Method for solidifying arsenic-calcium residue or arsenic-iron residue

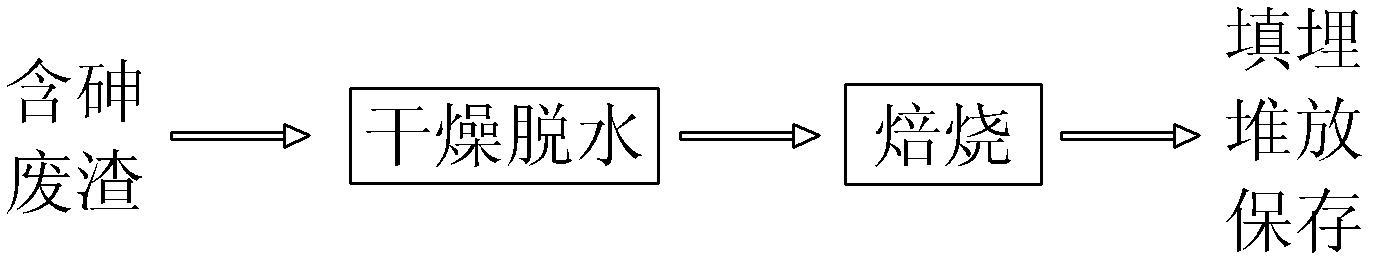

A solidification treatment and oxidation treatment technology, applied in the field of harmless treatment of solid hazardous waste, can solve the problems of high equipment material requirements, low arsenic recovery rate, insufficient safety, etc., achieve compact treatment process, reduce As leaching toxicity, and benefit The effect of landfill storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

