Method and device for realizing connection of pipe and plate by utilizing plastic deformation of pipe

A technology of plastic deformation and plate connection, which is applied in metal processing equipment, forming tools, manufacturing tools, etc., can solve the problems of welding seam defects affecting the strength of use, low production efficiency of welding methods, and inability to meet the connection strength, etc., to achieve precise and labor-saving plasticity Instability, high production efficiency, high repeatability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] A method of utilizing the plastic deformation of the pipe to realize the connection between the pipe and the plate according to the present invention comprises three processes of flanging the plate, shrinking the pipe and connecting the plate and the pipe:

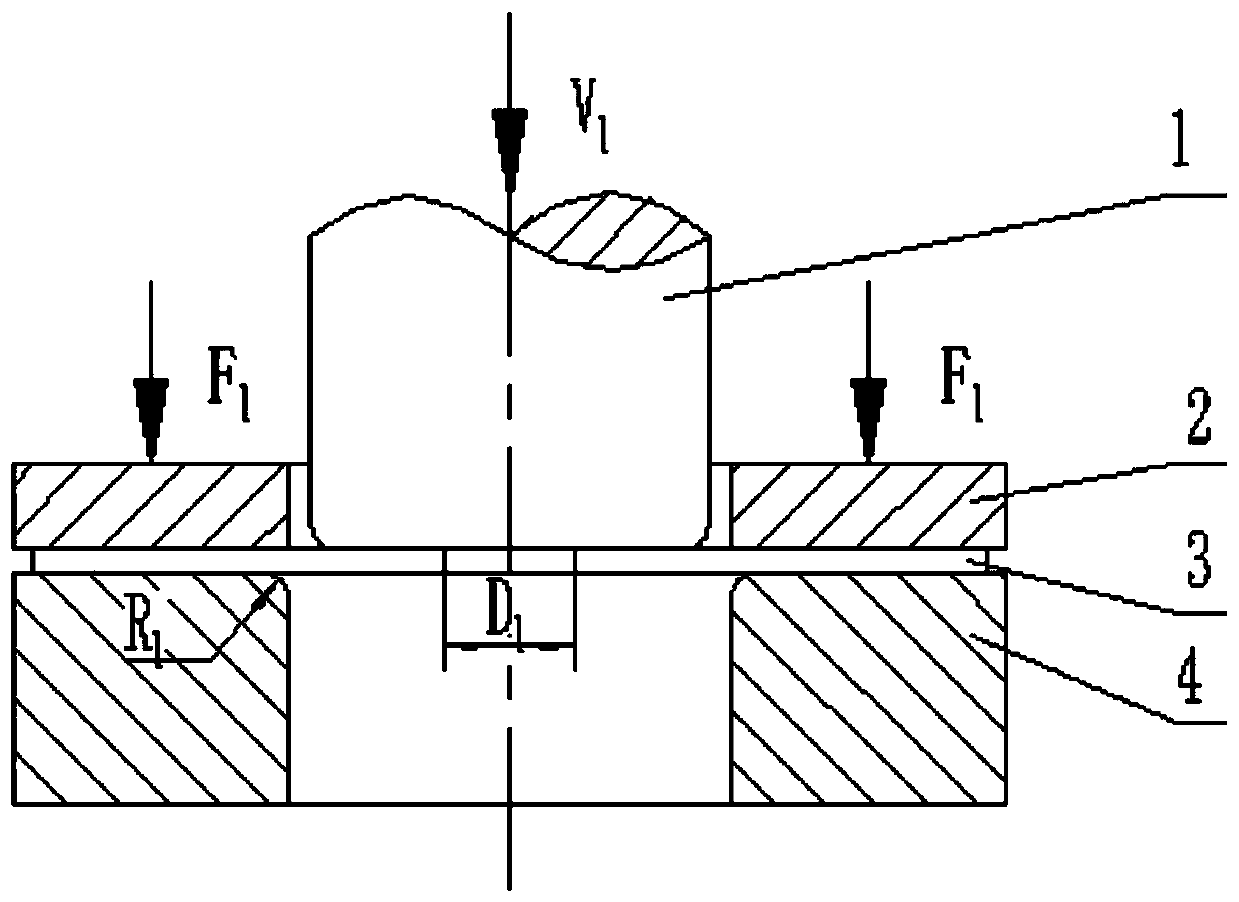

[0042] Plate flanging: Prefabricate a round hole on the intended connection part of the plate, fix the plate, and perform flanging at the round hole to form a ring-shaped flange;

