Rubber spacer light track structure with vibration reduction and noise reduction functions

A rubber cushion, vibration reduction and noise reduction technology, applied in the engineering field, can solve the problems of affecting the restraint rigidity of connecting rods, unfavorable vibration damping element arrangement, endangering train running safety, etc. The effect of resisting bending moment of inertia and improving construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

other Embodiment approach

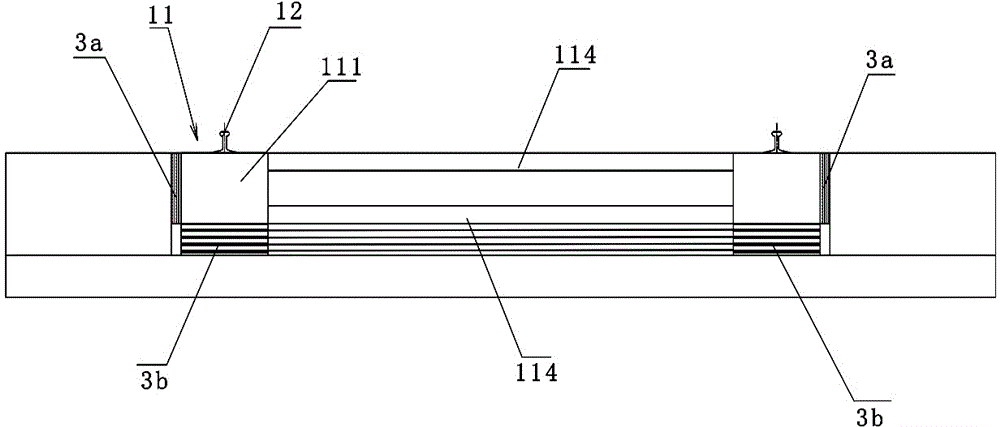

[0045] In other embodiments, the connecting rods 114 can be assembled according to other layouts, such as three or more layers, or staggered layouts, etc., as long as the connecting rods 114 arranged between the track beam bodies 111 can increase the size of the track beam body. The transverse connection stiffness of 111 is sufficient.

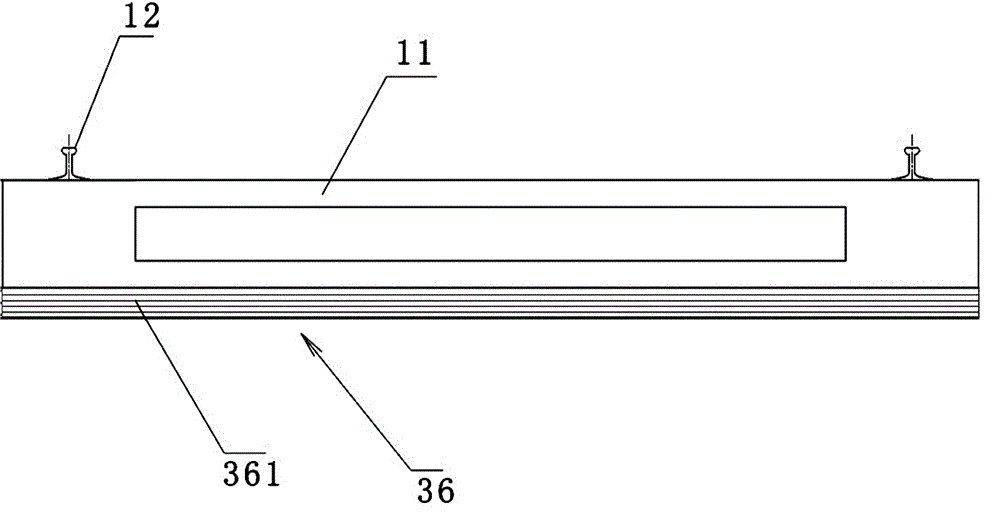

[0046] The horizontal vibration and noise reduction device 3a and the vertical vibration and noise reduction device 3b in the first embodiment and the second embodiment above are laminated rubber plates. According to structural differences, they can be implemented in the following three ways, specifically:

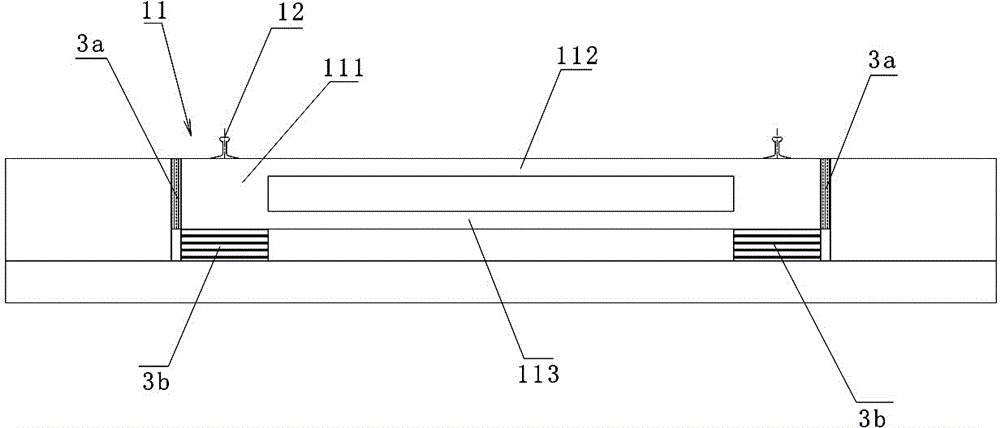

[0047] like Figure 8 As shown, it is a schematic cross-sectional structure diagram of Embodiment 1 of the laminated rubber sheet with a track structure with vibration and noise reduction functions according to the present invention.

[0048] The vibration and noise reduction device in this embodiment includes: multiple groups of laminate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com