Uvioresistant, flame-retardant, anti-melt-drop, moisture absorption and sweat facilitating polyester monofilament and preparation method

A technology of moisture absorption and perspiration and polyester monofilament, which is applied in the fields of moisture absorption and perspiration polyester monofilament and its preparation, anti-ultraviolet, flame retardant and anti-melt droplet. Less smoke, good flame retardant effect, and improved compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

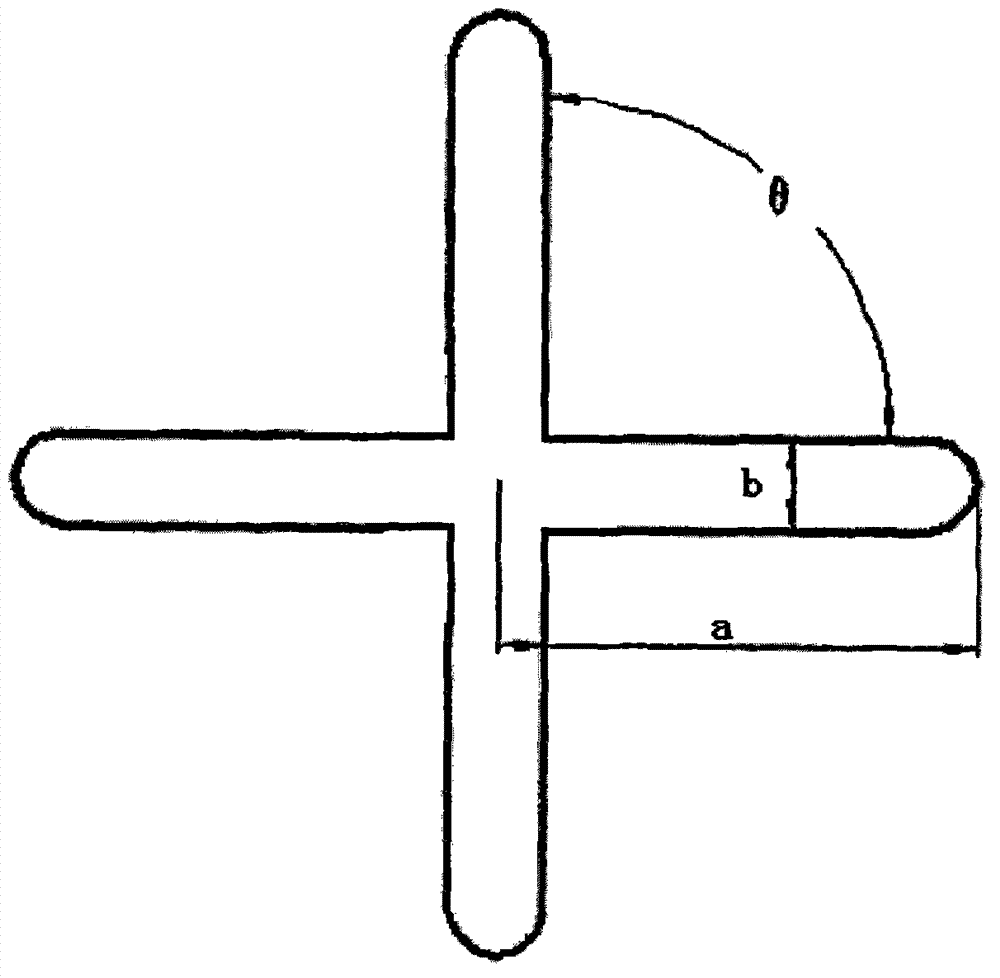

Image

Examples

Embodiment 1

[0033] An anti-ultraviolet, flame-retardant, anti-droplet, moisture-absorbing and sweat-wicking polyester monofilament, the mass percentage of its raw material components is:

[0034] The anti-ultraviolet, flame-retardant and anti-dripping polyester masterbatch 1%

[0035] Hydrophilic modified polyester chips 1%

[0036] Polyester chips 98%

[0037] The hydrophilic modified polyester chips are modified polyesters with hydrophilic groups such as hydroxyl groups or ether groups;

[0038] The mass percent of the raw material components of the anti-ultraviolet, flame-retardant and anti-dripping polyester masterbatch is:

[0039] Silane coupling agent coated ultra-fine ammonium polyphosphate 5%

[0040] Nano-scale anti-ultraviolet agent 5%

[0041] Polyester chips 90%

[0042] The silane coupling agent is γ-methacryloxypropyltrimethoxysilane;

[0043] The particle size of the ultrafine ammonium polyphosphate coated with the silane coupling agent is 0.5-5 μm;

[0044] The nan...

Embodiment 2

[0052] An anti-ultraviolet, flame-retardant, anti-droplet, moisture-absorbing and sweat-wicking polyester monofilament, the mass percentage of its raw material components is:

[0053] The anti-ultraviolet, flame-retardant and anti-dripping polyester masterbatch 2%

[0054] Hydrophilic modified polyester chips 3%

[0055] Polyester chips 95%

[0056] The hydrophilic modified polyester chips are modified polyesters with hydrophilic groups such as hydroxyl groups or ether groups;

[0057] The mass percent of the raw material components of the anti-ultraviolet, flame-retardant and anti-dripping polyester masterbatch is:

[0058] Silane coupling agent coated ultra-fine ammonium polyphosphate 8%

[0059] Nano-scale anti-ultraviolet agent 8%

[0060]Polyester chips 84%

[0061] The silane coupling agent is γ-methacryloxypropyltrimethoxysilane;

[0062] The particle size of the ultrafine ammonium polyphosphate coated with the silane coupling agent is 0.5-5 μm;

[0063] The nano...

Embodiment 3

[0071] An anti-ultraviolet, flame-retardant, anti-droplet, moisture-absorbing and sweat-wicking polyester monofilament, the mass percentage of its raw material components is:

[0072] The anti-ultraviolet, flame-retardant and anti-dripping polyester masterbatch 3%

[0073] Hydrophilic modified polyester chips 5%

[0074] Polyester chips 92%

[0075] The hydrophilic modified polyester chips are modified polyesters with hydrophilic groups such as hydroxyl groups or ether groups;

[0076] The mass percent of the raw material components of the anti-ultraviolet, flame-retardant and anti-dripping polyester masterbatch is:

[0077] Silane coupling agent coated ultra-fine ammonium polyphosphate 10%

[0078] Nano-scale anti-ultraviolet agent 10%

[0079] Polyester chips 80%

[0080] The silane coupling agent is γ-methacryloxypropyltrimethoxysilane;

[0081] The particle size of the ultrafine ammonium polyphosphate coated with the silane coupling agent is 0.5-5 μm;

[0082] The n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com