A Process for Improving the Dewatering Performance of Excess Sludge

A technology with excess sludge and dewatering performance, applied in water/sludge/sewage treatment, sludge treatment, sludge treatment and other directions, it can solve the corrosion of the reaction system and pipeline, the investment of large equipment and manpower, and it is difficult to temper the sludge. and other problems, to achieve the effect of harmless resource treatment and disposal, low equipment investment cost, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

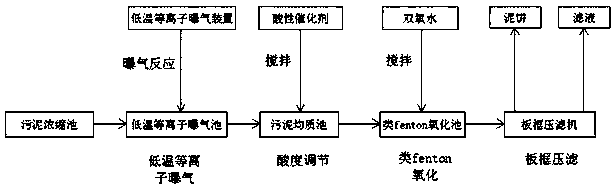

[0023] refer to figure 1 , a process for improving the dewatering performance of excess sludge, comprising the following steps:

[0024] Step 1: Low-temperature plasma aeration: pass the remaining sludge in the sludge thickening tank into the low-temperature plasma aeration tank through a hydraulic pump, and aerate for 30 minutes under the action of the low-temperature plasma aeration device to remove the sulfide in the remaining sludge Hydrogen, ammonia, cyanide, methane, methyl mercaptan and other reducing substances can improve the quality of sludge and reduce the amount of subsequent oxidants added;

[0025] Step 2: Acidity adjustment: Put the reacted sludge in step 1 into the sludge homogeneous tank with a stirring device through a hydraulic pump, turn on the stirring device, and use a metering pump to add 320g of 15% of the absolute dry weight of the sludge / L concentration of acidic catalyst solution to adjust the sludge pH to 6.0;

[0026] Step 3: Fenton-like oxidati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com