Full-automatic paving method of ceramic mosaic tiles and full-automatic paving line

A kind of ceramic mosaic tile, fully automatic technology, applied in covering/lining, building, building structure, etc., can solve the problems of not being able to adapt to automatic paving production, etc., achieve high production efficiency, reduce damage, and save costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

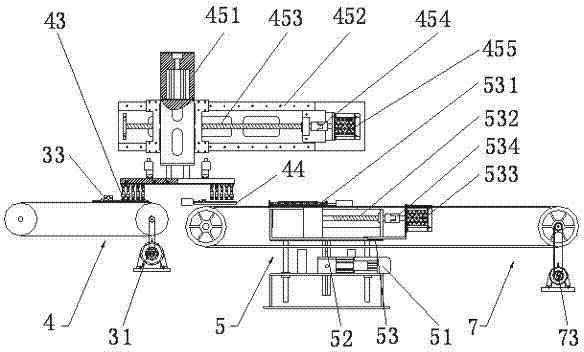

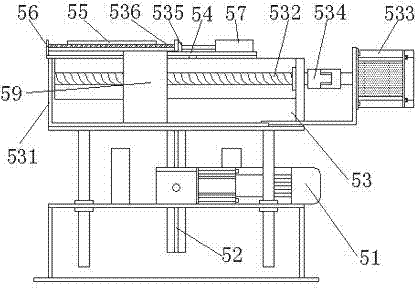

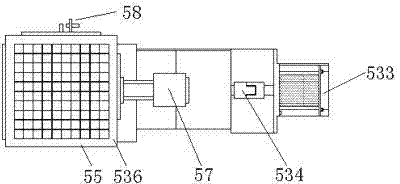

[0054] The present invention will be described in further detail below in conjunction with accompanying drawing:

[0055] The fully automatic paving method of the ceramic mosaic tiles comprises:

[0056] ⑴The finished ceramic tiles are formed into ceramic mosaic tiles by a multi-head cutting machine;

[0057] (2) Ceramic mosaic tiles are neatly arranged on the laying line, and transferred to the positioning receiving tray through the suction cup 42 (43);

[0058] (3) Paste the nylon mesh with adhesive to the surface of the ceramic mosaic tiles in the positioning receiving tray to form a unit connection;

[0059] (4) Flip the positioning receiving tray, and the unit is connected to the flat plate to receive;

[0060] ⑸The flat-plate loading unit is conveyed by the conveyor belt to the low-temperature roller kiln for drying.

[0061] The process (2) further includes: the positioning receiving tray is made of PVC material, corresponding to the specifications of the unit, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com