Water application method optical cable laying and construction method

A technology of optical cable laying and construction method, which is applied in the direction of optical fiber/cable installation, etc., which can solve the problems that the ratio cannot be too small and construction cannot be done, and achieve the effects of avoiding too loose or too tight, avoiding waste, and quick response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

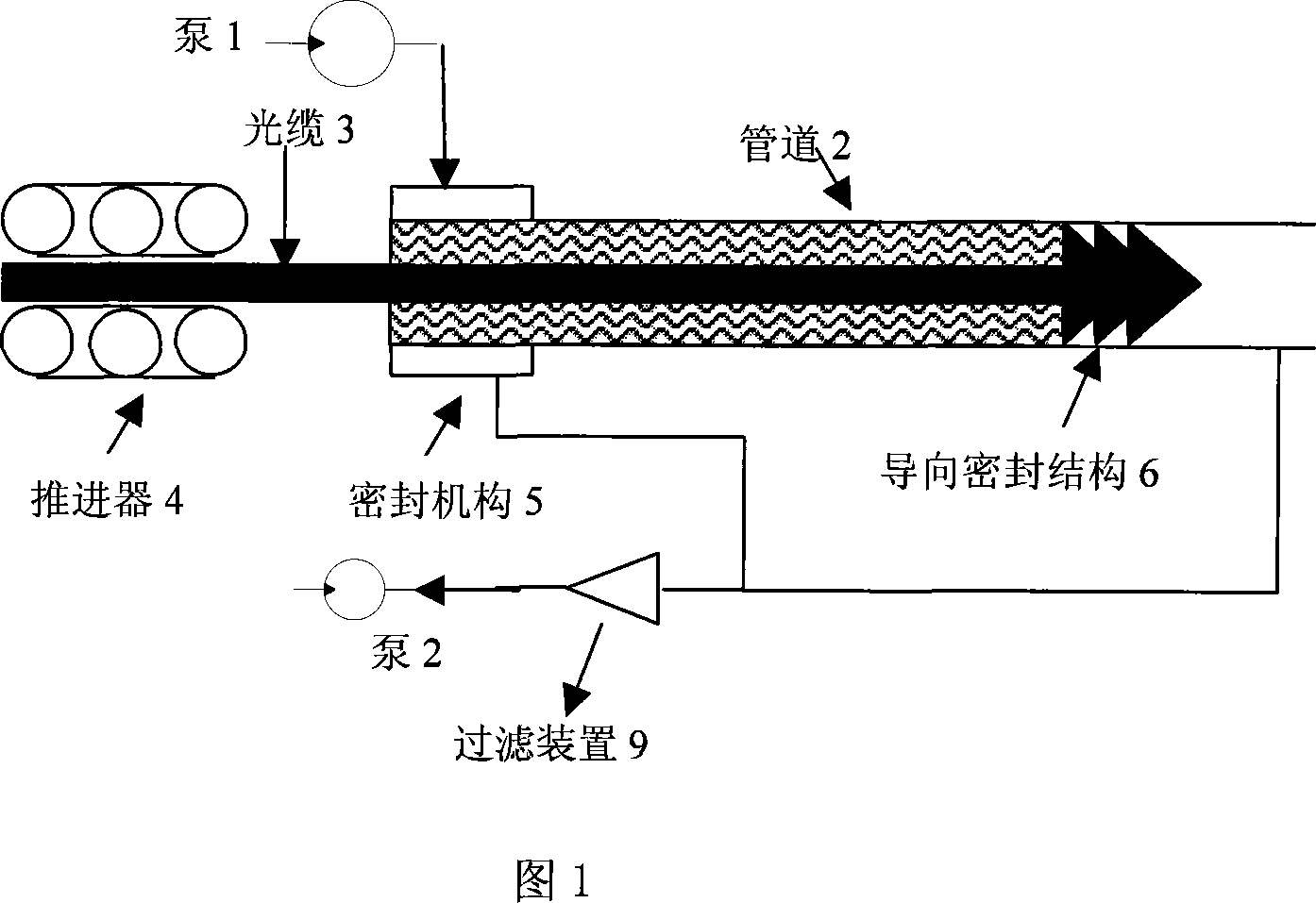

