Foldable building units

a technology of building units and building components, applied in the direction of skylights/domes, doors/window fittings, stairways, etc., can solve the problems of ineffective cost-efficiency of this approach, the total cost of these prefabricated non-foldable building units to rise to levels detrimental to competition with conventional construction, and the installation cost of prefabricated non-foldable building units was substantial. , to achieve the effect of reducing or eliminating material damage, and easy prefabricated

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047]A description of example embodiments of the invention follows.

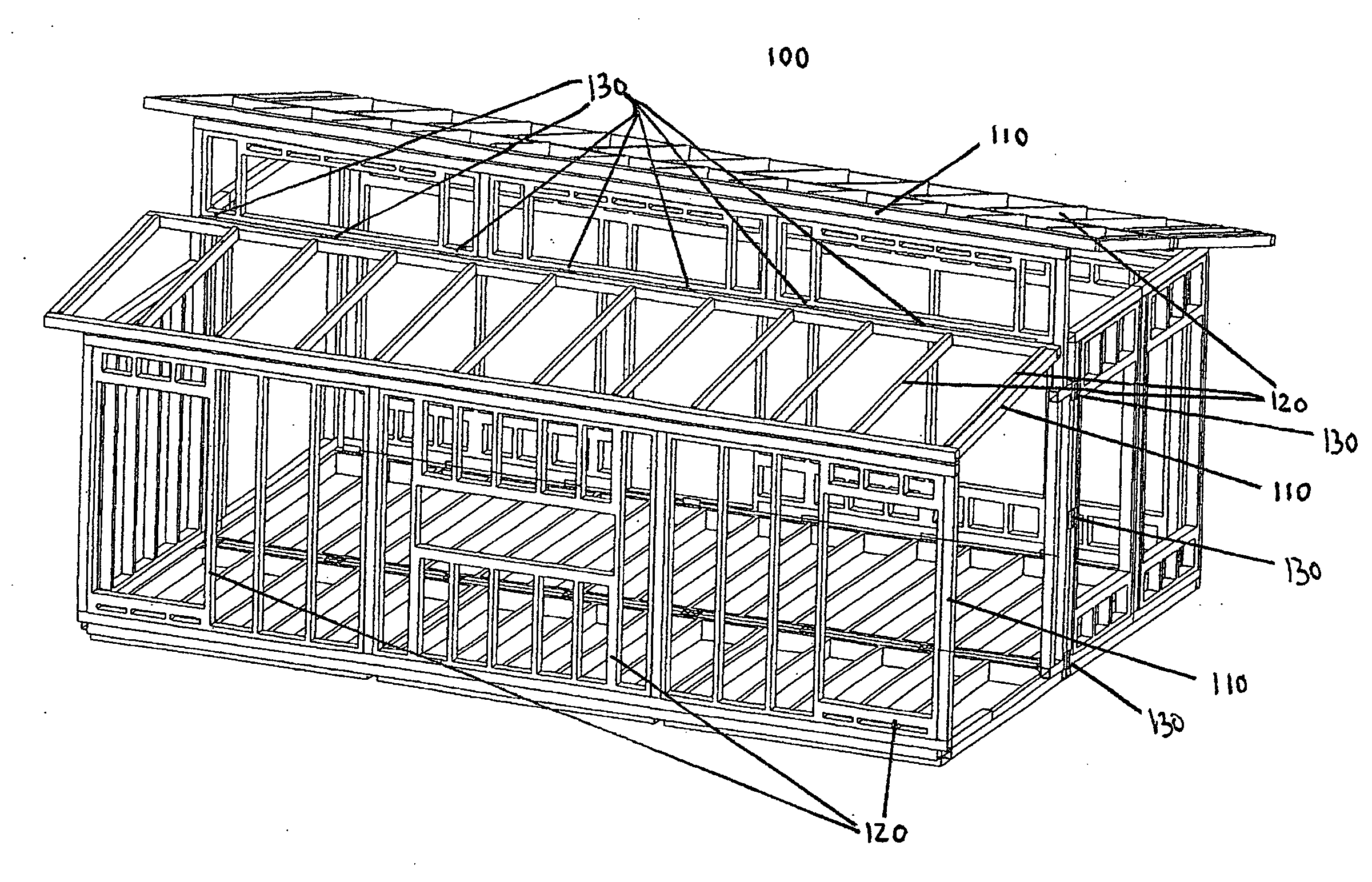

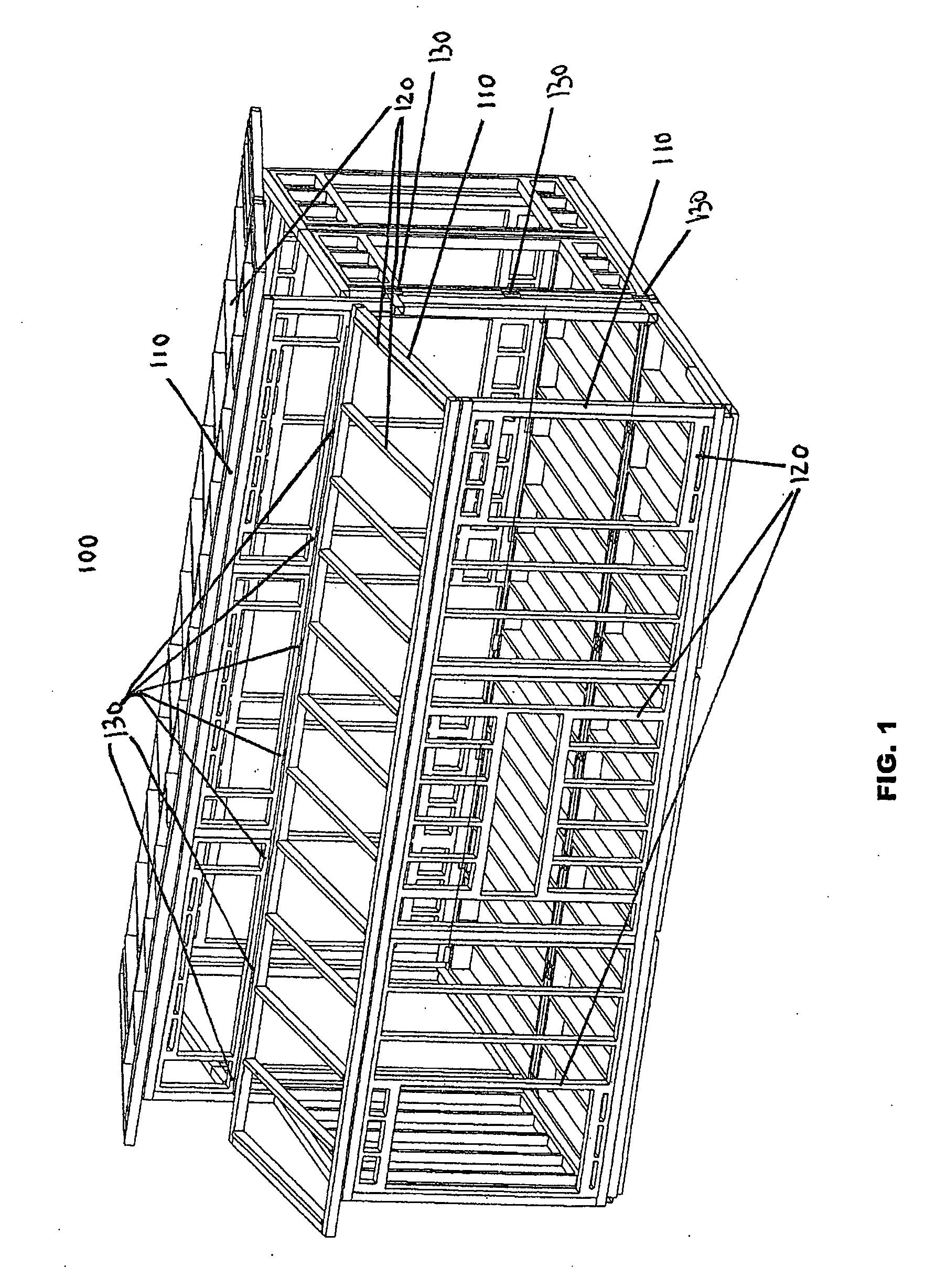

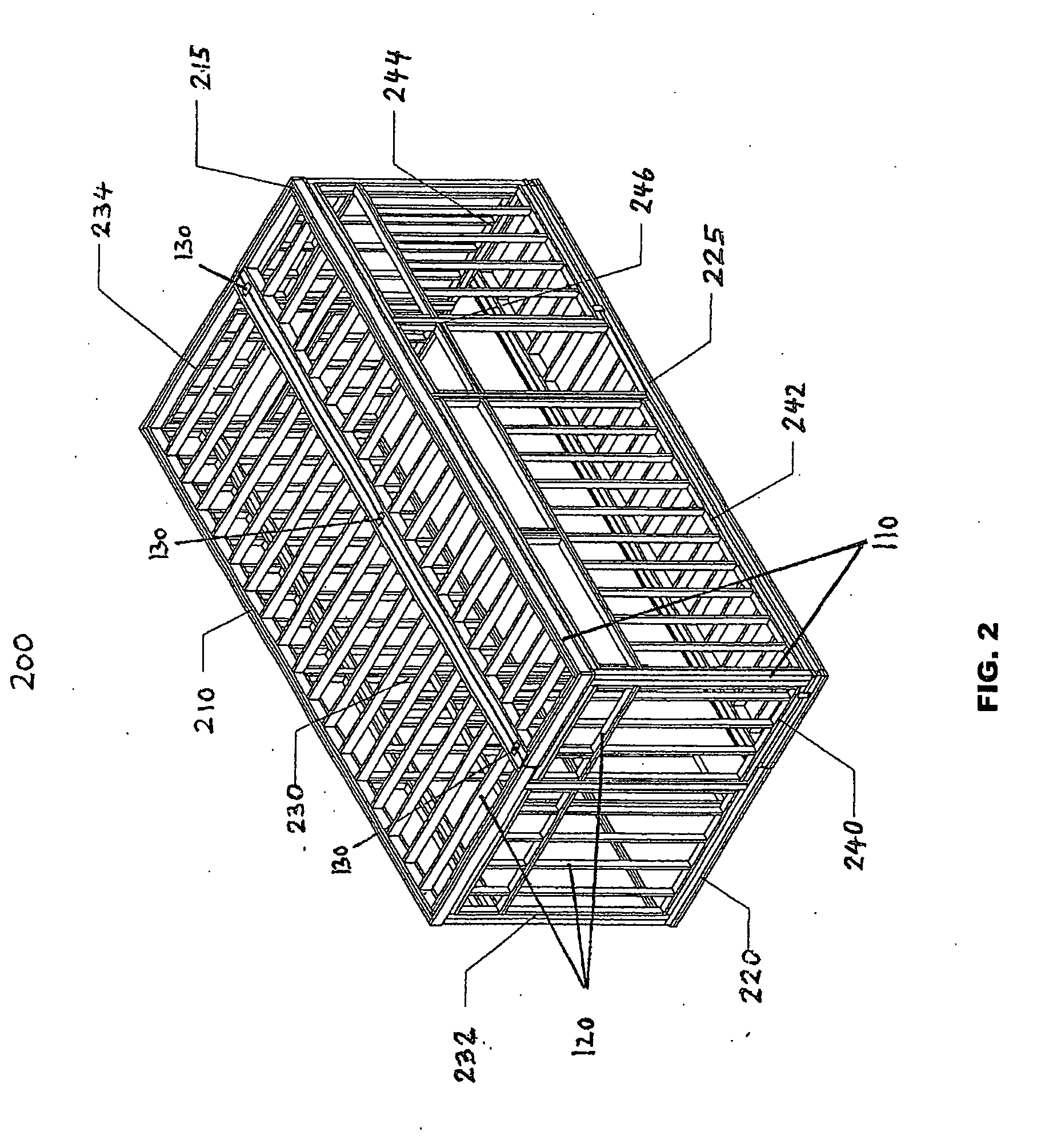

[0048]Although the teachings of the present invention are applicable to a wide variety of structures of different weight, size, shape and materials for a variety of diverse uses, for purposes of the following description, the present invention will be described in the context of prefabricated foldable building units.

[0049]The foldable buildings (and, more generally, foldable building units) of the present invention can be prefabricated such that the foldable buildings, after unfolding on the building site, are substantially in finished condition. That is, they do not require or significantly reduce the addition of further building sections such as wall panels, floor and roof sections, or the addition of interior and exterior finish materials with the exception of minor, non-structural finishing in areas required for folding movement. However, the prefabrication process can be reduced substantially, even to the exten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com