[0043] Pipe necking: fix the pipe, and shrink the end of the pipe to be connected. The diameter of the necking end is larger than the outer diameter of the plate flange, and the diameter of the necking end is generally 105% to 120% of the outer diameter of the plate flange.

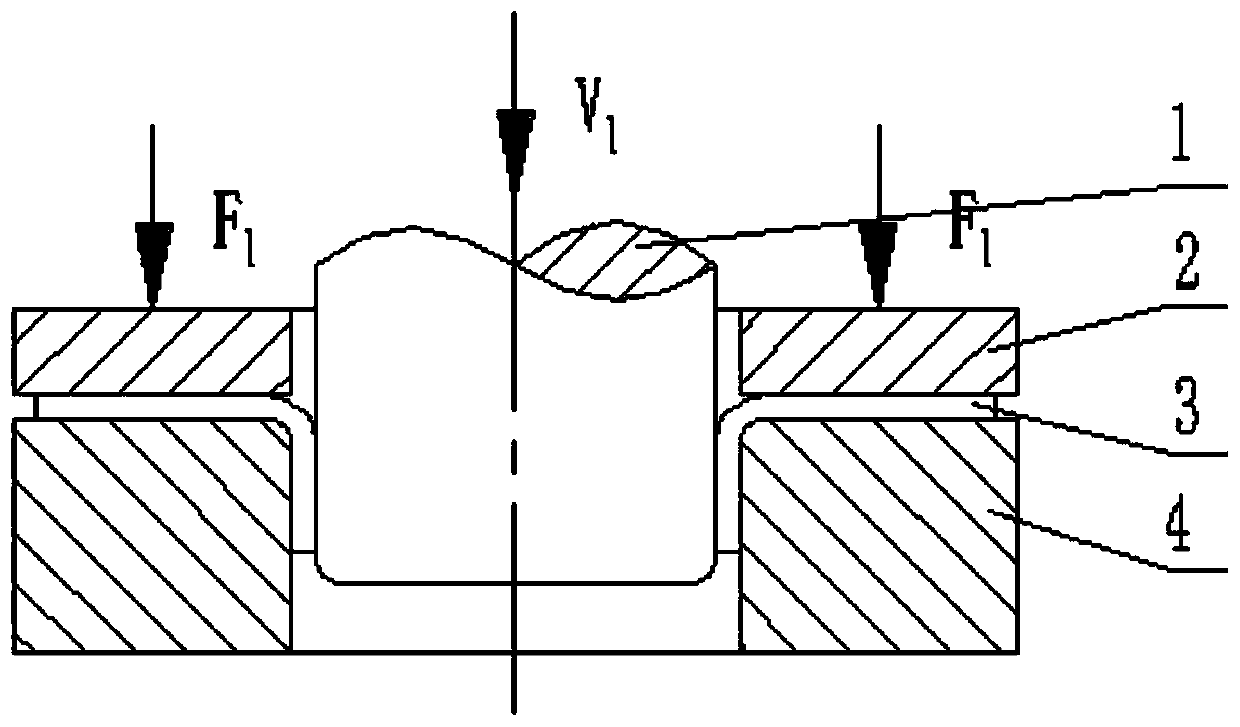

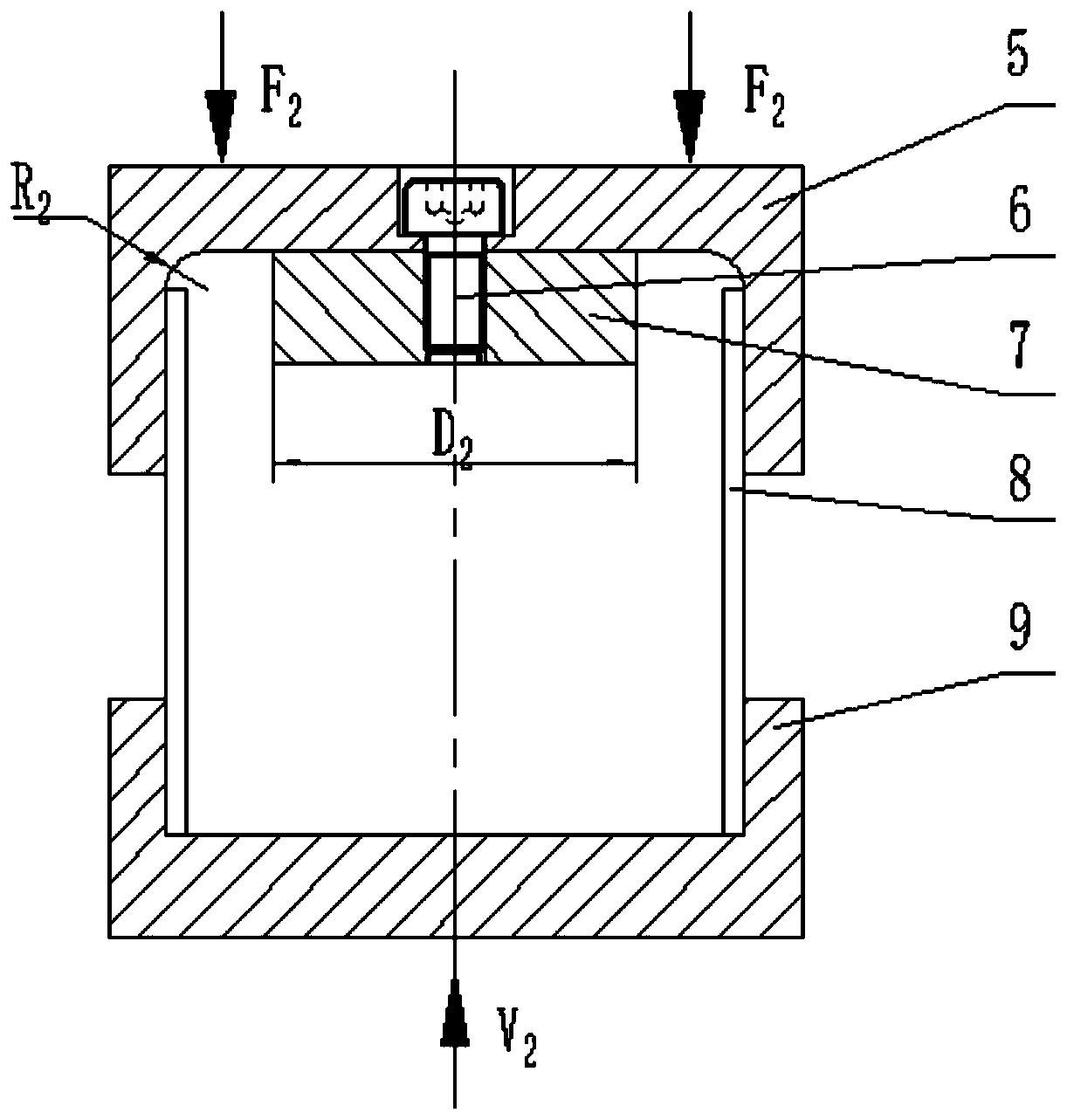

[0044] Connection between the plate and the pipe: put the shrinking end of the pipe on the outside of the flange of the plate to fix the plate and the pipe; Magnetic induction heating, and then apply pressure to the flange of the plate, so that the flange of the plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com