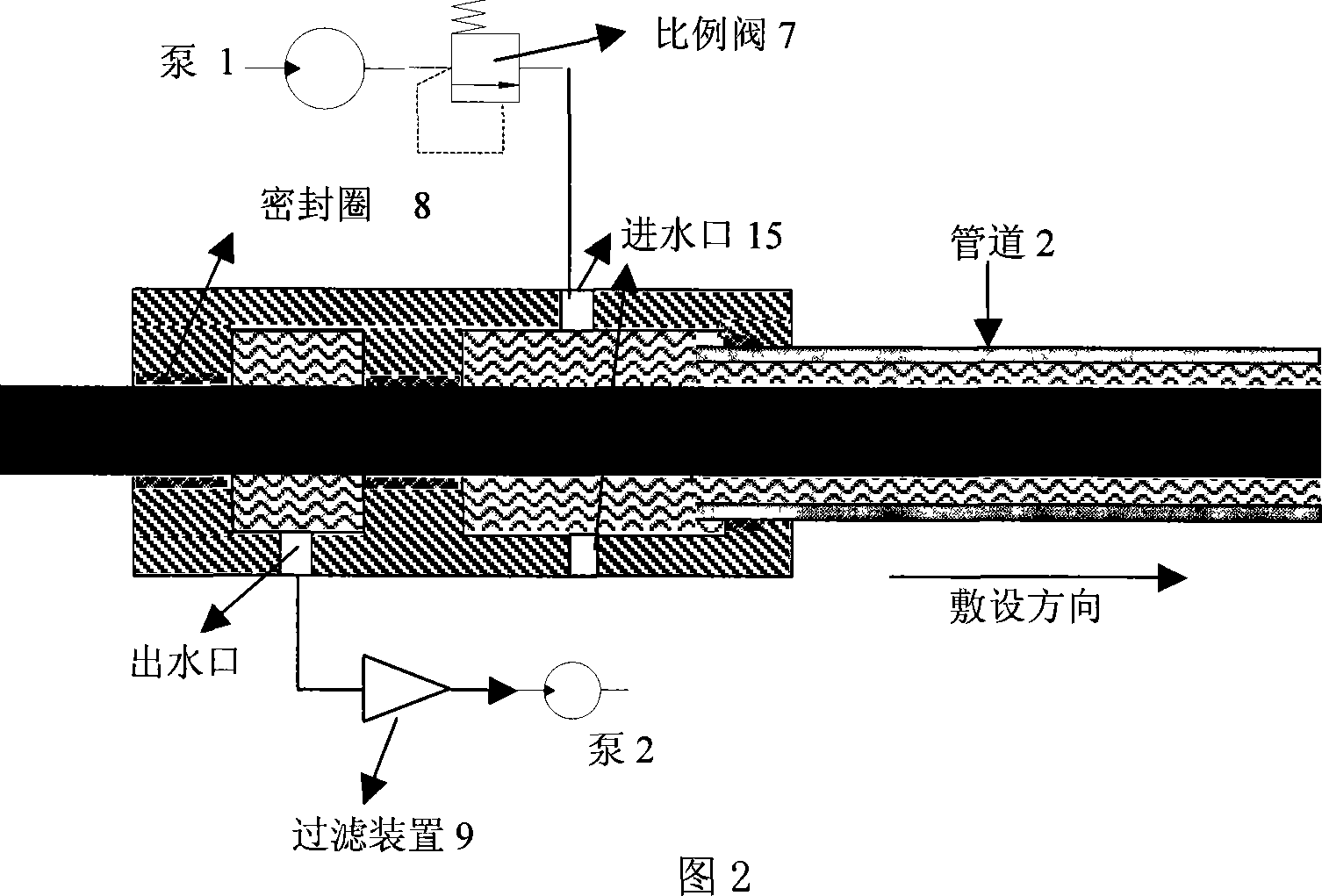

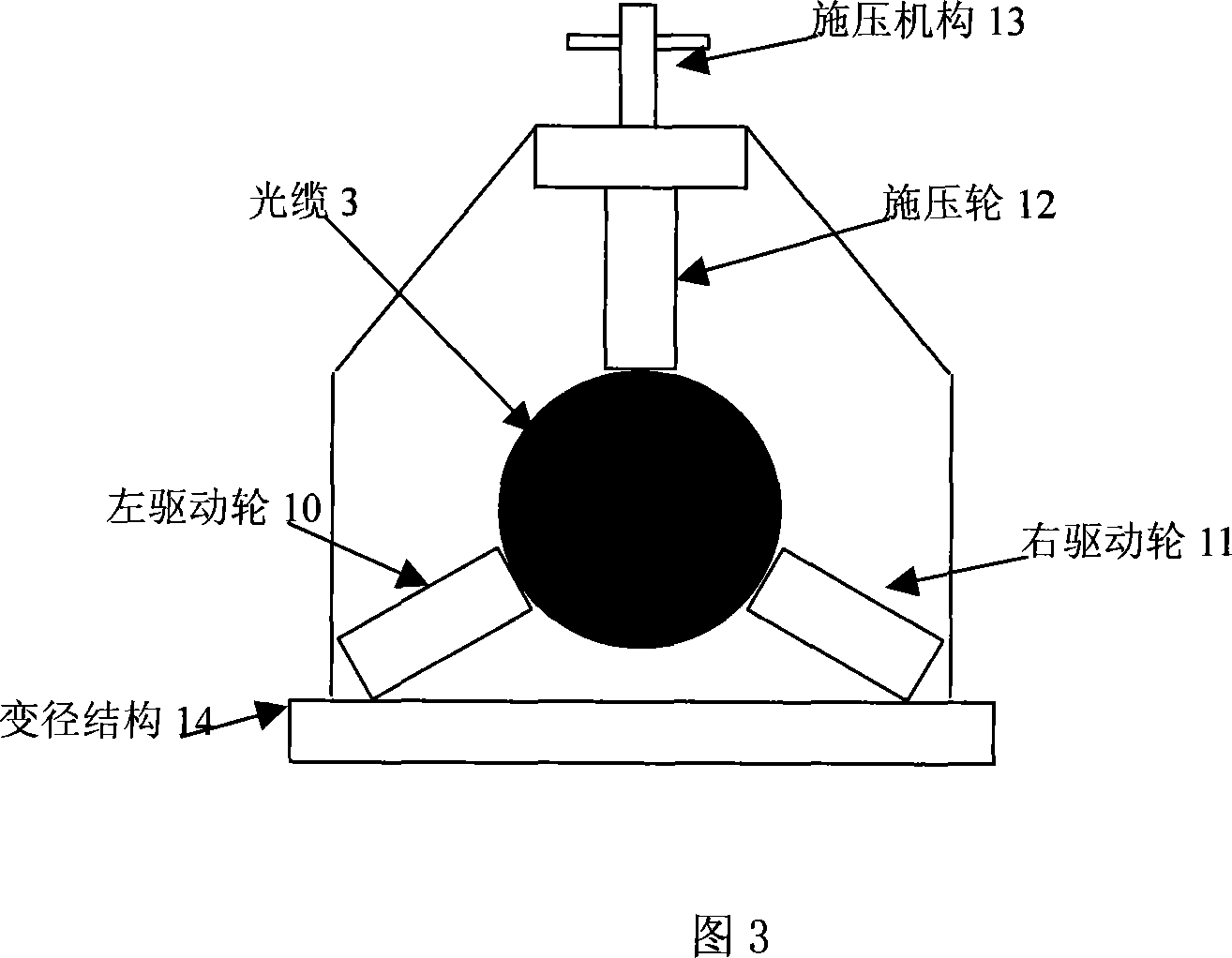

[0028] The embodiments of the present invention are described in detail below in conjunction with the accompanying drawings: the present embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and processes are provided, but the protection scope of the present invention is not limited to the following implementations example.

[0029] In FIG. 1 , the guide sealing structure 6 and the optical cable 3 are tightly fixed together by bolts. In Fig. 1 and Fig. 2, the pump for entering water is pump 1, and the pump for water recovery is pump 2. In Fig. 2, filter device 9 is used to filter impurities such as soil to protect the pump. The guide sealing structure 6 has a sealing ring 8 inside and a nylon structure on the outside, which just fits with the pipeline and plays the role of sealing and guiding. The water outlet of the water pump 1 is connected to the water inlet of the sealing structure 5 through the pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com