Perfluoropolyether modified antifouling droplet-preventing copolyester and preparation method thereof

A technology of perfluoropolyether and copolyester, applied in the direction of single-component copolyester rayon, etc., can solve the problem of polyester antifouling, flame retardant and anti-droplet properties, and the synergistic effect of modified components is not clear , the effect of polyester fiber formation and other issues, to achieve excellent anti-droplet performance, good market application prospects, and low cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

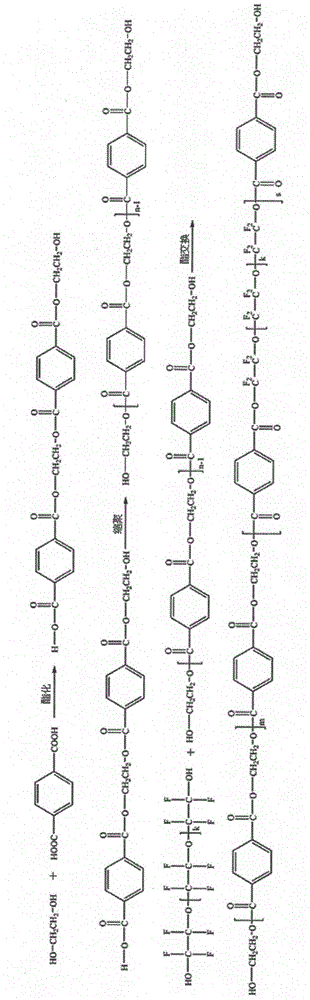

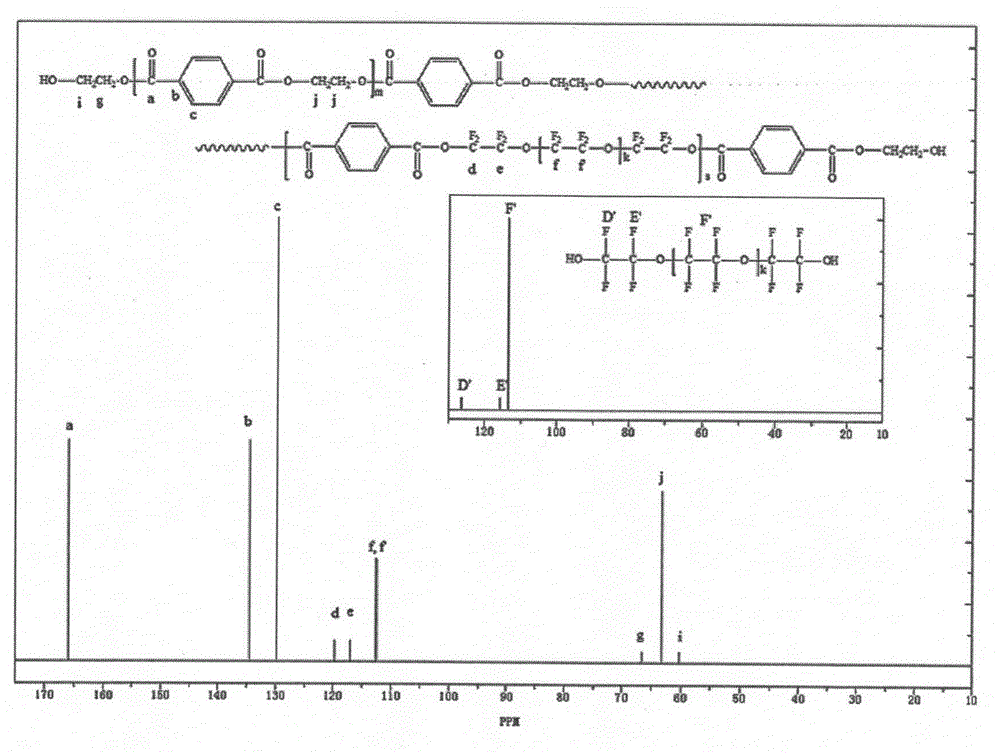

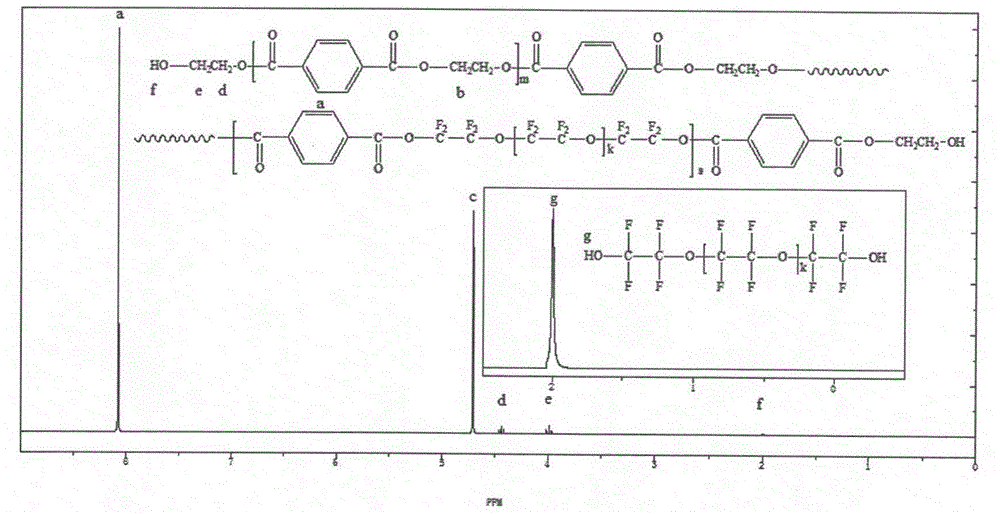

Method used

Image

Examples

Embodiment 1

[0023]The preparation method of anti-fouling and anti-droplet copolyester uses terephthalic acid, ethylene glycol, and hydroxyl-terminated perfluoropolyether as raw materials, and according to the molar ratio of terephthalic acid and ethylene glycol is 1: 1.67, the first step First, ethylene glycol and terephthalic acid are mixed in proportion. Under the protection of nitrogen, under the condition of 0.3MPa, the esterification reaction of terephthalic acid and ethylene glycol is carried out under the pressure condition of the first step. The esterification reaction The temperature is 260°C, and the reaction is 3h. In the second step, then add the hydroxyl-terminated perfluoropolyether to carry out precondensation at high temperature and normal pressure, and the molar ratio of terephthalic acid to perfluoropolyether is 1:0.20; the average mass-average molecular weight of the perfluoropolyether is It is 3000; control the precondensation reaction temperature at 260°C and keep it ...

Embodiment 2

