P-Br synergistic high-expansion and flame-retardation PET material and preparation method thereof

A high-expansion, compound flame retardant technology, applied in the field of flame retardant, can solve the problems of unfavorable health of processing personnel, significant impact on mechanical properties, and difficulty in adding process, so as to maintain excellent mechanical properties, improve flame retardant performance and melt resistance The effect of drop performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

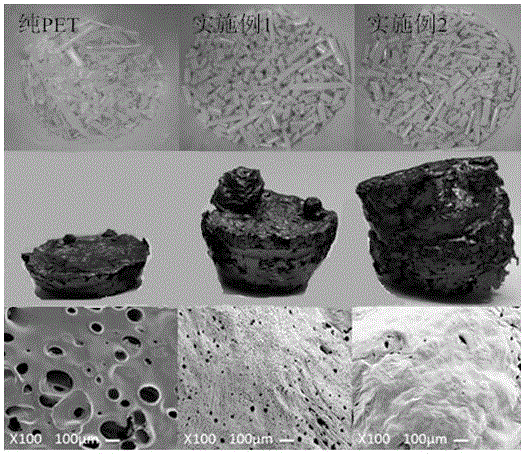

Image

Examples

Embodiment 1

[0019] Embodiment 1, raw material formula is as follows:

[0020] PET resin 900g

[0021] Aluminum Diethylphosphinate 50g

[0022] Pentabromobenzyl polyacrylate 50g

[0023] Prepared according to the following steps:

[0024] (1) The raw material PET was dried in a vacuum oven at 120°C for 24 hours; aluminum diethyl hypophosphite and pentabromobenzyl polyacrylate were dried in a vacuum oven at 120°C for 6 hours;

[0025] (2) Mixing of raw materials: mix polyethylene terephthalate, aluminum diethyl hypophosphite, and pentabromobenzyl polyacrylate in a high-speed mixer at room temperature for 3 to 5 minutes according to the above-mentioned weighing grams, so that Each component is dispersed evenly;

[0026] (3) Add the mixture obtained in step (2) to the feeding port of the twin-screw extruder, and set the temperature of the first zone to the ninth zone of the twin-screw extruder to be 232 / 237 / 247 / 257 / 262 / 262 / 257 / 257 / 252°C, the temperature of the machine head is 247°C, and...

Embodiment 2

[0028] Embodiment 2, raw material formula is as follows:

[0029] PET resin 850g

[0030] Aluminum Diethylphosphinate 100g

[0031] Pentabromobenzyl polyacrylate 50g

[0032] Prepared according to the following steps:

[0033] (1) The raw material PET was dried in a vacuum oven at 120°C for 24 hours; aluminum diethyl hypophosphite and pentabromobenzyl polyacrylate were dried in a vacuum oven at 120°C for 6 hours;

[0034] (2) Mixing of raw materials: mix polyethylene terephthalate, aluminum diethyl hypophosphite, and pentabromobenzyl polyacrylate in a high-speed mixer at room temperature for 3 to 5 minutes according to the above-mentioned weighing grams, so that Each component is dispersed evenly;

[0035] (3) Add the mixture obtained in step (2) to the feeding port of the twin-screw extruder, and set the temperature of the first zone to the ninth zone of the twin-screw extruder to be 232 / 237 / 247 / 257 / 262 / 262 / 257 / 257 / 252°C, the temperature of the machine head is 247°C, an...

Embodiment 3

[0037] Embodiment 3, raw material formula is as follows:

[0038] PET resin 800g

[0039] Aluminum Diethylphosphinate 100g

[0040] Pentabromobenzyl polyacrylate 100g

[0041] Prepared according to the following steps:

[0042] (1) The raw material PET was dried in a vacuum oven at 120°C for 24 hours; aluminum diethyl hypophosphite and pentabromobenzyl polyacrylate were dried in a vacuum oven at 120°C for 6 hours;

[0043] (2) Mixing of raw materials: mix polyethylene terephthalate, aluminum diethyl hypophosphite, and pentabromobenzyl polyacrylate in a high-speed mixer at room temperature for 3 to 5 minutes according to the above-mentioned weighing grams, so that Each component is dispersed evenly;

[0044] (3) Add the mixture obtained in step (2) to the feeding port of the twin-screw extruder, and set the temperature of the first zone to the ninth zone of the twin-screw extruder to be 232 / 237 / 247 / 257 / 262 / 262 / 257 / 257 / 252°C, the temperature of the machine head is 247°C, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com