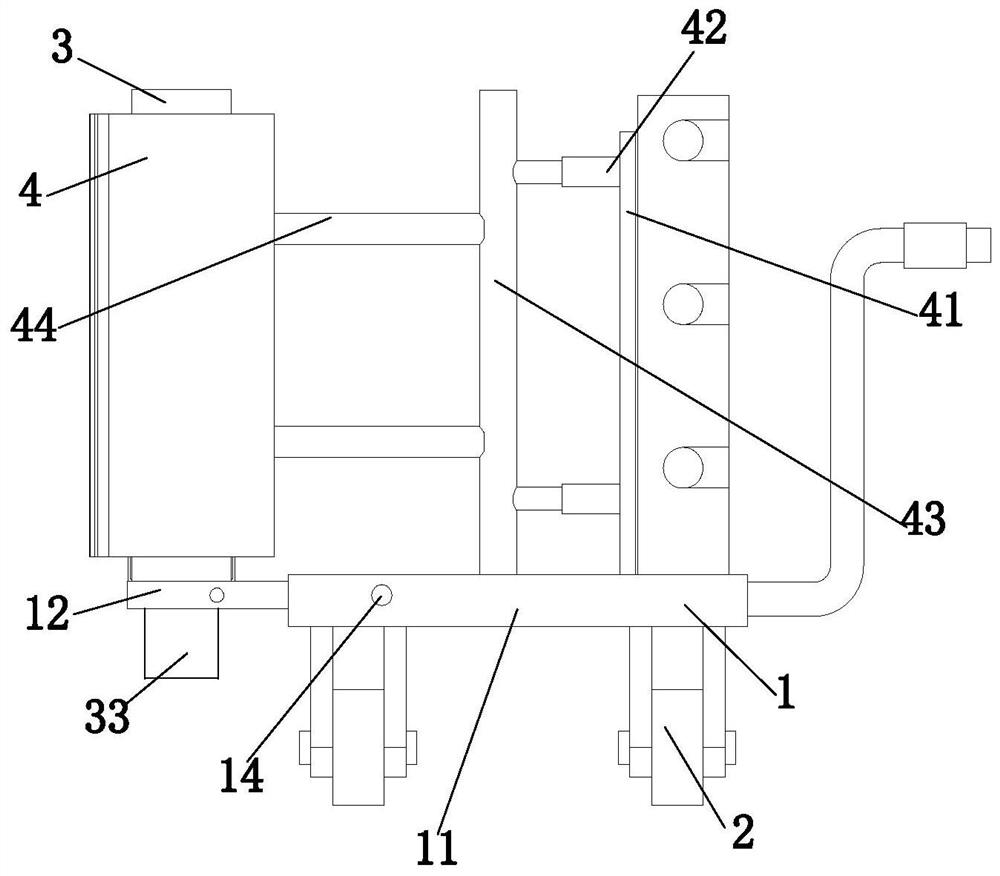

[0036]Such asFigure 1 to 7As shown, a waterproof construction method for building an exterior wall is used, which uses a web laving device including a rack 1, a moving wheel 2, a laying device 3 and auxiliary device 4, and the lower end of the rack 1. Move wheel 2, the upper end of the rack 1 is sequentially mounted from left to right, and the specific method flow of the waterproof construction of the building facade is used by the above-mentioned web laying equipment.

[0037]S1. Volume Mounting: The waterproof web to be used is mounted on the laying device 3 and ensures the installation of the waterproof web to prevent the waterproof coil from shaking;

[0038]S2. Cleaning: Use a brush to clear the dust, stone of the grass layer, and ensure the flatness and dryness of the surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com