A garbage disposal device

A garbage disposal device and compression device technology, which is applied in the direction of manufacturing tools, stamping machines, presses, etc., can solve the problems of low automation and insufficient stability of the extrusion process, and achieve enhanced use safety, simple structure, and convenient operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

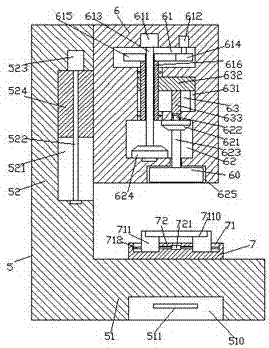

[0021] Such as Figure 1-Figure 4 As shown, a garbage disposal device of the present invention includes a frame body 5 composed of a backboard 52 and a workbench 51, the right side of the backboard 52 is provided with a compression device 6, and the top of the workbench 51 is provided with a fixing device 7. The top surface of the fixing device 7 corresponds to the bottom surface of the compression device 6, and the compression device 6 is provided with a first cavity 63, a second cavity 61 and a third cavity 62 inside, and the first cavity The inner surface of the right side of the compartment 63 is provided with a second sliding groove 631, and the left side of the first empty compartment 63 is provided with an external threaded sleeve 616 extending up and down, and the top extension block of the external spiral sleeve 616 penetrates The inner top surface of the first empty chamber 63 is screwed and connected, the tip of the extension block at the top of the outer threaded s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com