Dual-path gas injection system for physical foaming process and gas injection method thereof

A technology of physical foaming and gas injection, which is applied in the field of physical foaming process of polyethylene insulating materials, can solve the problems affecting the performance index of leaky cables, restricting the electrical performance of the cable core and production cost, and the large foaming layer, etc., to achieve structural Compactness, reduced production cost, less material used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

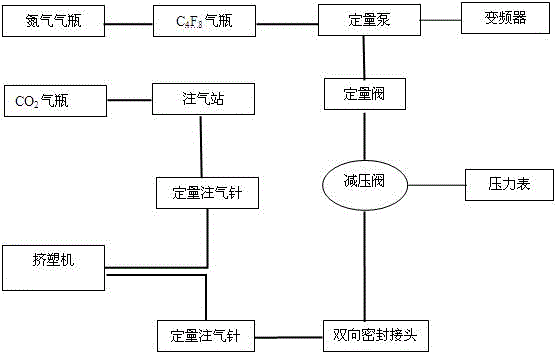

[0014] Refer to attached figure 1 , a two-way gas injection system used in the physical foaming process includes two parts: a carbon dioxide gas injection device and an octafluorocyclobutane gas injection device. The carbon dioxide gas injection device includes quantitative gas injection needle, gas circuit, gas injection machine and gas cylinder; the gas cylinder is connected to the gas pipe and then connected to the gas injection machine. The pressured gas is injected into the extruder and dissolved in the molten polyethylene foam to form a fine cell structure.

[0015] The octafluorocyclobutane gas injection device includes a nitrogen gas cylinder, an octafluorocyclobutane gas cylinder, a frequency converter, a quantitative pump, a pressure reducing valve, a gas pipe, a quantitative valve, a two-way sealing joint and a quantitative gas injection needle; the nitrogen gas cylinder passes through the gas pipe Connected with the octafluorocyclobutane gas cylinder, the nitrogen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com