Method for producing water conservancy concrete wrest block and four-pin hollow block by using pipe pile wastewater slurry

A technology for concrete and hollow blocks, applied in chemical instruments and methods, clay preparation devices, mixing operation control, etc., to achieve obvious economic and social benefits, protection of ecological environment, and obvious effects of social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further elaborated below in conjunction with specific examples.

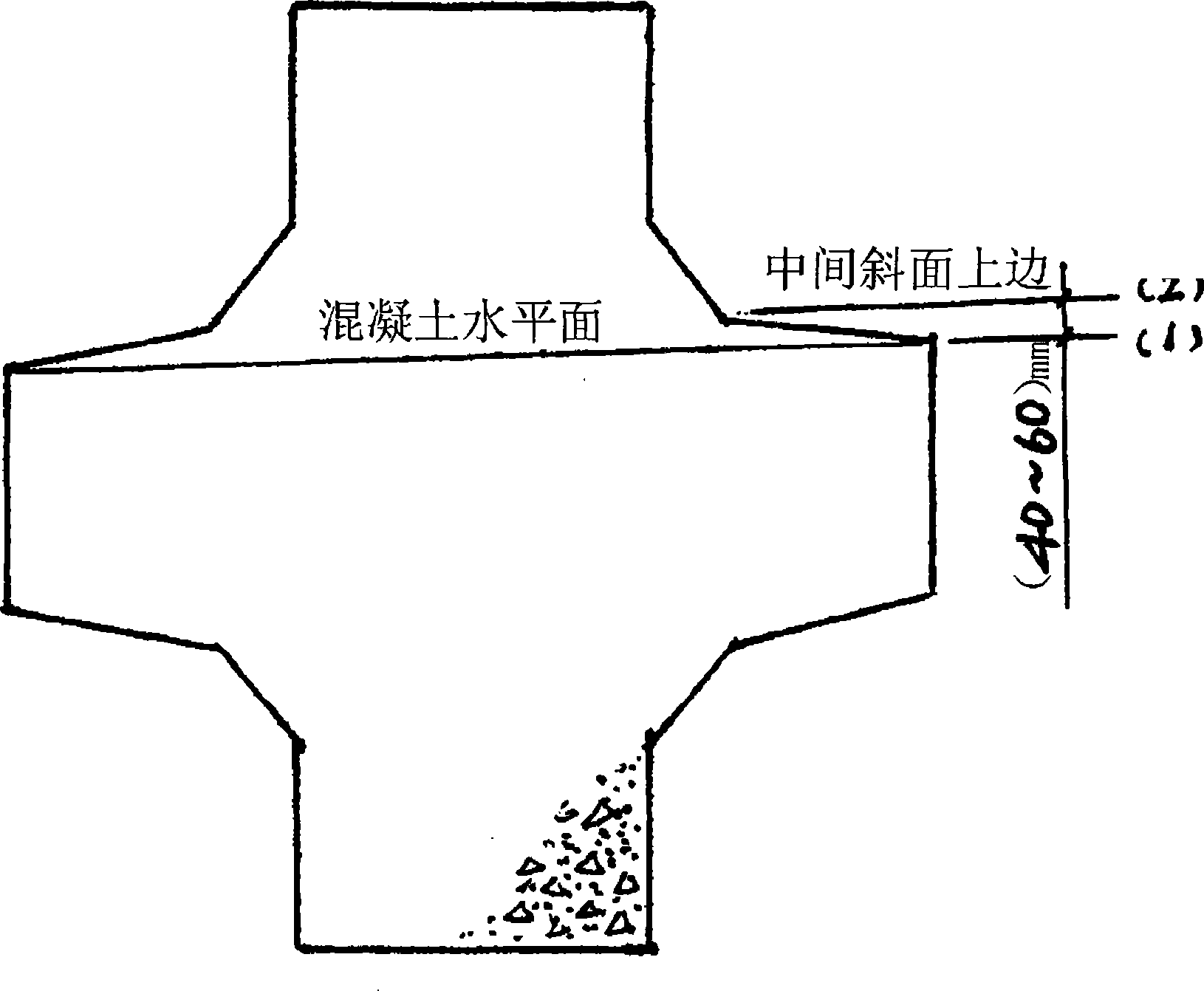

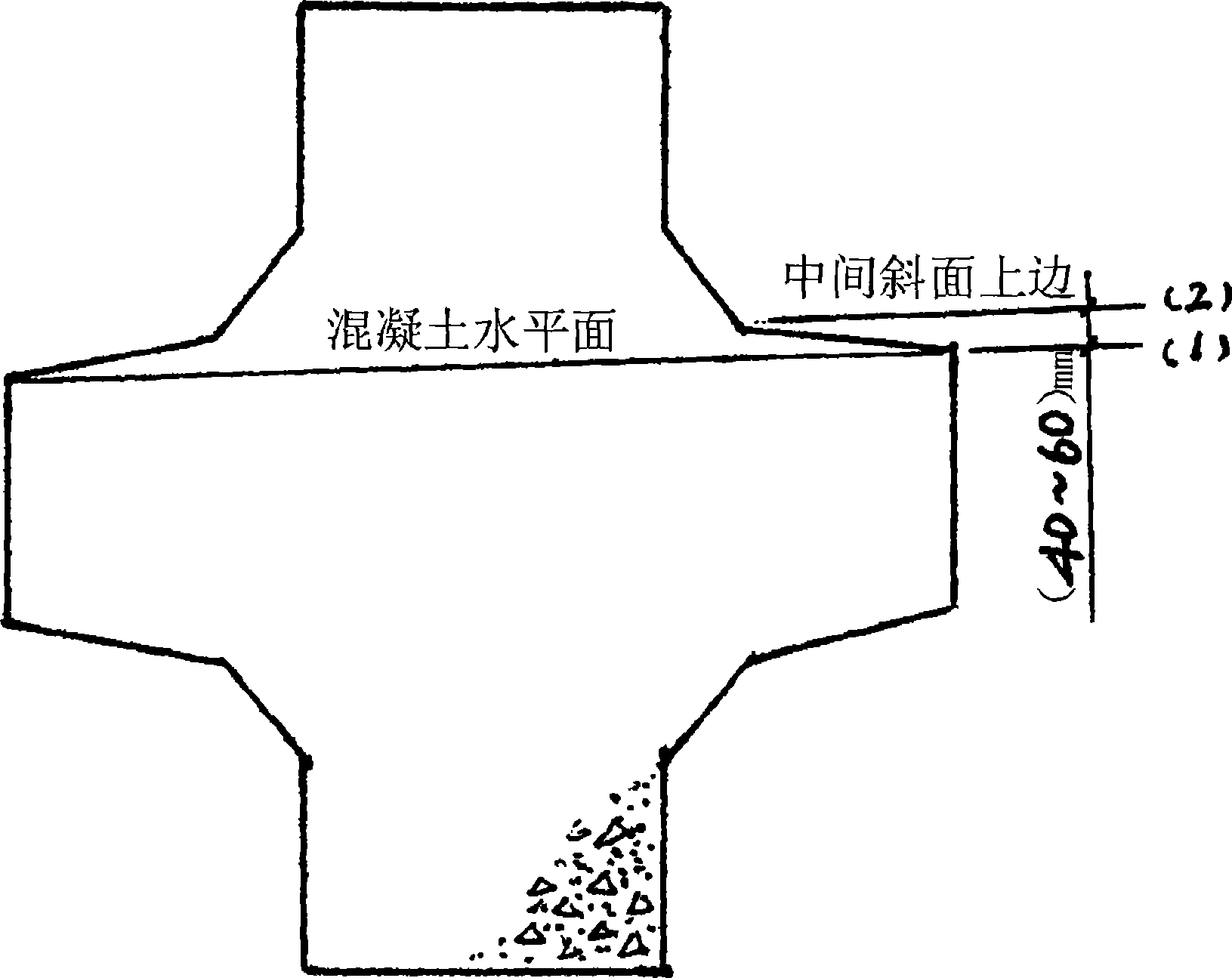

[0031] Such as figure 1 Shown, the method for utilizing pipe pile waste slurry shown in the present invention to produce water conservancy torsion king block and tetrapod hollow block, its steps are as follows:

[0032] (1) Clean the inside and outside of the mold, especially the cement slag at the bottom should be completely removed, if there is welding slag, it should be smoothed with a grinding wheel. If the bottom is deformed, it should be corrected to ensure that the mold meets the requirements.

[0033] (2) Clean the damaged sealing strip on the mold frame, apply glue, and then paste a new sealing strip. The joints of the sealing strips should be well combined without gaps. .

[0034] (3) Clean up the fixed pile position. Pad a piece of foamed soft plastic, and then cover with a layer of plastic film.

[0035] (4) After evenly brushing the release agent on the botto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com