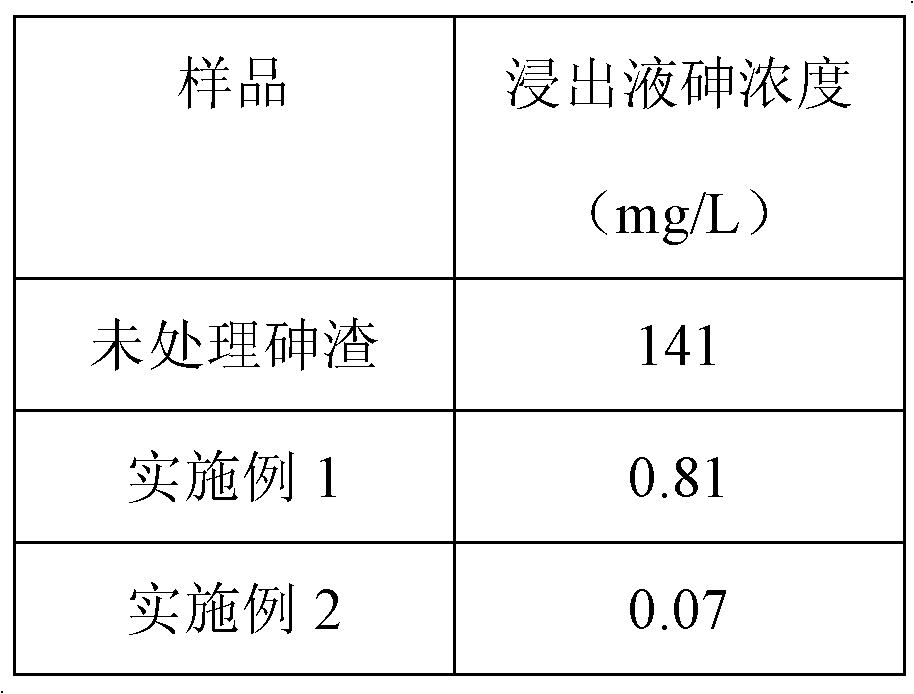

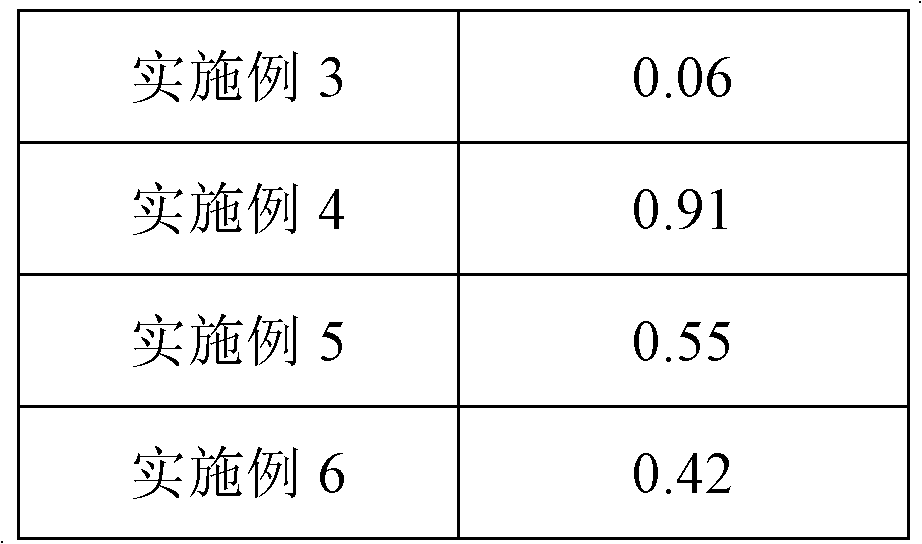

Embodiment 1

[0016] Taking calcium arsenate slag after sewage acid treatment in a non-ferrous smelter as the research object, the moisture content is 50-55%, and its dry basis main components are: CaO 32-33% (wt%), As 22-23% (wt%) %).

[0017] Solidification treatment process of calcium arsenate slag: take 20g of calcium arsenate slag and put it into a crucible, place it in an oven for drying treatment at 150°C, remove most of the water in the waste slag, and keep the moisture content of the arsenic slag below 20%; Put the crucible containing calcium arsenate slag into the muffle furnace for oxidative roasting. The roasting temperature is 600°C, and the roasting time is 1h. At the same time, ensure that the air flows continuously, and stir the materials in the crucible every 15 minutes. To ensure that the curing reaction is exposed to an oxidizing atmosphere; after the reaction, the sample is cooled to complete the curing process.

Embodiment 2

[0019] Taking calcium arsenate slag after sewage acid treatment in a non-ferrous smelter as the research object, the moisture content is 50-55%, and its dry basis main components are: CaO 32-33% (wt%), As 22-23% (wt%) %).

[0020] Solidification process of calcium arsenate slag: put 20g of calcium arsenate slag into a crucible, place it in an oven for drying treatment at 200°C, remove most of the water in the waste slag, and keep the moisture content of the arsenic slag below 20%; Put the crucible containing calcium arsenate slag into the muffle furnace for oxidative roasting, the roasting temperature is 800°C, and the roasting time is 3 hours. At the same time, ensure that the air flows continuously, and stir the materials in the crucible every 15 minutes. To ensure that the curing reaction is exposed to an oxidizing atmosphere; after the reaction, the sample is cooled to complete the curing process.

Embodiment 3

[0022] Taking calcium arsenate slag after sewage acid treatment in a non-ferrous smelter as the research object, the moisture content is 50-55%, and its dry basis main components are: CaO 32-33% (wt%), As 22-23% (wt%) %).

[0023] Solidification process of calcium arsenate slag: put 20g of calcium arsenate slag into a crucible, place it in an oven for drying treatment at 200°C, remove most of the water in the waste slag, and keep the moisture content of the arsenic slag below 20%; Put the crucible containing calcium arsenate slag into the muffle furnace for oxidation roasting. The roasting temperature is 1000°C, and the roasting time is 2 hours. At the same time, ensure that the air flows continuously, and stir the materials in the crucible every 15 minutes. To ensure that the curing reaction is exposed to an oxidizing atmosphere; after the reaction, the sample is cooled to complete the curing process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com