PLA-based degradable antibacterial flame-retardant wig fiber and preparation method thereof

A fiber and wig technology, applied in the field of degradable antibacterial and flame-retardant wig fiber and its preparation, can solve the problems of increased casualties and economic losses, poor flame-retardant performance of PLA, rapid melting, etc., to achieve good smoothness and gloss, enhance long-lasting, excellent elastic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The PLA-based degradable antibacterial flame-retardant wig fiber is prepared according to the following steps:

[0034] (1) Take raw materials according to the weight ratio, PLA 95%, composite flame retardant 2%, composite antibacterial agent 1.5%, dyeing agent 0.4%, additive 0.5%, dispersant 0.4%, plasticizer 0.2%, raw material in Dehumidification and drying at 80°C; the total time of dehumidification and drying is 8 hours, and the moisture content of raw materials is controlled within 50ppm;

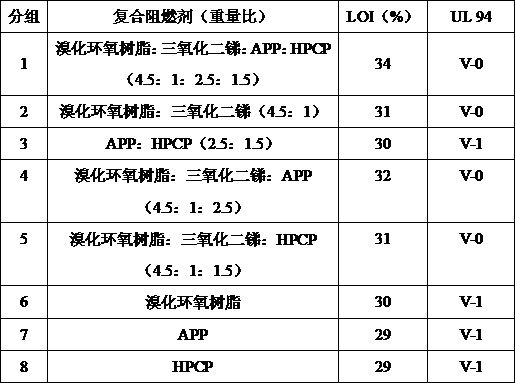

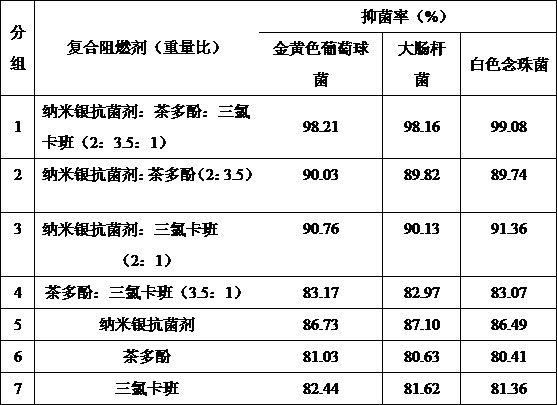

[0035]Among them, the intrinsic viscosity of PLA is 1.65dl / g; the composite flame retardant is composed of brominated epoxy resin, antimony trioxide, APP, and HPCP with a weight ratio of 4.5:1:2.5:1.5; the composite antibacterial agent is composed of a weight ratio of 2: 3.5: 1 chitosan, tea polyphenols, triclocarban; dyeing agent is black masterbatch; additive is talcum powder; dispersant is vinyl bis stearamide; plasticizer is acetyl citric acid tributyl ester.

[0036] (2) ...

Embodiment 2

[0042] A kind of degradable antibacterial flame-retardant PLA wig fiber, different from embodiment 1 is:

[0043] Raw materials are taken according to the weight ratio, PLA 95%, composite flame retardant 2%, composite antibacterial agent 1.5%, dyeing agent 0.4%, additive 0.5%, dispersant 0.4%, plasticizer 0.2%, and the raw materials are heated at 80°C Dehumidification and drying; the total time of dehumidification and drying is 8 hours, and the moisture content of raw materials is controlled within 50ppm;

[0044] Among them, the intrinsic viscosity of PLA is 1.65 dl / g; the composite flame retardant is composed of brominated epoxy resin, antimony trioxide, APP, and HPCP in a weight ratio of 3:1.5:3:2; the composite antibacterial agent is composed of a weight ratio of 3:4:1.5 nano-silver antibacterial agent, tea polyphenols, triclocarban; dyeing agent is brown color masterbatch; additive is nano-calcium carbonate in weight ratio; dispersant is polyethylene wax with a molecular ...

Embodiment 3

[0047] The PLA-based degradable antibacterial flame-retardant wig fiber is prepared according to the following steps:

[0048] (1) Take raw materials according to the weight ratio, PLA 80%, composite flame retardant 10%, composite antibacterial agent 5%, dyeing agent 0.8%, additive 1.7%, dispersant 1.8%, plasticizer 0.7%, raw materials in Dehumidification and drying at 80°C; the total time of dehumidification and drying is 8 hours, and the moisture content of raw materials is controlled within 50ppm;

[0049] Among them, the intrinsic viscosity of PLA is 1.85dl / g; 4.5:1:2.5:1.5 brominated epoxy resin, antimony trioxide, APP, HPCP; Composed of sugar, tea polyphenols and triclocarban; the dyeing agent is black masterbatch; the additive is silicon dioxide and talcum powder with a weight ratio of 1:1; the dispersant is vinyl bis stearamide; the plasticizer is Acetyl tributyl citrate.

[0050] (2) Put the raw materials into a single-screw extruder, perform spiral melt extrusion t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com