Large bone defect assist bone graft magnesium alloy stent and production method thereof

A magnesium alloy stent and bone defect technology, applied in the field of medical auxiliary bone graft stent research, can solve problems such as increased infection opportunities, loosening of fixation screws, fractures, nerve paralysis, etc., to reduce costs, shorten preparation time, and improve matching. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

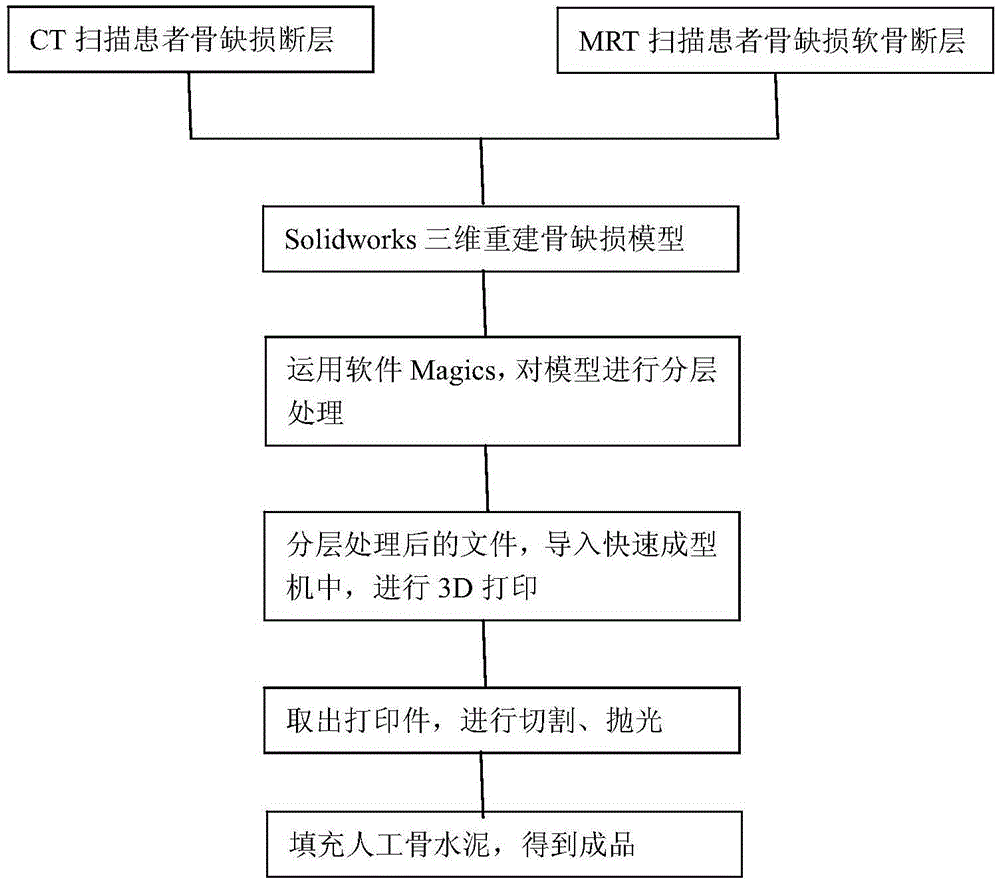

[0030] (1) Combining CT and MRT data, reconstruct the model of the bone defect of the patient through solidwors, (2) process the model in layers through mgics software, and output the STL format file of the bone defect, (3) print the bone defect of the patient through M2803D Bracket, (4) wire-cutting the printed model to remove the bracket, polishing and grinding, (5) filling the magnesium alloy bracket with bone cement.

[0031] see figure 1 In this embodiment, a method for preparing an auxiliary bone grafting magnesium alloy scaffold for large bone defects comprises the following steps:

[0032] (1) Use CT to scan the patient's bone defect section to create a DICOM format file; use MRT to scan the patient's bone defect cartilage section to create a DICOM format file; import the above DICOM format file into the 3D software solidworks, and then segment and repair the image After processing, the model of the defect bone is obtained, and the model of the defect bone is built in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com