Flame-retardant protective clothing polyester fabric

A technology of flame retardant polyester and protective clothing, applied in the field of clothing processing, can solve the problems of insufficient flame retardant durability, human injury, and too many chemical reagents, and achieve the effect of improving grade, small environmental impact, and smooth hand feel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] A fabric for flame-retardant polyester protective clothing, comprising preparation of flame-retardant polyester fiber, preparation of base fabric, soft finishing, and drying treatment. The specific operation steps are:

[0015] 1) Preparation of flame-retardant polyester fiber: Melt blending and granulation of ethylene terephthalate and polyphenylene sulfide with a twin-screw extruder, the amount of polyphenylene sulfide added is ethylene terephthalate 8% by weight, prepared flame-retardant polyester chips, pre-crystallized by vacuum drying at 80°C for 12 hours, and then crystallized at 115°C for 24 hours, then melt-spun, cooled by ring blowing, oiled, and drawn for the first time. In the second drawing, the flame-retardant polyester fiber is formed by winding. The cooling temperature of the ring air is 70°C, the first drawing temperature is 170°C, the draw ratio is 1.8 times, and the second drawing temperature is 140°C. The expansion ratio is 3.0 times. Polyphenylene s...

Embodiment 2

[0020] A fabric for flame-retardant polyester protective clothing, comprising preparation of flame-retardant polyester fiber, preparation of base fabric, soft finishing, and drying treatment. The specific operation steps are:

[0021] 1) Preparation of flame-retardant polyester fiber: Melt blending and granulation of ethylene terephthalate and polyphenylene sulfide with a twin-screw extruder, the amount of polyphenylene sulfide added is ethylene terephthalate 8% by weight, prepared flame-retardant polyester chips, pre-crystallized by vacuum drying at 80°C for 13h, and then crystallized at 115°C for 24h, then melt-spun, cooled by ring blowing, oiled, and drawn for the first time. In the second drawing, the flame-retardant polyester fiber is formed by winding. The cooling temperature of the surrounding air is 70 ° C, the first drawing temperature is 180 ° C, the drafting ratio is 1.6 times, the second drawing temperature is 130 ° C, and the drafting temperature is 130 ° C. The e...

Embodiment 3

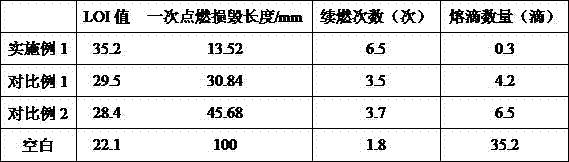

[0026] Combustion performance test:

[0027] Select invention embodiment 1, comparative example and blank to carry out self-cleaning test and washability test, wherein, comparative example 1: repeat the preparation process of the flame-retardant polyester protective clothing fabric in the embodiment, wherein, adopt the non-added polyphenylene sulfide The other conditions are all unchanged; Comparative example 2: Repeat the preparation process of the flame-retardant polyester protective clothing fabric in the embodiment, wherein, no flame-retardant fiber is added when the base fabric is prepared, and the other conditions are all unchanged; the blank is untreated. Treated polyester fiber fabric.

[0028] Combustion performance test: Weigh 1.0g and 0.5g of yarn respectively to prepare samples required for LOI test and yarn vertical burning test. The vertical combustion test was used to test the damage length of the sample, the number of times of flame contact, and the number of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com