Plugging method for grout blanket at connecting position of upper layer and lower layer of assembling shear wall building

A shear wall, prefabricated technology, applied in the processing of building materials, construction, building structure, etc., can solve the problem that the vertical load cannot be guaranteed smoothly on the upper and lower floors, the flatness of the grouting layer 4 cannot be guaranteed, and the grouting layer 4 cannot be guaranteed. Strength and other issues, to achieve the effect of saving materials, good impact resistance, and convenient prefabrication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

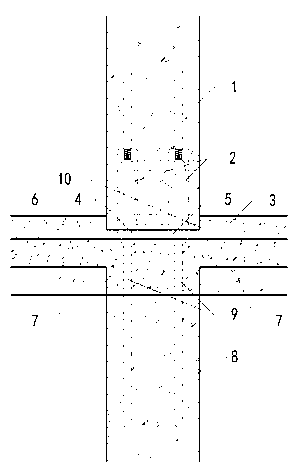

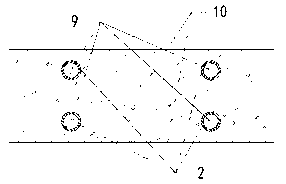

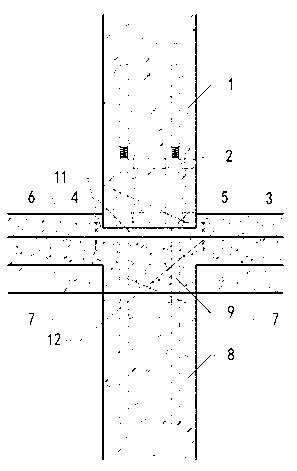

[0022] First fix the wooden strip 11 with steel nails 12 on both sides of the grouting layer 4 to completely block both sides of the grouting layer 4, then fill the high-strength grouting material 5 and the grouting layer 4, and wait until the high-strength grouting material 5 is completely solidified to reach a certain strength After that, the wooden strips were removed and recycled 11. The use of wooden strips 11 as the lateral blocking material of the grouting layer 4 in the present invention can ensure the flatness of one side of the grouting layer 4, ensure that the high-strength grouting material 5 completely fills the grouting layer 4, and completely transfers the load between the upper and lower layers. In application, the wood type of the wooden strip 11, the cross-sectional size of the wooden strip 11, the material of the steel nail 12, and the size of the steel nail 12 are determined according to the actual force of the project, such as Figure 3 ~ Figure 4 Shown...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com