[0026] The preparation method of anti-fouling and anti-droplet copolyester uses terephthalic acid, ethylene glycol, and hydroxyl-terminated perfluoropolyether as raw materials, and according to the molar ratio of terephthalic acid and ethylene glycol is 1: 1.25, the first step First, ethylene glycol and terephthalic acid are mixed in proportion. Under the protection of nitrogen, under the condition of 0.2MPa, the esterification reaction of terephthalic acid and ethylene glycol is carried out under the pressure condition of the first step. The esterification reaction The temperature was 220°C, and the reaction was carried out for 5 hours. In the second step, then add the hydroxyl-terminated perfluoropolyether to carry out precondensation at high temperature and normal pressure, and the molar ratio of terephthalic acid to perfluoropolyether is 1:0.05; the average mass-average molecular weight of the perfluoropolyether is It is 20000; control the precondensation reaction temperat...

Embodiment 3

[0029] The preparation method of anti-fouling and anti-droplet copolyester uses terephthalic acid, ethylene glycol, and hydroxyl-terminated perfluoropolyether as raw materials, and the molar ratio of terephthalic acid and glycol is 1: 1.25. The first step First, ethylene glycol and terephthalic acid are mixed in proportion. Under the protection of nitrogen, under the condition of 0.3MPa, the esterification reaction of terephthalic acid and ethylene glycol is carried out under the pressure condition of the first step. The esterification reaction The temperature was 240°C, and the reaction was carried out for 5 hours. In the second step, then add the hydroxyl-terminated perfluoropolyether to carry out precondensation at high temperature and normal pressure, and the molar ratio of terephthalic acid to perfluoropolyether is 1:0.20; the average mass-average molecular weight of the perfluoropolyether is It is 6000; control the precondensation reaction temperature at 260°C and keep i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface energy | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| surface energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com